A mold grinding device

A mold and grinding disc technology, applied in the field of mold manufacturing, can solve the problems of work efficiency impact, time-consuming and laborious, powder human health damage, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

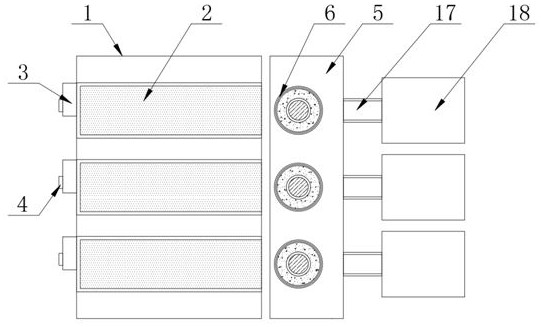

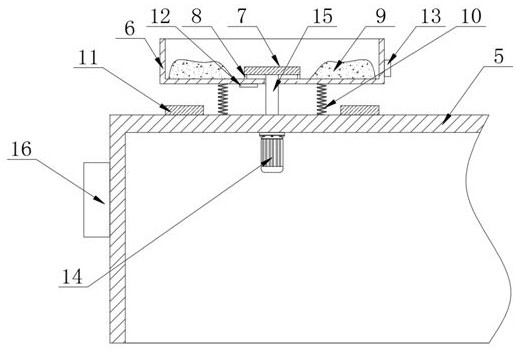

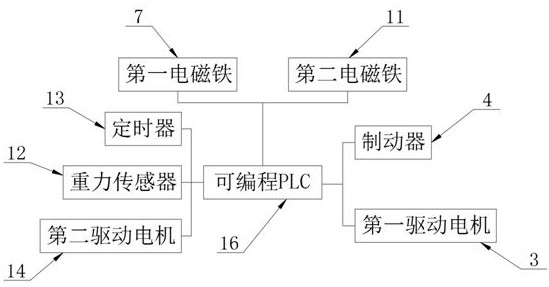

[0025] The present invention provides such Figure 1-3 A mold grinding device shown includes a feeder 1, a conveyor belt 2 is provided on the top of the feeder 1, a first drive motor 3 is provided at one end of the conveyor belt 2, and a brake is provided on one side of the first drive motor 3 4. There is a grinding frame 5 on one side of the feeder 1, and a grinding disc 6 is installed on the top of the grinding frame 5. The grinding disc 6 is made of iron material. The gravity sensor 12 senses the weight increase and transmits the signal to Programmable PLC16, programmable PLC16 controls the brake 4 to stop the continuous feeding of the conveyor belt 2, the inside of the grinding disc 6 is provided with a first electromagnet 7, and a deformation pad is provided between the first electromagnet 7 and the inner wall of the grinding disc 6 8. The outside of the first electromagnet 7 is provided with grinding sand 9, a first return spring 10 is provided between the grinding disc ...

Embodiment 2

[0029] The present invention provides such Figure 4-6 As shown in a mold grinding device, one end of the discharge slideway 17 is provided with a storage box 18, and the connection between the storage box 18 and the discharge slideway 17 is provided with a through groove 19, and the inner wall of the storage box 18 is provided with Buffer pad 20, the cavity of the storage box 18 is provided with a support plate 21, a second return spring 22 is provided between the support plate 21 and the inner wall of the storage box 18, and the mold falls to the top of the support plate 21 and is driven by its own weight. The two return springs 22 shrink, thereby realizing the storage mode of the layered arrangement of the moulds, the discharge slide 17 is arranged obliquely, the through groove 19 runs through the storage box 18, and the through groove 19 is matched with the discharge slide 17 , the user takes out the polished mold from the grinding disc 6 and puts it on the discharge slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com