Method for growing large-size high-temperature oxide crystals by using top-seeded temperature gradient method

A high-temperature oxide and seed crystal temperature technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., to achieve the effect of reducing dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

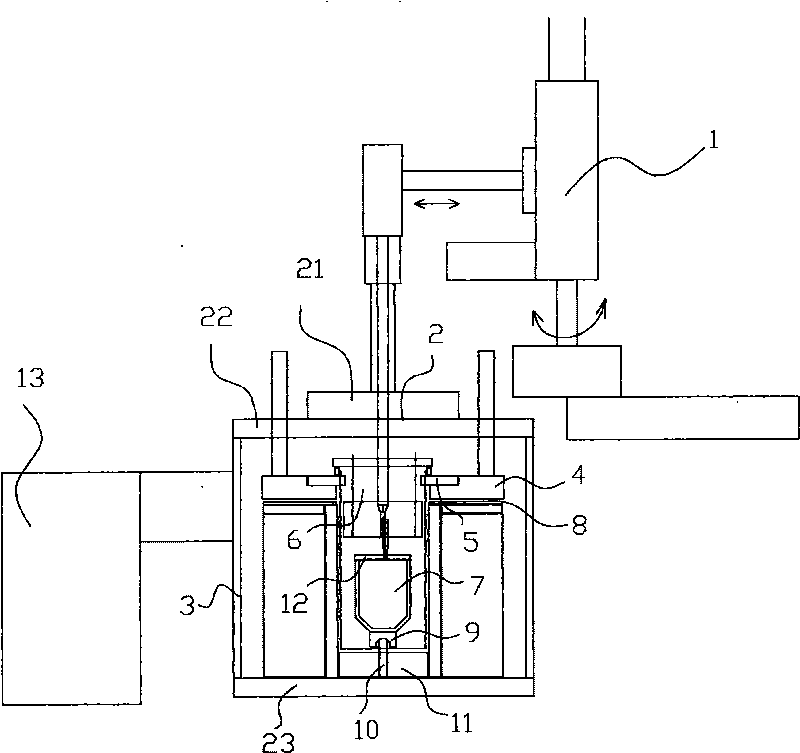

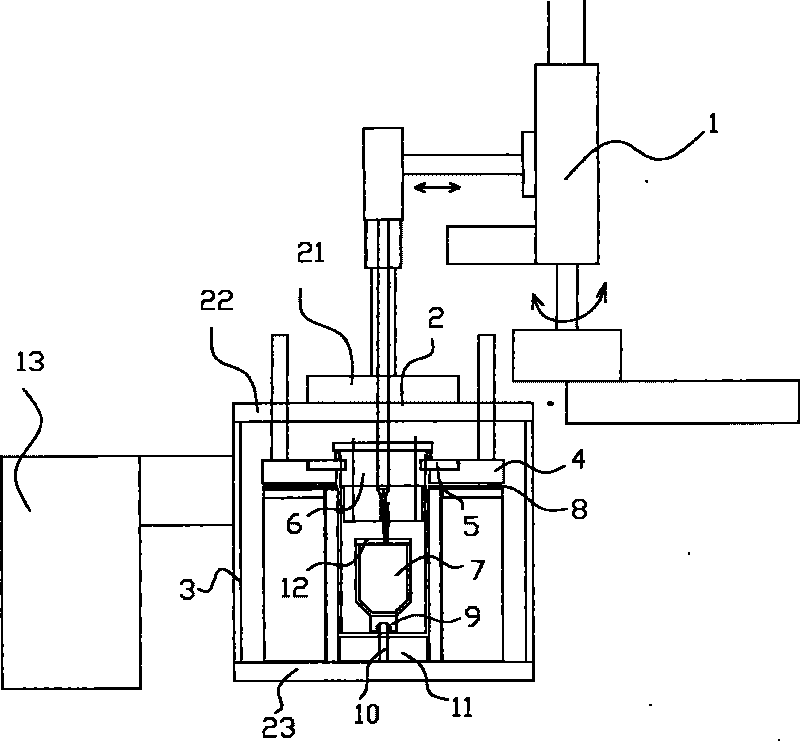

[0014] Such as figure 1 As shown, a method for growing large-sized high-temperature oxide crystals by the top seed crystal temperature gradient method includes a pulling structure 1, and connecting the pulling structure 1 with the furnace cover 2 and the furnace 3, wherein a flange seat is installed in the furnace 3 4. Metal heating body 5, heat preservation cover 6 and crucible 7, metal heating body 5 is placed on flange seat 4, ring-shaped combined insulation layer 8 is fixed under flange seat 4, crucible support 9 and crucible support rod are installed under crucible 7 10 is used to support the crucible 4, the crucible supporting rod 10 passes through the lower heat preservation cover 11, and a layer of ceramic insulator is coated on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com