Thread clamping mechanism for hosiery circular knitting machine

A thread clamping mechanism and knitting machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problem that old loops are easy to float, wear and tear of Huff needles and knitting needles, and interfere with the work of Huff needles and knitting needles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

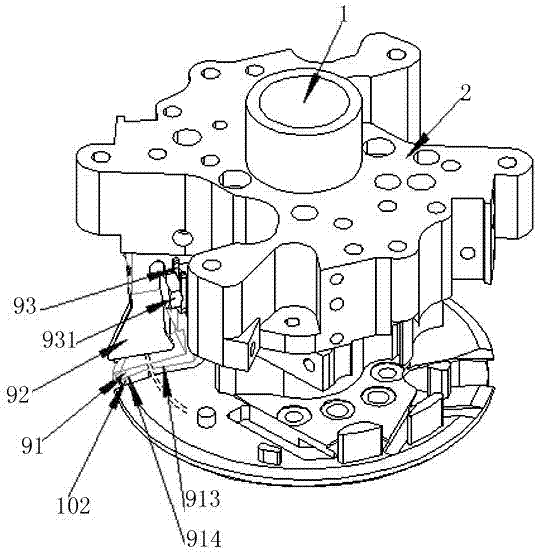

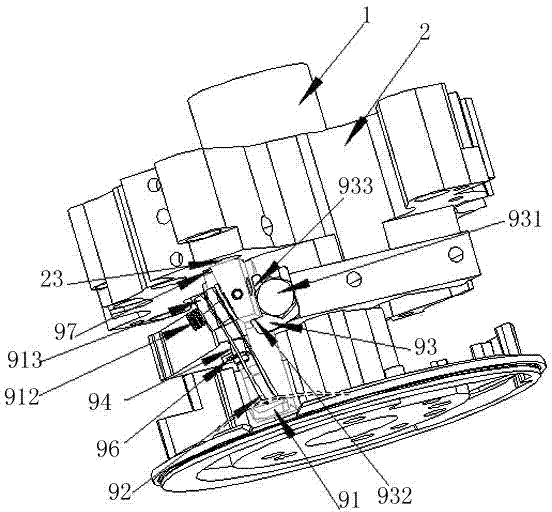

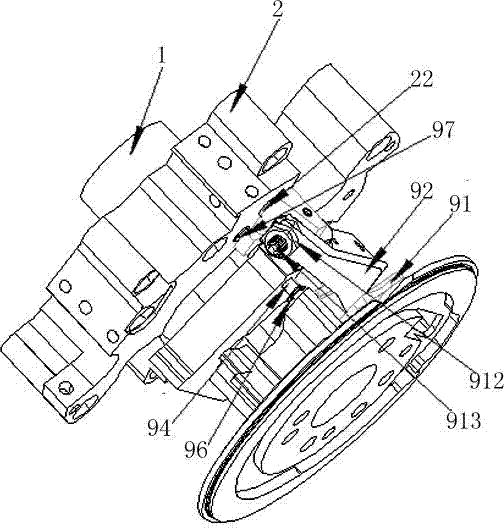

[0013] See attached picture. This embodiment includes a clamping base 91, the clamping base 91 is fixed on the air valve seat 2, and there is a clamping pneumatic piston 23 on the relative position of the valve seat 2, the clamping base 91 is L-shaped, in The upper end of the L-shaped vertical axial section has a protruding surface, on the protruding surface of the upper end of the clamping base 91, a pressure spring piece 92 is installed through a set screw 913 and a hex nut 912, and the pressure spring piece 92 is on the top. Narrow and wide trapezoid, there is a blocking piece 93 on one side of the protruding surface, the bottom end 932 of the blocking piece 93 can be in conflict with the bottom of the protruding surface of the clamping base 91, and the blocking piece 93 is installed on the gas cylinder by a hex head bolt 931. On the valve seat 2, the side of the blocking piece 93 is a guide surface 933, on the trajectory of the downward movement of the clamping base 91; on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com