Solar photovoltaic panel grinding device

A photovoltaic solar energy and bottom plate technology, which is used in grinding machines, seat grinders, grinding workpiece supports, etc., can solve the problem of high labor intensity of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further detailed explanation through specific implementation mode below:

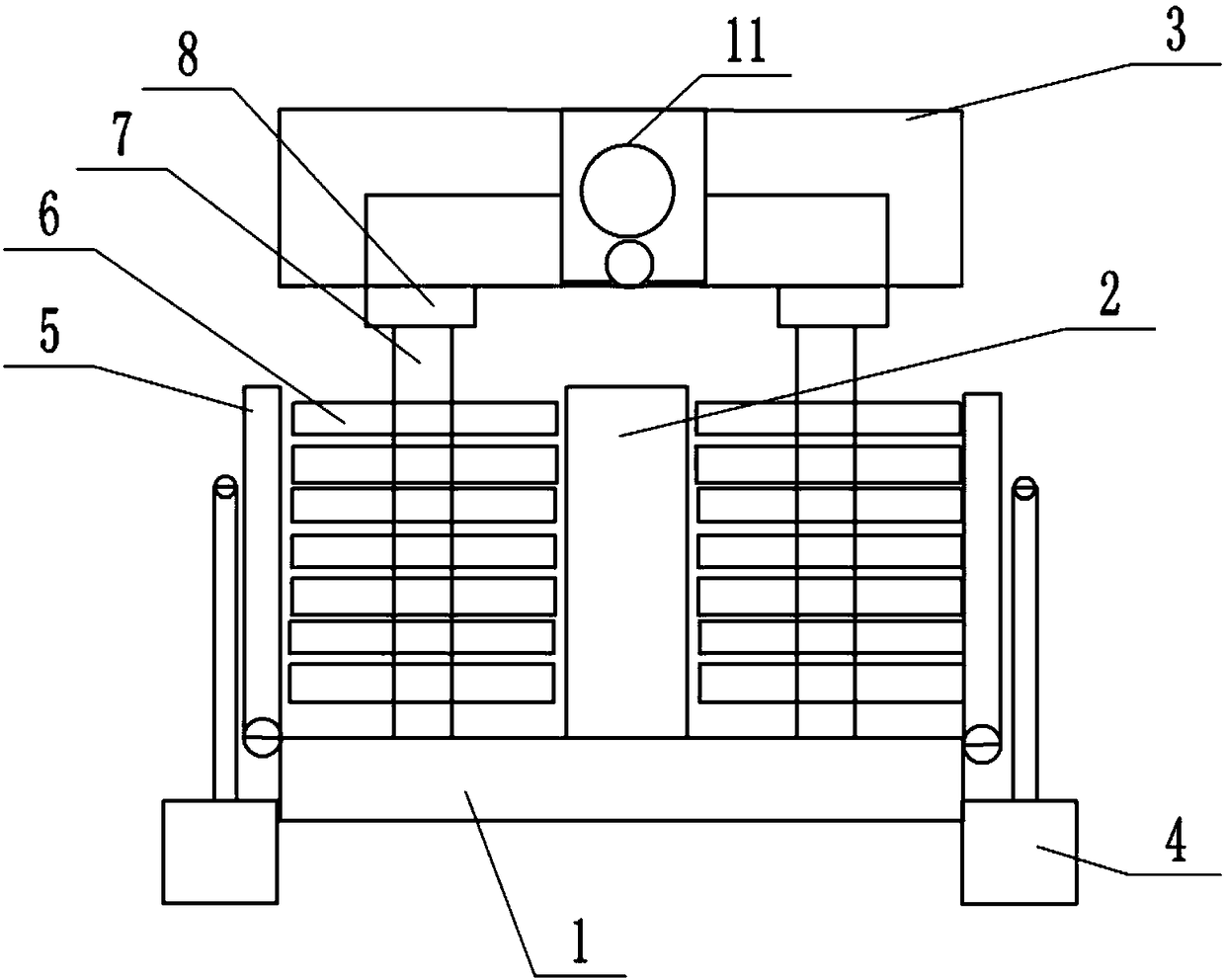

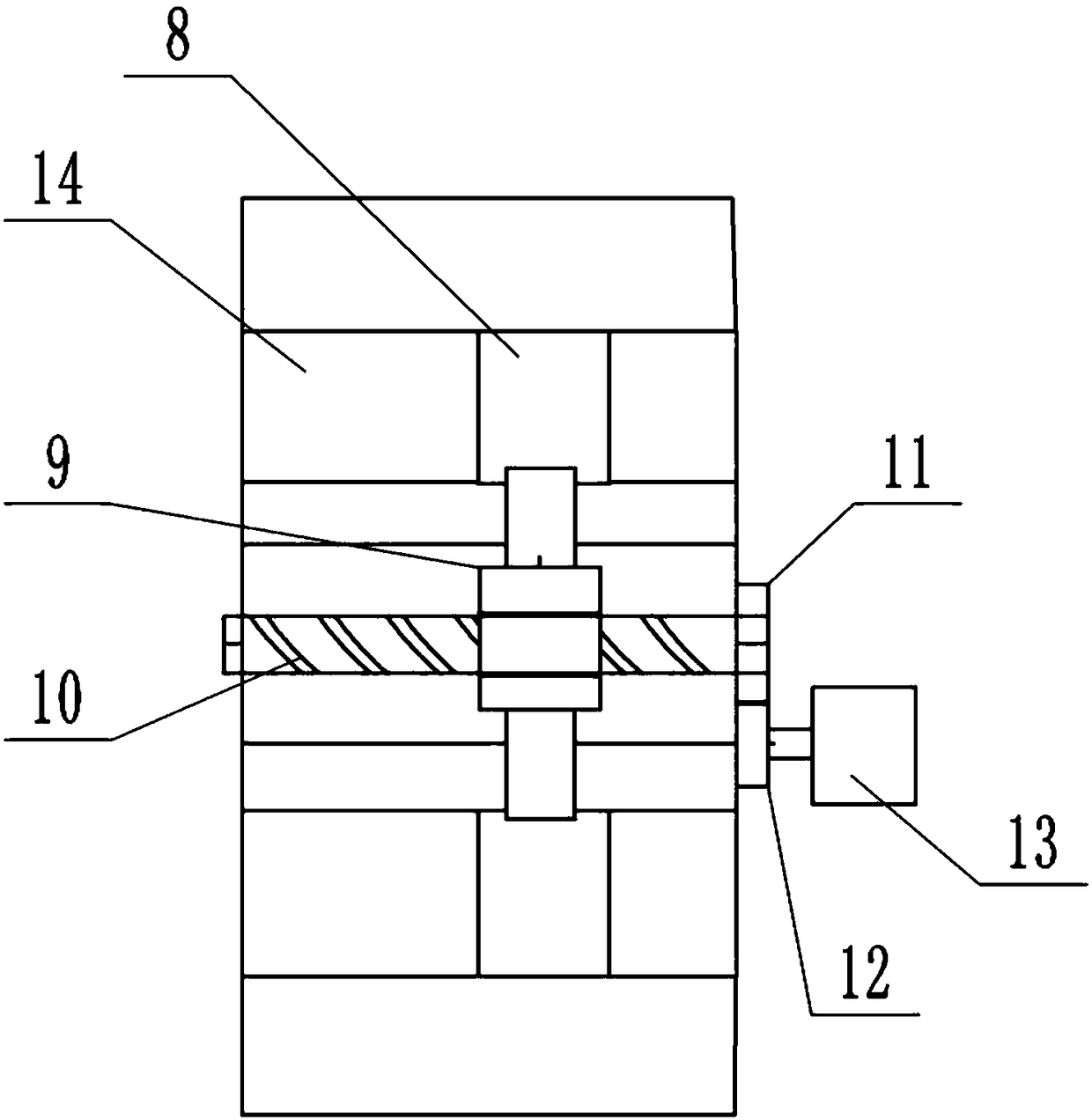

[0013] The reference signs in the drawings of the description include: bottom plate 1, positioning plate 2, top plate 3, hydraulic cylinder 4, cover plate 5, photovoltaic solar panel 6, drive belt 7, slider 8, transmission block 9, threaded rod 10, from Moving gear 11, driving gear 12, motor 13.

[0014] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0015] A photovoltaic solar panel grinding device, comprising a base plate 1, a top plate 3 is arranged above the base plate 1, a positioning plate 2 is fixedly installed in the middle of the base plate 1, and a positioning plate 2 is fixedly installed on both sides of the base plate 1, which is driven by a hydraulic cylinder 4 and can maintain a vertical state. The cover plate 5, several overlapping photovoltaic solar panels 6 to be polished are placed between each cover plate 5 and the positioning plate 2, and the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com