Automatic anchor chain polishing device

An anchor chain, automatic technology, applied in the direction of grinding automatic control device, grinding machine, grinding feed movement, etc., can solve the problems of low processing yield, air environment impact, time-consuming labor intensity, etc., to save labor and ensure efficiency and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following structural drawings further describe the present invention;

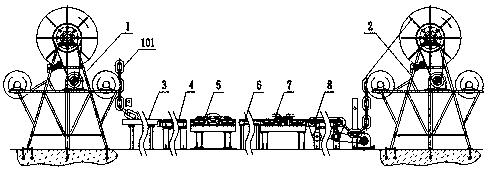

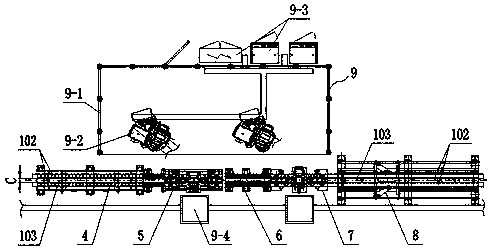

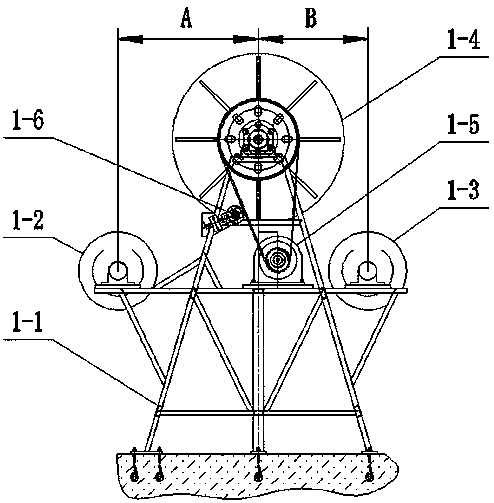

[0026] In the accompanying drawings: the anchor chain automatic grinding device, which is characterized by: including the first tower wheel conveying device 1 and the second tower wheel conveying device 2 respectively arranged at both ends; the first tower wheel conveying device 1 and the second tower wheel conveying device An anchor chain bracket 3, an anchor chain feeding track 4, a vertical chain clamping device 5, an adjustment transition device 6, a flat chain clamping device 7, and an anchor chain unloading track 8 are sequentially arranged between the tower wheel conveying devices 2; Cooperate with the vertical chain clamping device 5 and the flat chain clamping device 7 to polish the robot assembly 9 of the anchor chain 101; the robot assembly 9 includes a guardrail 9-1, a robot 9-2 arranged in the guardrail 9-1, The control cabinet 9-3 connected with the robot 9-2, and the dust removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com