Polishing device for battery protection shell of reconnaissance robot

A kind of protective shell and robot technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, device for fixing grinding wheel, etc. The effect of dead angle, ensuring efficiency and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

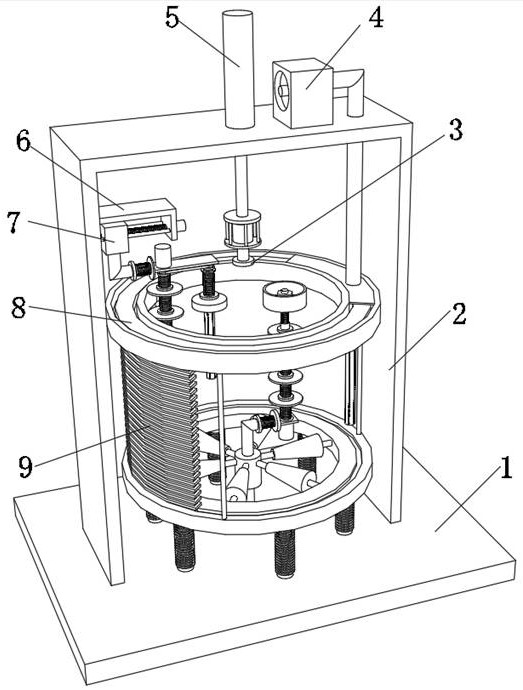

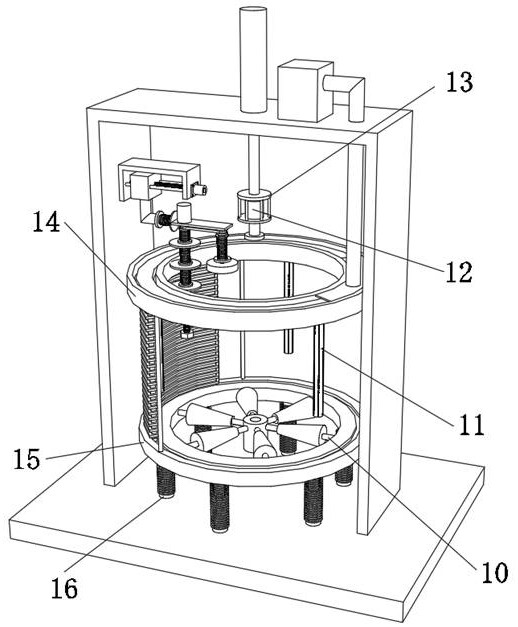

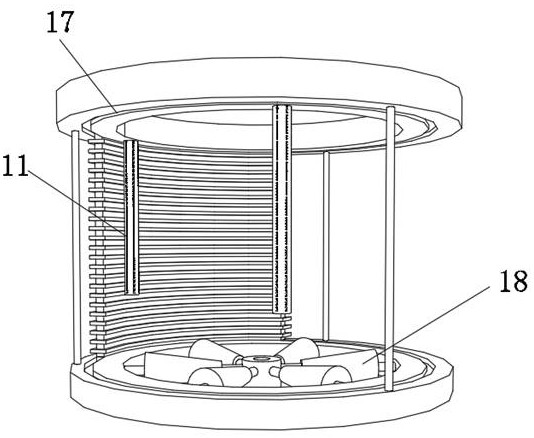

[0036] A reconnaissance robot battery protective shell grinding device, such as Figure 1-5 As shown, it includes a base 1 and a supporting mechanism. The outer wall of the top of the base 1 is fixed with a support frame 2 by bolts, and the inner wall of one side of the support frame 2 is fixed with an electric screw slide rail 6 by bolts. The electric screw slide rail 6 The output end is slidably connected with a slider 7, the outer wall on one side of the slider 7 is fixed with a telescopic frame 20 by bolts, the inner wall on one side of the slider 7 and the inner wall on the side of the telescopic frame 20 are clamped with the same spring 4 31, the top outer wall of the telescopic frame-20 is fixed with a grinding motor-21 by bolts, the bottom outer wall of the telescopic frame-20 is rotatably connected with a mounting column-28, and the output end of the polishing motor-21 is connected to the Described mounting post-28 top inner wall, described mounting post-28 circumfere...

Embodiment 2

[0045] A reconnaissance robot battery protective shell grinding device, such as Figure 7 As shown, in order to facilitate the grinding of the rectangular protective casing; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of the top of the connecting frame 10 is connected to the rotating seat 41 through bearing rotation; at the same time, due to the shape of the battery protective casing Be cylindrical, also may be rectangular, by being provided with telescopic frame 120 and spring 4 31 can when grinding wheel 129 is polished to the prismatic cylindrical protective shell outer wall, make grinding wheel 129 circumference outer walls can be better ground and the surface of the prismatic cylindrical protective shell to ensure the effect of grinding, while the telescopic frame 2 33 and the spring 5 35 have the same effect, and the rotating seat 41 can be used to place the rectangular protective shell to make crimping The motor 12 can d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com