Press welding method for semiconductor extension film

A technology of epitaxial wafers and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of slow heating rate, long cooling time, and affecting ohmic contact, and achieve fast heating rate, fast heating rate and cooling rate, and improved The effect of production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

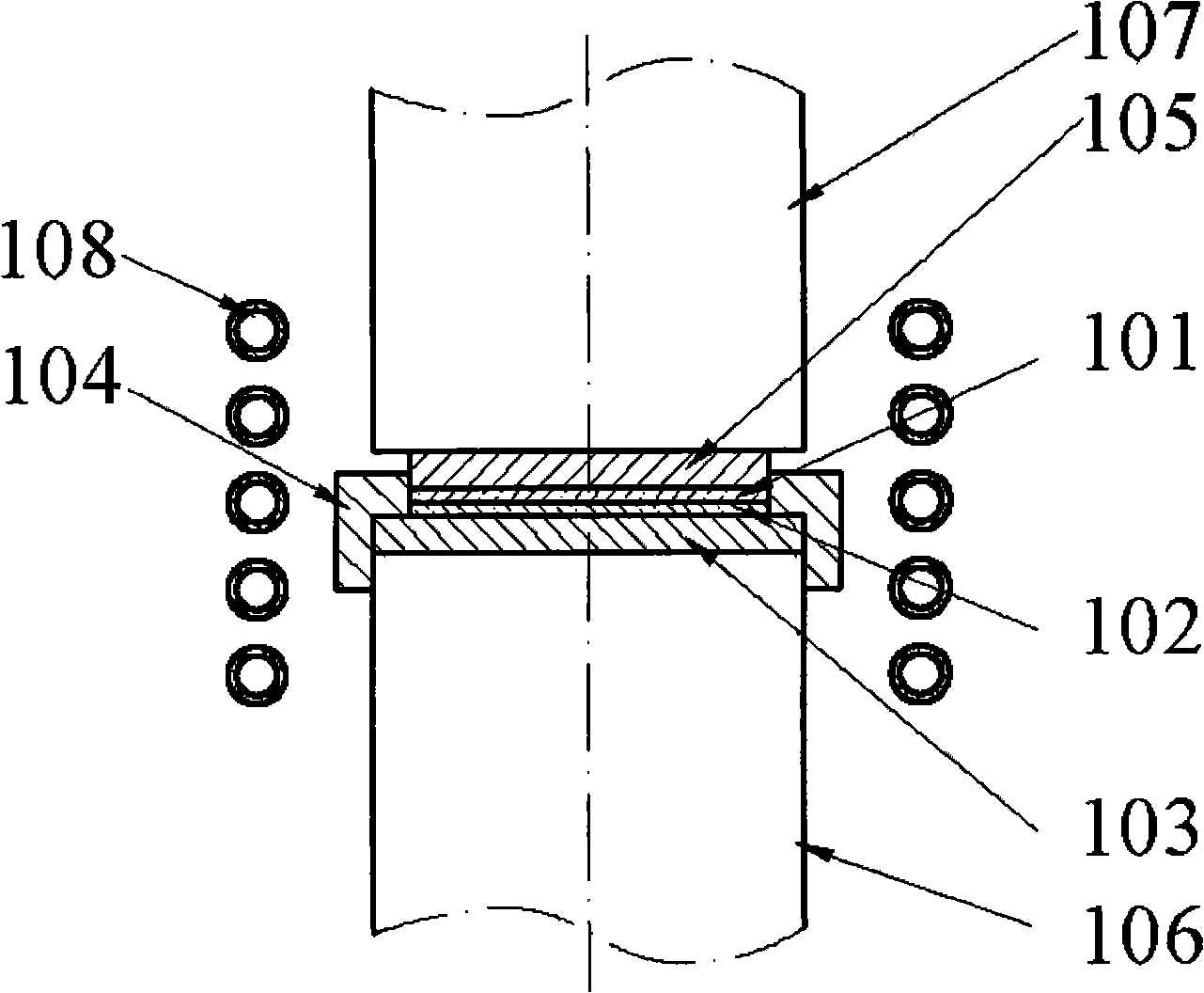

[0023] Construction embodiment one, refer to figure 1 shown. First, an ohmic contact layer and a metal bonding layer (that is, the bonding metal to be bonded) are prepared on the InGaAlN epitaxial wafer 101 , and the ohmic contact layer and the metal bonding layer are prepared on the substrate 102 . If the substrate 102 is metallic, it is not necessary to prepare an ohmic contact layer on the substrate 102 . Of course, it is also possible that only the bonding surface of the epitaxial wafer or one of the substrates has a bonding metal layer. The clamping device that applies pressure to the epitaxial wafer 101 and the substrate 102 includes a pressure applying member 107 and a pressure receiving member 106 . The pressure source of the pressure applying member 107 may be the pressure transmitted by air pressure or the pressure transmitted by hydraulic pressure. In order to obtain high-quality soldering products, the connection between the pressure applying member 107 and the ...

Embodiment 2

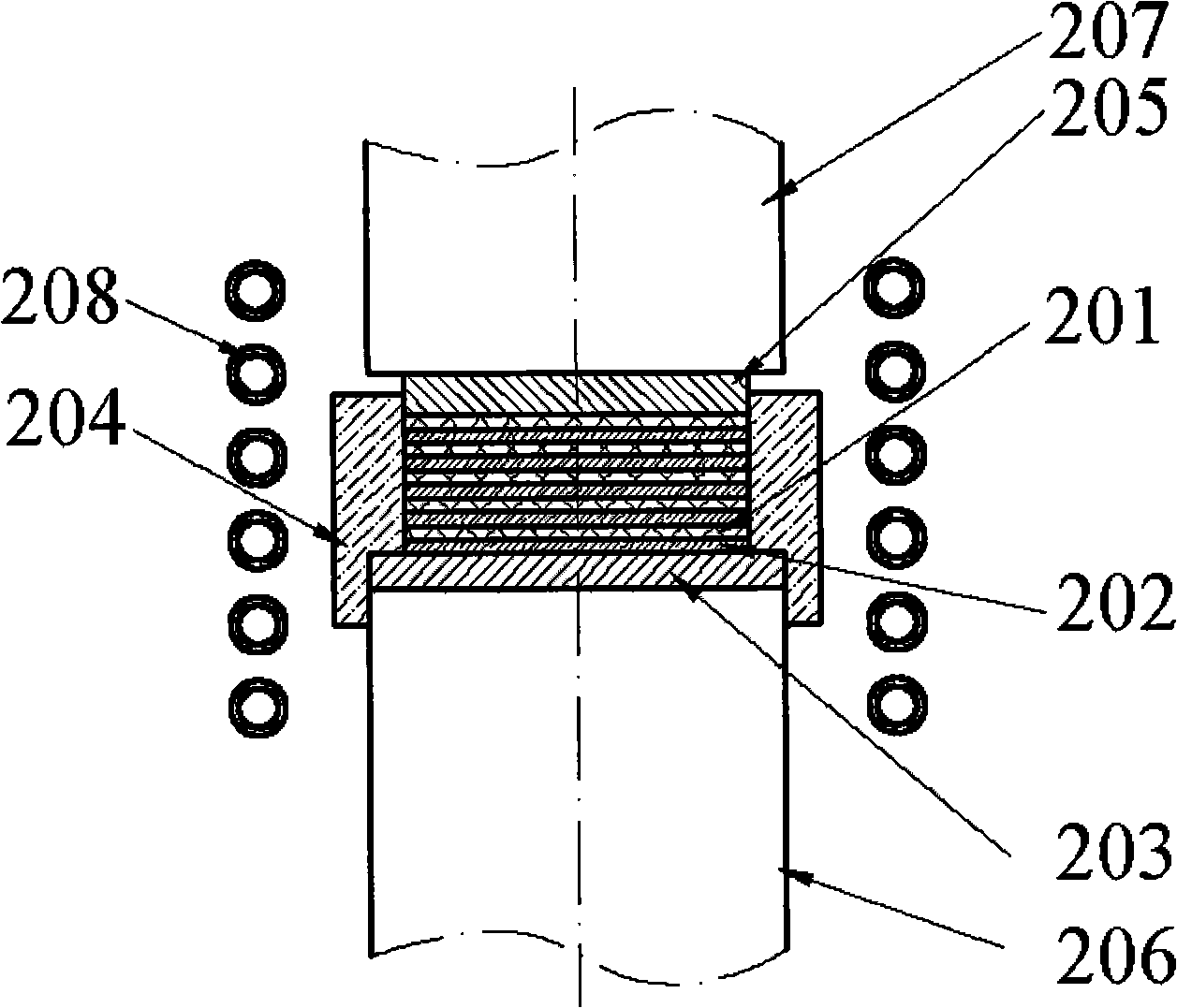

[0035] Construction embodiment two, such as figure 2 shown. An epitaxial wafer and a substrate form a pair of welded bodies. The structure of this embodiment is an improved structure on the structure of the first embodiment in order to improve production efficiency. It can weld multiple welded bodies at one time. This structure needs to lengthen the positioning ring 204 and thicken the upper positioning disc 205 and the lower positioning disc 203 . The structure of the pressing member 207, the pressure receiving member 206 and the electromagnetic coil 208 is the same as that of the first embodiment. The welding body composed of the epitaxial wafer 201 and the substrate 202 can be stacked and placed on the workbench for welding. Because the induced current of the electromagnetic coil heats the epitaxial wafer and the substrate, all the epitaxial wafers and the substrate have a consistent heating rate. The effect is as good as the single welding effect of the embodiment, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com