A construction steel pipe surface grinding and transportation device

A technology of transportation device and steel pipe, which is applied in the direction of abrasive surface adjustment device, transportation and packaging, grinding feed movement, etc., which can solve the problems of labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

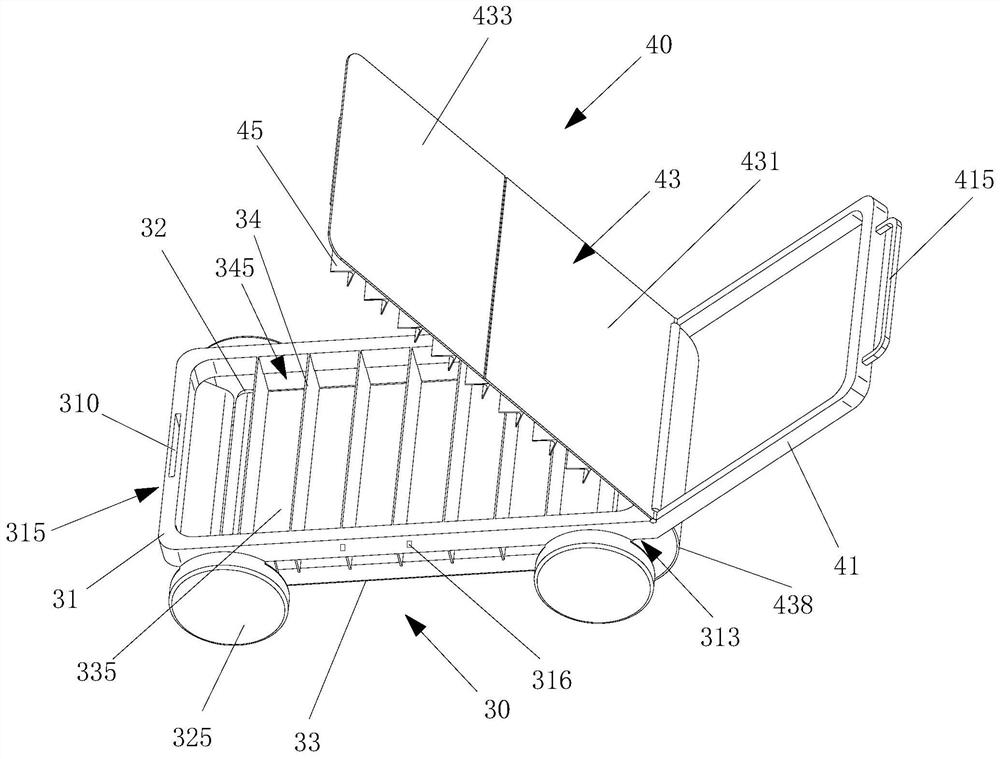

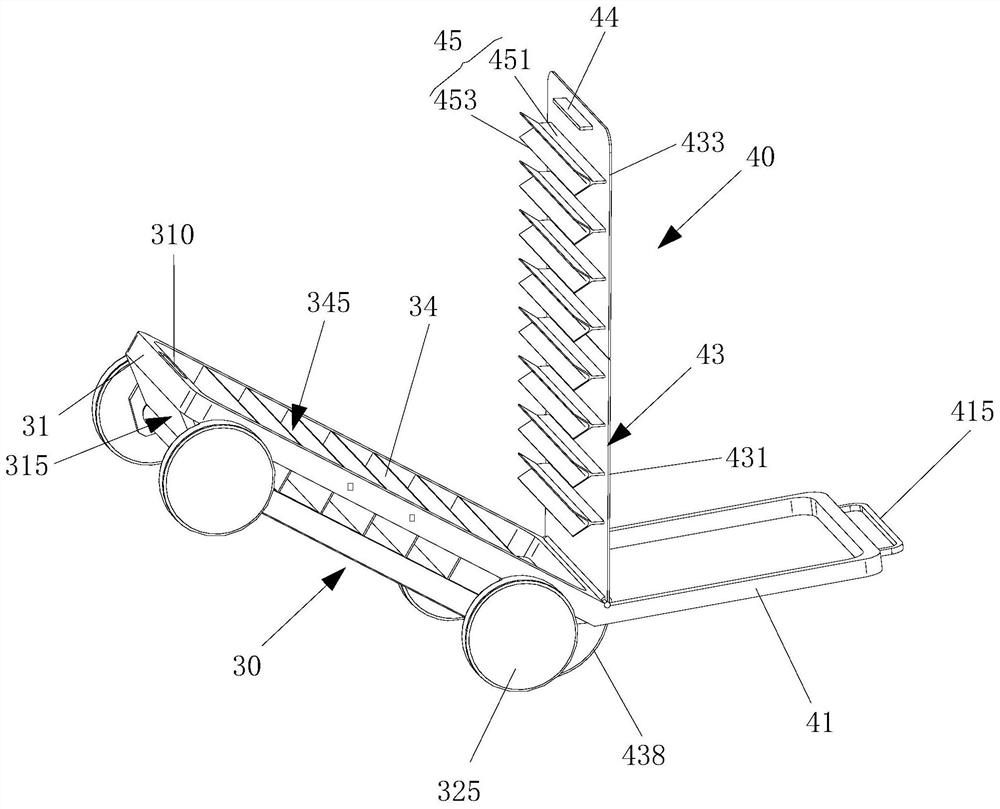

[0020] see Figure 1 to Figure 5 , a construction steel pipe surface grinding and transportation device, including a transportation assembly 30 and a cover assembly 40, the transportation assembly 30 includes a handling frame 31, a driving roller (not shown), a driven roller 32, a grinding endless belt 33 and a driving motor ( Not shown in the figure), a plurality of dividing plates 34 are fixed in the transport frame 31, and a grinding space 345 is formed between two adjacent dividing plates 34, and each grinding space 345 is used to accommodate a construction steel pipe 100, and the driving roller and The driven rollers 32 are respectively rotatably mounted on the bottoms of the opposite ends of the transport frame 31, tires 325 are mounted on the opposite ends of the driving rollers and the opposite ends of the driven rollers 32 respectively, and the middle part of the driving rollers is concavely provided with a ring groove, The peripheral surface of the groove is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com