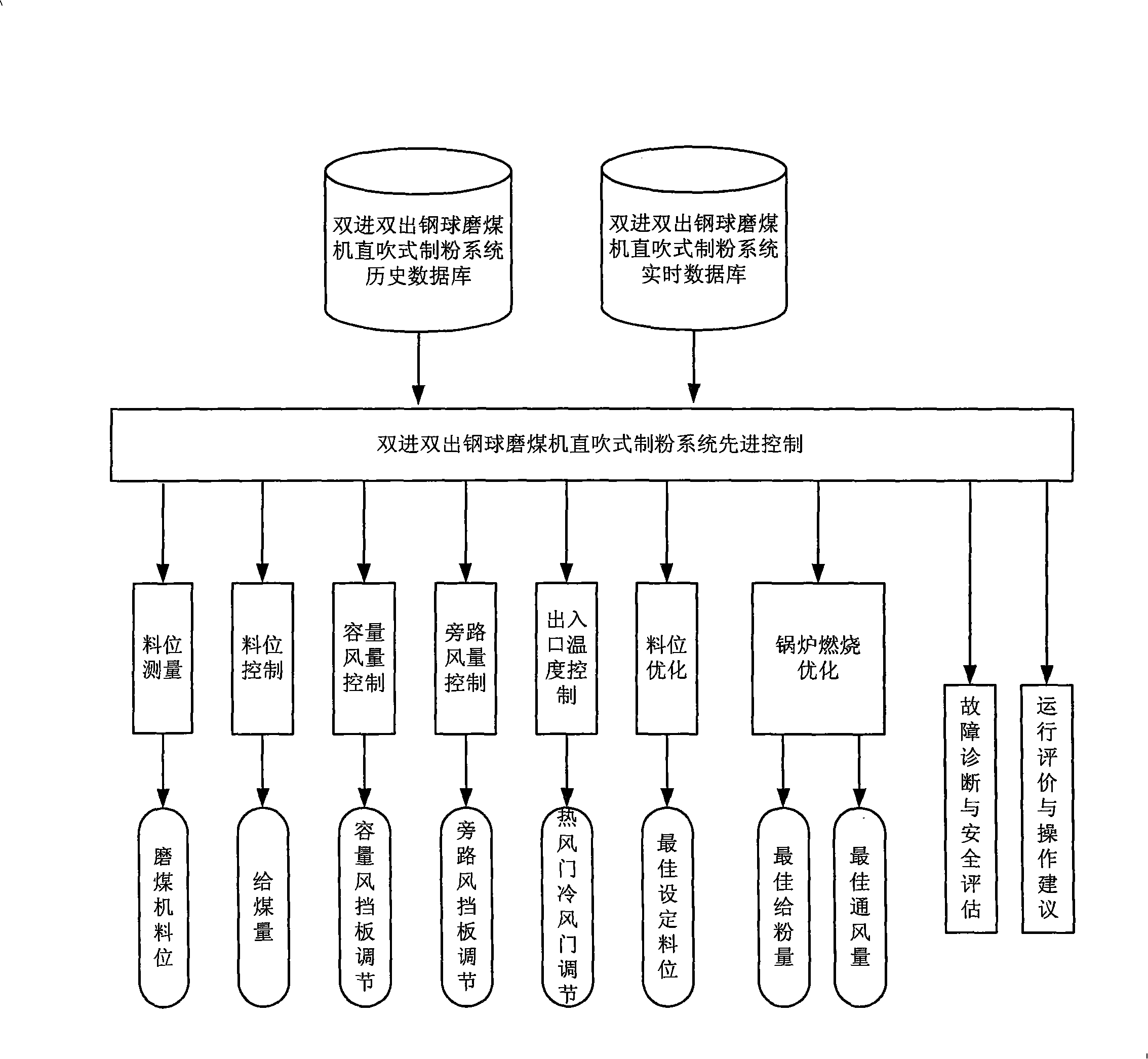

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

A steel ball coal mill and pulverizing system technology, applied in the direction of comprehensive factory control, electrical program control, grain processing, etc., can solve the problem of affecting the automatic input rate of the unit, the safe and economical operation of the unit, and the double-inlet and double-outlet steel ball mill coal pulverization system Complicated, automatic control fails to achieve the desired goal, etc., to achieve the effect of ensuring the unit consumption of pulverizing, qualified and stable pulverized coal fineness, and preventing failures or accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

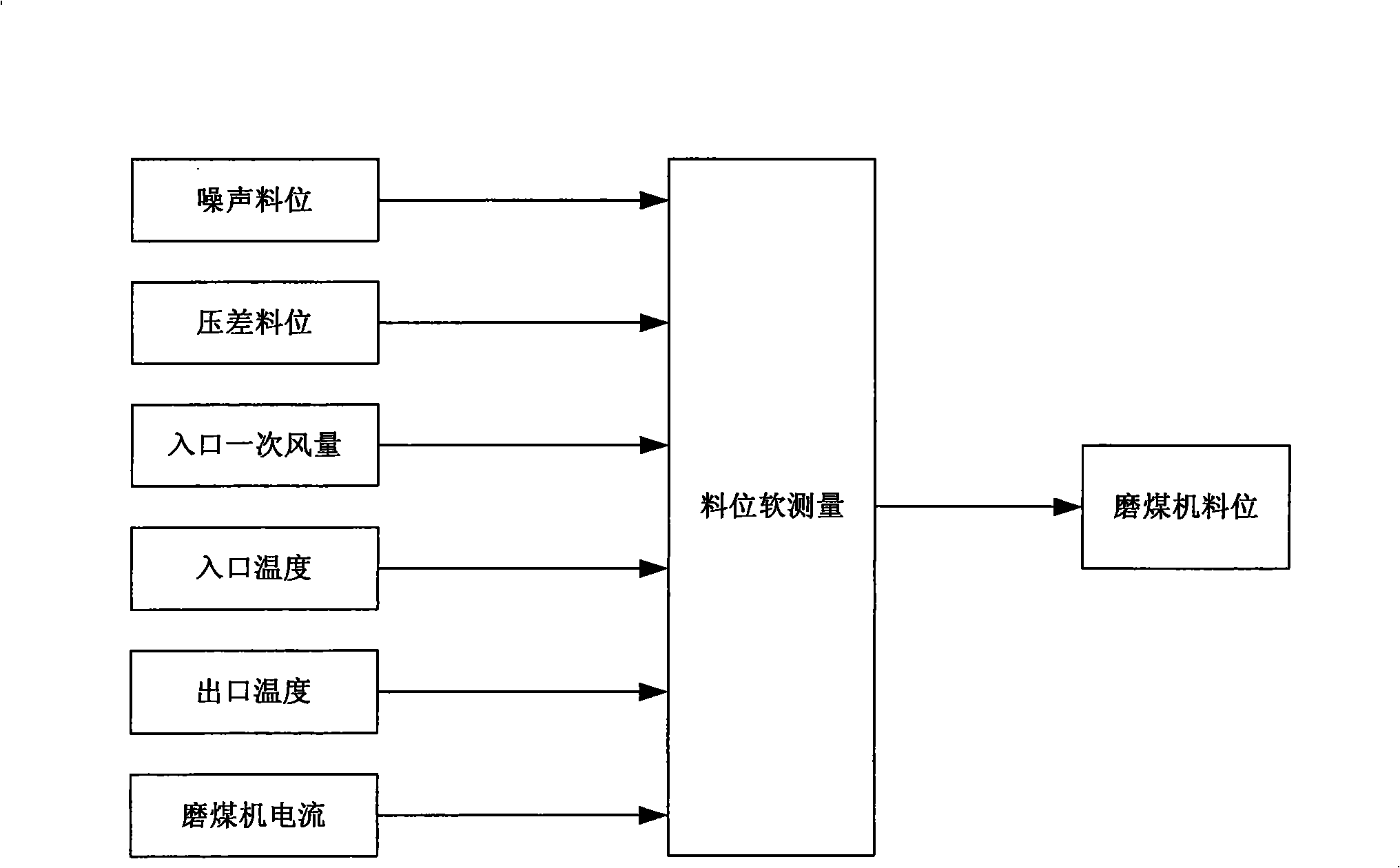

Method used

Image

Examples

Embodiment

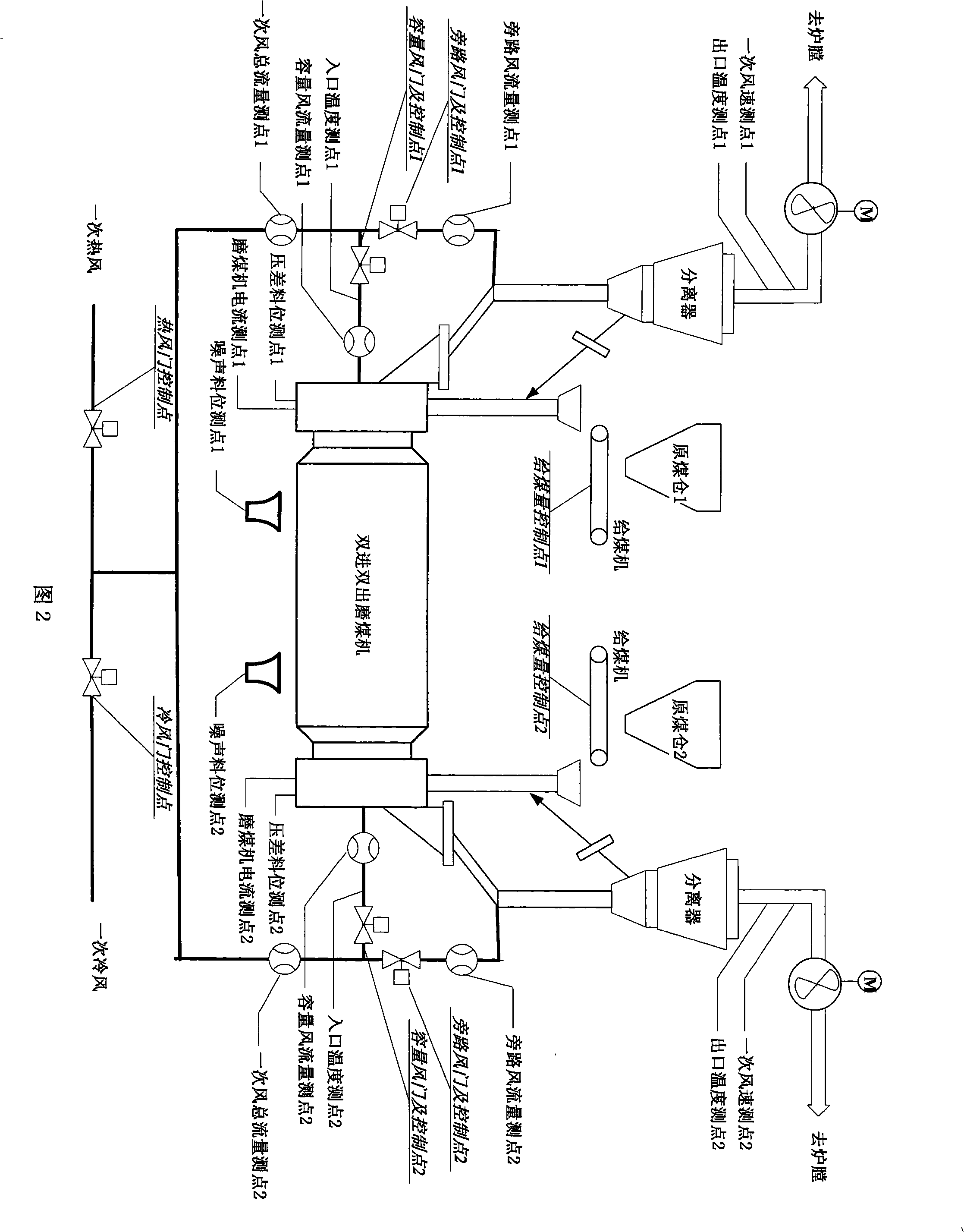

[0086] The 4# unit of a power plant has an installed capacity of 300MW. The pulverizing system is 4 sets of 14’-O’×18’-O’ double-inlet and double-outlet steel ball coal mills produced by Sweden’s SVEDALA company. Three are in operation and one is in standby. Each coal mill is equipped with two metering electronic belt scales, and the system control adopts Shanghai FOXBORO distributed control system. The boiler is an SC-1025 / 18.3-M type controlled circulating steam drum furnace, four corners are tangentially fired, six layers of pulverized coal burners, and the pulverizing system is a double-inlet and double-outlet steel ball mill positive pressure cooling primary air direct blowing system. The grinding belt has two layers of pulverized coal burners (one layer for each of the two powder outlets). 14’-O’×18’-O’ type steel ball coal mill Coal mill barrel speed: 16.77rpm, coal mill design maximum output 40t / h, maximum steel ball loading capacity: 99.9t.

[0087] The raw coal is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com