Rail jaw refiner of rocket sled sliding rail welding connector

A welded joint and rocket skid technology, which is applied in the field of rocket skid slide rail welded joint rail jaw fine grinding machine, can solve the problems of low working efficiency, inability to precisely control the grinding amount and grinding, and inability to grind the rail jaw, so as to save space, Simple structure and improved operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

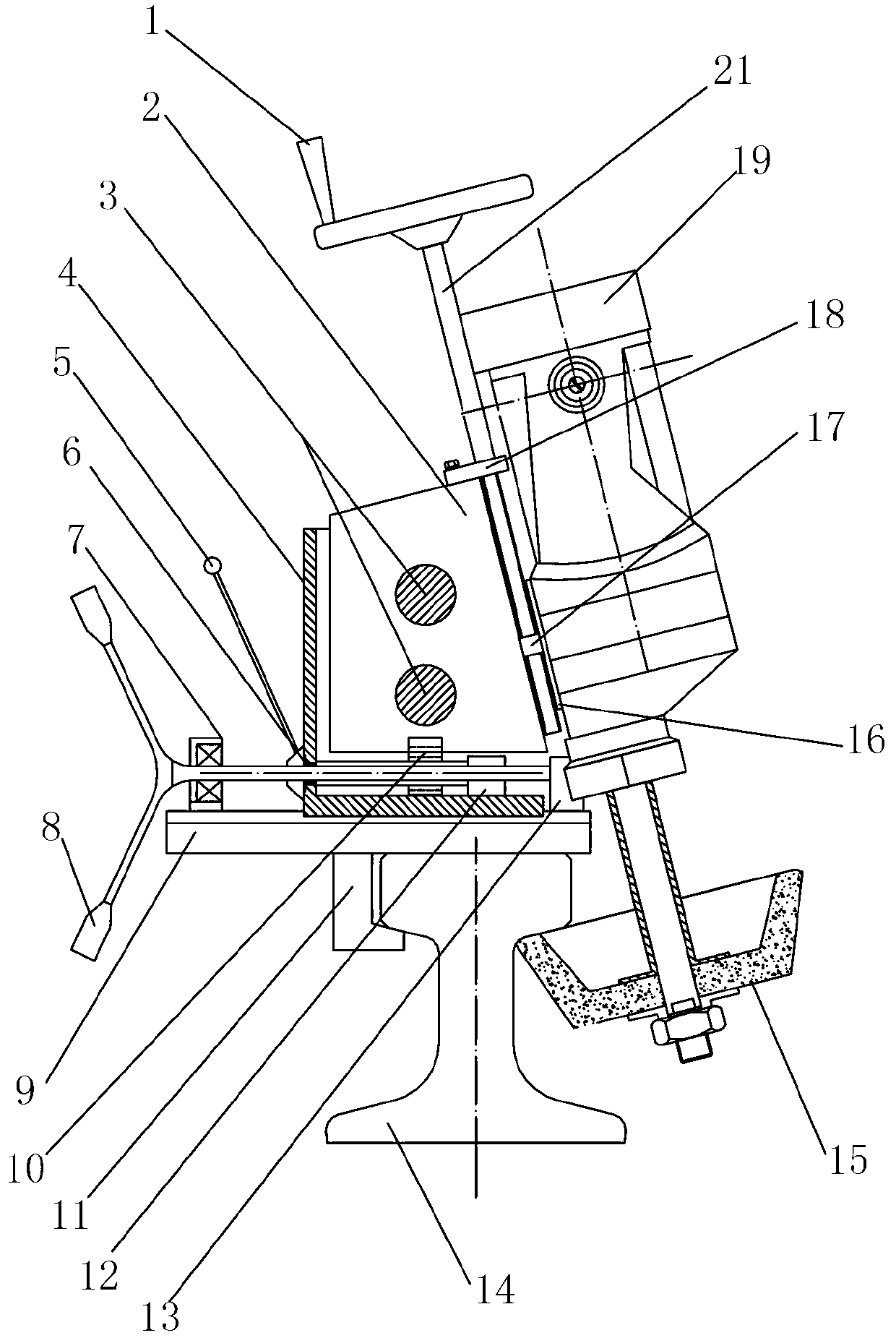

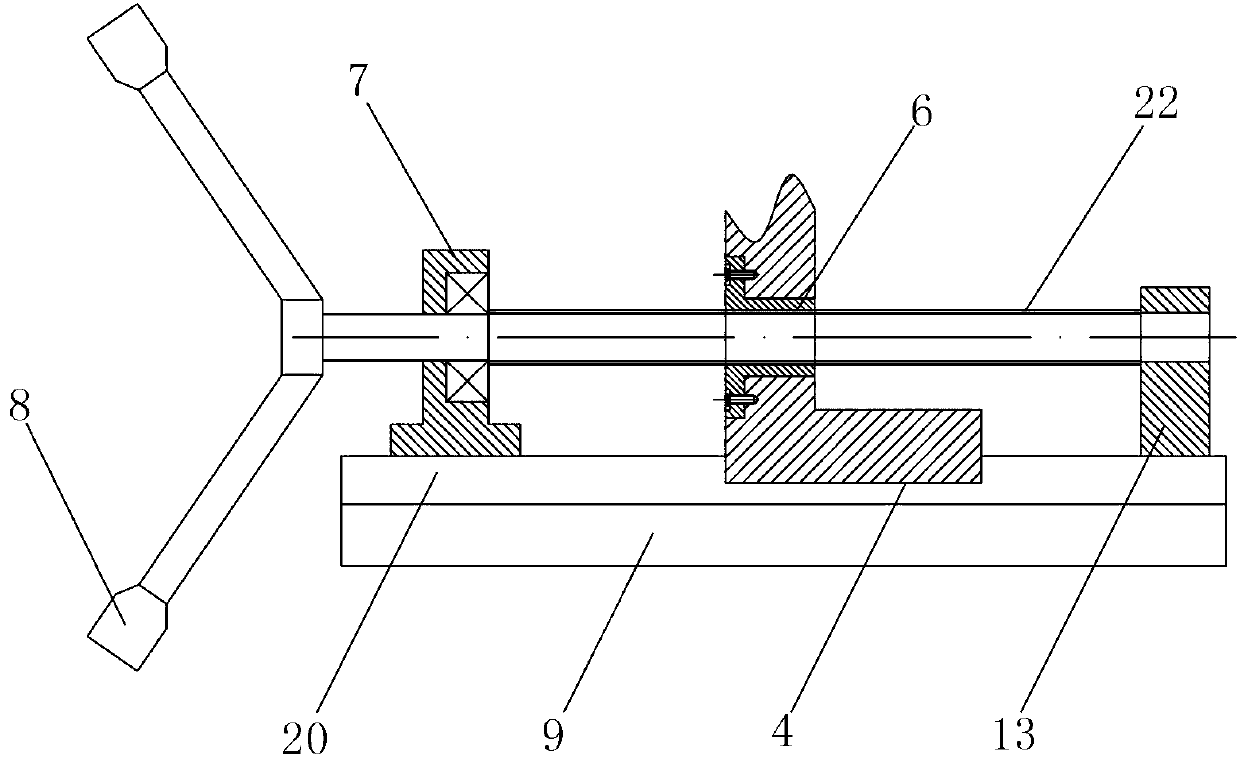

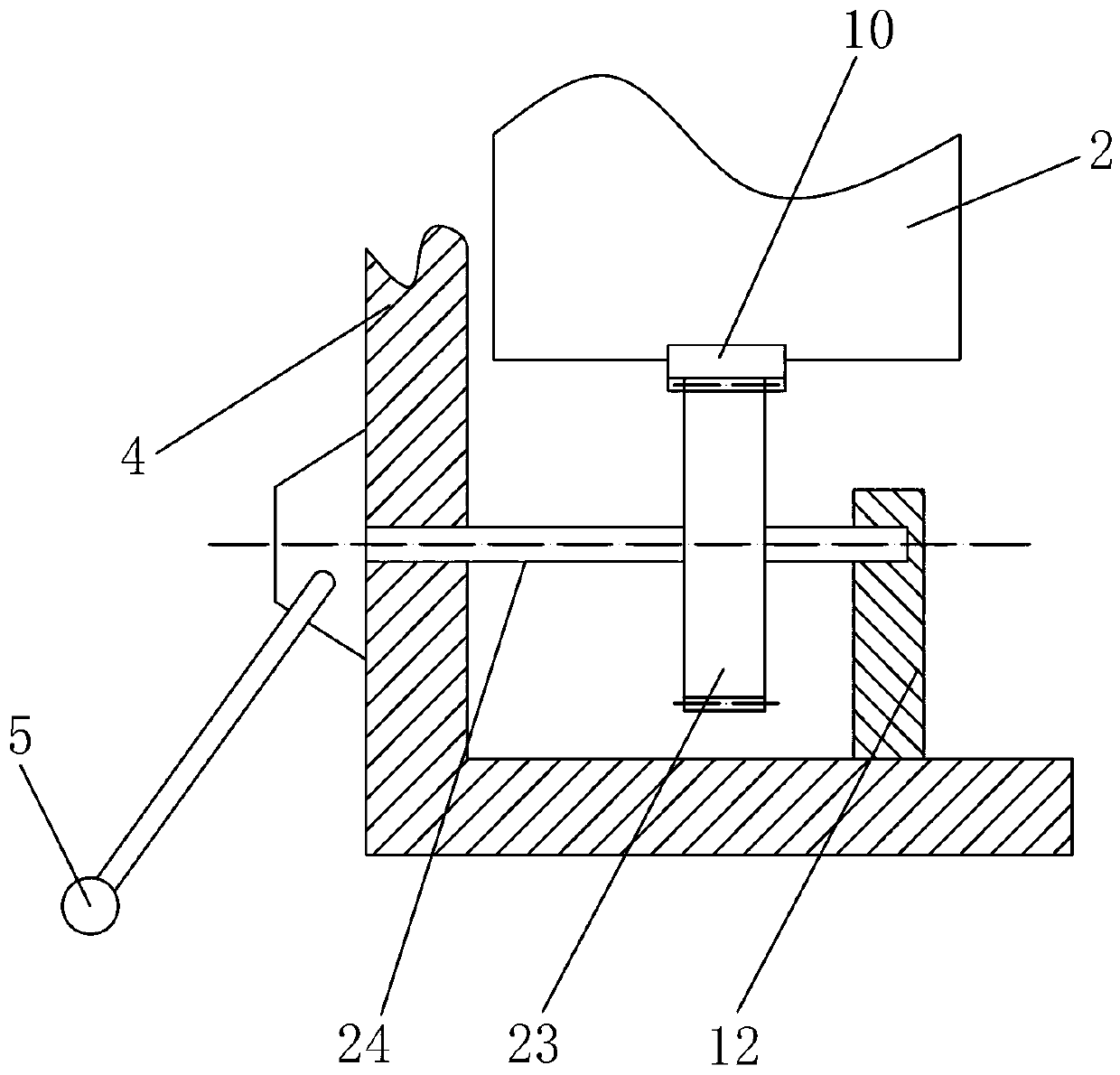

[0039] Such as figure 1 A rocket skid slide rail welding joint rail jaw refining machine shown includes a fixed base 9 fixedly installed on the rocket skid slide rail welding joint and a fixed base 9 arranged on one side of the rocket skid slide rail 14 and used for adjusting the rocket skid slide rail. A vertical grinder 19 for grinding the welded joint rail jaw, the upper surface of the grinding wheel 15 of the vertical grinder 19 fits the welded joint rail jaw of the rocket skid slide rail, and the fixed base 9 is equipped with a The horizontal adjustment mechanism for the horizontal movement of the skid slide rail 14, the horizontal adjustment mechanism is connected with a vertical adjustment mechanism for driving the vertical grinder 19 to move longitudinally along the rocket skid slide rail 14, and the vertical adjustment mechanism is used to drive the vertical The height adjusting mechanism that grinder 19 moves up and down is connected with straight grinder 19.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com