Magnesium alloy forged piece and manufacturing method thereof

A magnesium alloy and forging technology, which is applied to the field of high ductility and medium strength magnesium alloy large forgings and its preparation, can solve the problem that the magnesium alloy large forgings are difficult to process, the final forging temperature of ingots is low and easy to crack, and the yield and mechanical properties are low. and other problems, to achieve the effect of significant softening effect, significant grain refinement, and large dynamic recrystallization driving force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

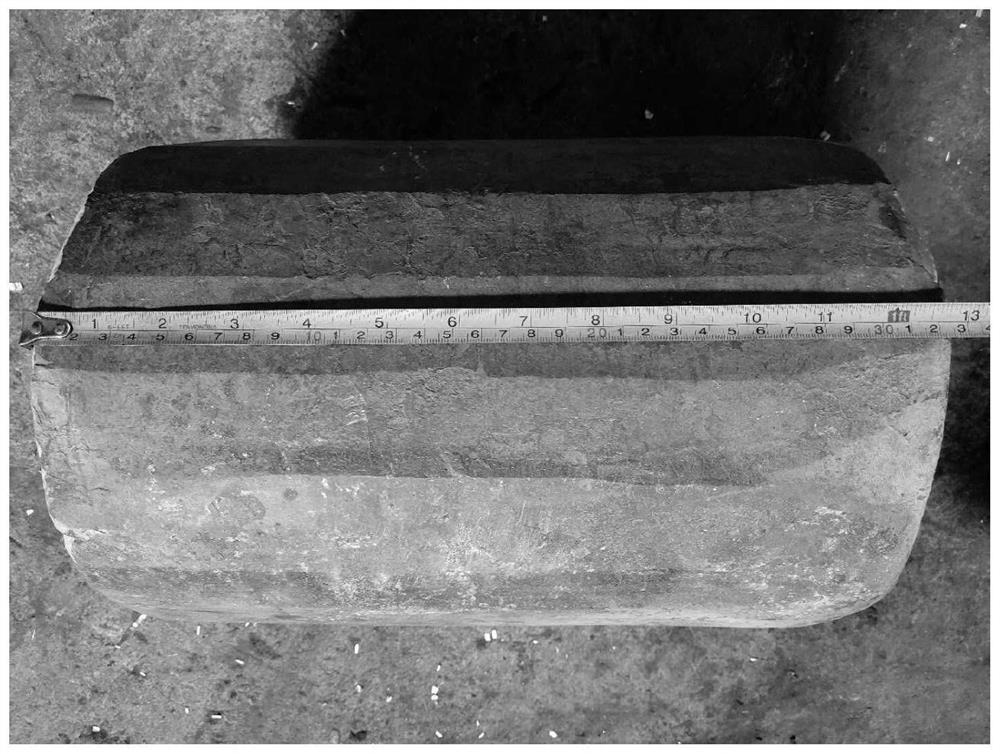

Image

Examples

Embodiment 1

[0068] The present invention will be described in detail below by taking an Mg-5Al-2.8Zn-0.3Mn-0.017Ca-0.08Gd (wt.%) alloy forging as an example.

[0069] 1. Using semi-continuous casting, the melt temperature in the furnace is 683°C during stable casting, the ingot pulling speed is 58mm / min, and a magnesium alloy casting rod with a diameter of Φ270mm and a length of 5000mm is obtained;

[0070] 2. After homogenized annealing at 420°C for 10 hours, the forged ingot with a diameter of Φ240mm and a length of 310mm was obtained by mechanical turning, ultrasonic flaw detection, sawing and blanking;

[0071] 3. Heat the ingot to 440°C for 8 hours, and preheat the upper and lower flat anvils of the hydraulic press to 400°C;

[0072] 4. Take the high direction of the ingot and any two vertical radial directions as the Z, Y, and X directions, first perform 4 passes of upsetting along the Z and Y directions, the reduction speed is 12-15mm / s, and the reduction amount of each pass 35-50...

Embodiment 2

[0075] The present invention will be described in detail below by taking a Mg-4.0Al-2.9Zn-0.6Mn-0.007Ca-0.09Gd-0.24Y (wt.%) alloy forging as an example.

[0076] 1. Using semi-continuous casting, the melt temperature in the furnace is 675°C during stable casting, and the ingot pulling speed is 60mm / min, to obtain a magnesium alloy cast rod with a diameter of Φ270mm and a length of 5000mm;

[0077] 2. After the cast rod is homogenized and annealed at 420°C for 10 hours, the forged ingot with a diameter of Φ240mm and a length of 355mm is obtained by mechanical turning, ultrasonic flaw detection, sawing and blanking;

[0078] 3. Heat the ingot to 420°C for 8 hours, and preheat the upper and lower flat anvils of the hydraulic press to 400°C;

[0079] 4. Take the high direction of the ingot and any two vertical radial directions as the Z, Y, and X directions. Firstly, carry out 4 passes of upsetting along the Z and Y directions, the reduction speed is 10-14mm / s, and the reduction a...

Embodiment 3

[0082] The present invention will be described in detail below by taking a Mg-4.3Al-3.2Zn-0.1Mn-0.004Ca-0.46Y (wt.%) alloy forging as an example.

[0083] 1. Using semi-continuous casting, the melt temperature in the furnace is 680°C during stable casting, and the ingot pulling speed is 44mm / min, to obtain a magnesium alloy cast rod with a diameter of Φ310mm and a length of 4500mm;

[0084] 2. After the cast rod is homogenized and annealed at 420°C for 10 hours, the forged ingot with a diameter of Φ270mm and a length of 540mm is obtained by mechanical turning, ultrasonic flaw detection, sawing and blanking;

[0085] 3. Heat the ingot to 440°C for 10 hours, and preheat the upper and lower flat anvils of the hydraulic press to 420°C;

[0086] 4. Take the height direction of the ingot and any two vertical radial directions as the Z, Y, and X directions. Firstly, carry out 5 passes of upsetting along the Z and Y directions, the reduction speed is 10-15mm / s, and the reduction amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com