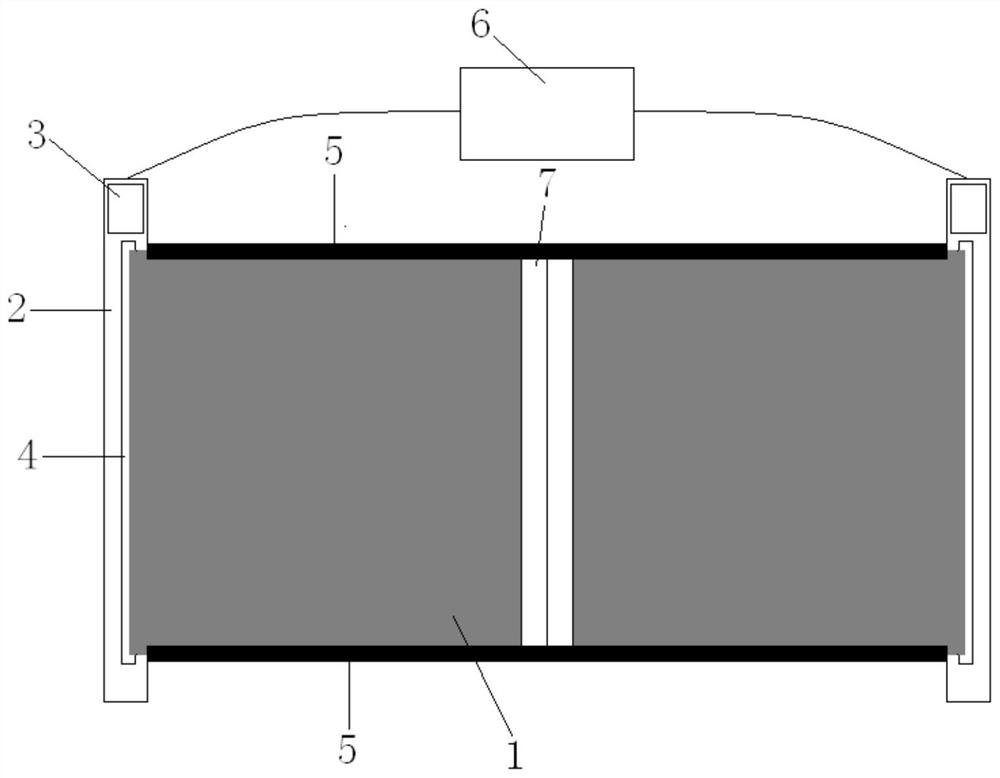

Conductive wrapping wire with function of electrostatic adsorption of PM2.5 particles, conductive woven fabric, filter screen and sunshade system

A technology of PM2.5 and electrostatic adsorption, which is applied in the fields of filter screens and sunshade systems, conductive coated wires, and conductive woven fabrics. It can solve the problems of PM2.5 particle sunshade systems, which are rarely reported, and achieve good conductivity and easy cleaning. , good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

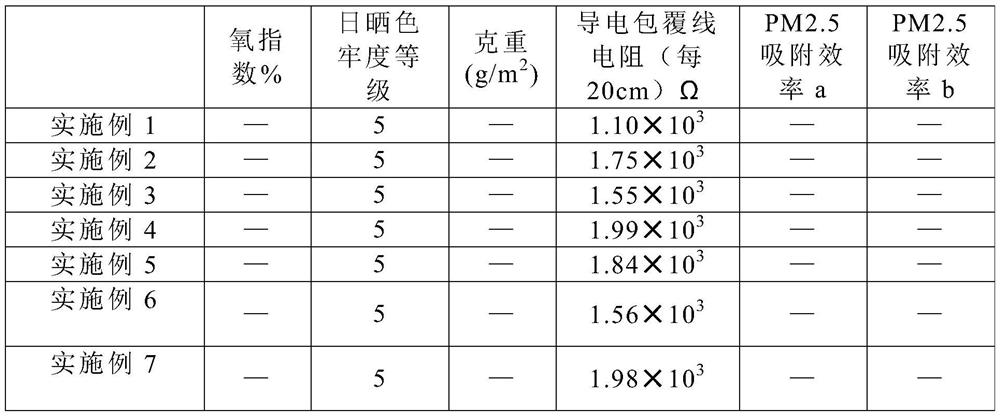

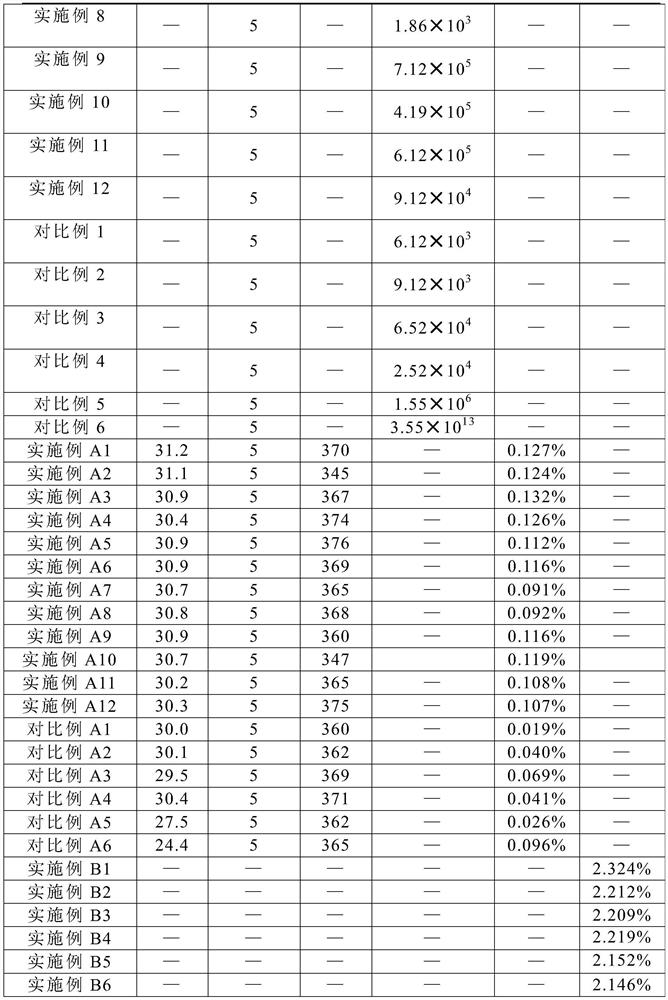

Embodiment 1

[0048] Conductive coated wire with electrostatic adsorption of PM2.5 particles.

[0049] Preparation of conductive polyvinyl chloride composite material: Weigh 70 parts of polyvinyl chloride resin, 30 parts of chlorinated polyethylene, 4 parts of calcium-zinc composite stabilizer, 30 parts of dioctyl terephthalate, 6 parts of flame-retardant Agent antimony trioxide, 0.3 parts of ethylene bis stearamide, 0.4 parts of antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.4 parts of anti-ultraviolet Add 2-hydroxyl-4-n-octyloxybenzophenone into a high-speed mixer for mixing, and when the temperature rises to 110°C, add 10 parts by weight of 1:0.3:0.07 Silver-plated nano-graphite flakes, nickel-coated copper powder (the mass content of nickel is 30%), the conductive filler of single-armed carbon nanotubes, and then add 13 parts of equal proportions of ethylene-vinyl acetate copolymer resin and vinyl chloride-acetic acid For the mixture...

Embodiment 2

[0053] The difference between this embodiment and Example 1 is only that adding 8 parts by weight in this embodiment is silver-plated nano-graphite microflakes and nickel-coated copper powder (the mass content of nickel is 30% of 1:0.3:0.07) ), the conductive filler of single-armed carbon nanotubes; the diameter of the prepared conductive coated wire is 0.28mm. Others are the same as in Example 1.

Embodiment 3

[0055] The difference between this embodiment and Example 1 is that the electrostatic cleaner solution is prepared as follows in this embodiment: 3 parts of calcium sulfide, 3 parts of ferric oxide, 3 parts of zinc stannate, 3 parts of Add magnesium hydroxide, 12 parts of vinyl chloride-vinyl acetate copolymer resin, 0.15 parts of dispersant BYK-110, and 65 parts of butyl acetate into the stirring device, and stir at room temperature for 1.5 hours to prepare an electrostatic dust collector solution. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com