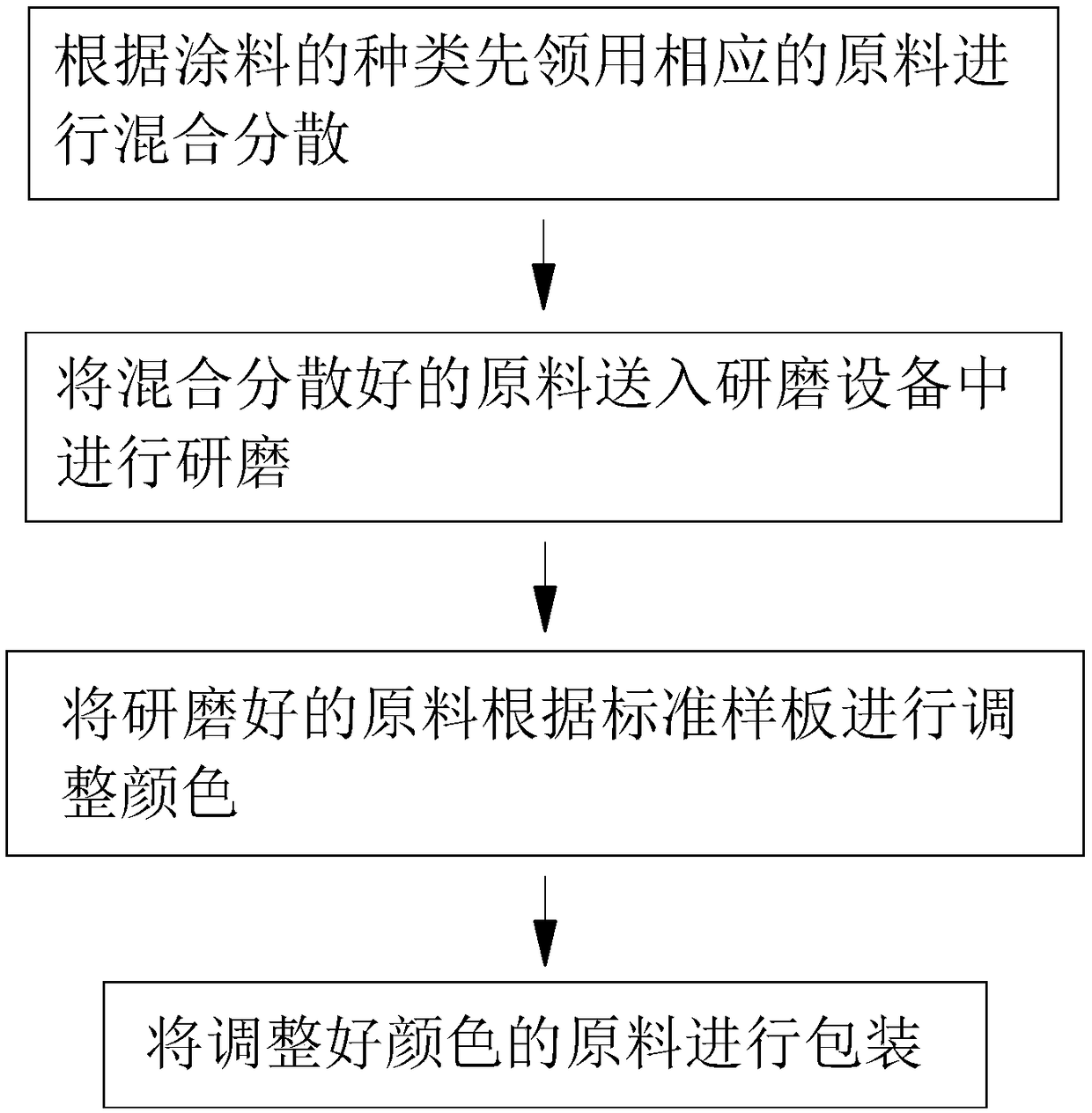

Powder coating production technology

A production process and powder coating technology, applied in the field of powder coating production technology, can solve the problems of insufficient grinding, affecting the quality of the coating, and difficulty in the process, so as to achieve fine coating powder, improve rolling efficiency and good crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

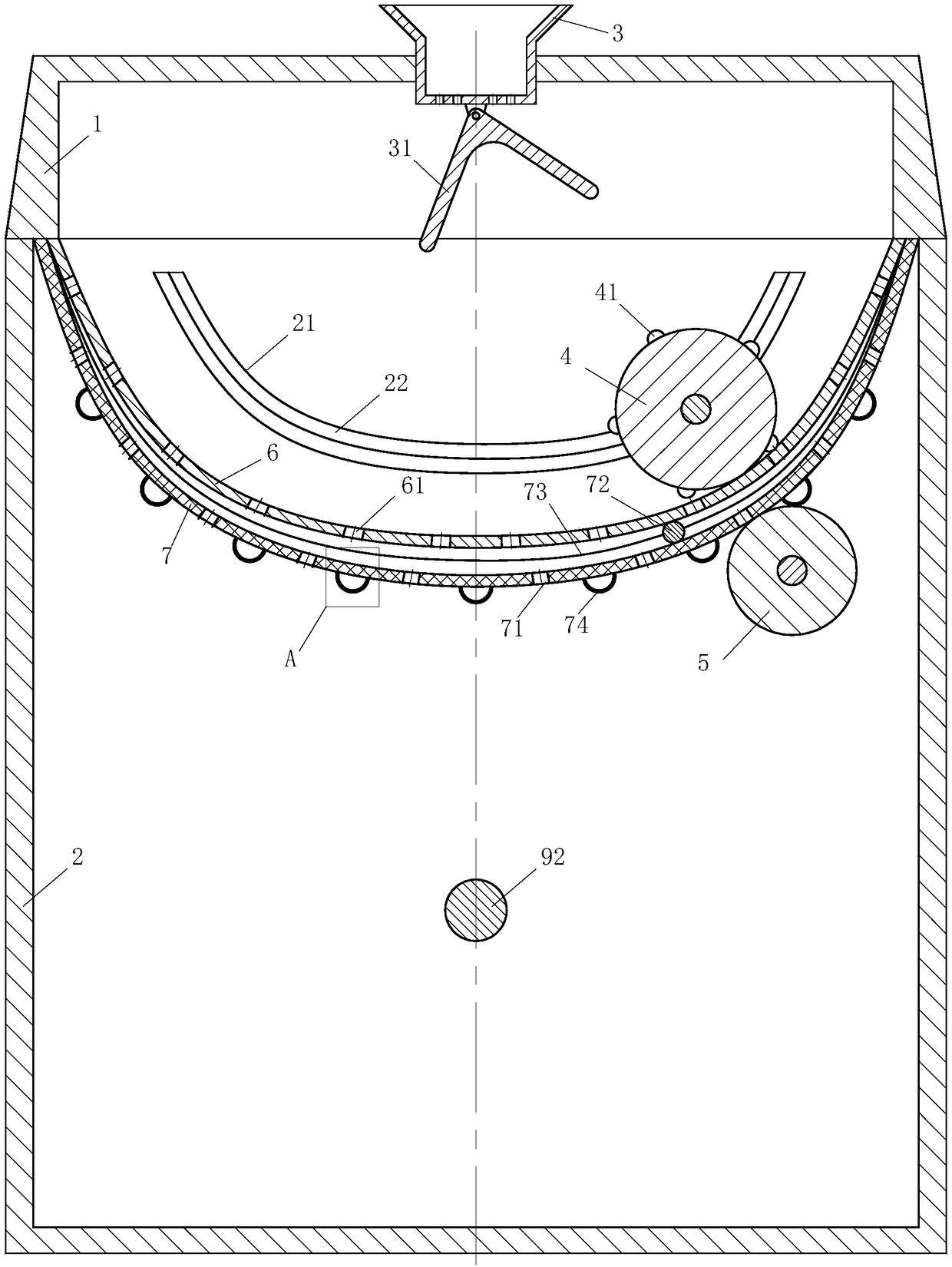

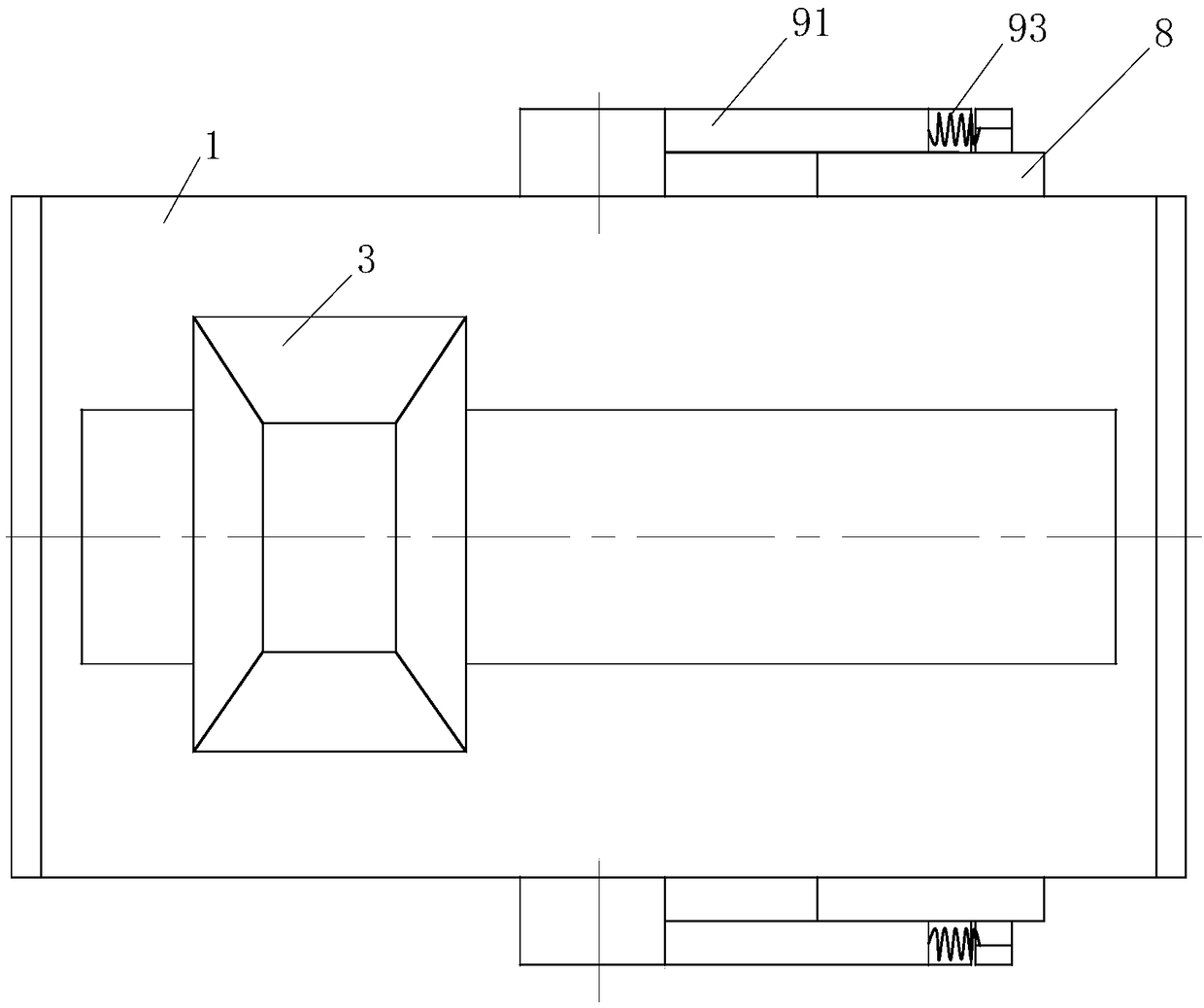

[0041] As an embodiment of the present invention, the drive motor is a high-speed and high-torque motor; when in use, the high-speed and high-torque motor can obtain a very high speed in an instant to ensure the swing speed of the swing arm 91, and then drive the grinding roller 4 to have a High rolling speed, the higher the rolling speed of the grinding roller 4, the better the crushing effect, thereby ensuring the grinding efficiency and grinding quality of the grinding roller 4.

[0042] When in use, the granular paint is fed into the upper casing 1 from the feed hopper 3, and the paint particles are evenly sprinkled on the inner wall of the grinding liner 6 by the L-shaped plate 31 that swings back and forth from side to side, and the driving motor drives the swing arm 91 from One side swings quickly to the other side, and the swing arm 91 drives the connecting plate 8 to move through the pull rope 9, and then drives the grinding roller 4 and the rolling roller 5 on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com