Pulverizing mill for producing activated carbon

A technology of activated carbon production and pulverizing machine, which is applied in grain processing and other directions, can solve the problems of low pulverizing and grinding efficiency, high manufacturing cost, unreasonable design, etc., and achieve the effects of shortening production cycle, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

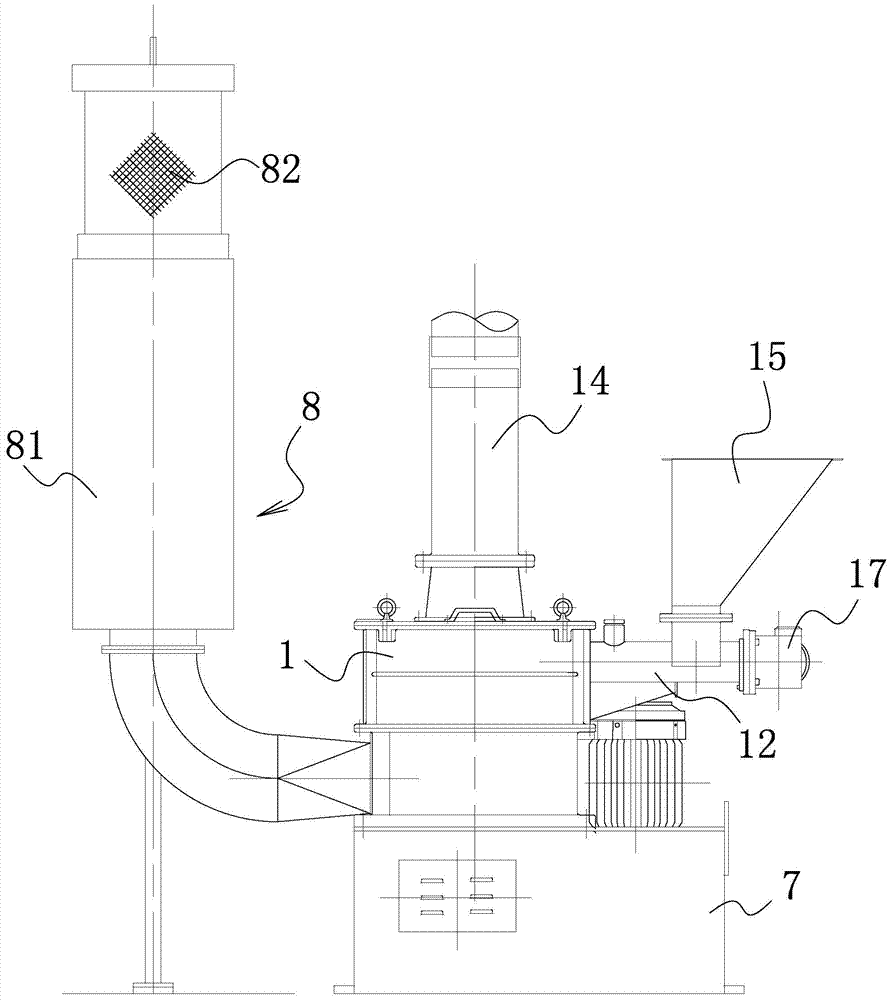

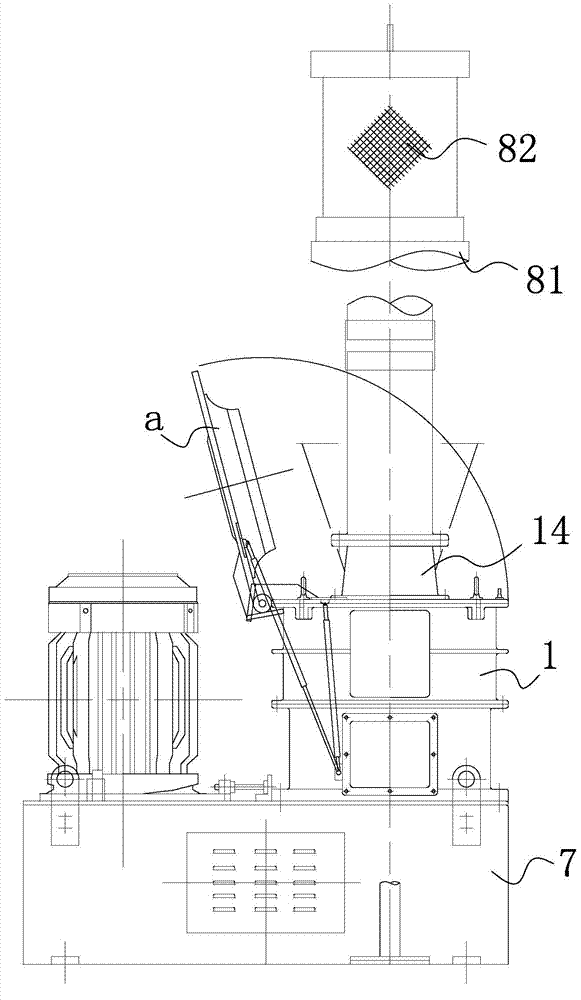

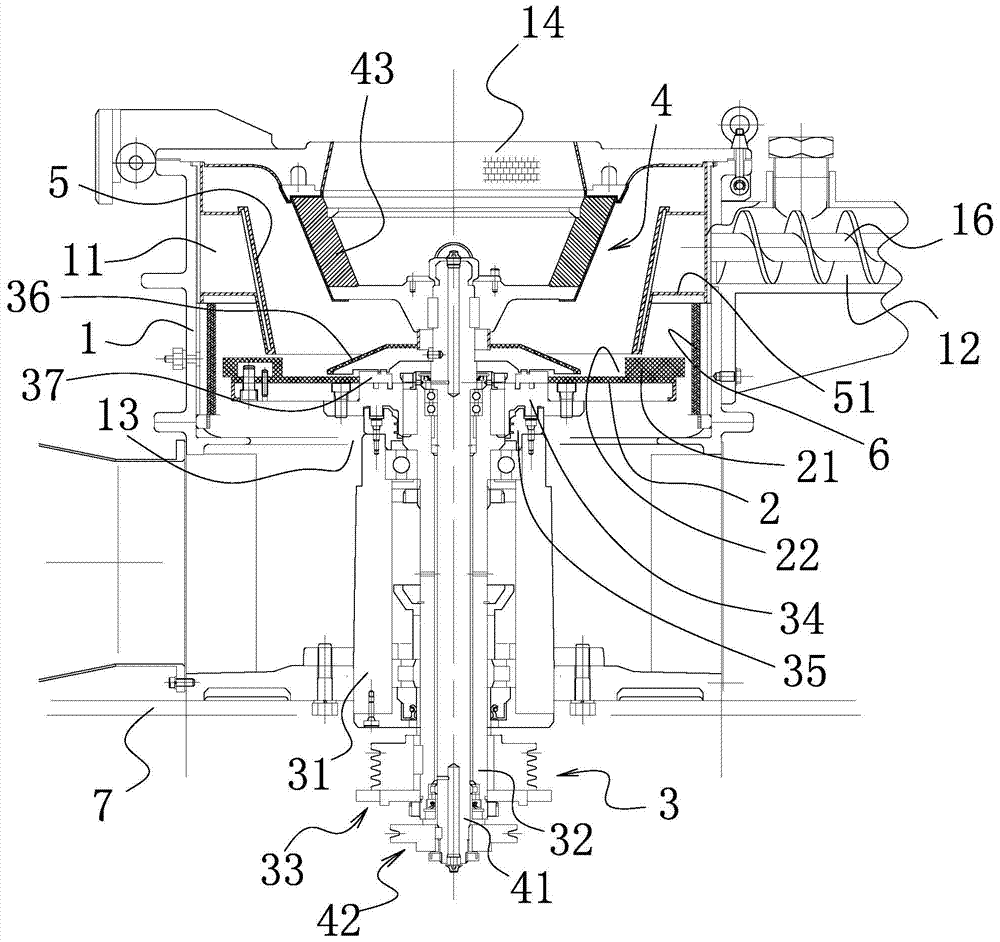

[0023] Such as Figure 1-3 As shown, the pulverizer for activated carbon production comprises a base 1 with a chamber 11, a feed port 12 is provided on the base 1, a feed hopper 15 is connected to the feed port 12 and a feed hopper is provided in the feed port 12. There is a feeding screw 16 which is connected to a feeding screw motor 17 which can drive its rotation. The base 1 of this embodiment is arranged on the positioning seat body 7, and there is an air inlet hole 13 communicating with the chamber 11 at the bottom of the base 1, and at least one airflow generator connected to the air inlet hole 13 is provided on the positioning seat body 7. Mechanism 8; specifically, the airflow generating mechanism 8 here includes an air inlet pipe 81, at least one fan is arranged in the air inlet pipe 81, and an air inlet filter 82 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com