Bone nail for the heel and osteosynthesis suite

A bone nail and heel technology, which is applied in the field of osteosynthesis kits, can solve the problems of small curvature radius and inability to consider the application of the heel area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

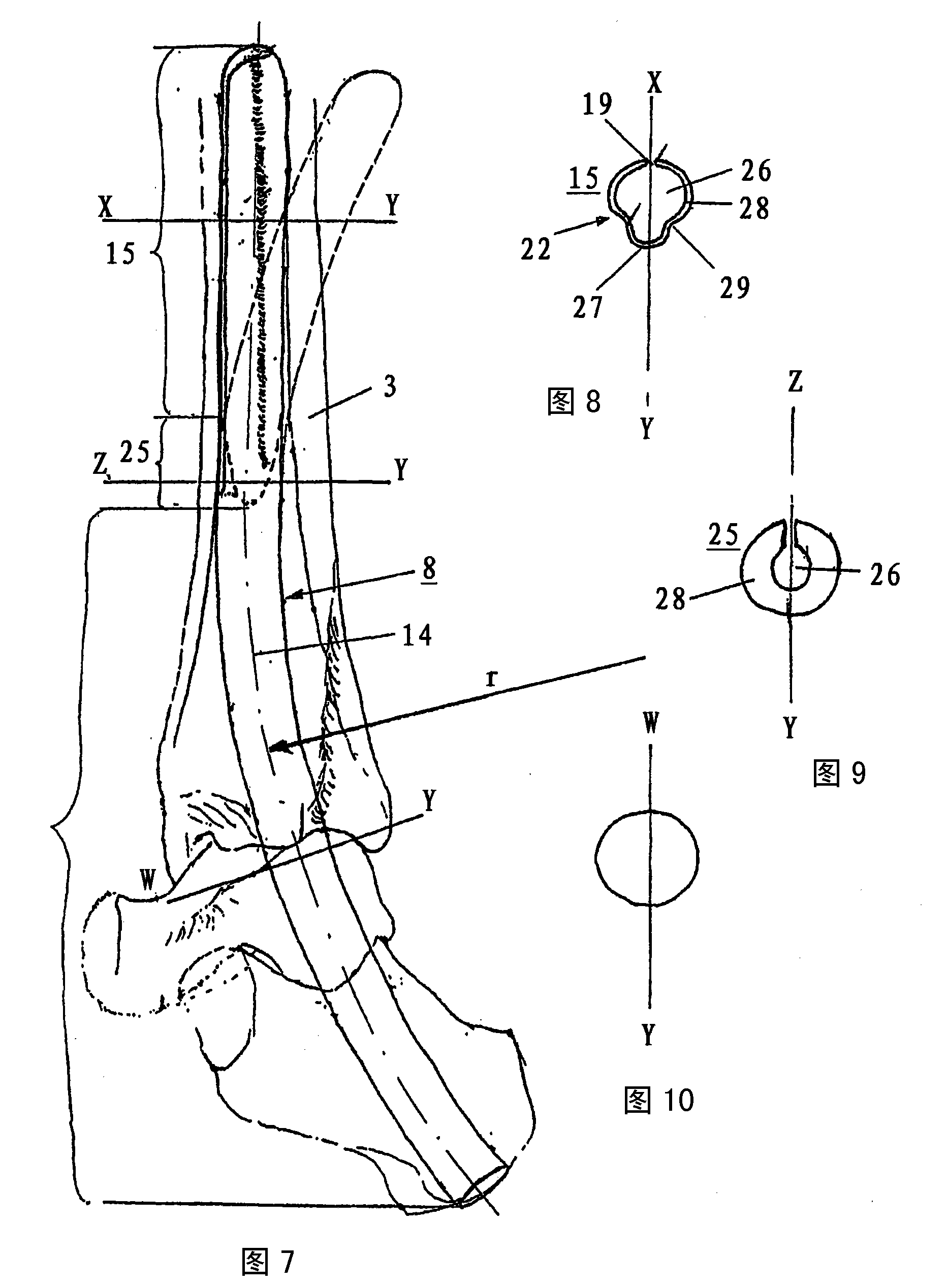

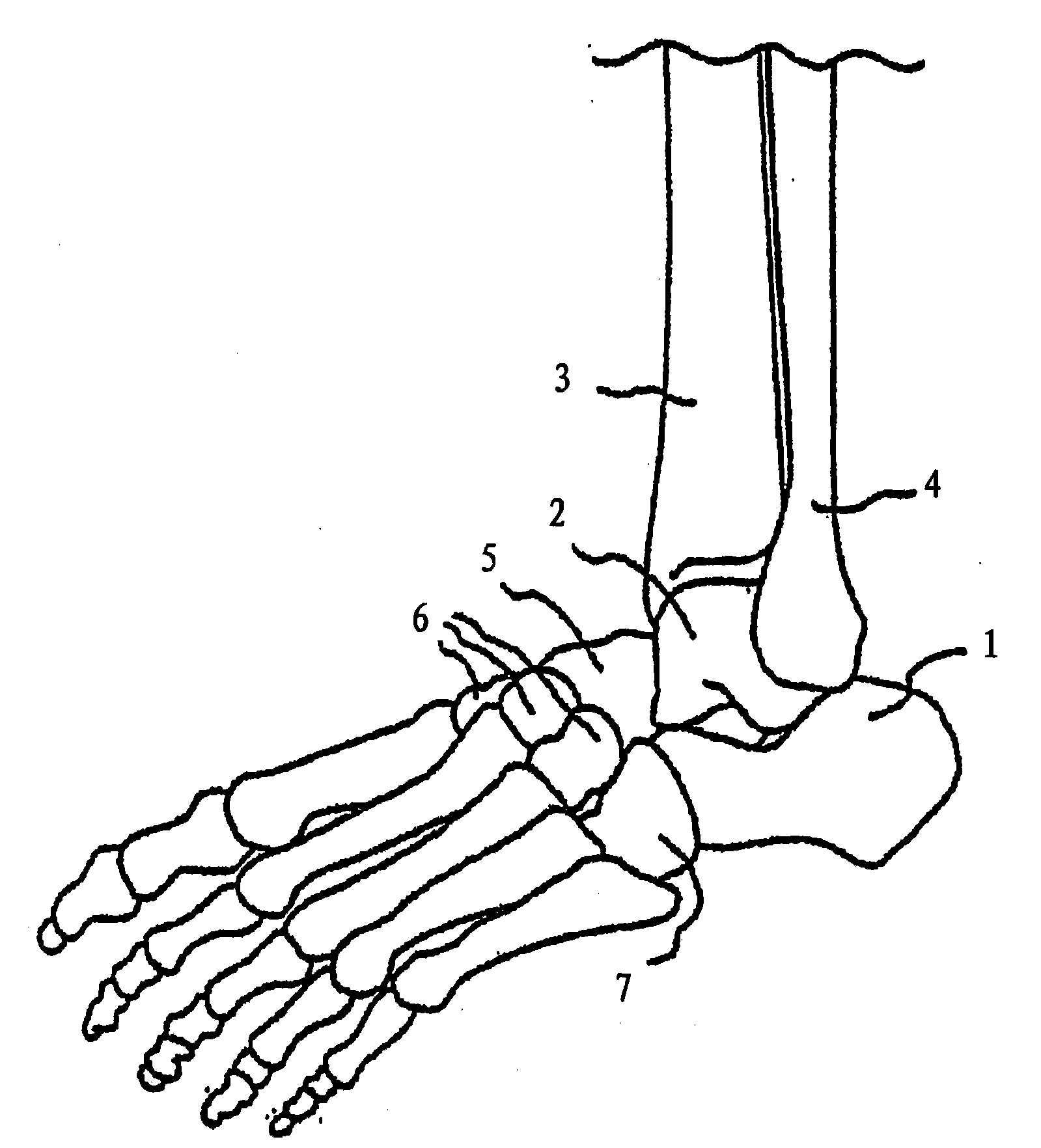

[0058] figure 1 The lower leg is shown in a position rotated approximately 45° medially. The figure shows the bone which is important for the application of the bone screw according to the invention. This is primarily the calcaneus 1, the talus 2 and the tibia 3. The fibula 4, navicular 5, cuneiform 6 and cuboid 7, also shown, are drawn for completeness purposes only.

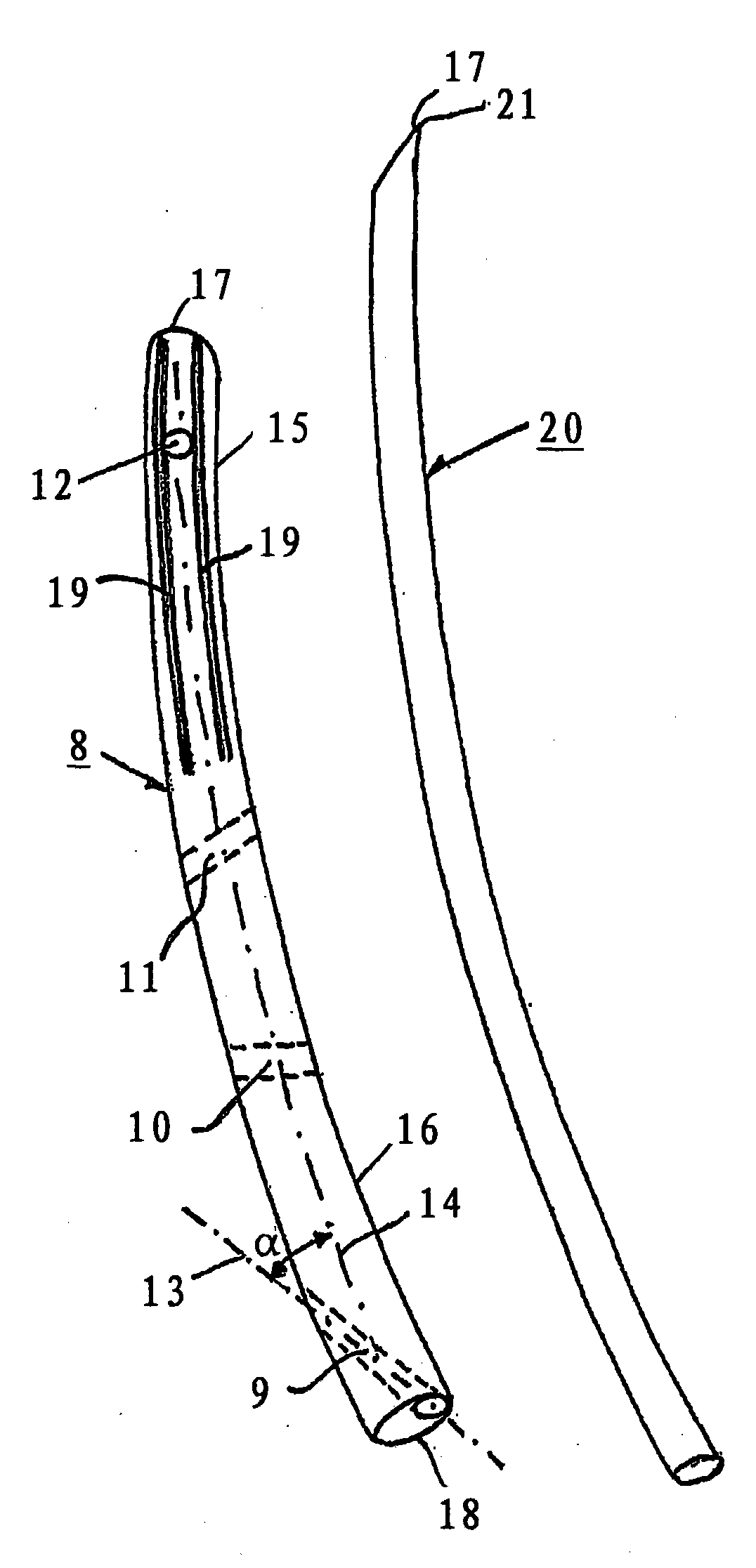

[0059] exist figure 2 The bone screw according to the invention, which is formed as an implant 8 , is shown in the middle, which is implanted through the calcaneus 1 and the talus 2 to the lower part of the tibia 3 . like image 3 As shown, the implant 8 is continuously curved in a plane with a radius of curvature R of typically 190 mm. The bend is over the entire length L of the implant 8 I Extended above, this length is typically 140mm. its diameter D 1 Usually 11mm. Length L of implant 8 I and diameter D 1 The ratio between L I / D 1 Usually 12.7.

[0060] The implant 8 comprises a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com