Formula of wood-plastic bathroom plate and production method

A bathroom and wood-plastic technology, which is applied in the formulation and preparation of wood-plastic materials, can solve the problems of cumbersome processes of additives, and achieve the effects of wide source of raw materials, easy processing and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Preparation of nano-silver ion modified carbon black antibacterial agent is prepared by the following method:

[0071] 1) reacting an aqueous solution of a soluble silver salt with a concentration of 2M and ammonia to form a silver-ammonia complex alkaline aqueous solution; wherein the molar ratio of the aqueous solution of a soluble silver salt to ammonia is 1:10;

[0072] 2) Add carbon black to hydrogen peroxide, mix well and let it stand for 60 minutes, then add it to the alkaline aqueous solution of silver ammonia complex prepared in step 1) to carry out the reduction reaction. After the completion, the precipitate is separated and washed, and the obtained brown-black solid is nano Silver particles modify carbon nanotubes; the mass of carbon black is 0.5 times the mass of the silver ion; the molar amount of hydrogen peroxide is twice the molar mass of the silver ion.

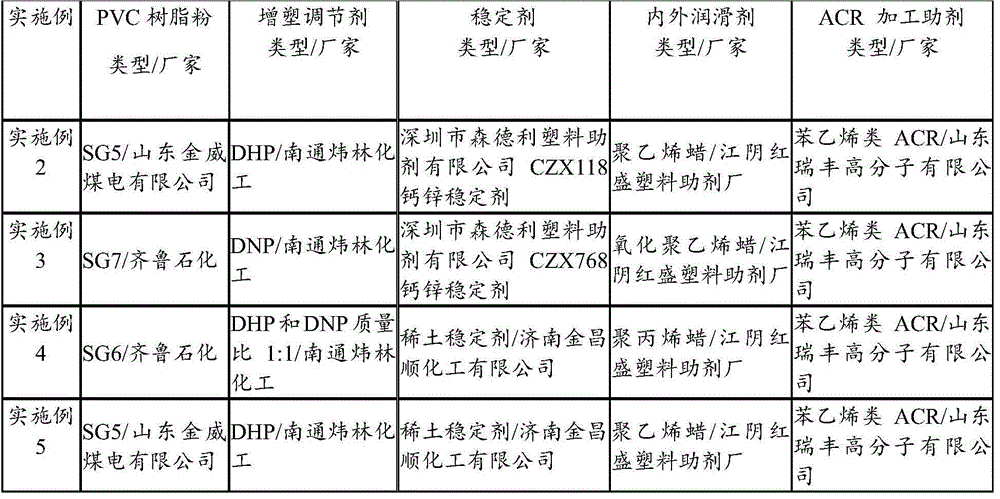

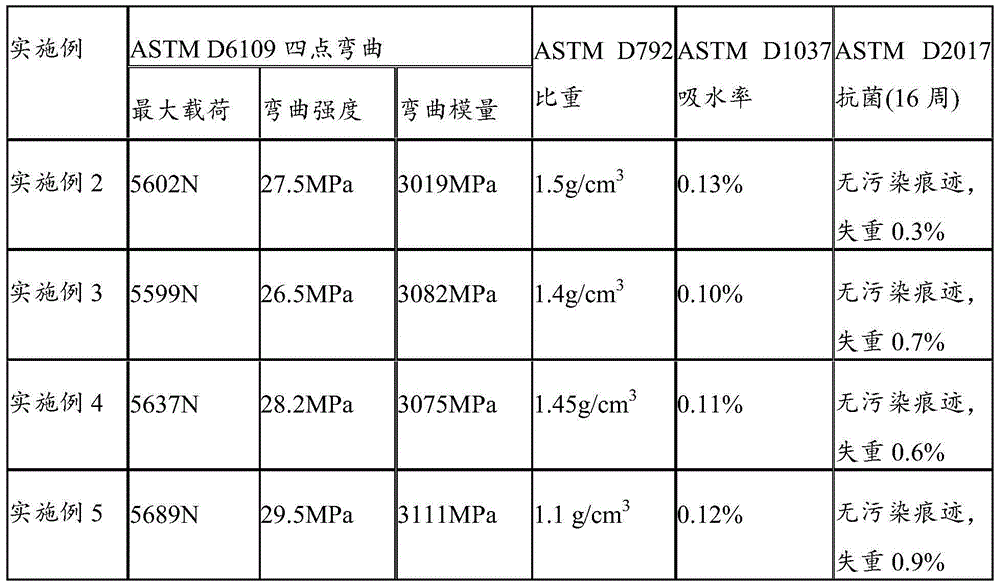

Embodiment 2

[0074] Take each raw material by following parts by weight, wherein silver ion modified carbon black antibacterial agent adopts the antibacterial agent prepared by embodiment 1:

[0075] PVC resin powder: 30 parts;

[0076] Calcium filler: 5 servings;

[0077] Silver ion antibacterial agent: 1 part;

[0078] The bottom layer is made of the following raw materials in parts by weight:

[0079] PVC resin powder: 70 parts;

[0080] Wood fiber powder: 30 parts;

[0081] Calcium filler: 35 parts;

[0082] Plasticizing regulator: 10 parts;

[0083] Stabilizer: 6 parts;

[0084] Internal and external lubricant: 2.0 parts;

[0085] ACR processing aid: 7 parts;

[0086] Foaming agent: 2 parts.

[0087] The present invention also provides a preparation method for the above-mentioned wood-plastic bathroom panel, comprising the following steps:

[0088] 1) Bottom material: mix calcium filler, wood fiber powder, plasticizing regulator, stabilizer, internal and external lubricant, ...

Embodiment 3

[0094] Take each raw material by the following parts by weight:

[0095] PVC resin powder: 20 parts;

[0096] Calcium filler: 25 parts;

[0097] Silver ion antibacterial agent: 1 part;

[0098] The bottom layer is made of the following raw materials in parts by weight:

[0099] PVC resin powder: 80 parts;

[0100] Wood fiber powder: 30 parts;

[0101] Calcium filler: 25 parts;

[0102] Plasticizing regulator: 8 parts;

[0103] Stabilizer: 8 parts;

[0104] Internal and external lubricant: 1.0 parts;

[0105] ACR processing aid: 6 parts;

[0106] Foaming agent: 1.2 parts.

[0107] The present invention also provides a preparation method for the above-mentioned wood-plastic bathroom panel, comprising the following steps:

[0108] 1) Bottom material: mix calcium filler, wood fiber powder, plasticizing regulator, stabilizer, internal and external lubricant, ACR processing aid and foaming agent, add to a stirring mixer and mix for 10 minutes, then add PVC resin powder, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com