Projection lens manufacturing apparatus, projection lens manufacturing method, projection lens manufactured by the projection lens manufacturing method and projector having the projection lens

A projection lens and manufacturing device technology, applied in projection devices, installation, optics, etc., can solve the problems of increased number, difficult fine-tuning, light source offset, etc., and achieve the effects of reducing manufacturing costs, easy fine-tuning, and high-precision adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] 1. The first form of implementation

[0090] Next, a first embodiment of the present invention will be described based on the drawings.

[0091] [1. The main structure of the projector]

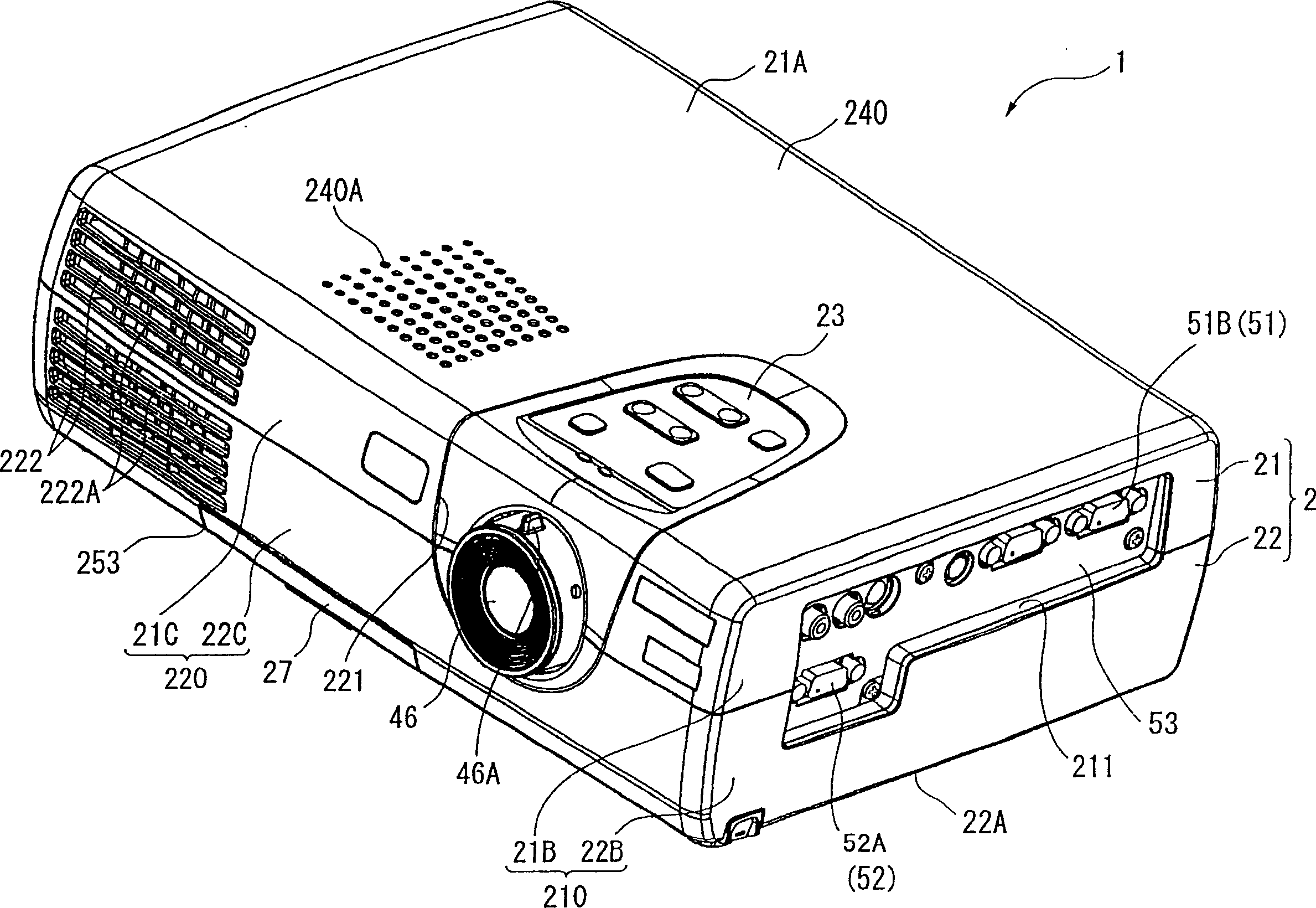

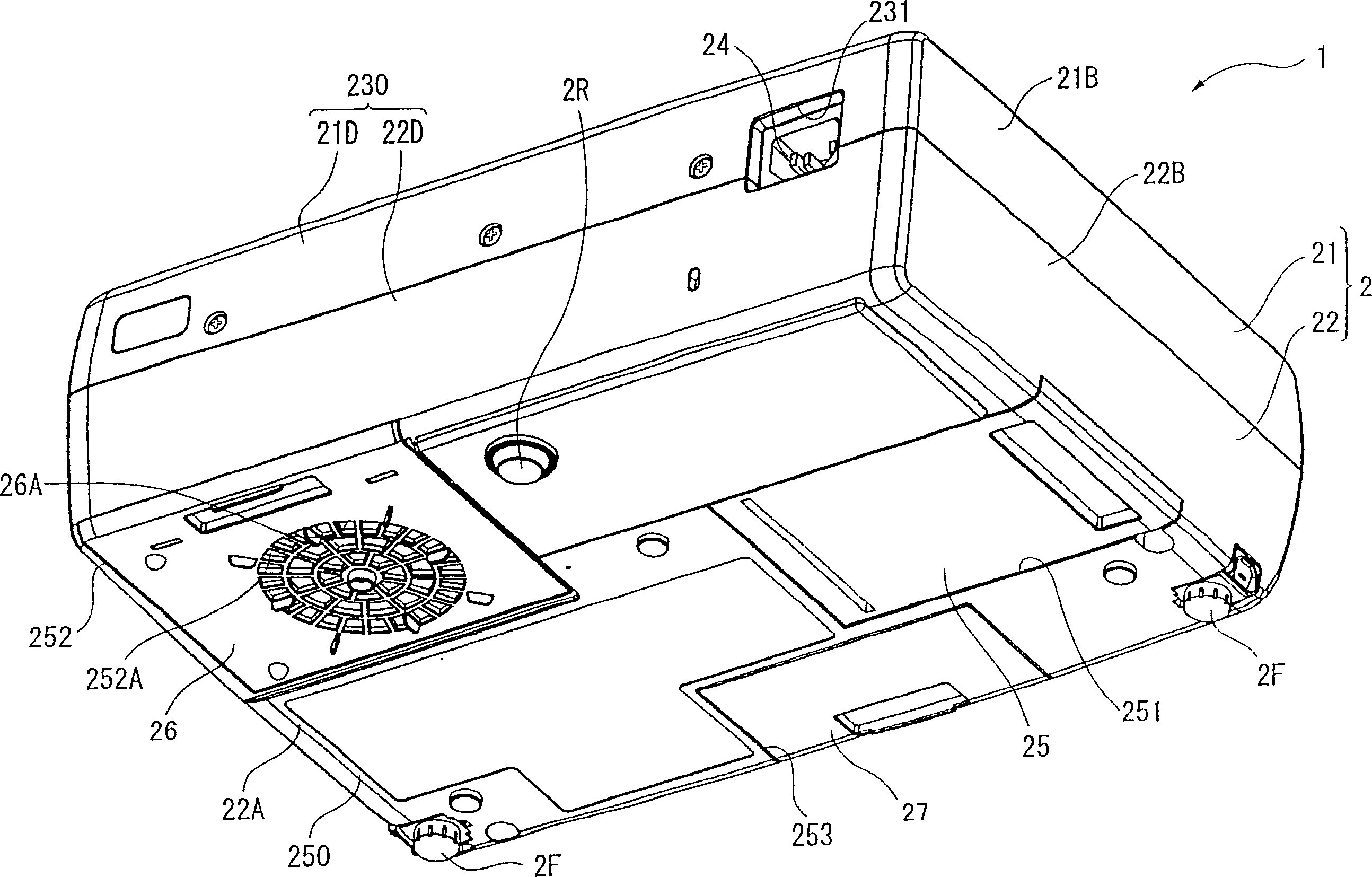

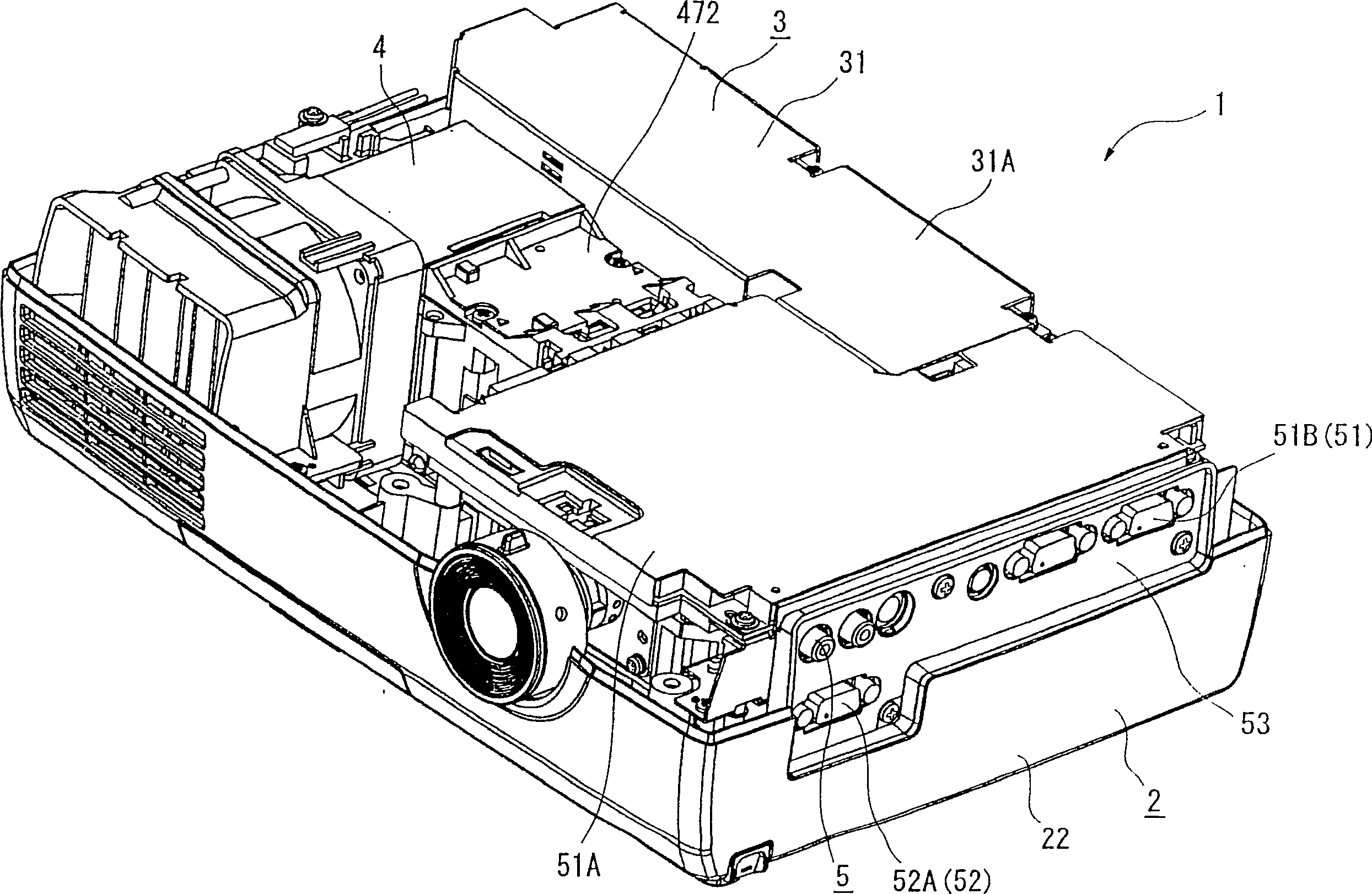

[0092] figure 1 is a perspective view of the projector 1 according to the present invention seen from the upper front side. figure 2 It is a perspective view of the projector 1 seen from the lower rear side.

[0093] Such as figure 1 or figure 2 As shown, the projector 1 includes a substantially rectangular parallelepiped outer casing 2 formed by injection molding. The outer cabinet 2 is a casing made of synthetic resin that accommodates the main body of the projector 1 , and includes an upper cabinet 21 and a lower cabinet 22 . These casings 21, 22 are mutually detachable.

[0094] Upper casing 21, such as figure 1 , 2 As shown, an upper portion 21A, a side portion 21B, a front portion 21C, and a rear portion 21D respectively constituting the upper face, the side face, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com