Rotational-speed-controlling variable piston pump

A technology of speed control and variable plunger, which is applied in the direction of pump control, pump, multi-cylinder pump, etc., and can solve problems such as pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

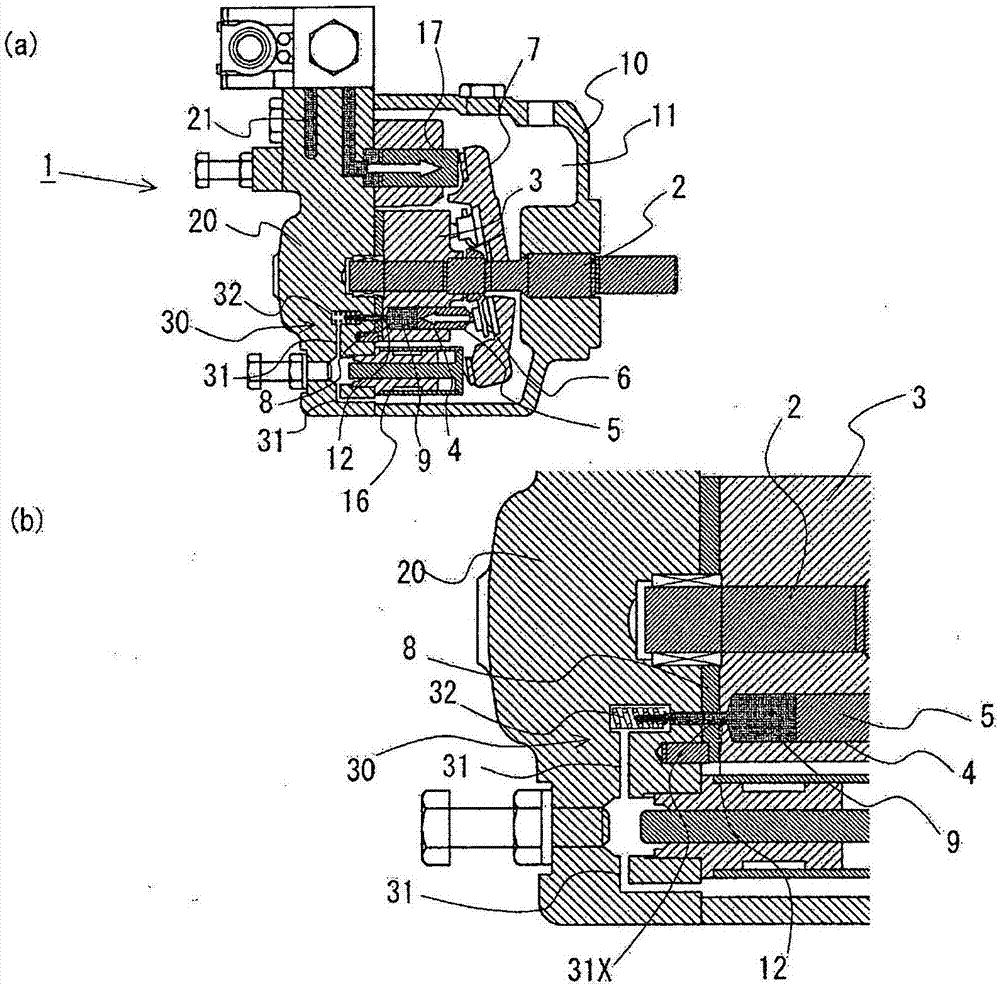

[0036] As the first embodiment of the present invention, in figure 1 The figure in the middle indicates a 2-capacity variable displacement plunger pump for rotation speed control equipped with a hydraulic circuit for avoiding abnormal pressure using a safety valve. figure 1 (a) is an overall longitudinal sectional view, and (b) is a partial sectional view showing a hydraulic circuit for avoiding abnormal pressure.

[0037] The basic configuration of the plunger pump unit other than the hydraulic circuit for avoiding abnormal pressure in the two-capacity variable plunger pump 1 for rotational speed control of this embodiment and image 3 and Figure 4 The example shown is the same.

[0038] That is, in the pump chamber 11 formed by closing the pump cover 20 of the container-shaped pump body main body 10, the rotary shaft 2 driven by the motor and the cylinder body 3 integrally rotated with the rotary shaft 2 are assembled as a single unit structure. , a plurality of bores 4...

Embodiment 2

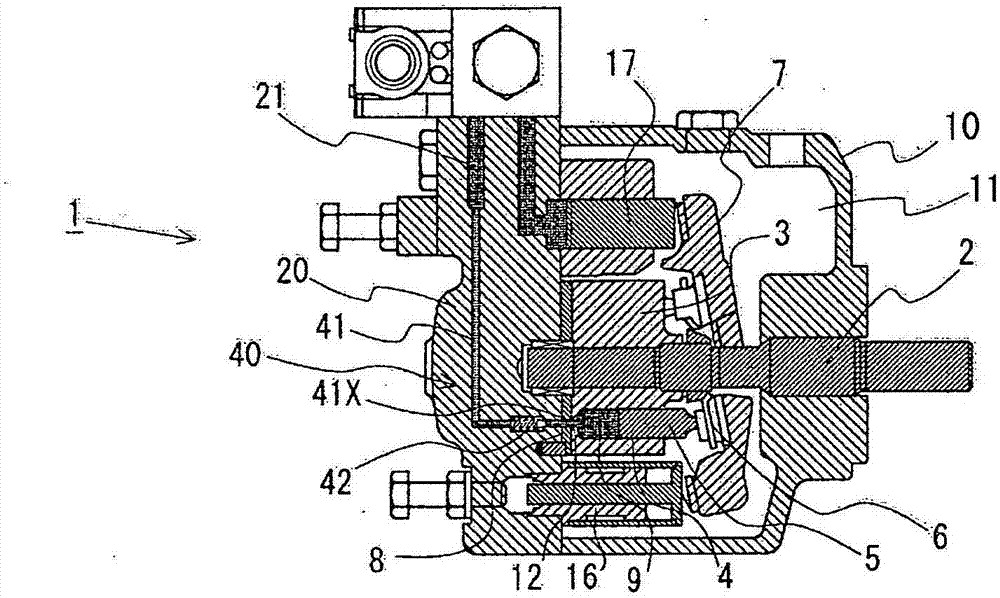

[0045] As a second embodiment of the present invention, a two-capacity variable-displacement plunger pump for speed control equipped with a hydraulic circuit for avoiding abnormal pressure using a check valve is shown in figure 2 longitudinal section view.

[0046] The basic configuration of the plunger pump unit other than the hydraulic circuit for avoiding abnormal pressure in the two-capacity variable plunger pump 1 for rotational speed control of this embodiment and figure 1 The basic configuration of the plunger pump unit of the first embodiment shown above is the same.

[0047] The hydraulic circuit 40 for avoiding abnormal pressure in this embodiment forms a pressure relief oil passage in the pump cover 20 that communicates the chamber 9 between the suction port and the discharge port of the flow plate 8 with the discharge oil passage 21 41. A one-way valve 42 is arranged in the pressure relief oil passage 41, at a position close to the downstream of the chamber 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com