Machine comprising a lifting device for receiving bulk material of a track bed

A technology for excavating devices and machines, applied in the directions of tracks, roads, ballast layers, etc., can solve problems such as damage, and achieve the effect of preventing machine failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

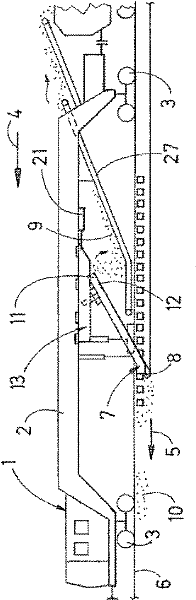

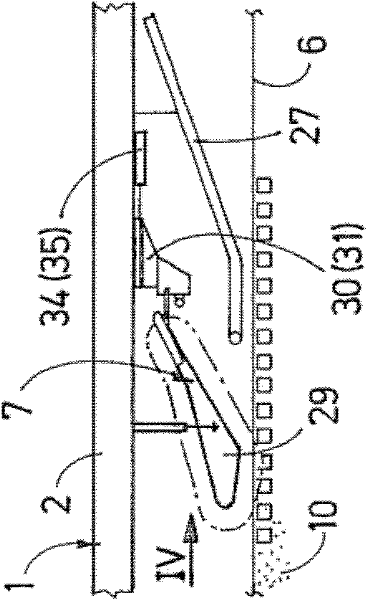

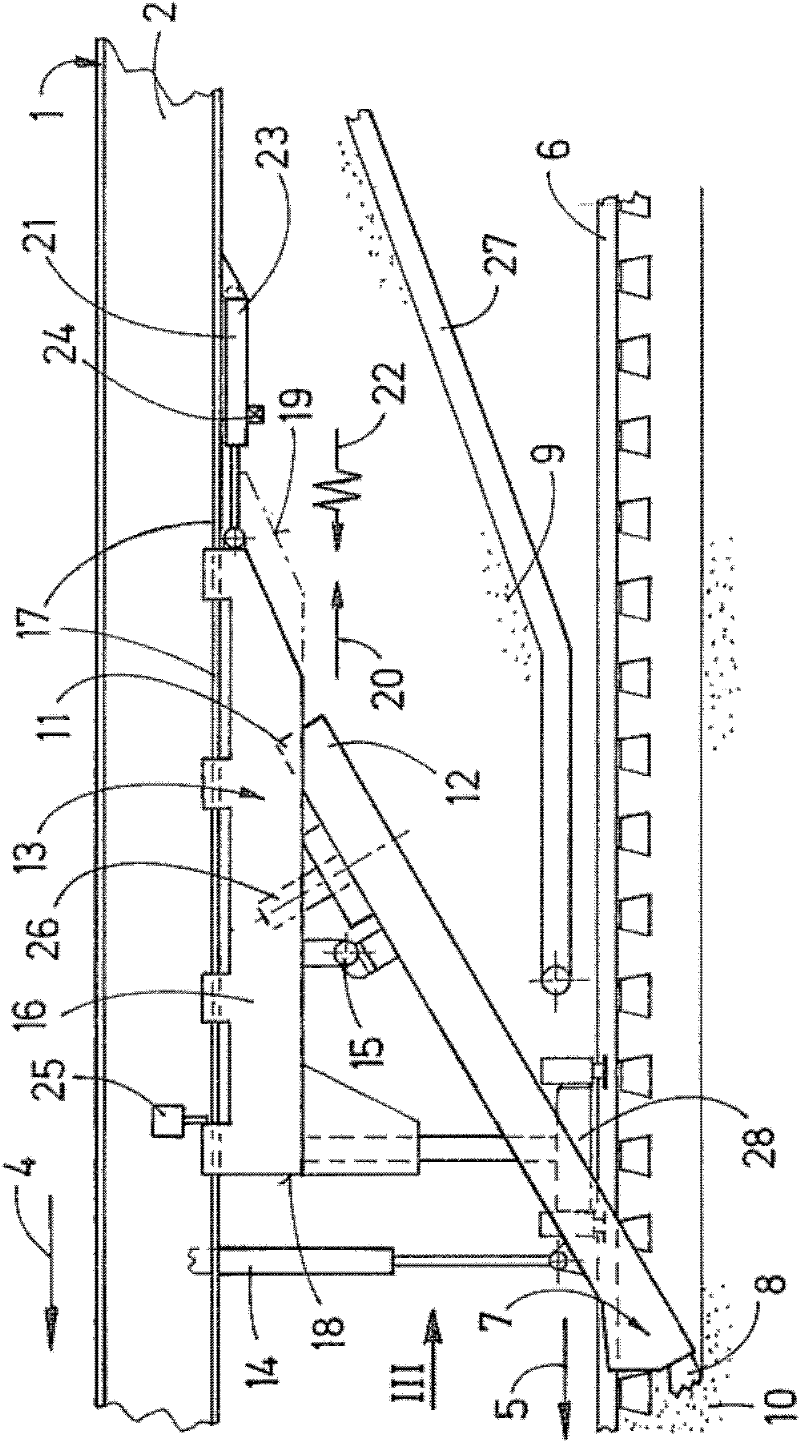

[0013] Figure 1a The shown machine 1 has an upwardly recessed machine frame 2 which is displaceable by means of an on-rail chassis 3 on a rail 6 in a working travel 5 in a working direction 4 . An excavating device 7 consisting essentially of a rotatable conveyor chain 8 connected end to end is arranged between the running gear 3 on the track. In this example, a conveyor chain 8 is guided under the track 6 during working operation and is used to collect chunks 9 from the track bed 10 . In the region of the upper conveyor chain offset 11 of the excavating device 7 is arranged a discharge device 12 for discharging the collected lump material 9 transported away via the conveyor device 27 .

[0014] figure 2 and image 3 As can also be seen in more detail in FIG. 2 , the excavating device 7 is articulated to the machine frame 2 by means of brackets 13 arranged in the region of the conveyor chain offset 11 . With the help of a drive 14 coupled to the machine frame 2, this brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com