Ball mill

A ball mill and body technology, applied in the field of crushing devices, can solve the problems of insufficient grinding of materials, etc., and achieve the effects of sufficient grinding of materials, uniform materials, and uniform product diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

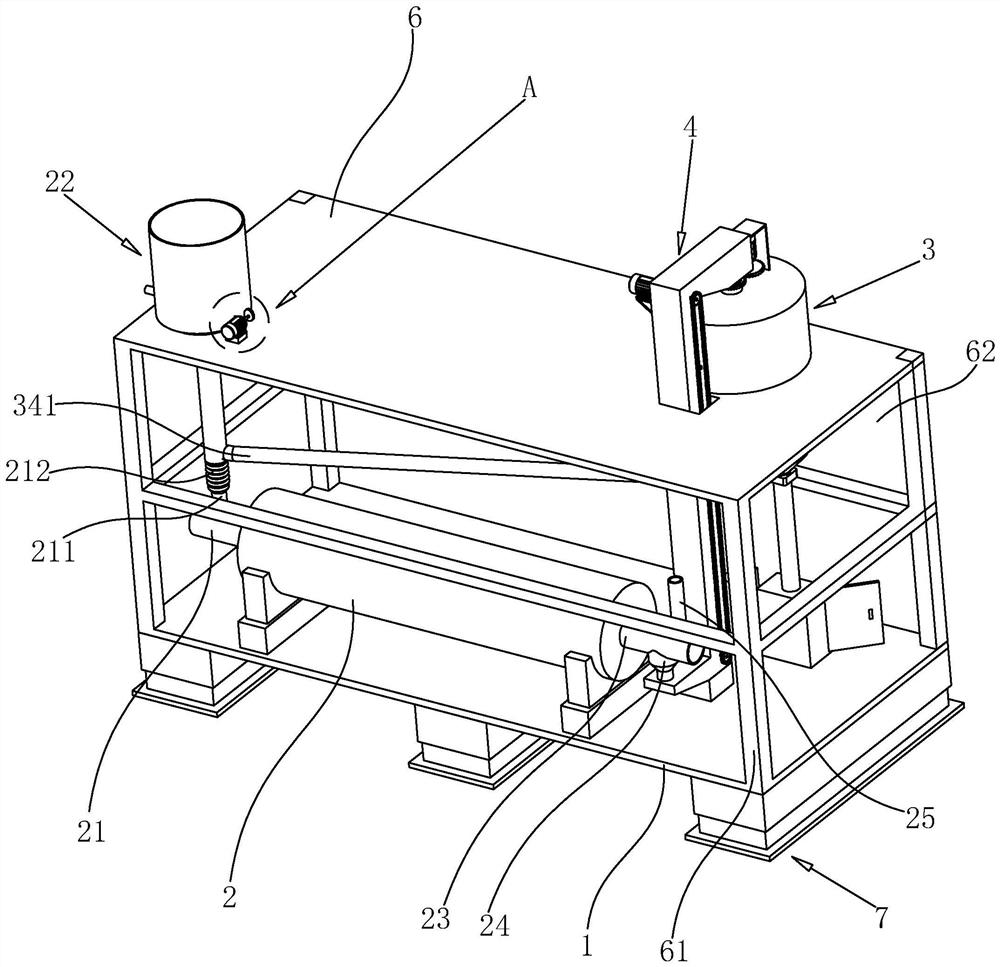

[0036] The following is attached Figure 1-7 The application is described in further detail.

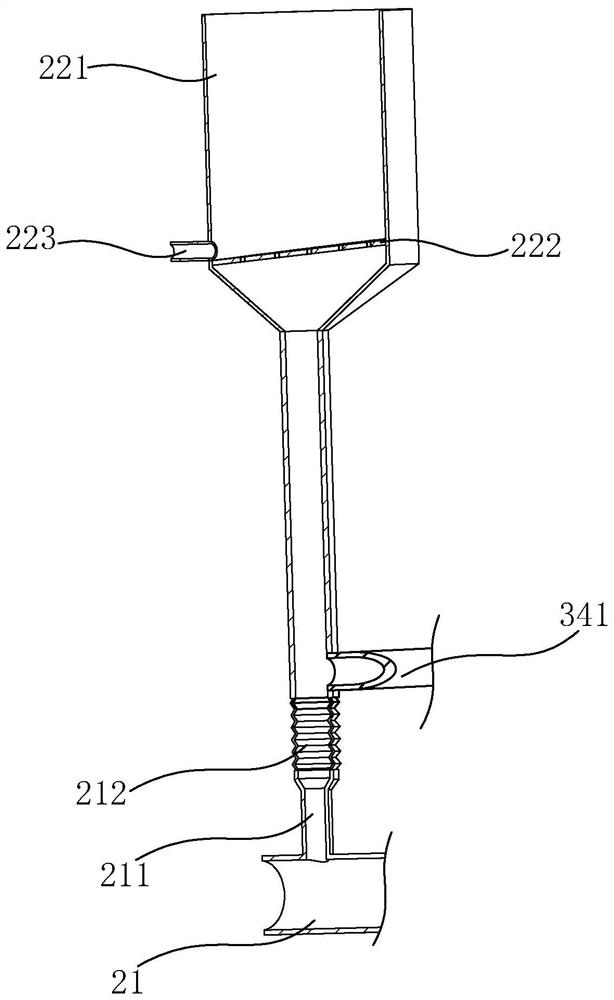

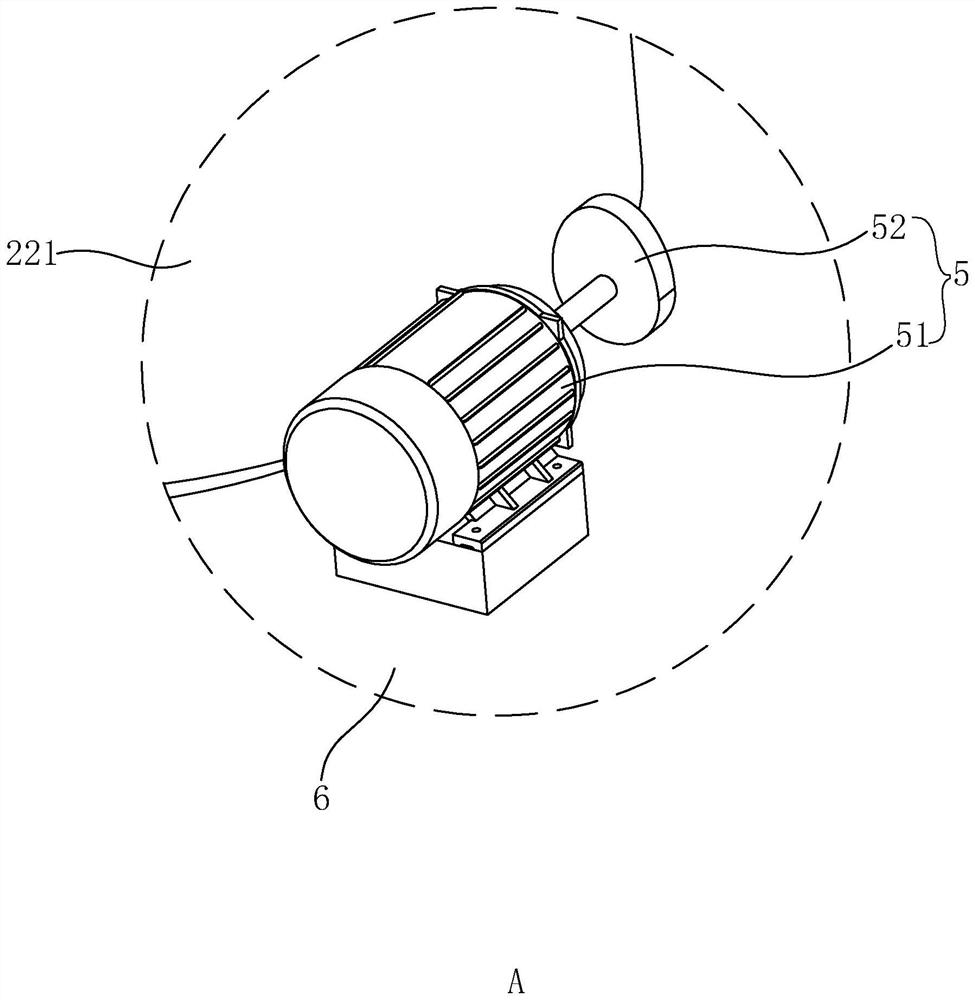

[0037] The embodiment of the present application discloses a ball mill. refer to figure 1A ball mill comprises a support 1 and a ball mill body 2 fixed on the top of the support 1 by bolts. One end of the ball mill body 2 is welded with an air inlet pipe 21, and the top of the air inlet pipe 21 is connected and welded with a first feed pipe 211. The first feed pipe The top of the pipe 211 is connected with a coarse filter feed hopper 22, and the other end of the ball mill body 2 is provided with a discharge pipe 23 for connecting with the driving device of the ball mill. The driving device of the ball mill is a driving motor, and the output shaft of the driving motor passes through the discharging pipe 23. The coupling is connected, the bottom of the discharge pipe 23 is connected and welded with the lower hopper 24, the top of the discharge pipe 23 is connected and welded with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com