Polishing workbench

A workbench and operating table technology, applied in the direction of grinding workpiece supports, grinding machines, manufacturing tools, etc., can solve problems such as affecting grinding efficiency, unfavorable use, unfavorable long-term use, etc., and achieve the effect of ensuring accuracy and grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

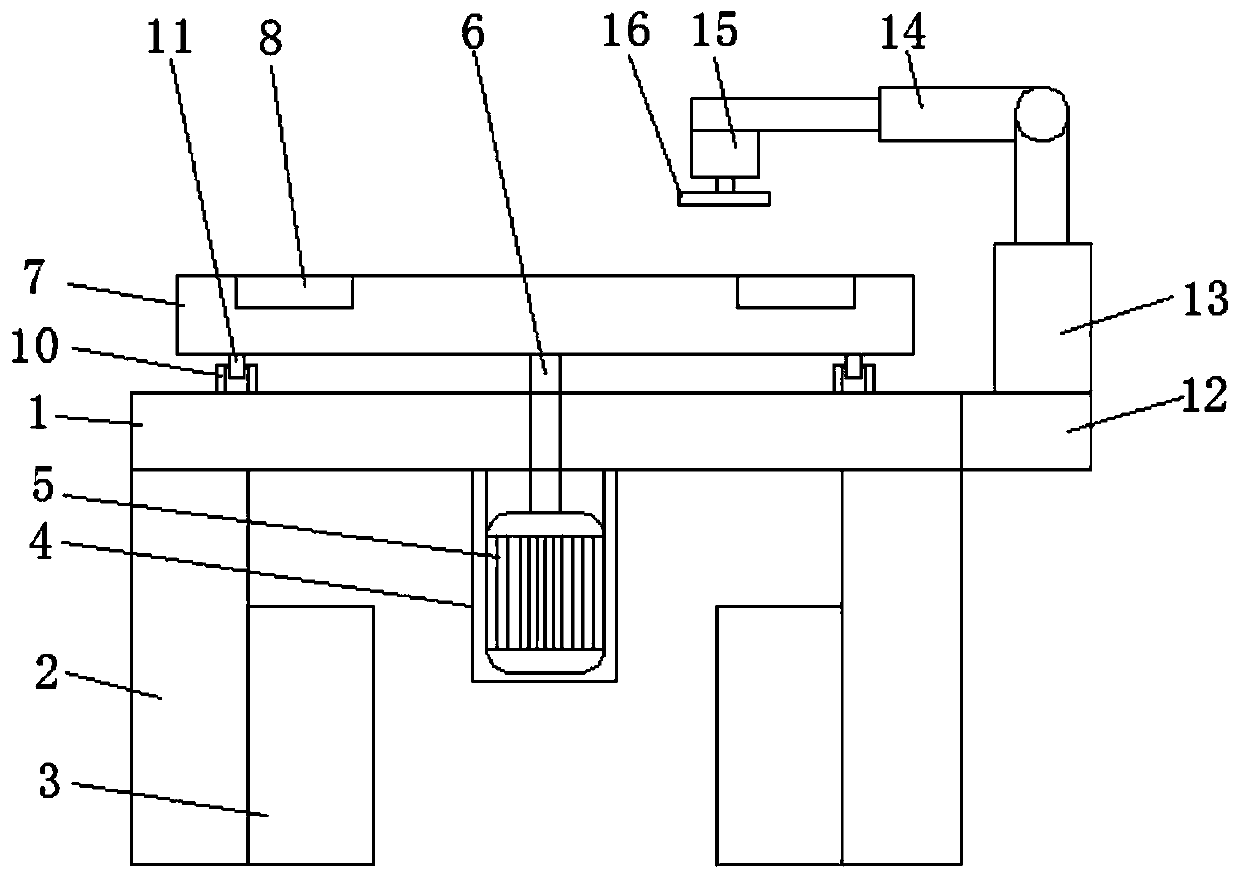

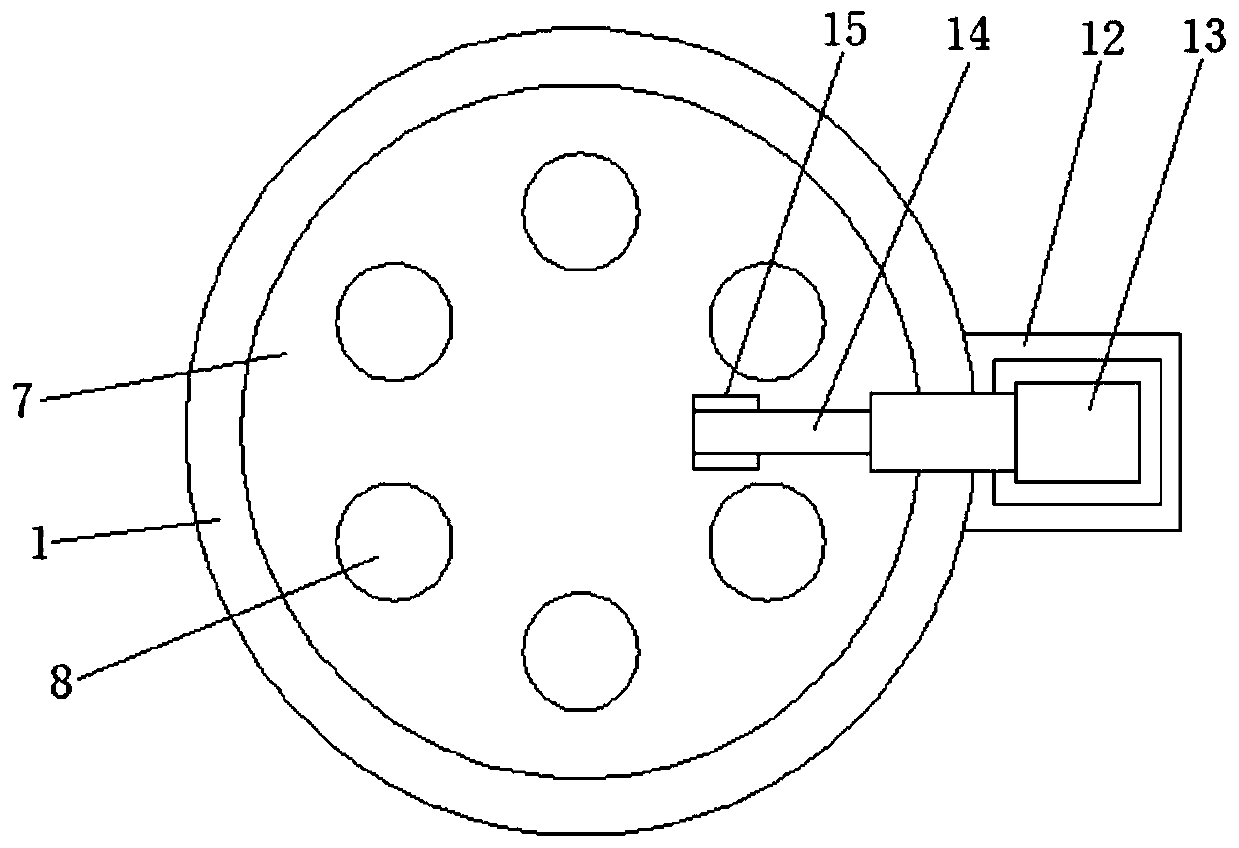

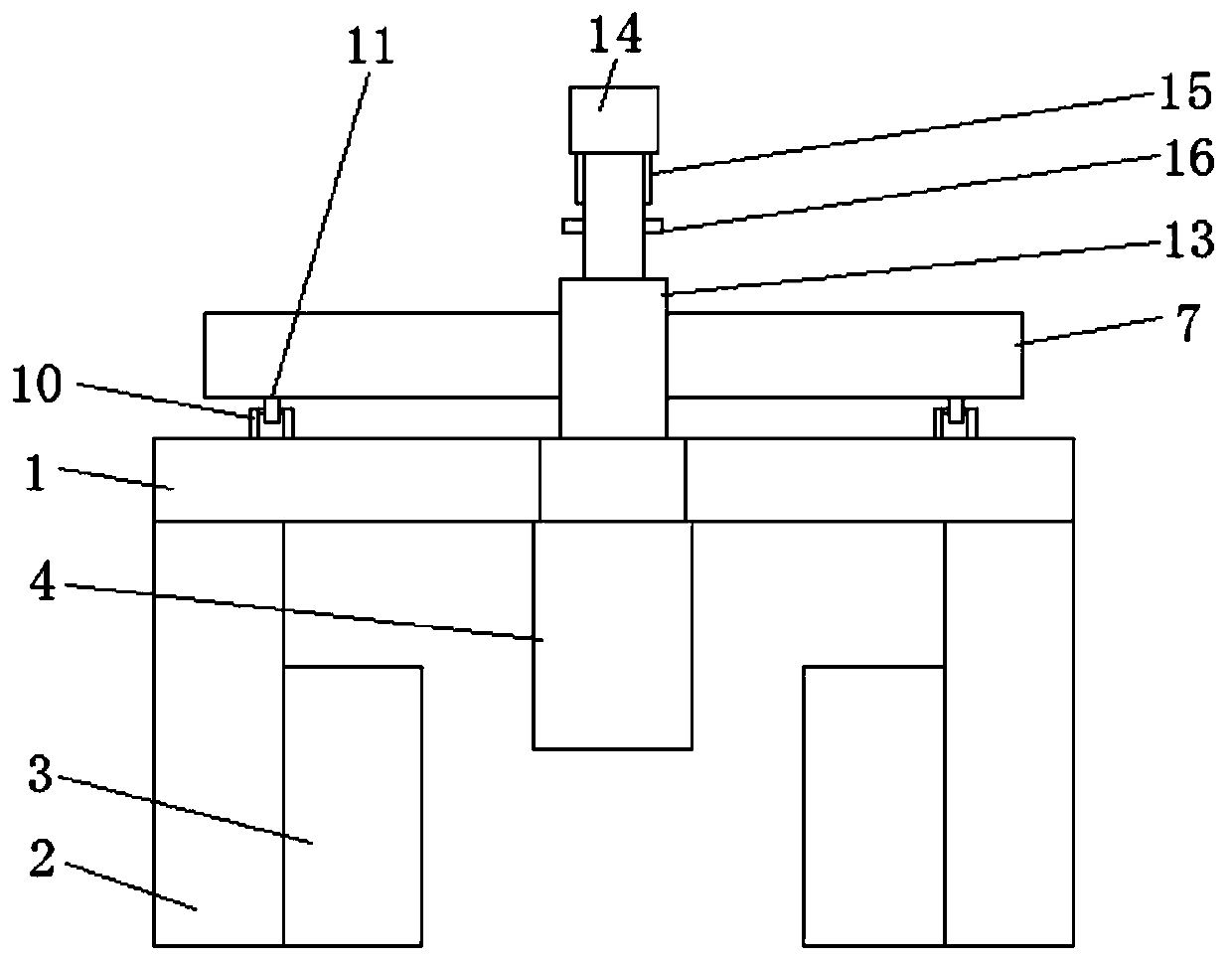

[0026] see Figure 1-4 , the present invention provides the following technical solutions: a grinding workbench, including a console 1, a fixed foot 2 is fixedly connected around the bottom of the console 1, a storage box 3 is movably connected to the inner side of the fixed leg 2 through a chute, and the bottom of the console 1 The center is fixedly connected with a motor box 4 by bolts, the inner cavity of the motor box 4 is fixedly connected with a rotating motor 5, the center of the top of the rotating motor 5 is movably connected with a rotating shaft 6, and the rotating shaft 6 runs through the center of the console 1, and the top of the rotating shaft 6 is fixedly connected with a The turntable 7, the turntable 7 is located above the operating table 1, the top of the turntable 7 is provided with a circular groove 8, the center of the top of the turntable 7 is fixedly connected with a fixed column 9, and the top of the operating table 1 is fixedly connected with a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com