Active discharge liquid trap for fuel system

A liquid capture and fuel system technology, applied in the charging system, liquid fuel feeder, engine components, etc., can solve the problems of Venturi pump flow rate reduction, gas-liquid blockage, and affect the adsorption of Venturi pump, etc., to achieve Prevents adsorption from being affected, increases discharge speed, and prevents clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

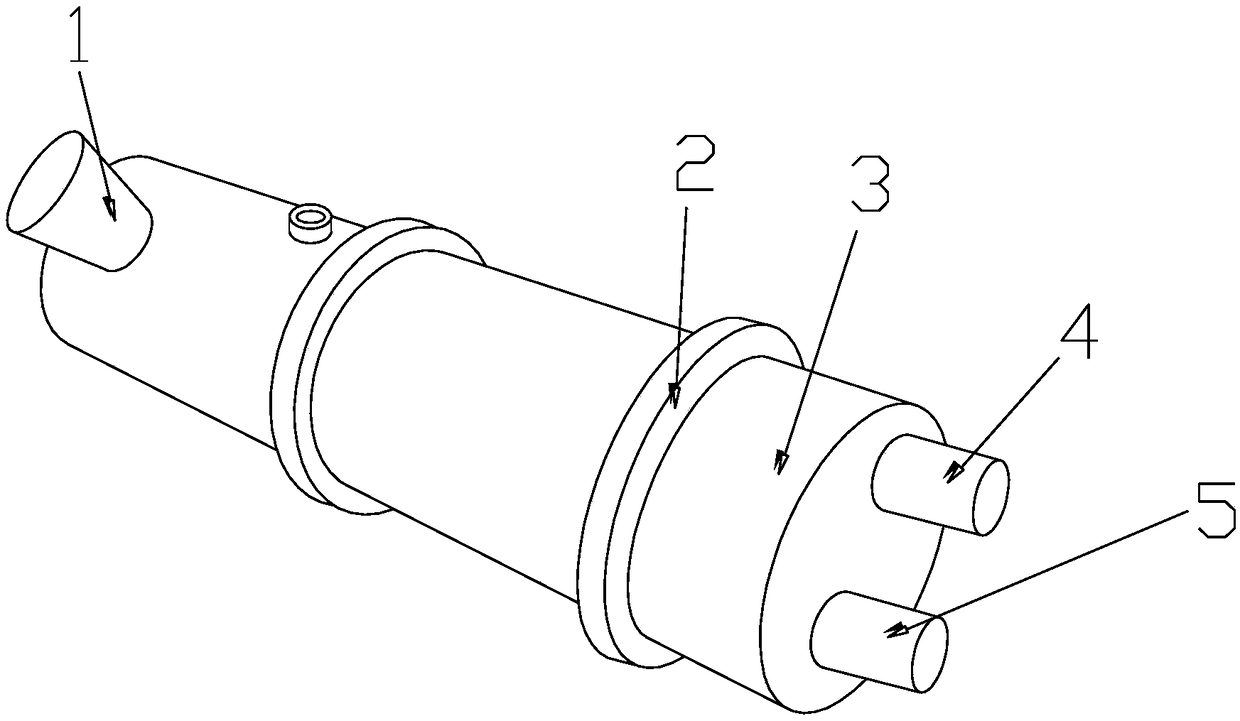

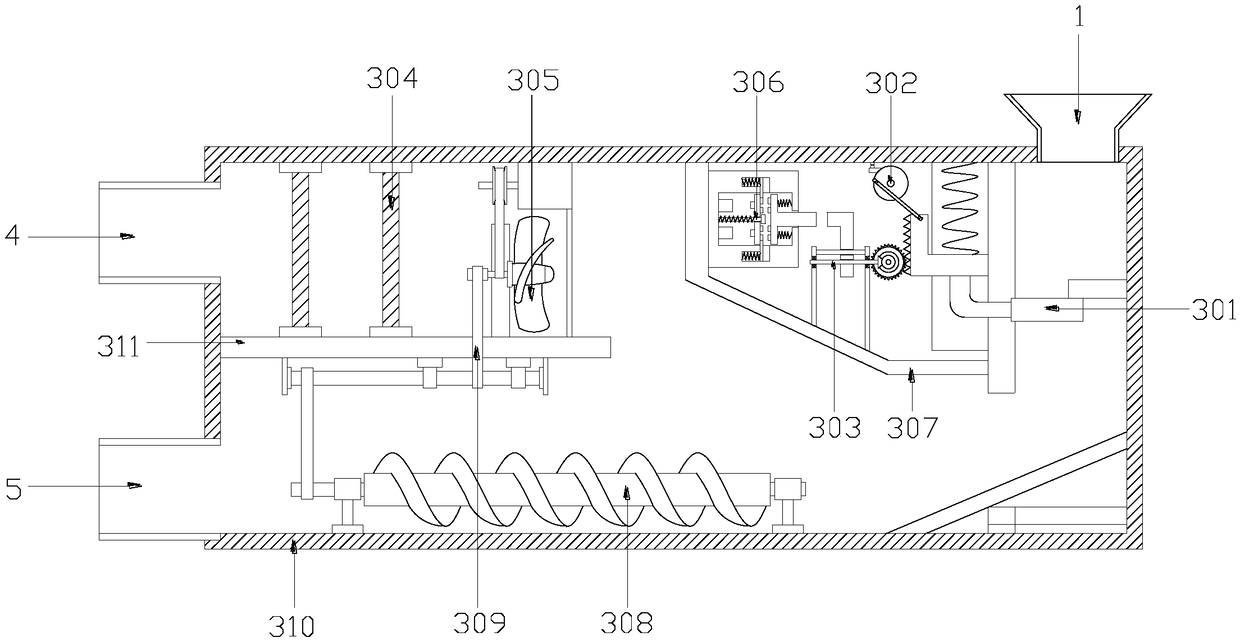

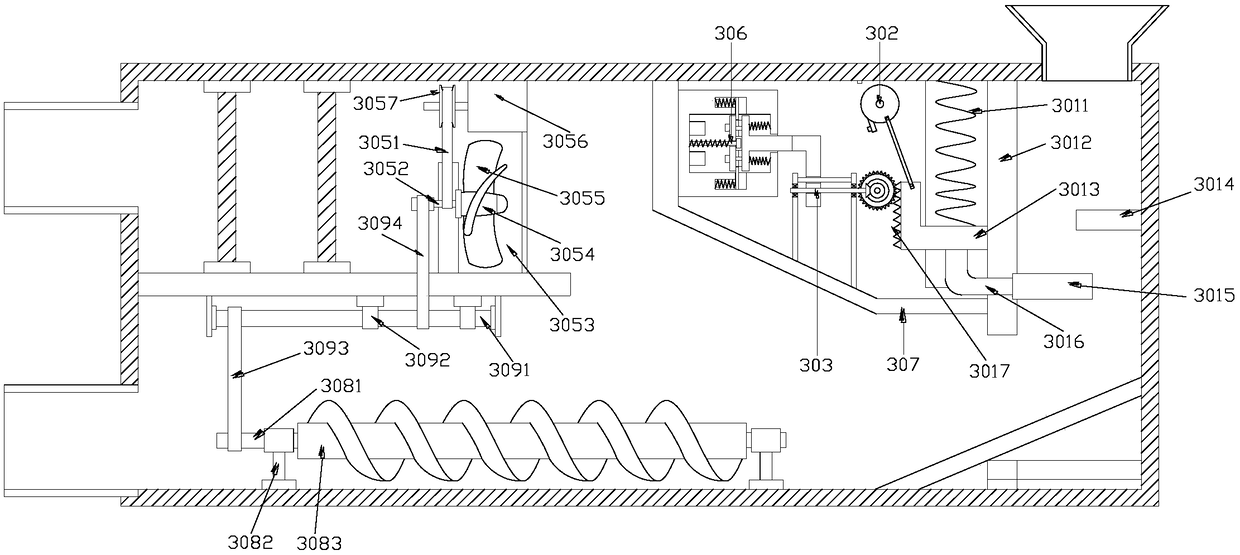

[0023] see Figure 1-Figure 6 , the present invention provides an active drain liquid trap for a fuel system, comprising a fixed ring 2 and a trapping bin 3, the trapping bin 3 is a cylindrical structure, and the right end face of the trapping bin 3 is symmetrical A gas outlet 4 and a liquid outlet 5 are provided, and a fluid inlet 1 is arranged on the top of the trapping bin 3 near the left end face, and the inside of the trapping bin 3 communicates with the fluid inlet 1, the gas outlet 4 and the liquid outlet 5, so that There are two fixing rings 2 and they are installed on both ends of the surface of the trapping bin 3 through fitting;

[0024] It is worth noting that the collection bin 3 includes a sealing mechanism 301, a cutting mechanism 302, a pressing mechanism 303, a particle collecting plate 304, an air guiding mechanism 305, a control mechanism 306, a partition plate 307, a flow guiding mechanism 308, The second transmission mechanism 309, the main body of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com