Crystallization process of di-trimethylolpropane

A ditrimethylolpropane, process technology, applied in the field of ditrimethylolpropane crystallization process, can solve the problems of affecting the liquid part, fine particle size of the product, supersaturated concentration, etc., to achieve increased efficiency and fast cooling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

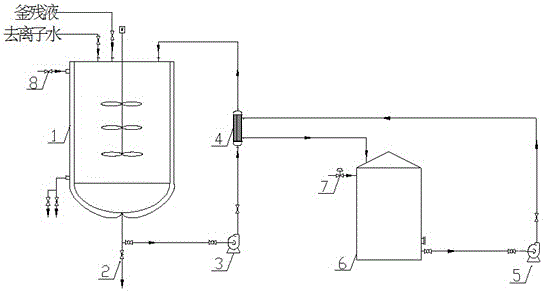

[0023] The crystallization system adopted in the crystallization process of the ditrimethylolpropane of the present embodiment, such as figure 1 As shown, it includes a crystallization stirred tank 1 , a tube and tube heat exchanger 4 and a circulating water tank 6 .

[0024] A frame-type stirrer is arranged in the crystallization stirred tank 1, and the outer wall of the crystallized stirred tank 1 is provided with a jacket, and the upper end of one side of the jacket is provided with a hot water or frozen water inlet connected thereto, and a connected inlet is provided at the lower end. The liquid outlet, and the steam or frozen water inlet is connected with the hot water or frozen water inlet valve 8; A discharge pipe is arranged in the center of the end, and a discharge valve 2 is arranged on the discharge pipe.

[0025] The discharge pipe above the discharge valve 2 is connected to the tube-and-tube heat exchanger 4 through the pipe A, and the feed liquid external circul...

Embodiment 2

[0034] (1) Add 2 tons of 120°C ditrimethylolpropane-containing residual liquid into the crystallization kettle, and start the crystallization kettle to stir;

[0035] (2) Start the frame agitator, first pass steam in the jacket to heat the feed liquid to 80°C until the solids in the feed liquid are completely dissolved, close the steam inlet valve, and empty the condensate in the jacket;

[0036](3) Start the cooling water circulation pump, feed liquid external circulation pump and program temperature control system to slowly cool the feed liquid. When the feed temperature drops to about 60°C, add 25Kg of ditrimethylolpropane as a seed crystal , and then continue to step down to 30±2°C according to the setting of the program temperature control system;

[0037] (4) Close the valve in front of the feed liquid external circulation pump, and continue pumping for 3 minutes, so that the feed liquid in the tube-and-tube heat exchanger can be pumped back to the stirred crystallizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com