Device for recovering and treating magnetorheological fluid and treatment method

A magnetorheological fluid, recovery and treatment technology, applied in the direction of magnetic fluid, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of energy waste, environmental pollution, lack of efficient recovery and treatment devices for magnetorheological waste liquid, etc. To achieve the effect of fast cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

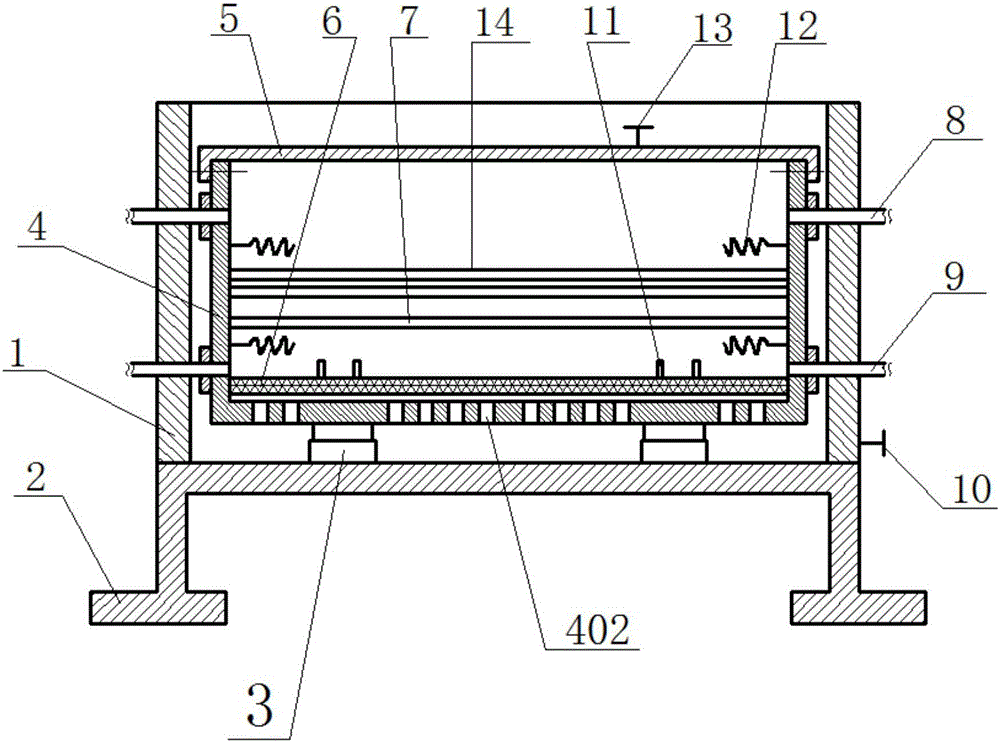

[0055] Such as figure 1 As shown, a magneto-rheological fluid recovery and treatment device based on temperature change and high-pressure filter breaking action includes an outer barrel body 1 and a pressurized filter device 4, and bases 2 are provided at both ends of the bottom of the outer barrel body 1; pressurized The filter device 4 is arranged in the outer barrel body 1, and the specific structure of the pressurized filter device 4 is a hollow container with an opening at the upper end, and a detachable sealing cover 5 is provided at the opening, and a sealing rubber ring is arranged on the sealing cover 5 to ensure that the sealing cover 5 and the pressurized filter device 4, the sealing cover 5 is also provided with an exhaust valve 13 for exhausting gas during the temperature change process, and the exhaust capacity of the exhaust valve 13 is at least 3.5L / s; The bottom of the pressurized filter device 4 is provided with a filter screen 6, and the bottom of the pressu...

Embodiment 2

[0084] Such as figure 1 As shown, a magneto-rheological fluid recovery and treatment device based on temperature change and high-pressure filter breaking action includes an outer barrel body 1 and a pressurized filter device 4, and bases 2 are provided at both ends of the bottom of the outer barrel body 1; pressurized The filter device 4 is arranged in the outer barrel body 1, and the specific structure of the pressurized filter device 4 is a hollow container with an opening at the upper end, and a detachable sealing cover 5 is provided at the opening, and a sealing rubber ring is arranged on the sealing cover 5 to ensure that the sealing cover 5 and the pressurized filter device 4, the sealing cover 5 is also provided with an exhaust valve 13 for exhausting gas during the temperature change process, and the exhaust capacity of the exhaust valve 13 is at least 3.5L / s; The bottom of the pressurized filter device 4 is provided with a filter screen 6, and the bottom of the pressu...

Embodiment 3

[0114] Such as figure 1 As shown, the device for reclaiming and processing magnetorheological fluid has the same structure as that in Embodiment 1. The diameter of filter hole 401 is about 4mm, and the surface area of electrode plate 14 is 90cm 2 , The spacing between positive and negative plates is 15mm. The method for recovering and processing the magnetorheological fluid by using the device is as follows:

[0115] The magnetorheological fluid treated in this embodiment is the magnetorheological fluid with oleic acid as the main component of the surfactant, the dispersed particles are hydroxyl iron powder, the magnetic saturation is 2.3T, and the concentration of the magnetic substance in the magnetorheological fluid is About 30g / mL, the carrier liquid is mineral oil, the magnetorheological fluid waste liquid to be treated in this embodiment is the solution after its use exceeds its shear fatigue life, at this time its zero shear viscosity and adjustable multiple During...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com