Saw blade type numerical control cutting and chamfering machine

A technology of chamfering machine and saw blade, which is used in metal sawing equipment, sawing machine equipment, metal processing equipment and other directions, can solve the problems of poor effect, prone to eccentricity, and easily damaged blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

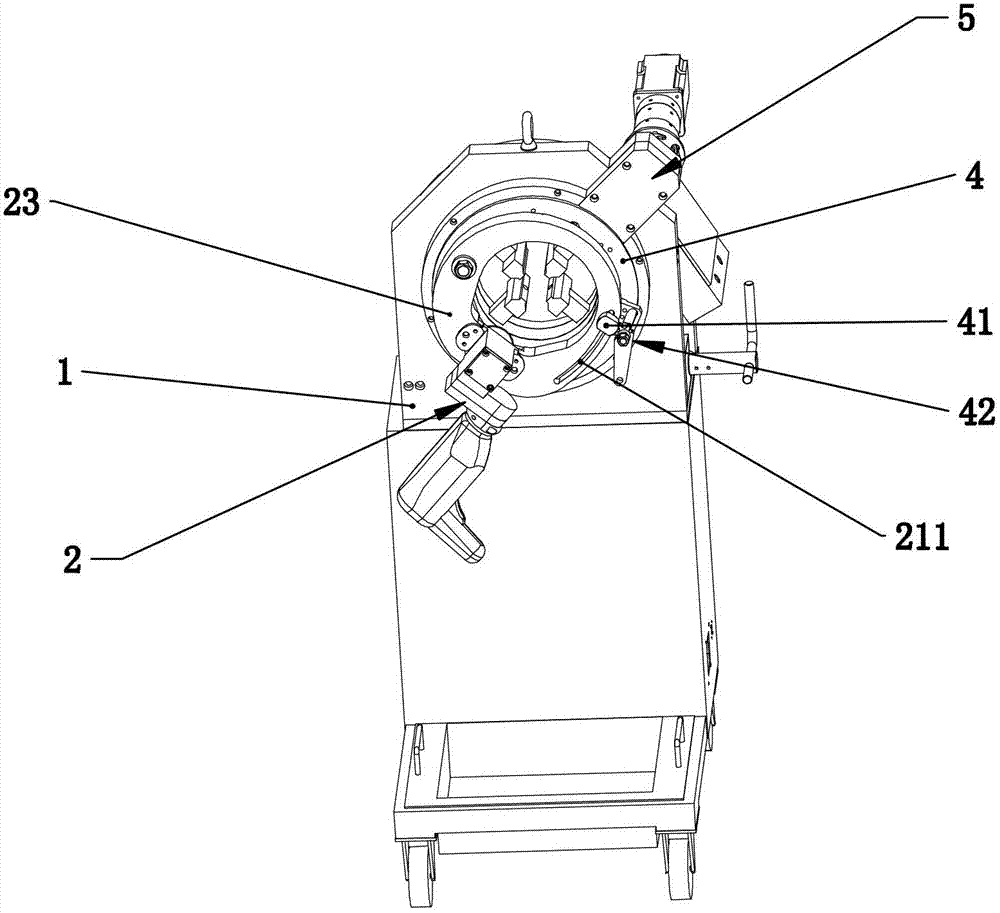

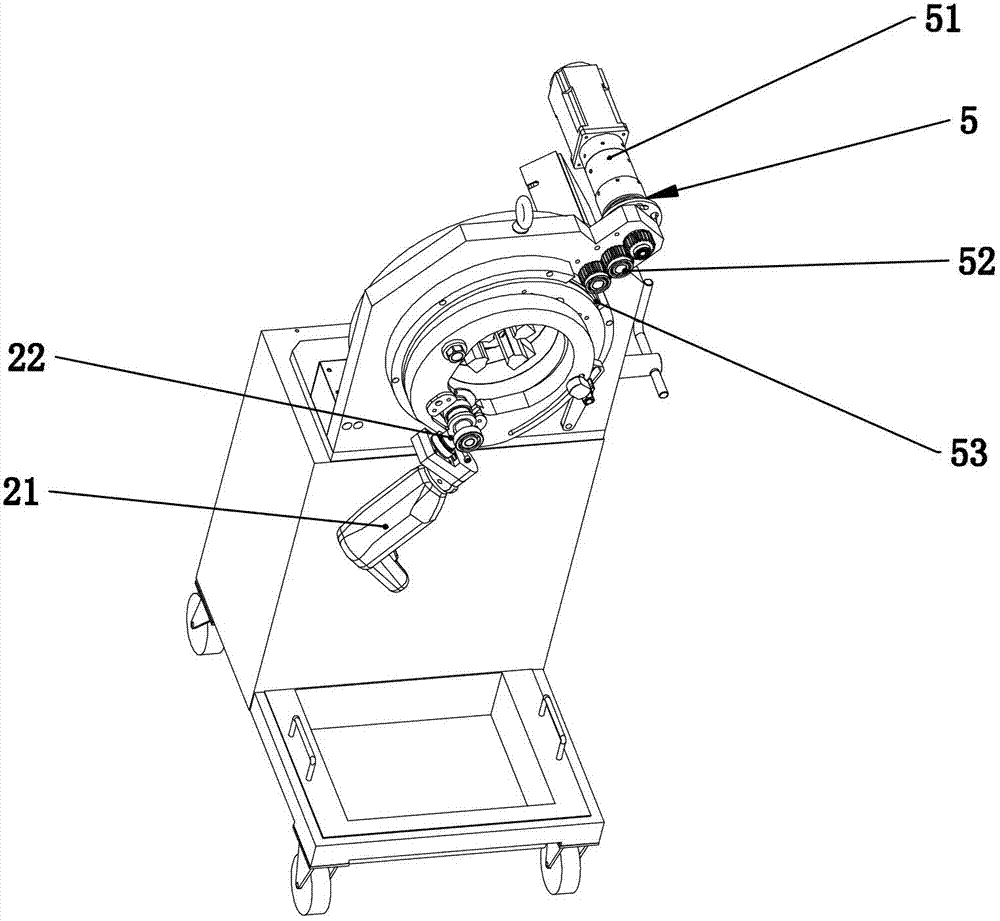

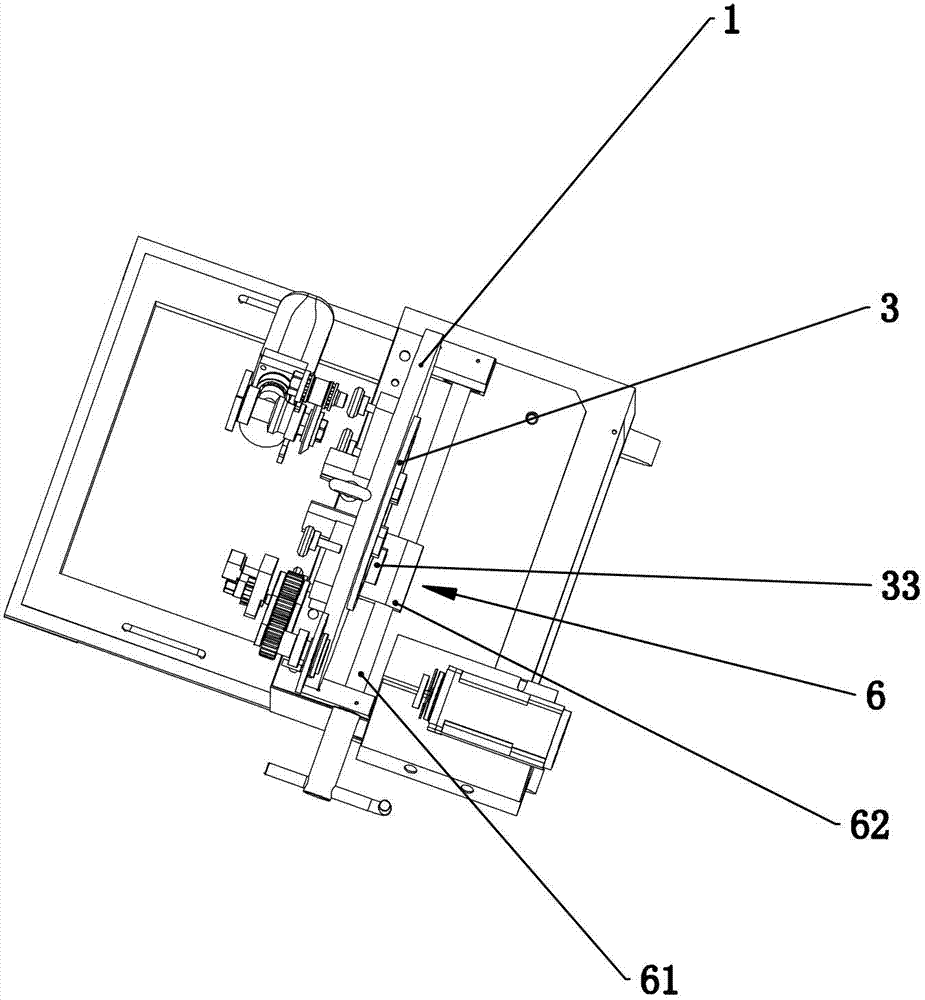

[0014] Such as figure 1 — Figure 5 As shown, a saw blade type CNC cutting and chamfering machine includes a frame 1, a cutting and chamfering device 2, a pipe clamping disk 3 and a rotating disk 4, and a rotating device 5 is arranged between the frame 1 and the rotating disk 4 , the rotating device 5 includes a motor 51, an output gear 52 and a gear plate 53, wherein the gear plate 53 is fixedly arranged on the rotary plate 4 or integrally arranged with the rotary plate 4, the output shaft of the motor 51 is linked with the output gear 52, and the output gear 52 meshes with the gear plate 53. In the example of the present invention, the clamping plate 3 and the frame 1 form a rotational fit, and the rotating plate 4 is hingedly provided with a cutting and chamfering device 2 mounting bracket 23, which One side of 23 is hinged with the rotating disk 4, and the other side is provided with a long through hole 211. The rotating disk 4 is fixedly provided with a limit pin 41, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com