Air floatation circumferential chamfering machine

A chamfering machine and air flotation technology, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as low work efficiency, inconvenient operation, and worker injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

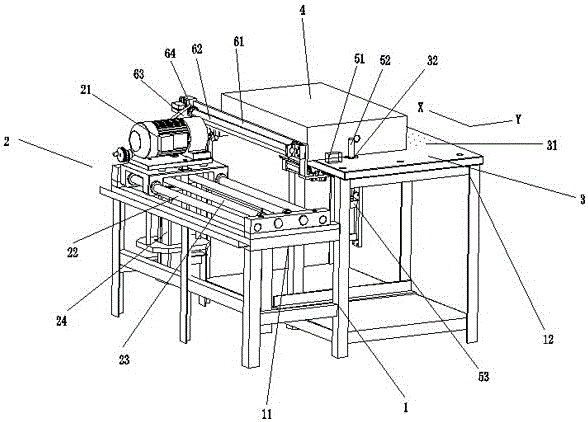

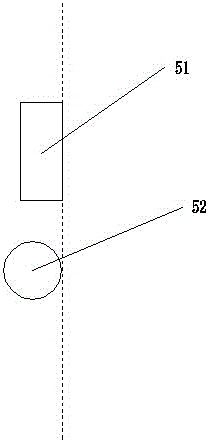

[0018] Such as Figure 1-2 Shown, a kind of air-floating four-sided chamfering machine comprises frame 1, feeding device 2 and discharging device, and feeding device 2 and discharging device are arranged on frame 1, and feeding device 2 comprises cutter head, Motor 21, motor guide plate, lifting cylinder 24, cylinder guide sleeve, rodless cylinder rod 23 and guide shaft 22, the top of the feeding device has a horizontal workpiece placement platform 3, specifically, the frame 1 becomes a ladder type, and the feed device Be positioned at lower lower frame 11, discharge device is positioned at higher upper frame 12, under the drive of motor 21 and lift cylinder 24, cutter head can be chamfered alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com