Workstation for polishing plastic cylindrical workpiece

A cylindrical, workstation technology, used in grinding workpiece supports, machine tools designed for grinding workpiece rotating surfaces, grinding machine components, etc., can solve the problem of poor consistency of cylindrical workpieces, inability to meet industrial needs, high decibel noise Contamination and other problems, to achieve the effect of consistency, reducing grinding costs and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

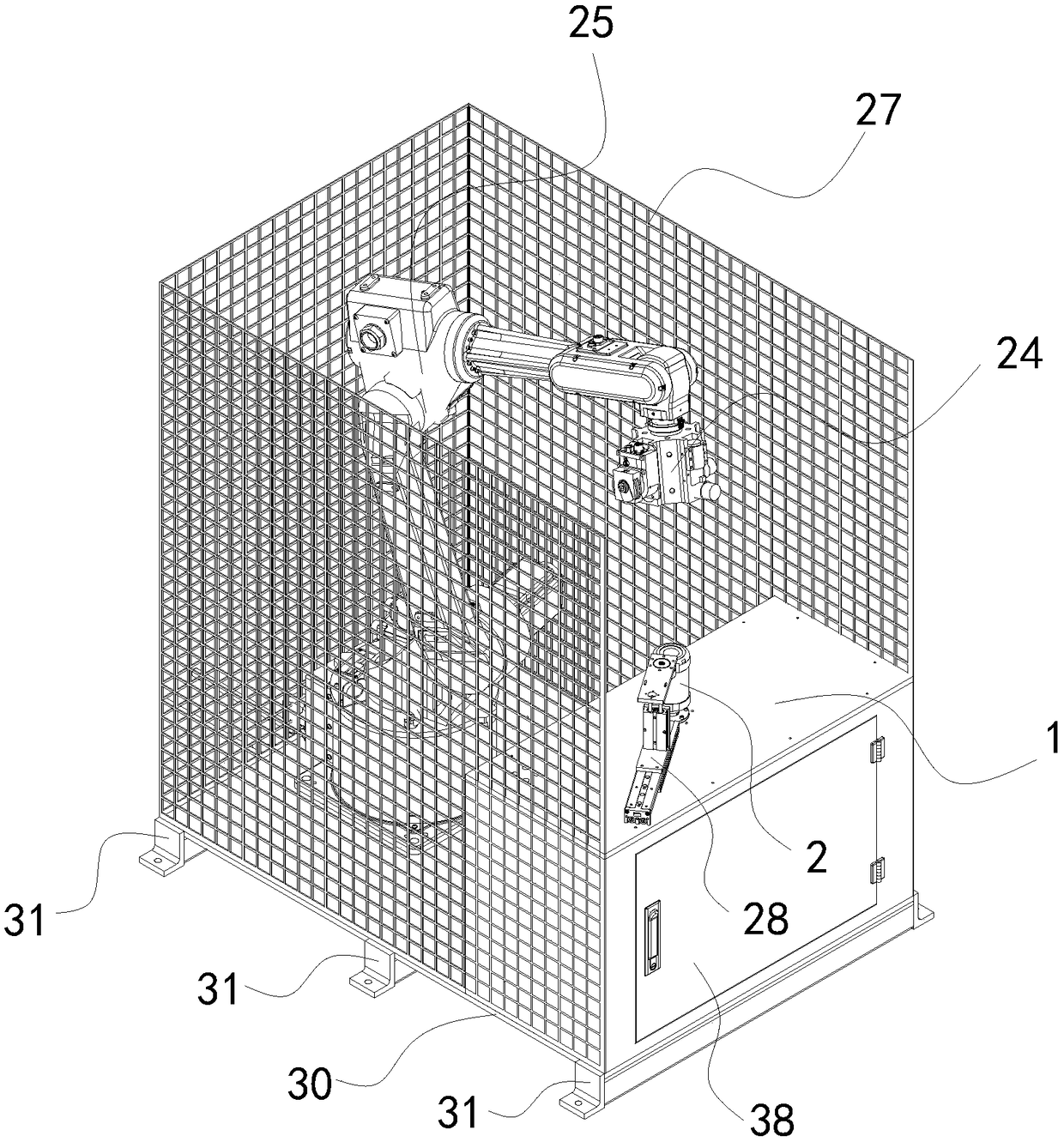

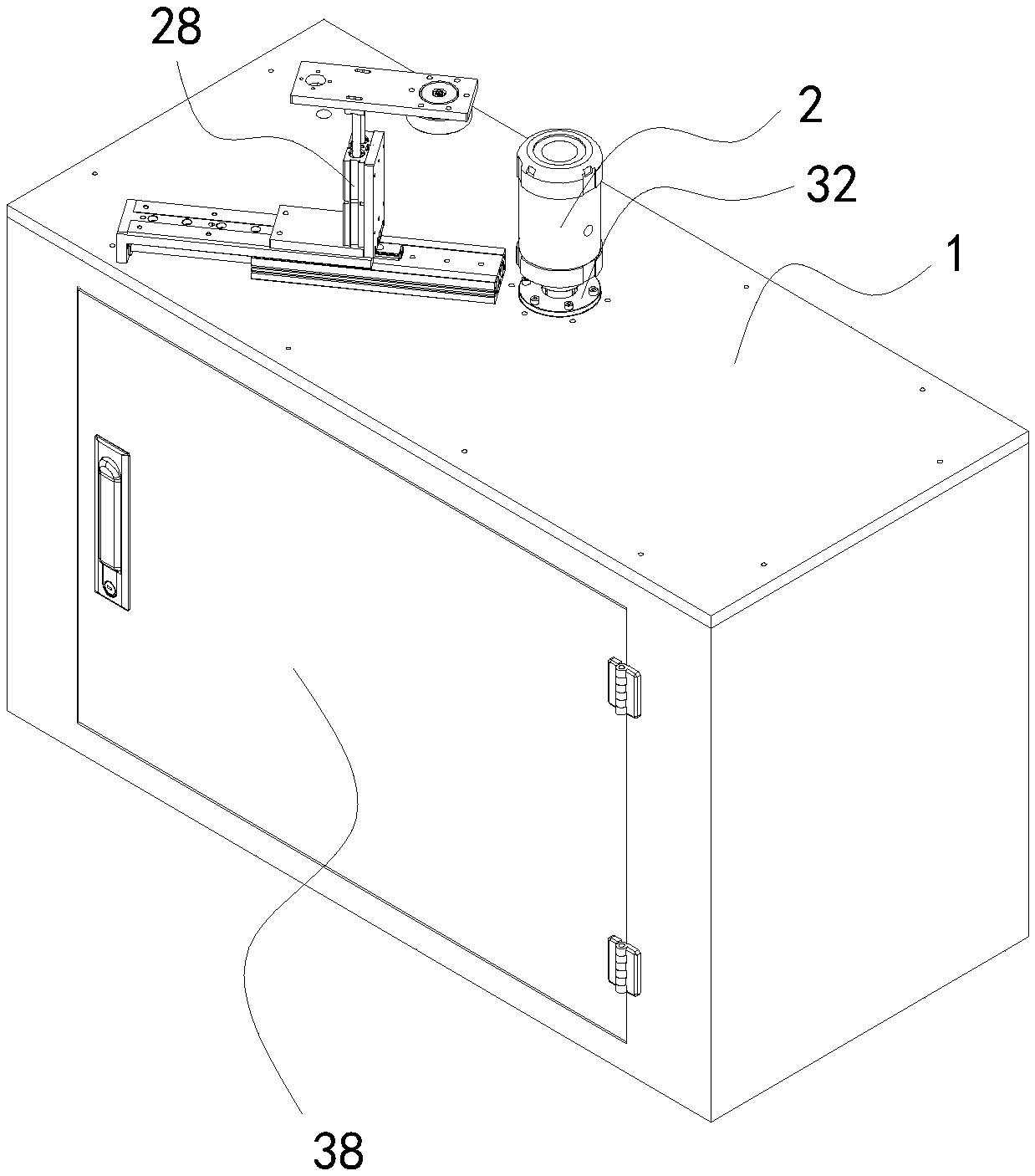

[0044] Such as figure 1 As shown, the workstation for grinding plastic cylindrical workpieces includes a base assembly, a grinding assembly for grinding cylindrical workpieces, a workpiece fixture platform assembly for fixing cylindrical workpieces, and a controller. The grinding assembly and the workpiece fixture platform assembly are fixed on the base assembly, the grinding assembly is located on one side of the workpiece fixture platform assembly, and the base assembly is provided with a fence 27; The base assembly includes a base plate 30 and a plurality of bases 31 for supporting the base plate. In this embodiment, the base plate 30 is a rectangular plate structure, and the number of the bases 31 is three. The bases 31 are arranged at equal intervals on the lower surface of the base plate 30 along the long side of the base plate 30, and the three bases 31 are parallel to each other. In short, the base plate 30 is installed on the three bases. On the seat 31; the jig plat...

Embodiment 2

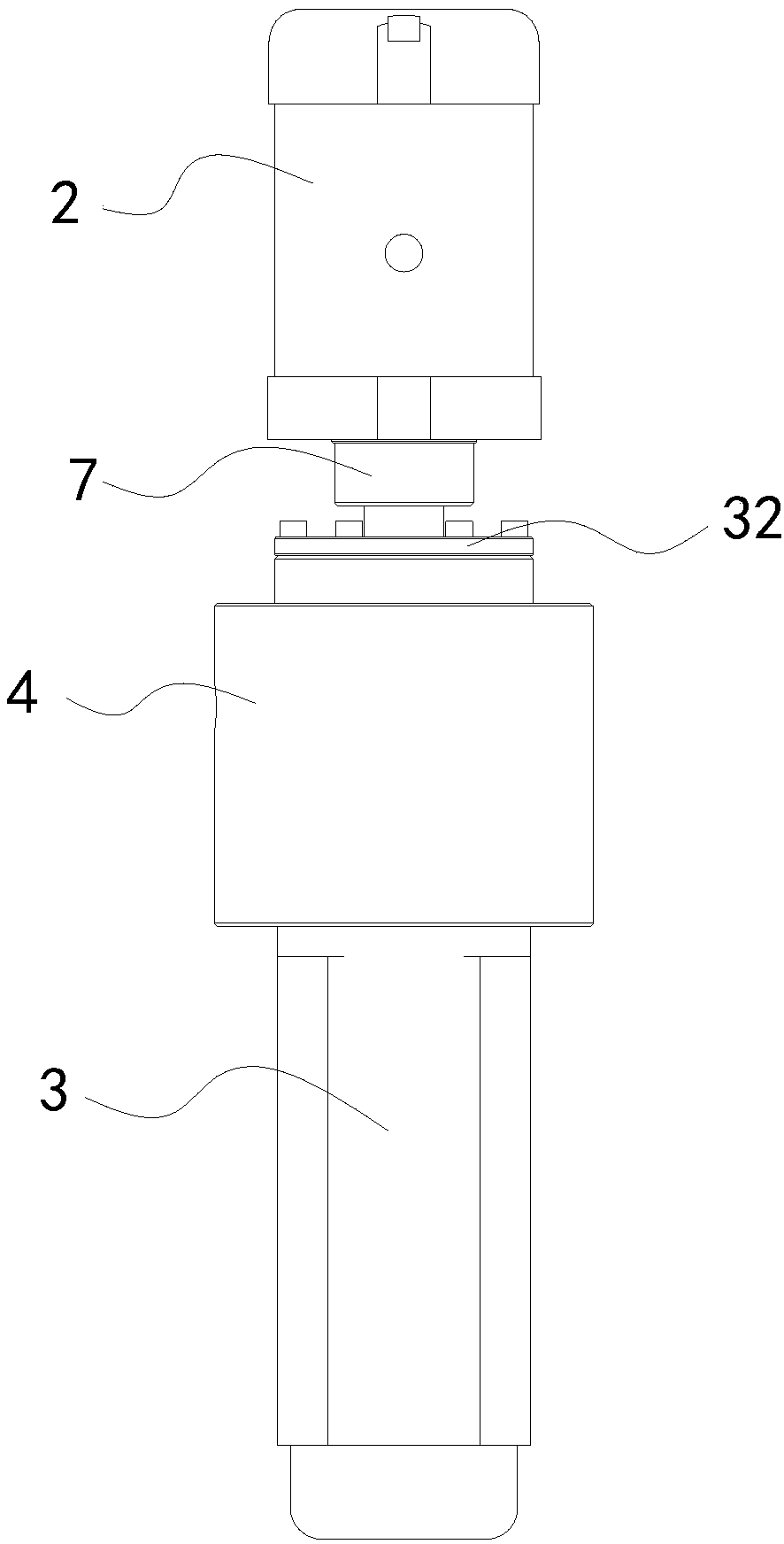

[0059] In this implementation, the driving device is different from the first embodiment, and the rest of the structure is the same as the first embodiment. The driving device includes a motor 3, a mounting base 4 and a bearing 5, and one end of the mounting base 4 is connected to the workbench 1. Fixed connection, the other end is connected with the motor 3, the output shaft of the motor 3 passes through the mounting seat 4 and is connected with the transmission of the profiling fixture 2, the middle part of the output shaft of the motor 3 is connected with the mounting seat 4 is connected by said bearing 5.

[0060] further, such as Figure 12 As shown, in this embodiment, on the basis of Embodiment 1, an opening 29 is provided on the side wall of the workbench 1, and a dust extraction device is provided inside the workbench 1, and the opening 29 and the suction The dust device is connected, which can absorb the dust scattered during the grinding process and reduce the dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com