Automatic chamfering equipment for building aluminum template sealing plate

An aluminum template and chamfering technology, applied in metal processing equipment, clamping, supporting and other directions, can solve the problems of cumbersome fixing and complex structure, and achieve the effect of easy chamfering, easy control, and preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

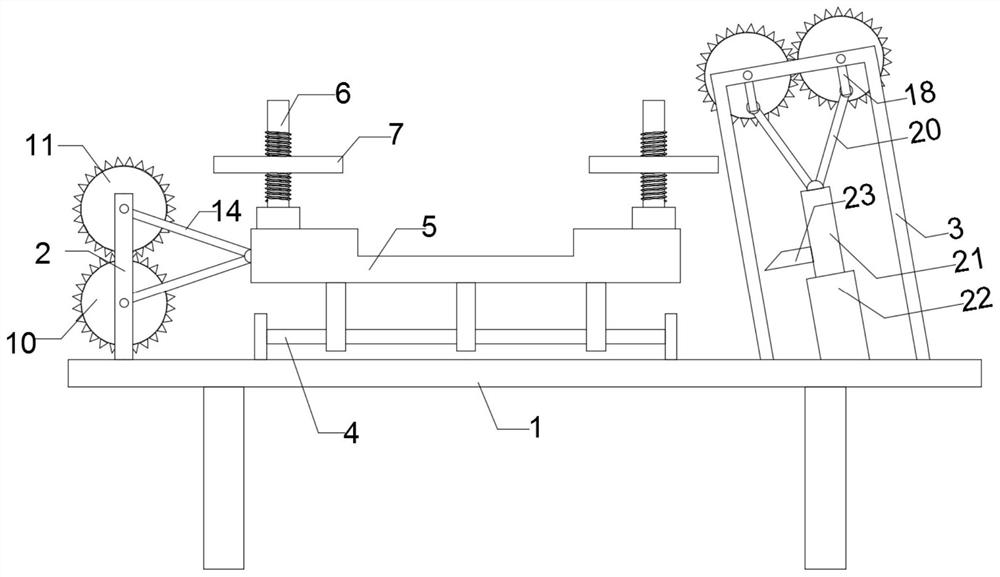

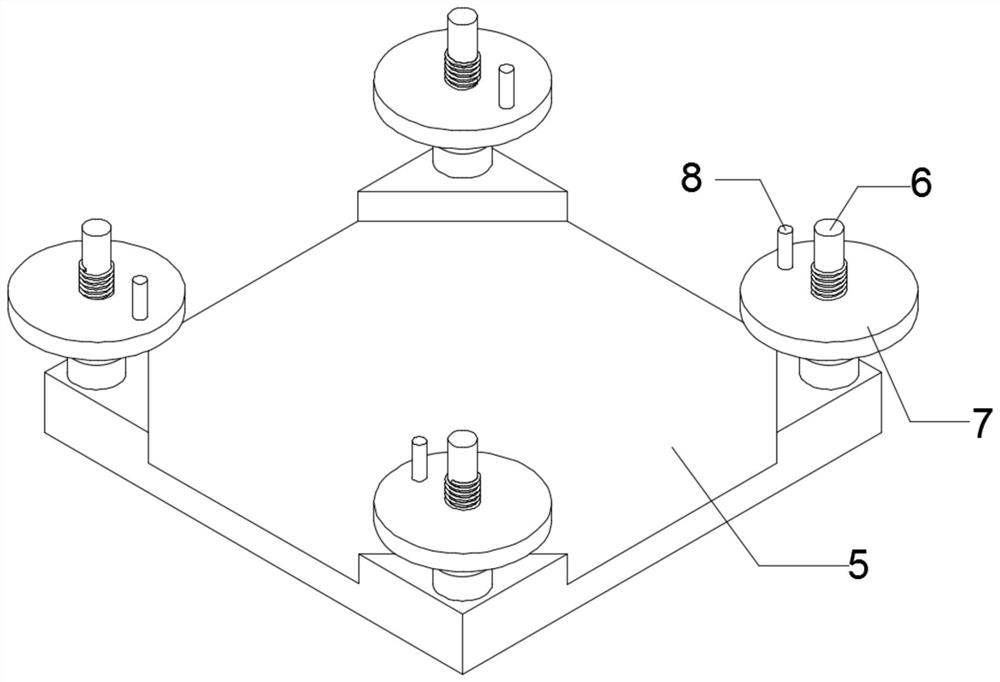

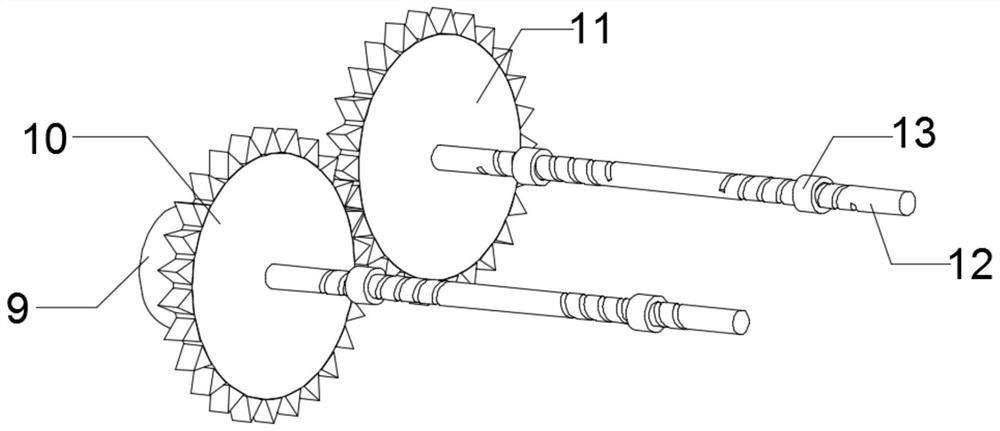

[0021] see Figure 1-4 , this embodiment provides an automatic chamfering equipment for building aluminum formwork, including a base 1, a left bracket 2, a right bracket 3 and a clamping mechanism; a plurality of positioning rods 4 are symmetrically fixed on the base 1, and the clamping The holding mechanism is slidably arranged on a plurality of positioning rods 4; the pushing mechanism that promotes the left and right movement of the holding mechanism is arranged on the left bracket 2, and the left bracket 2 is arranged on the left side of the upper end of the base 1; the upper end of the base 1 is on the right side The side is provided with a right bracket 3, and the right bracket 3 is provided with a chamfering mechanism for chamfering the sealing plate; the clamping mechanism includes a placement plate 5, a screw 6, a rotating disc 7 and a handle 8; the placement plate 5 is slidingly arranged on a plurality of positioning rods 4; the placement plate 5 is provided with a g...

Embodiment 2

[0030] This embodiment is further improved on the basis of Embodiment 1. The improvement is: in order to facilitate the operation of the control equipment, one side of the base 1 is also provided with control buttons for controlling the operation of the push motor 9 and the chamfering motor 15. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com