Magnetism column pin roller

A magnetic column and roller technology, applied in the field of roller presses, can solve the problems of reducing the surface protection of the roller body, reducing the grinding efficiency of the roller press, affecting the overall life of the rollers, etc., so as to reduce equipment maintenance costs and improve equipment operation efficiency. , to ensure the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

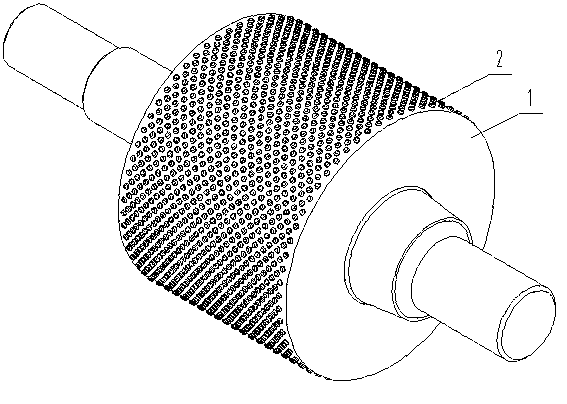

[0024] Embodiment 1, the magnetic stud 2 roller of the present invention comprises a magnetic roller body and a stud 2, and several studs 2 are evenly distributed on the surface of the magnetic roller body, wherein the stud 2 is made of hard alloy, and the magnetic roller body is made of It is made of magnetized hard magnetic materials (such as: rare earth permanent magnet materials, metal permanent magnet materials, ferrite permanent magnet materials, etc.), so that the roller body can evenly absorb the magnetic materials to form a material pad, and when the material pad is squeezed and slips When it is used, it has the function of automatically filling and forming a material pad. The magnetic strength of the magnetic roller body is 500 Gs, 1500 Gs or 2500 Gs, which can be set arbitrarily between 500-2500 Gs.

Embodiment 2

[0025] Embodiment 2 is similar to Embodiment 1, except that: the magnetic roller body and stud 2 are made of hard magnetic materials (such as rare earth permanent magnet materials, metal permanent magnet materials, ferrite permanent magnet materials, etc.) Made, so that the roller body and the stud 2 can evenly absorb the magnetic material to form a material pad, so that the material pad is less likely to be squeezed, even if it is squeezed and slipped, it can be quickly replenished by the newly passed magnetic material to form a complete The material pad, in which the magnetic field strength is 1000Gs or 2000Gs, can be set arbitrarily between 500-2500Gs.

Embodiment 3

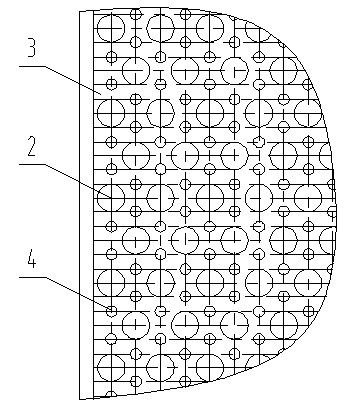

[0026]Embodiment 3 is similar to Embodiment 1, and its difference is: the magnetic roller body adopts the soft magnetic material (soft magnetic material is the material that when magnetization occurs at Hc not greater than 1000A / m, including pure iron and low carbon steel, iron-silicon alloy, iron-aluminum alloy, iron-silicon-aluminum alloy, soft ferrite, etc.), such as figure 2 As shown, the magnets 4 are evenly distributed on the surface of the roller body between the studs 2, so that the magnetic material can be evenly adsorbed on the surface of the roller body, so that the formed material pad is uniform, thereby realizing the protection of the roller body. Among them, the magnetic strength is 800 Gs, 1200 Gs or 1800 Gs or 2200Gs, which can be set arbitrarily between 500-2500Gs. In this example, the stud 2 can be selected to be made of a hard magnetic material according to actual needs, so that the stud 2 and the magnet 4 uniformly distributed on the surface of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com