Automatic precision grinding device for outer surfaces of shaft type workpieces

A technology for shaft workpieces and outer surfaces, which is applied in the field of automatic fine grinding devices for the outer surfaces of shaft workpieces, and can solve problems such as the decline in the grinding accuracy of the outer surface of shaft workpieces, difficulty in further improving the grinding progress, and interference with the accuracy of the outer surface of shaft workpieces. , to achieve the effect of improving grinding efficiency, low cost, and good magnetic grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

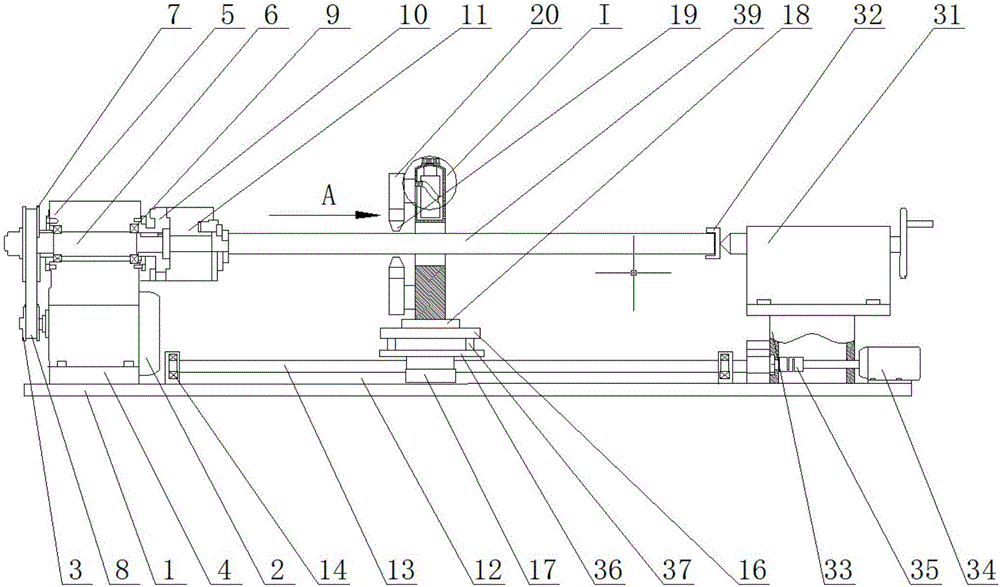

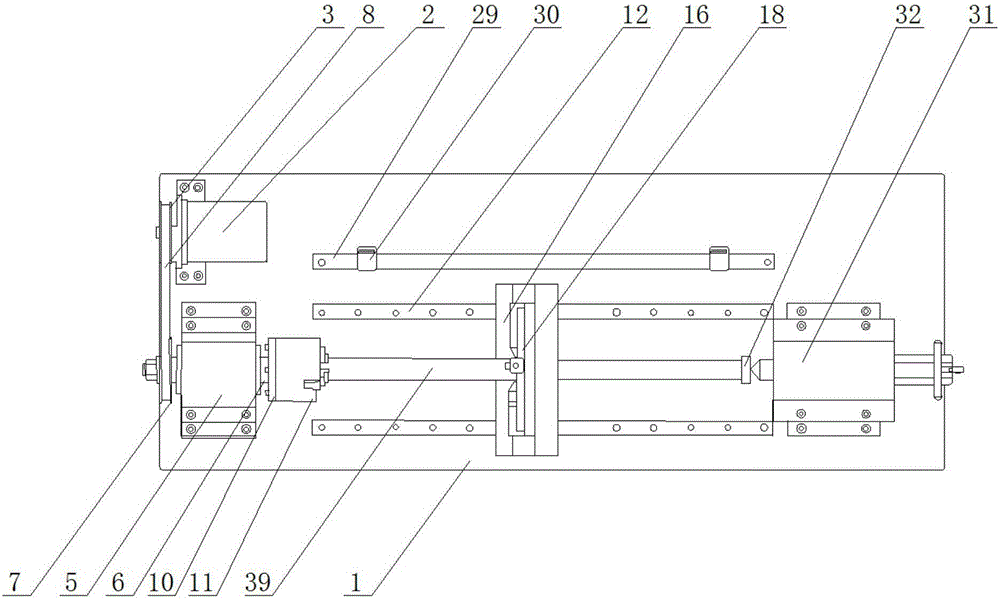

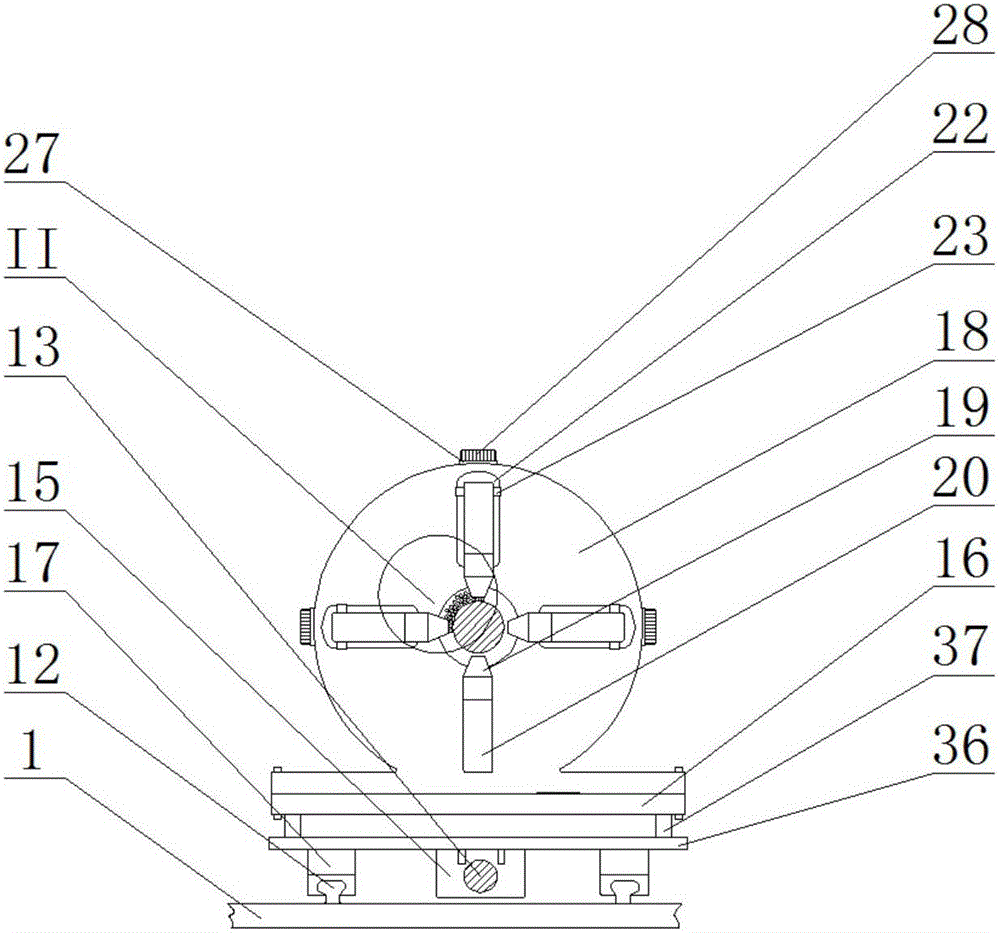

[0034] An automatic fine grinding device for the outer surface of a shaft workpiece, including a base plate 1, on which a first motor 2 is arranged. In this embodiment, the first motor is connected with the base plate by bolts, and the output shaft of the first motor 2 is A driving wheel 3 is provided, and a cushion block 4 is provided on one side of the first motor 2, and the cushion block 4 is fixedly connected with the bottom plate 1. In this embodiment, the bottom plate is connected with the cushion block by bolts. A transmission device is arranged on the pad 4, and the transmission device includes a first transmission box 5, and a transmission shaft 6 is arranged in the first transmission box 5, and the left and right ends of the transmission shaft 6 pass through the first transmission box 5. The casing wall is exposed outside the first transmission case 5, and a driven wheel 7 is arranged at one end of the transmission shaft 6, and a transmission belt 8 is installed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com