Deburring mechanism and filter screen assembly

A filter screen and component technology, applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of high labor intensity, dust pollution, low work efficiency, etc., to reduce labor intensity, The effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

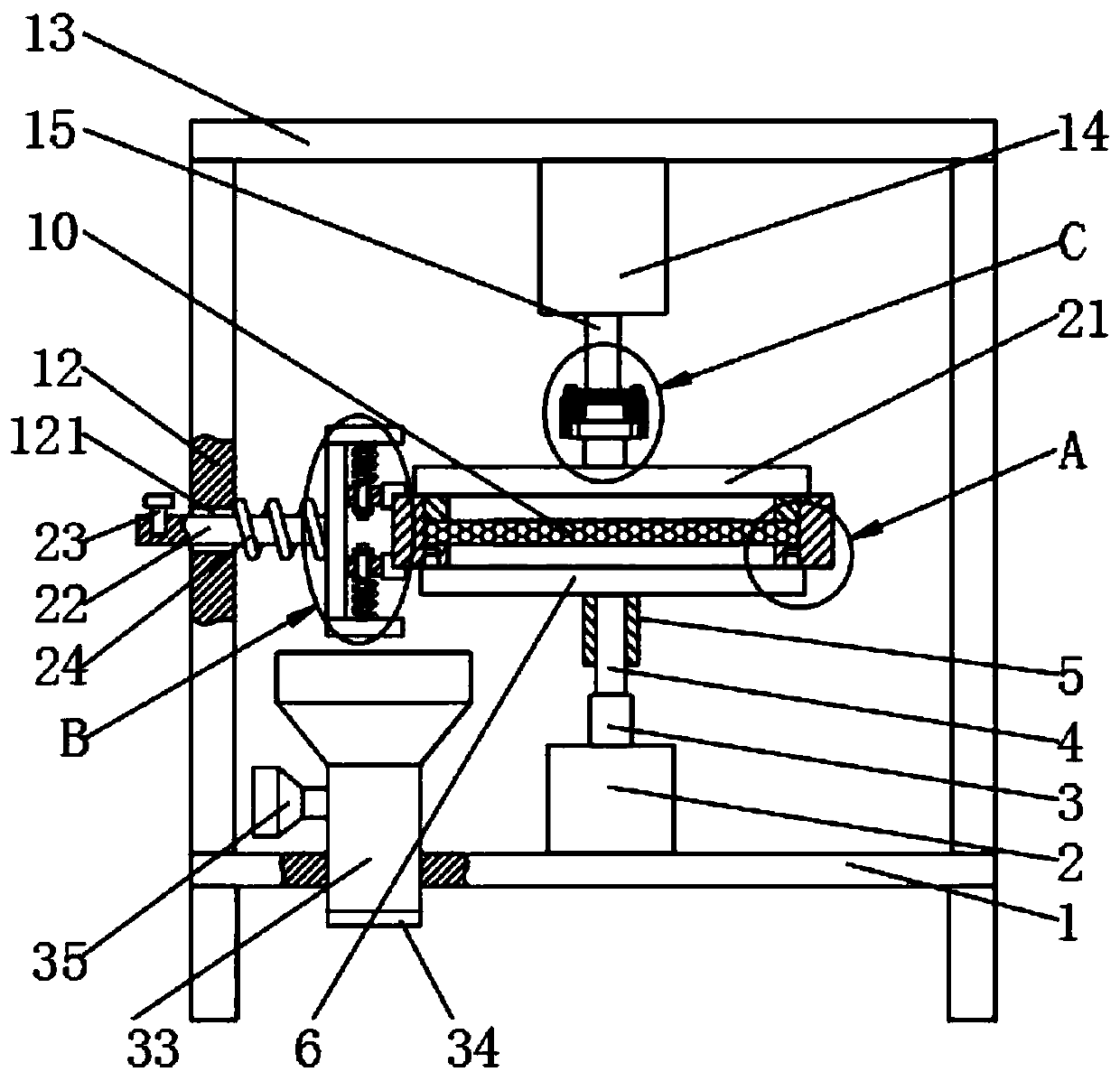

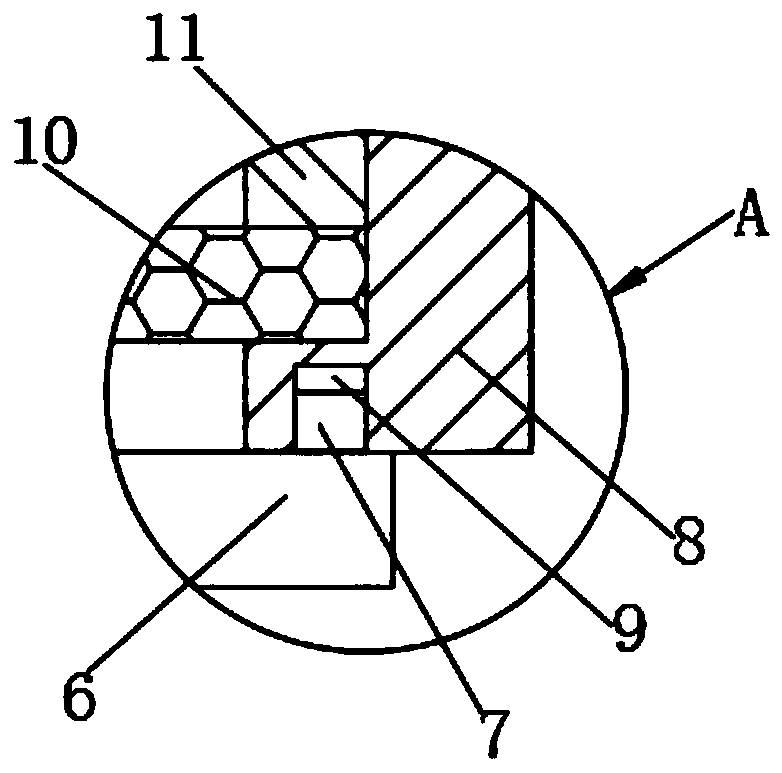

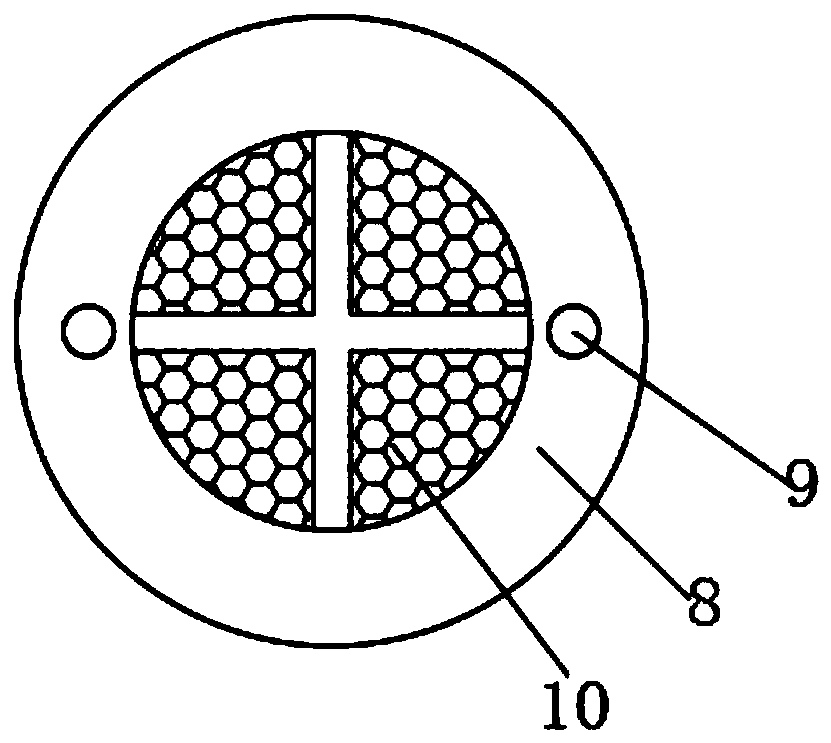

[0030] see Figure 1-7 , a hair removal mechanism and a filter assembly, including a support platform 1, a motor 2 is fixedly installed on the upper end of the support platform 1, the model is YE2, belongs to the prior art, and is equipped with a switch, and the upper end of the rotating shaft 3 of the motor 2 is provided with The square rod 4, the square rod 4 and the rotating shaft 3 are of an integrated structure, the outer side of the square rod 4 is slidingly sleeved with a square sleeve 5, the upper end of the square sleeve 5 is welded with a support disc 6, and the upper end of the support disc 6 is equipped with a mounting ring 8, A filter screen 10 is slidingly sleeved in the installation ring 8, and a fastening ring 11 is threaded in the installation ring 8;

[0031] The upper end of the support table 1 is welded with a support column 12, the upper end of the support column 12 is welded with a support frame 13, and the lower end of the support frame 13 is fixedly equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com