Multifunctional robot polishing equipment

A robotic and multi-functional technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve problems such as inconvenient collection, poor use of waste, and dust that is not environmentally friendly, so as to improve grinding efficiency and protect The effect of environment and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

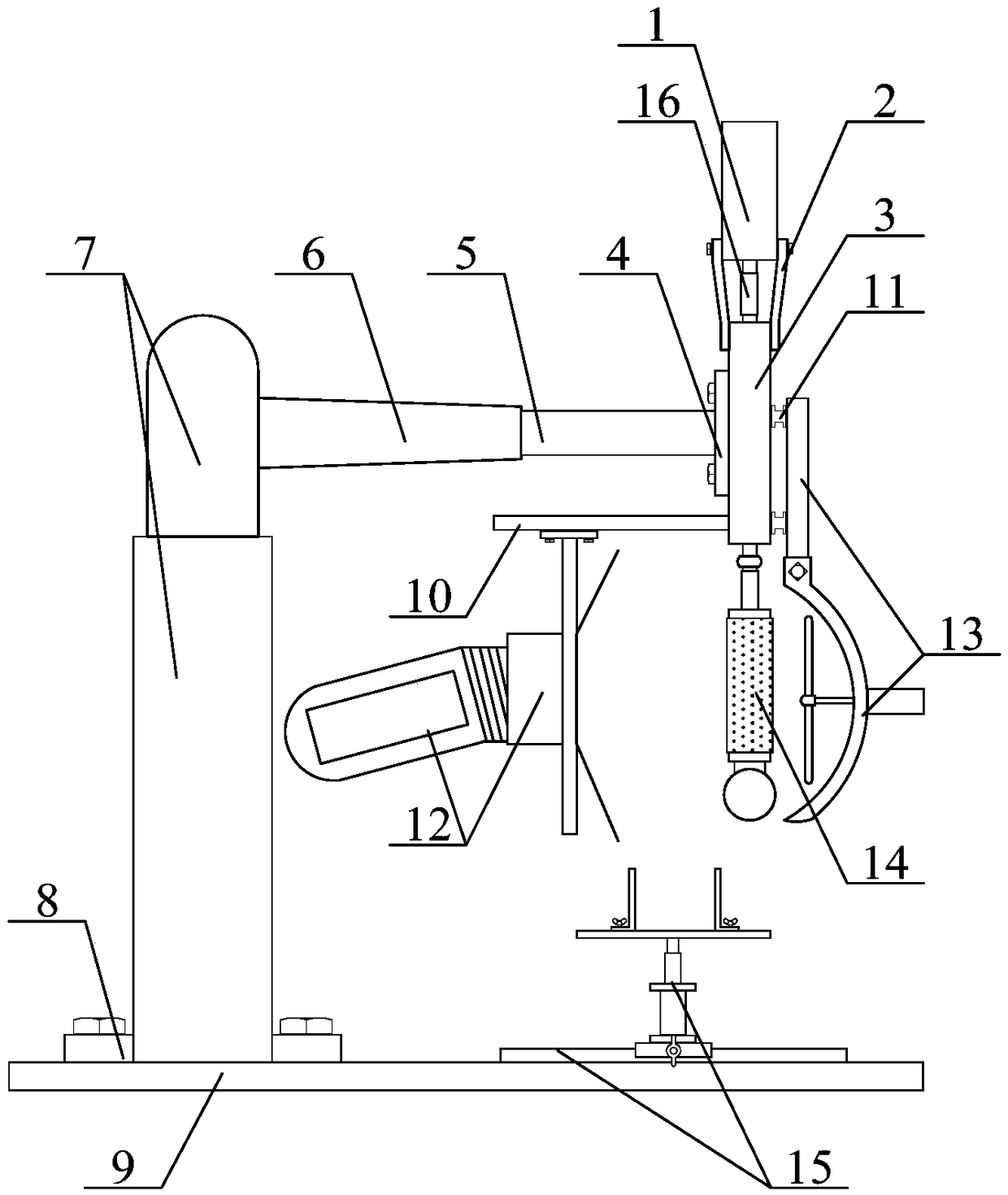

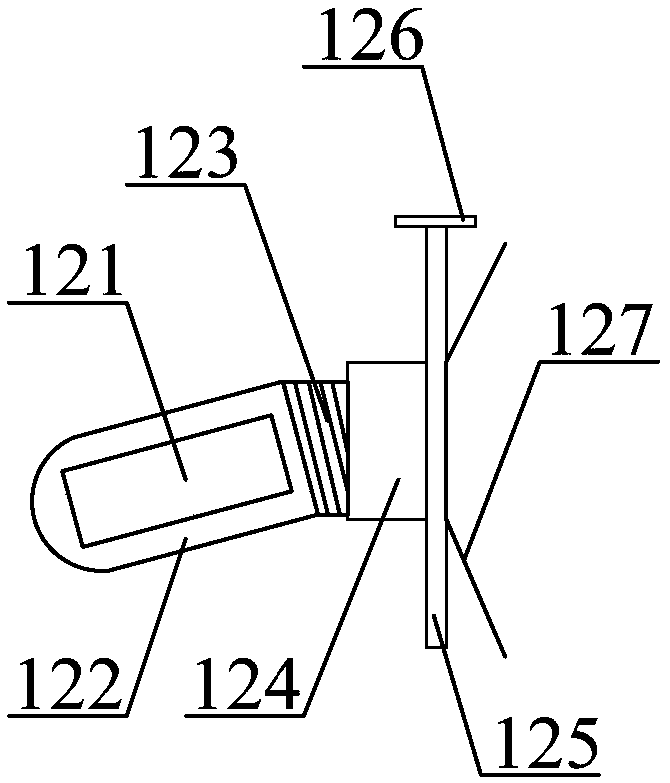

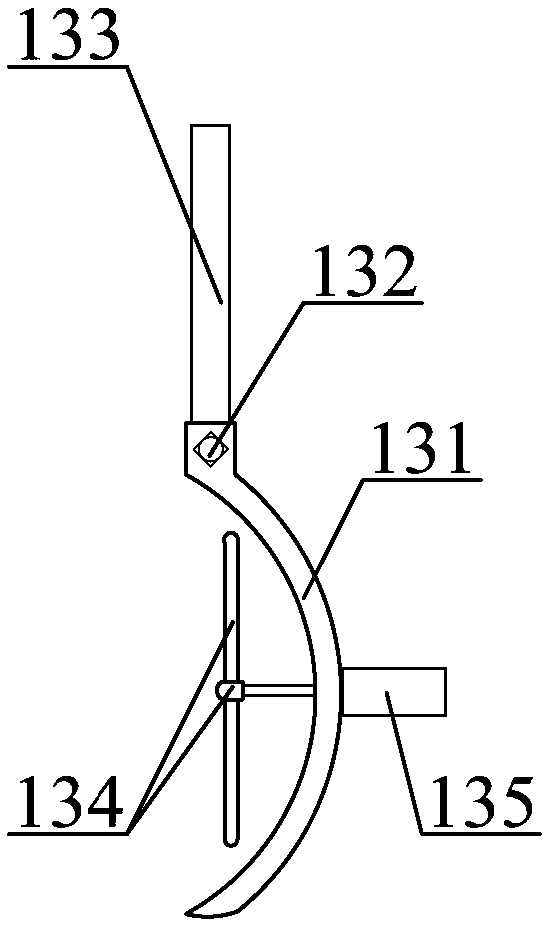

[0041] as attached figure 1 to attach Figure 5 shown

[0042] The invention provides a multi-functional robot grinding equipment, including a grinding motor 1, a fixed plate 2, a fixed sleeve 3, a connecting plate 4, a robot power arm 5, a robot telescopic arm 6, an ER50-3200 six-axis robot 7, and a fixed card Seat 8, base 9, support plate 10, I-shaped frame 11, waste and dust collection environment-friendly barrel structure 12, adjustable dust and waste blower structure 13, quick grinding and replacement rod structure 14, height-adjustable clamping plate structure 15 With the sleeve coupling 16, the grinding motor 1 is bolted to the upper position between the fixed plate 2 and the fixed plate 2; the fixed plate 2 is longitudinally welded on the left and right walls of the upper part of the fixed sleeve 3; The longitudinal bolts of the connecting plate 4 are installed in the middle position on the left side of the fixed sleeve 3; the longitudinal thread of the connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com