Three-terminal thermostat detection method and tooling for mechanical refrigerator

A technology for detecting tooling and temperature controllers, which is applied in the direction of instruments, general control systems, control/regulation systems, etc., can solve problems such as complete machine difficulties, lower production line efficiency, and complete machine failures, so as to avoid production processes and improve production efficiency , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

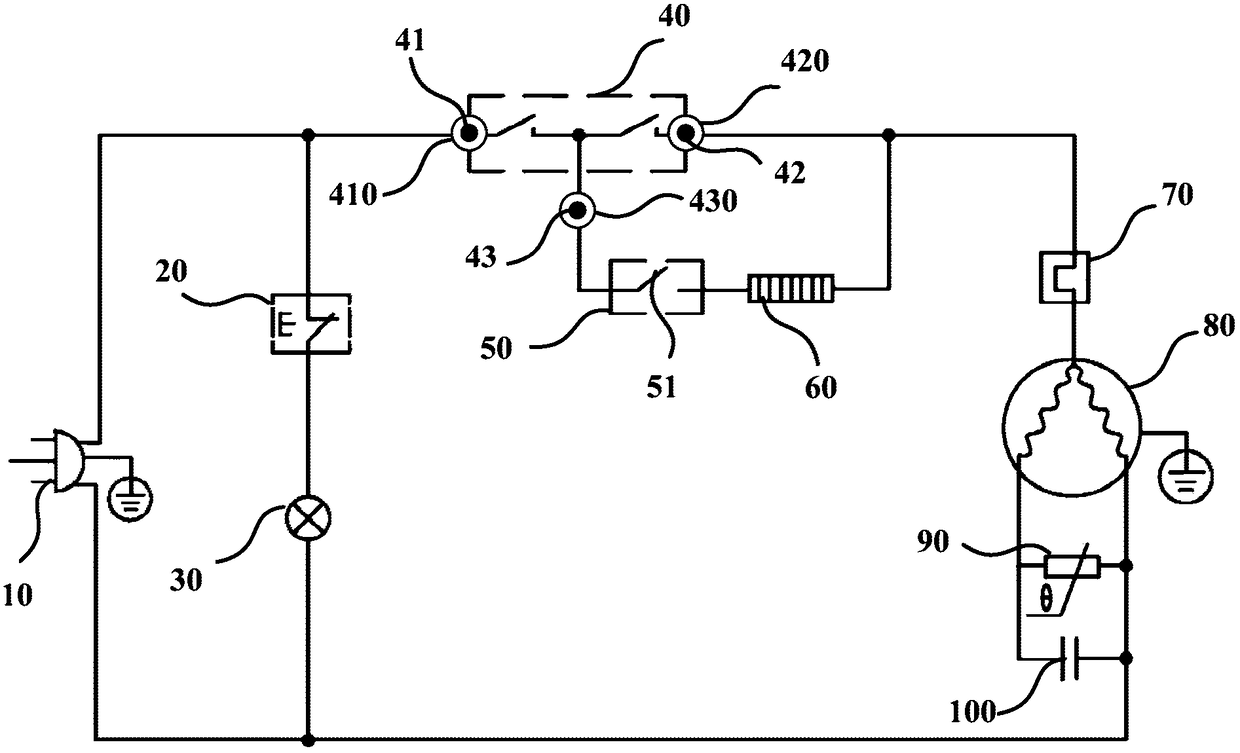

[0027] figure 1 It is a schematic diagram of the circuit principle of a three-terminal thermostat of a mechanical refrigerator according to an embodiment of the present invention, as shown in figure 1 As shown, the circuit includes: power plug 10, light switch 20, lighting lamp 30, three-terminal thermostat 40, magnetic temperature switch 51, compensation heating wire 60, overload protector 70, compressor 80, PTC 90 and running capacitor 100.

[0028] Wherein, the mechanical refrigerator includes: a thermostat interface, and the thermostat interface includes a first terminal 410 and a second terminal 420 respectively used to connect the common terminal 41, the compressor terminal 42, and the temperature compensation terminal 43 of the three-terminal thermostat 40 , the third terminal 430 .

[0029] exist figure 1 In the circuit shown, the power plug 10 is connected to the power supply, one end of the compressor 80 is connected to one end of the power plug 10, and the common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com