Four-edge chamfering cutter

A technology of chamfering cutter and cutter head, applied in cutting inserts, accessories of tool holders, tools for lathes, etc., can solve the problems of reducing the service life of tools and affecting the machining accuracy of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

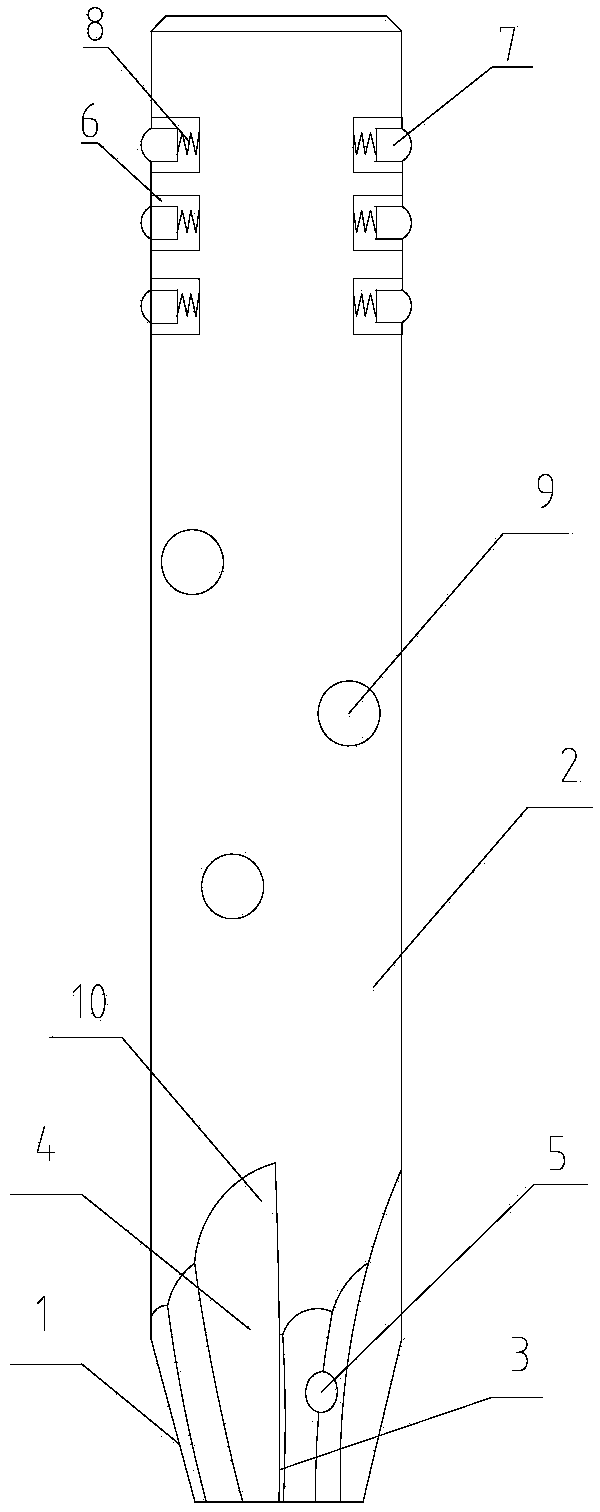

[0011] As shown in the figure, the four-edged chamfering knife includes a cutter head 1 and a handle 2. The cutter head 1 is set at the front end of the handle 2. The cutter head 1 and the handle 2 are integrally formed. The four cutting edge installation parts on the upper part, the cutting edge 3 is set on the outside of the installation part, the cutter head 1 is conical, and there is a chip removal groove 4 between the installation parts. The taper of the cutter head 1 is 28°, which is convenient for chamfering and convenient The tool is chamfered or processed with a taper hole. The upper side of the cutter head 1 is provided with a vent hole 5. The vent hole 5 communicates with the upper surface of the handle 2. The side surface of the handle 2 is provided with a vent hole 5. The round hole will generate a lot of heat when the cutter is working. The heat on the cutter head can be dissipated through the vent hole 5 on the cutter head 1, which improves the service life of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com