Artificial tooth material and preparation method thereof

A technology of artificial teeth and raw materials, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of poor mechanical properties, easy cracking of artificial tooth bases, etc., achieve good formability, meet personalized production requirements, and biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

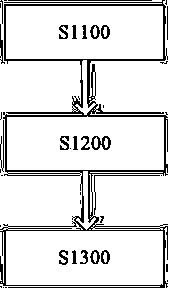

[0027] Specifically, the preparation method of the present invention includes:

[0028] First enter step S1100 to prepare wax emulsion: add a certain amount of emulsifier into water and mechanically stir vigorously, then add microcrystalline wax and paraffin wax and heat at 80-100°C for 20-60 minutes to make wax lotion. Then enter step S1200 nanocellulose surface lipophilic treatment: the nanocellulose is formulated into a nanocellulose aqueous solution with a concentration of 1-10% by mass, then mixed with the wax emulsion, dried at 105 ° C, and ground to obtain a surface hydrophilic Oily nanocellulose. The main purpose of this step is to coat a layer of wax on the surface of nanocellulose to improve its lipophilicity, thereby improving the dispersion uniformity of nanocellulose in polymethyl methacrylate, avoiding agglomeration, and further improving polymethacrylic acid. Mechanical strength of methyl esters. Preferably, this step further includes homogenizing the nanocel...

Embodiment 1

[0032] figure 1Shown is the preparation method of the artificial tooth material according to one embodiment of the present invention, as shown in the figure: first enter step S1100 and prepare wax emulsion: add 8 weight parts of ABS into water and stir, then add 10 weight parts of microcrystalline wax and paraffin wax The mixture (wherein the mass ratio of microcrystalline wax to paraffin wax is 2:5) is then heated at a heating temperature of 80° C. for 20 minutes to form a wax emulsion. Then enter step S1200 nanocellulose surface treatment: 6 parts by weight of nanocellulose are formulated into a nanocellulose aqueous solution with a mass percentage concentration of 1%, then obtain the emulsion of nanocellulose by high-pressure homogenizer homogenization, and mix it with Wax emulsions are mixed, homogenized with a high-pressure homogenizer, then dried and ground at 105° C. to obtain nanocellulose with surface lipophilicity. Finally enter step S1300 to prepare polymethyl meth...

Embodiment 2

[0034] figure 1 The preparation method of the artificial tooth material according to one embodiment of the present invention is shown, as shown in the figure: first enter step S1100 to prepare wax emulsion: add 8 parts by weight of the mixture of ABS and Span80 into water and stir, then add 10 parts by weight of microcrystalline The mixture of wax and paraffin (wherein the mass ratio of microcrystalline wax to paraffin is 2:5) is then heated at a heating temperature of 80° C. for 20 minutes to prepare a wax emulsion. Then enter step S1200 nanocellulose surface treatment: 8 parts by weight of nanocellulose are formulated into a nanocellulose aqueous solution with a mass percentage concentration of 1%, then obtain the emulsion of nanocellulose by high-pressure homogenizer homogenization, and mix it with Wax emulsions are mixed, homogenized with a high-pressure homogenizer, then dried and ground at 105° C. to obtain nanocellulose with surface lipophilicity. Finally enter step S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com