Automatic sheet stacking method and device for cut-to-length lines of silicon steel sheets

A lamination device and technology of silicon steel sheets, which are applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of untidy stacking, sheet damage, and great danger of collecting methods, and achieve fast and neat stacking. , The effect of reducing worker operations and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

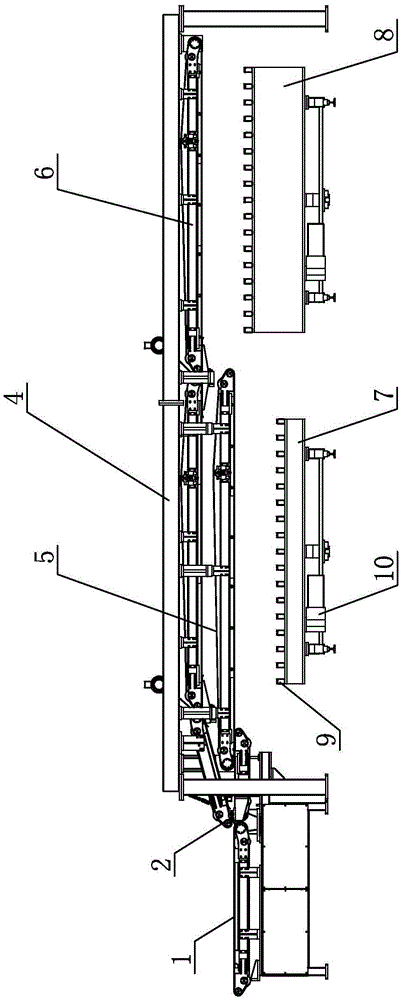

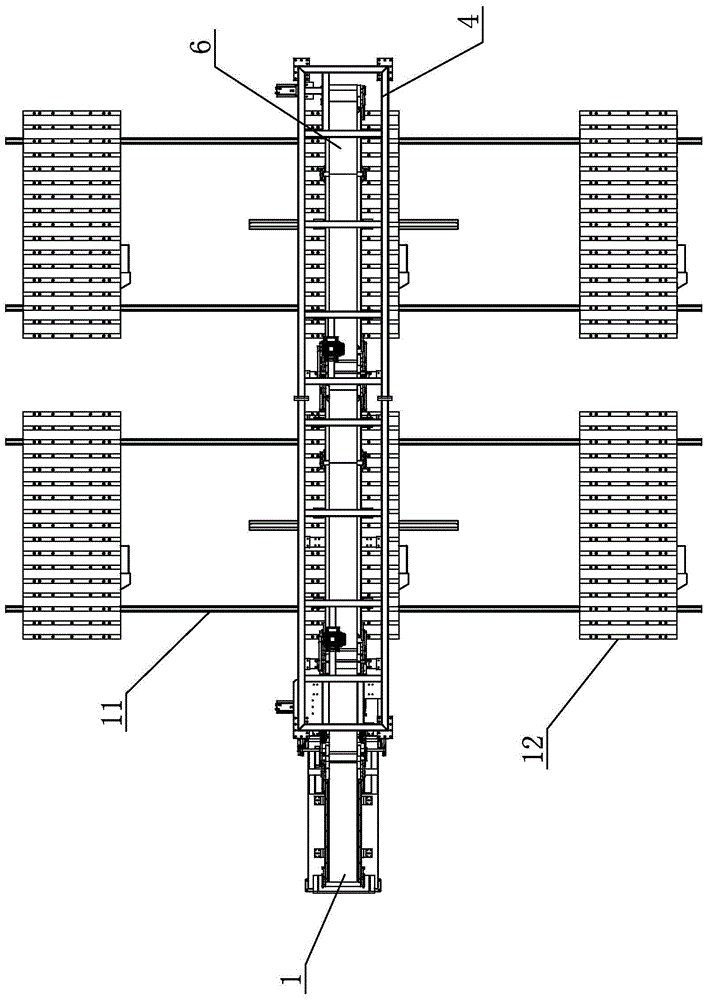

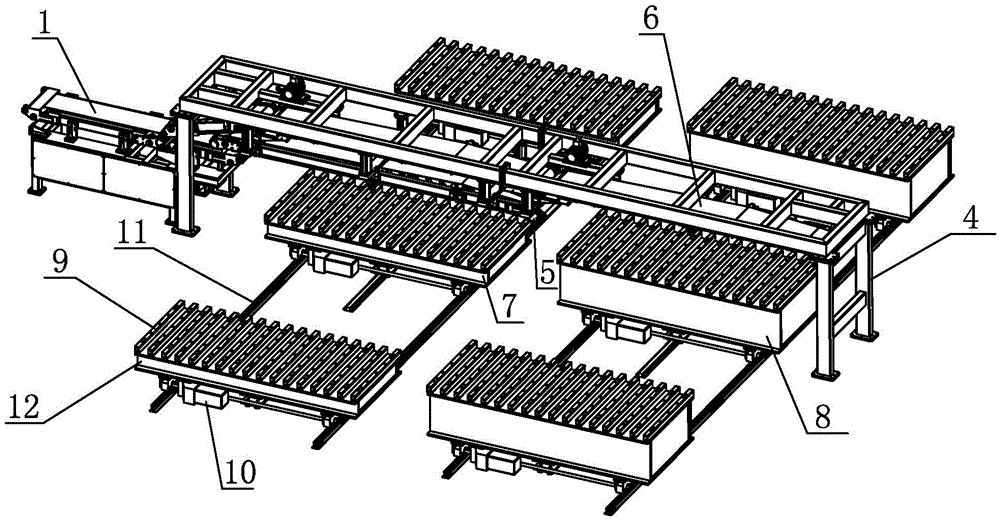

[0027] refer to Figure 1 to Figure 3 , a preferred embodiment provided by the present invention, an automatic lamination device for a silicon steel sheet cross-cutting line, includes a front conveyor belt 1, a material distribution mechanism 2 installed on the front conveyor belt 1, and is connected to the material distribution The lower road magnetic conveyor belt 5 at the mechanism 2 rear, the upper road magnetic conveyor belt 6 connected to the top of the material distribution mechanism 2, and the collecting vehicles 7, 8 respectively positioned under the two road magnetic conveyor belts.

[0028] In this embodiment, a lower magnetic conveyor belt 5 and an upper magnetic conveyor belt 6 are arranged behind the front conveyor belt 1 ; correspondingly, a material distributing mechanism 2 is arranged on the front conveyor belt 1 . The material distribution mechanism 2 is used to distribute the conveying route of the silicon steel sheet: when the material distribution mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com