Control system for bypassing material guide and control method thereof

A control method and a bypass material guide technology are applied in the field of control, control system, and control system of the bypass material guide device, which can solve the problems of difficult realization and difficult control, and achieve easy realization, Wide range of applications, timely and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

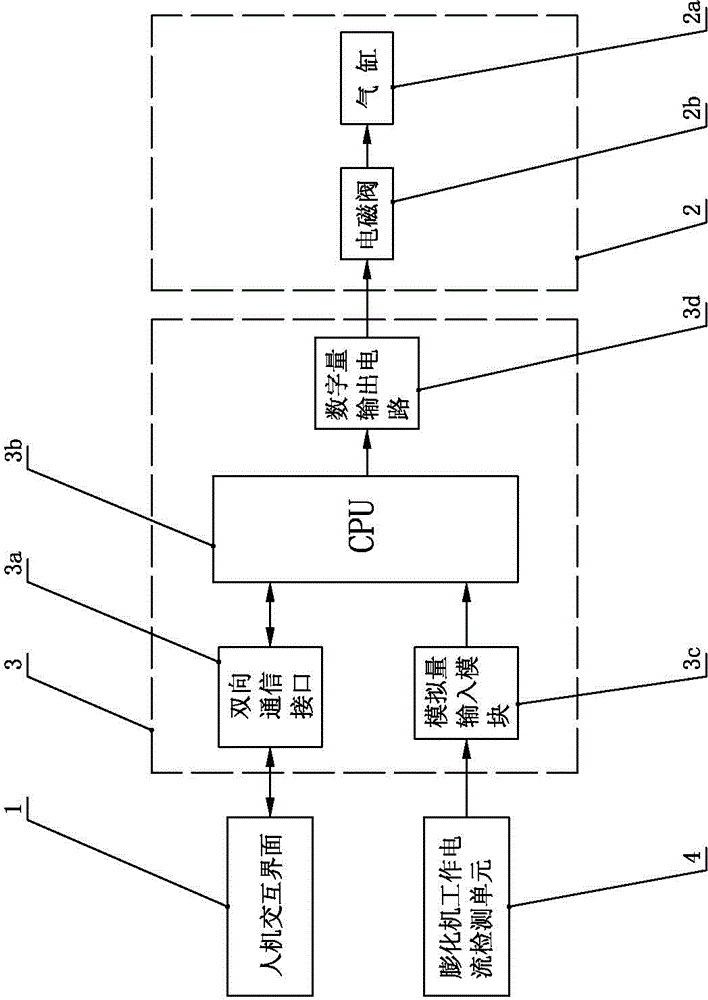

[0024] Such as figure 1 As shown, it is a block diagram of the working principle of the control system of the present invention, including a man-machine interface 1, an execution unit 2 and a PLC control unit 3; the man-machine interface 1 is used for system parameter setting and output display; the execution unit 2 includes a cylinder 2a and a The solenoid valve 2b used to control the intake and exhaust of the cylinder 2a; the PLC control unit 3 includes a two-way communication interface 3a, CPU3b, analog input module 3c and digital output circuit 3d, and the CPU3b includes an internal CPU timer; the man-machine interface 1 through The two-way communication interface 3a is connected with the PLC control unit 3; the input end of the analog input module 3c is connected with the working current detection unit 4 of the extruder, and the output end of the analog ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com