Anode tube roughness grinding system and method

An anode tube and roughness technology, applied in the field of anode tube, can solve the problems of unfavorable operator's health, cost a lot of manpower and material resources, low efficiency, etc., and achieve the effect of saving manpower and material resources, improving production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

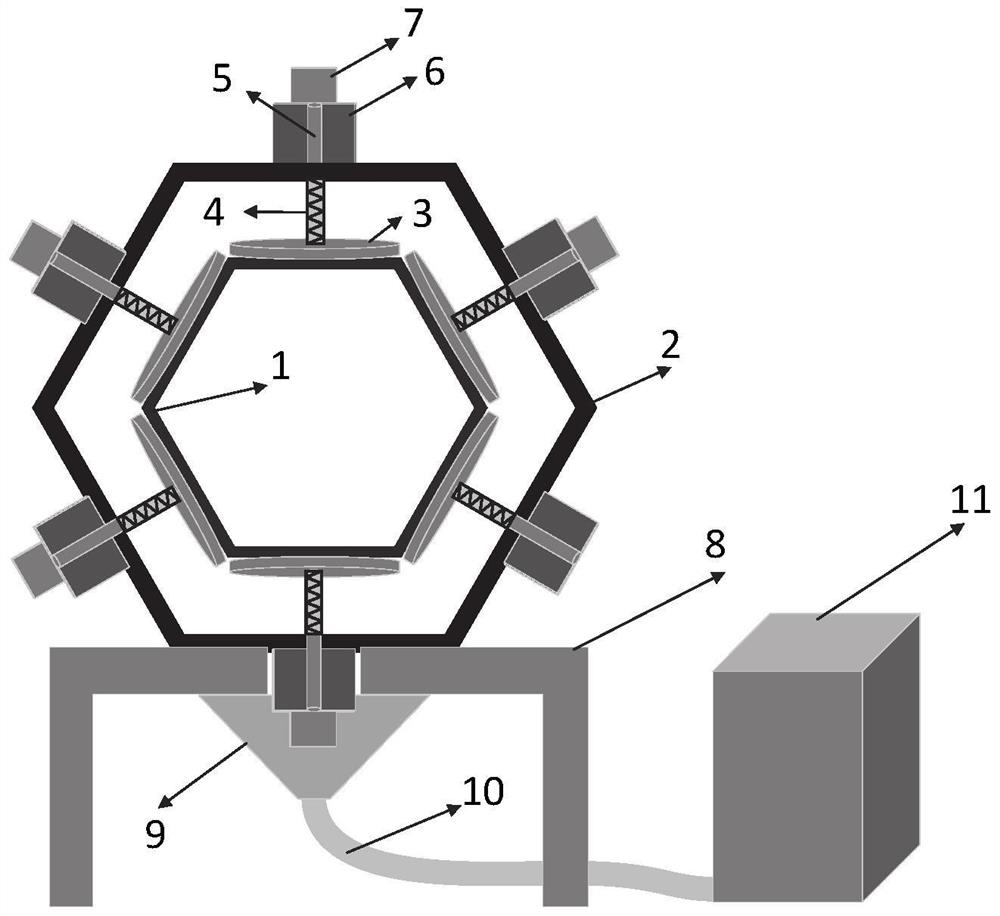

[0036] In one or more embodiments, an anode tube roughness grinding system is disclosed, referring to figure 1 , including: a support frame 2 matching the shape of the anode tube 1, the support frame 2 is connected to the fixed base 8; the support frame 2 is arranged on the outside of the anode tube 1, and on the support frame 2, each of the regular hexagonal anode tubes 1 is corresponding Grinding devices are respectively provided on the surface; the grinding device can be in contact with the outer surface of the anode tube 1; an opening is provided at the bottom of the supporting frame 2, and a dust collection device is arranged at the opening position.

[0037] Specifically, the cross-section of the support frame 2 is also a regular hexagon, which is the same shape as the anode tube 1, and each face of the support frame 2 is arranged parallel to each face of the anode tube 1; each face of the support frame 2 is provided with a grinding device , the grinding device includes:...

Embodiment 2

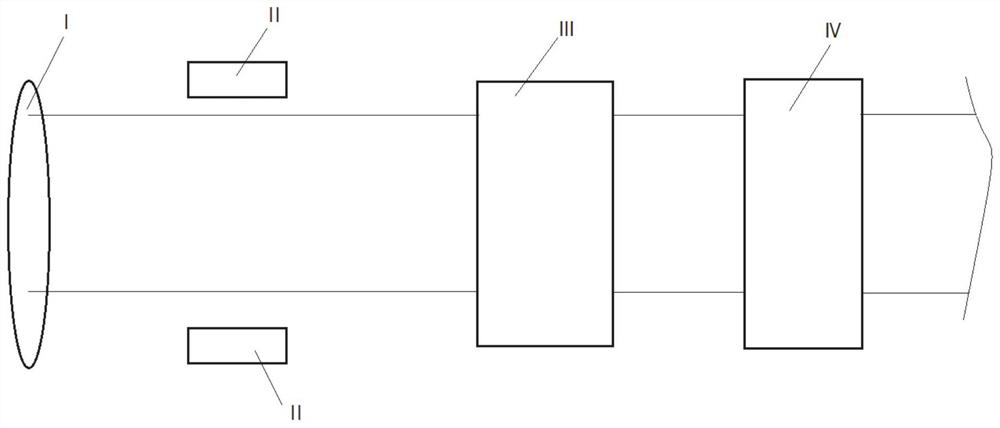

[0048] In one or more embodiments, an anode tube production system is disclosed, with reference to figure 2 , at the output end I of the anode tube production line, the anode tube pushing device II, the anode tube roughness grinding system III described in Embodiment 1, and the cutting device IV are arranged in sequence.

[0049] Specifically, the pushing device II can be a mechanical arm or a mechanical gripper, which is arranged on both sides of the anode tube, and can support and fix the anode tube and push it forward; the cutting device IV is the structure of the existing cutting device IV on the existing production line.

[0050] The specific working process of the anode tube production system is as follows:

[0051] The output end of the anode tube production line outputs the anode tube, and the anode tube is pushed forward at a set speed through the thrust of the pushing device II.

[0052] The position of the grinding device is initialized, the anode tube is pushed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com