Patents

Literature

38results about How to "Convenient positioning and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

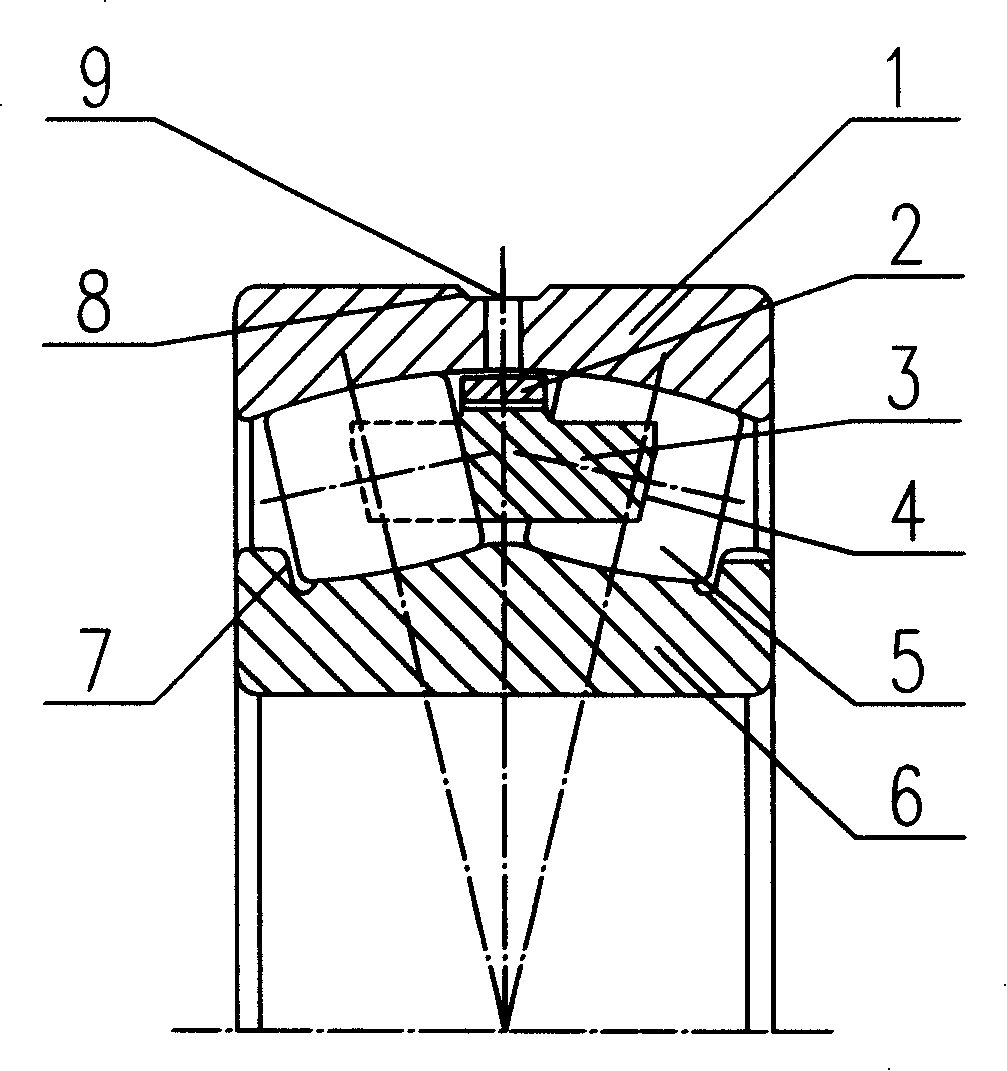

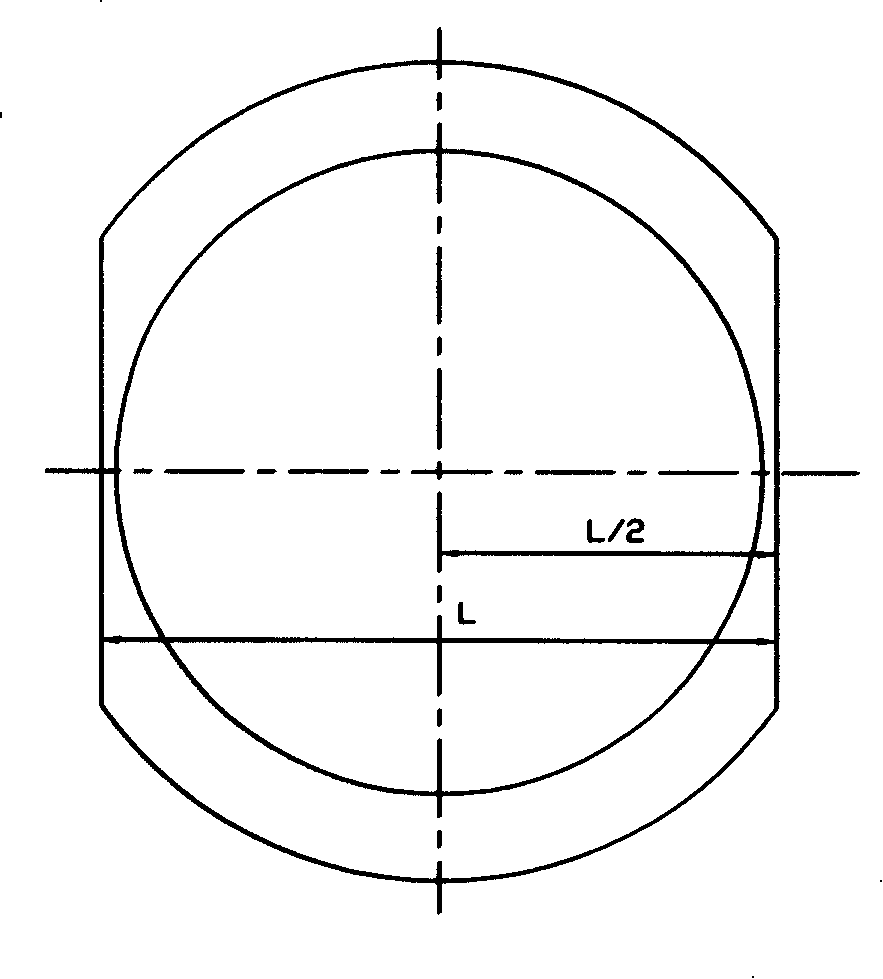

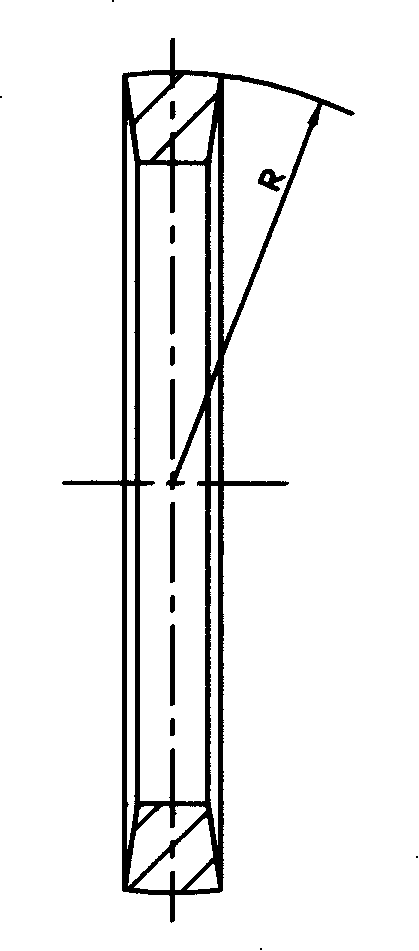

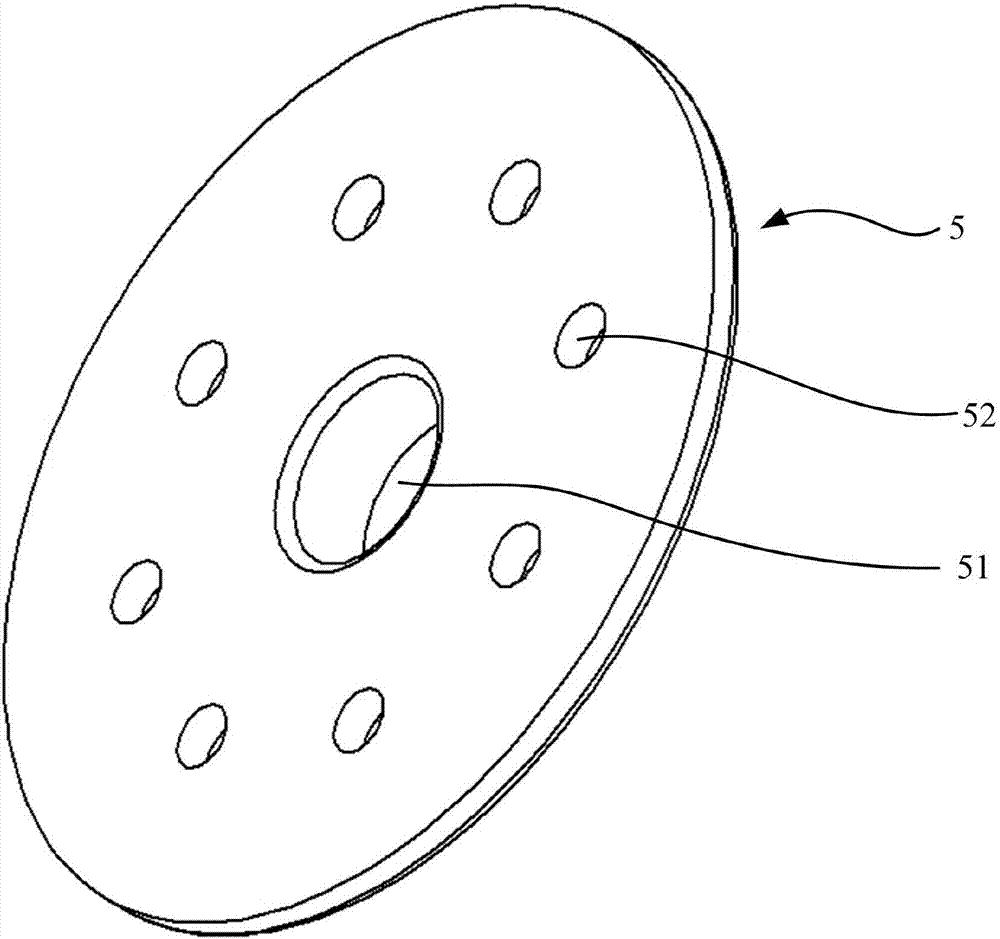

Light and narrow series double row symmetrical spherical roller bearing with solid cage

ActiveCN101169158AReduce frictionConvenient positioning and processingRolling contact bearingsBearing componentsSpherical roller bearingFlange

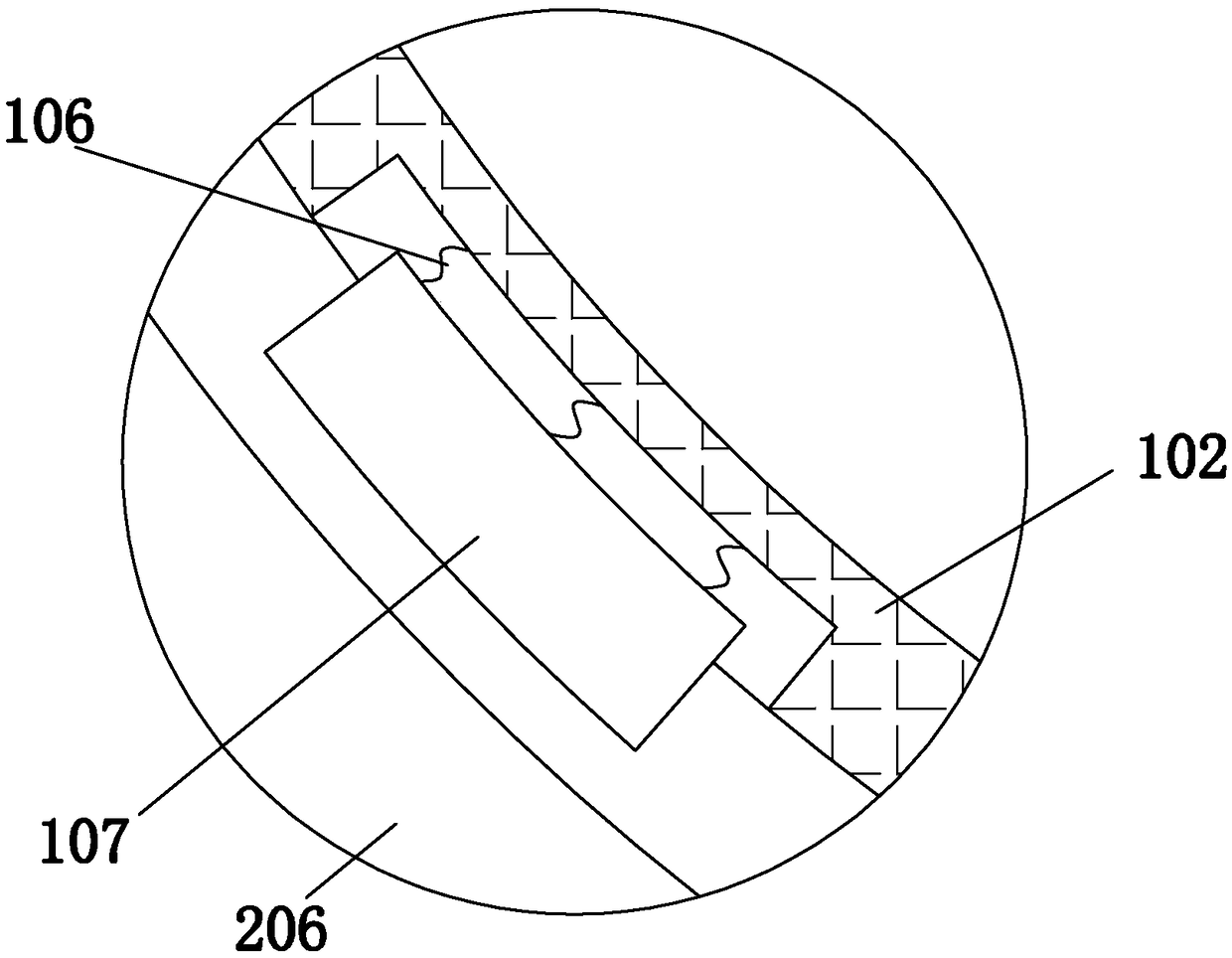

The invention discloses a light and narrow series double-row self-aligning roller bearing with a solid cage, the parts of which include an outer ring (1), an inner ring (6), a movable retaining ring (2) and a cage (3) , roller (5). An oil groove (8) is set on the center line of the outer ring (1), and oil holes (9) are evenly distributed on the oil groove (8); the angle of the small rib (7) of the inner ring is greater than the contact angle of the bearing by 30'; The outer diameter of the ring (2) is a concentric circle smaller than the raceway diameter of the outer ring (1), and the dimension (L) between its two sides is smaller than the minimum inner diameter of the outer ring (1). The invention has the characteristics of stable operation, high reliability, good lubricating performance, flexible rotation, short manufacturing cycle, low cost and the like.

Owner:LUOYANG PRECISION OF MACHINE EQUIP TECH CO LTD

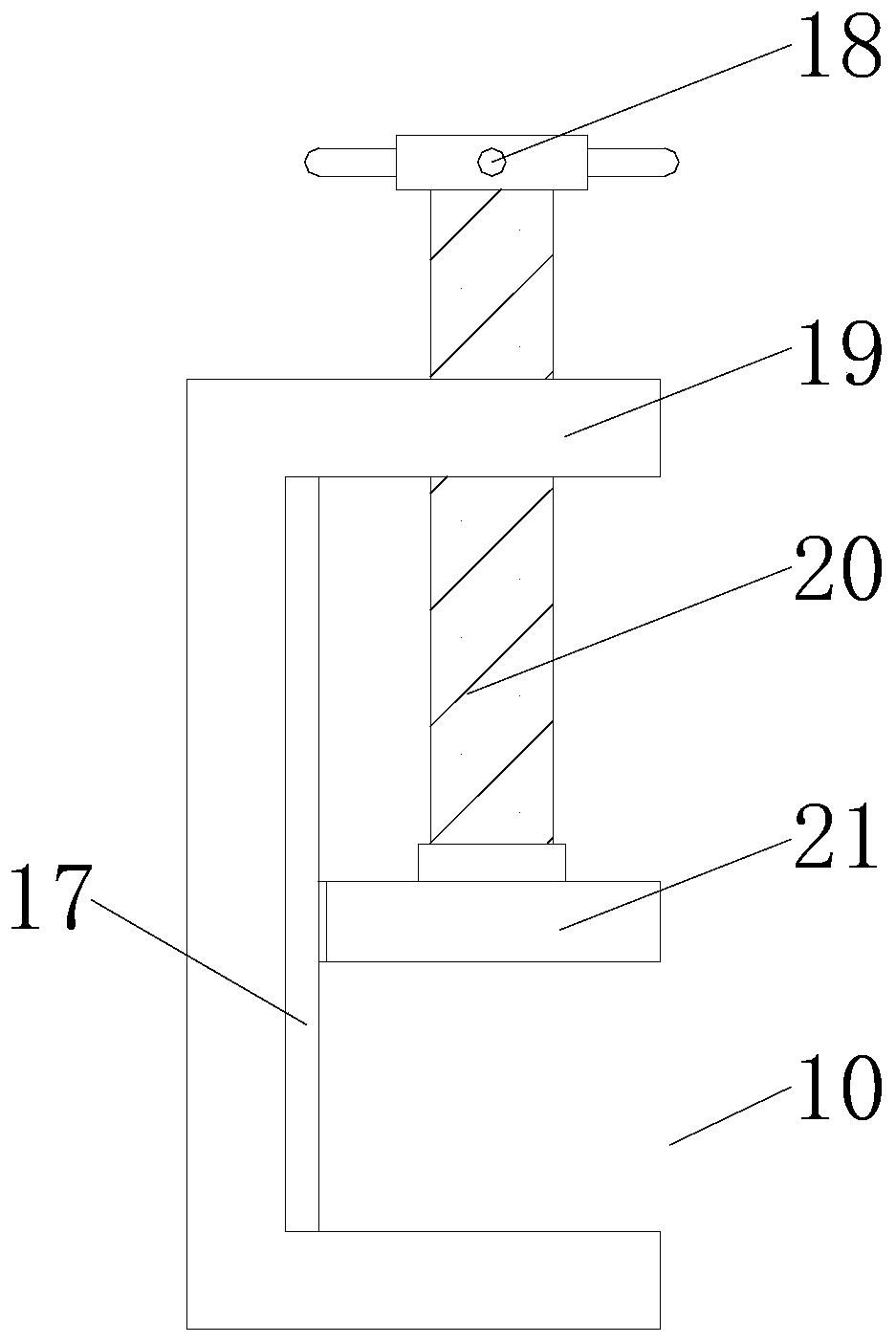

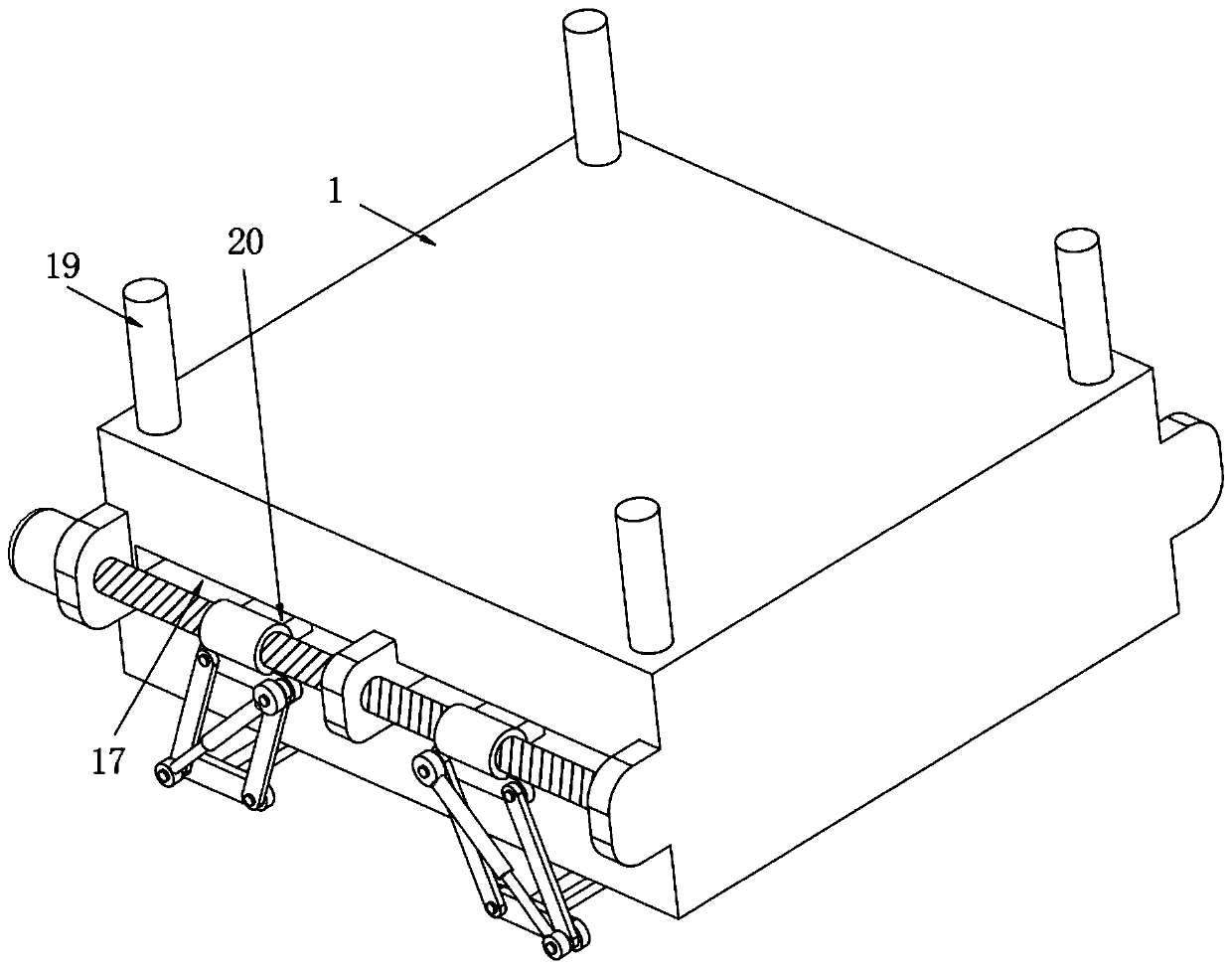

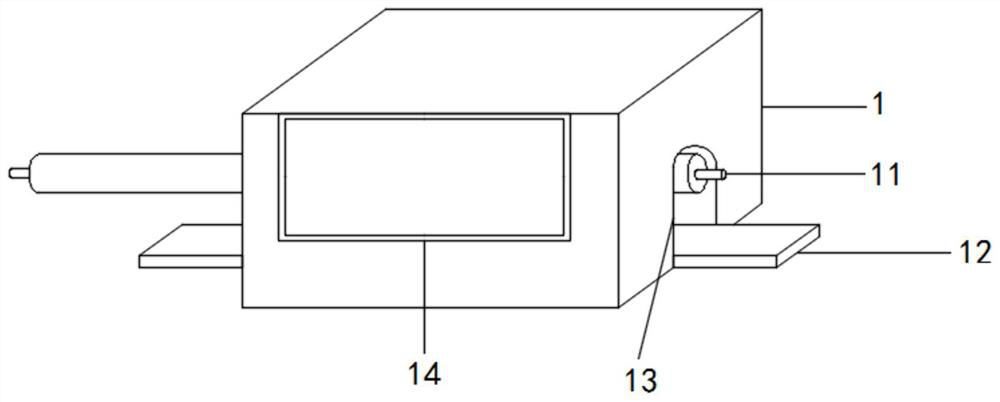

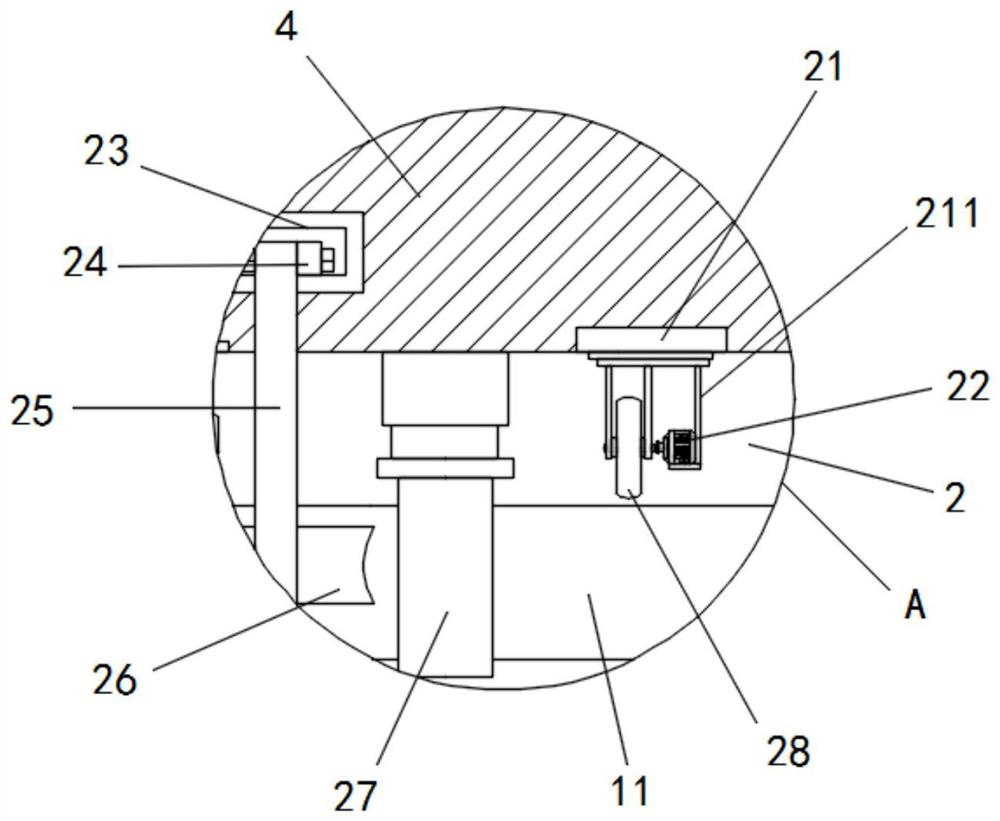

Fixing device facilitating machining of aluminum plate

InactiveCN110893554AEasy to installEasy to disassembleMeasurement/indication equipmentsWork benchesStructural engineeringThreaded rod

The invention discloses a fixing device facilitating machining of an aluminum plate, and relates to the technical field of aluminum plate machining. The fixing device comprises a box body, first threaded rods are rotatably mounted at the two sides of the interior of the box body through bearings, sliding rods are fixedly mounted at the two sides of the interior of the box body, and stop blocks arefixedly mounted at the tops of the sliding rods respectively. According to the fixing device, a first cushion block, an electric telescopic rod, a clamping mechanism, an L-shaped frame, a connectingsliding block, a sliding rail, a handle, mounting frames, a second threaded rod and a pressing plate are matched for use; the aluminum plate is clamped between the two mounting frames and is fixed less difficultly; the pressing plate can be moved up and down to be adjusted so that the top of clamps the aluminum plate; and the fixing stability of the aluminum plate is improved, the aluminum plate is prevented from falling accidentally, and the operation stability and safety of the device are improved.

Owner:湖州华利铝业有限公司

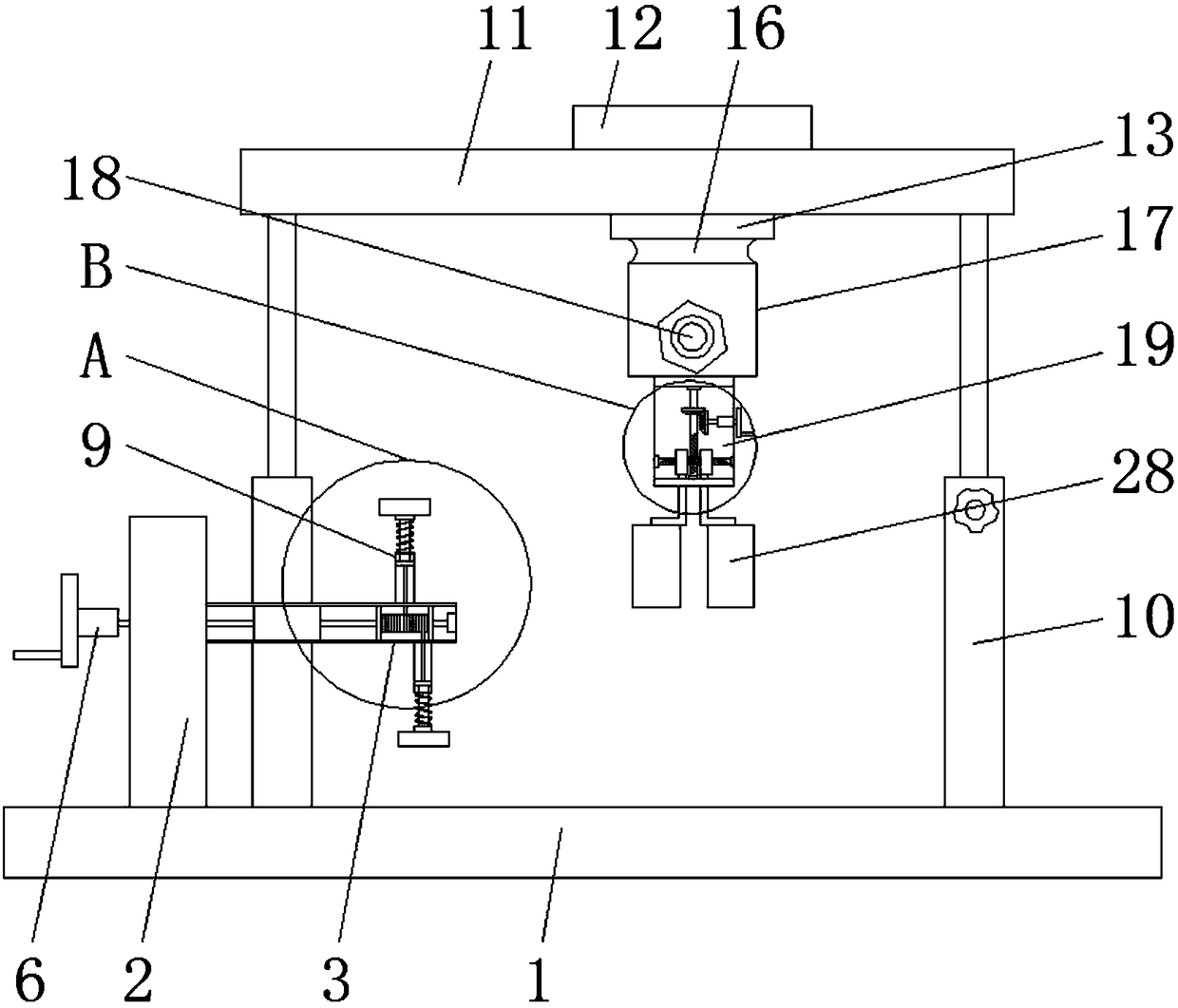

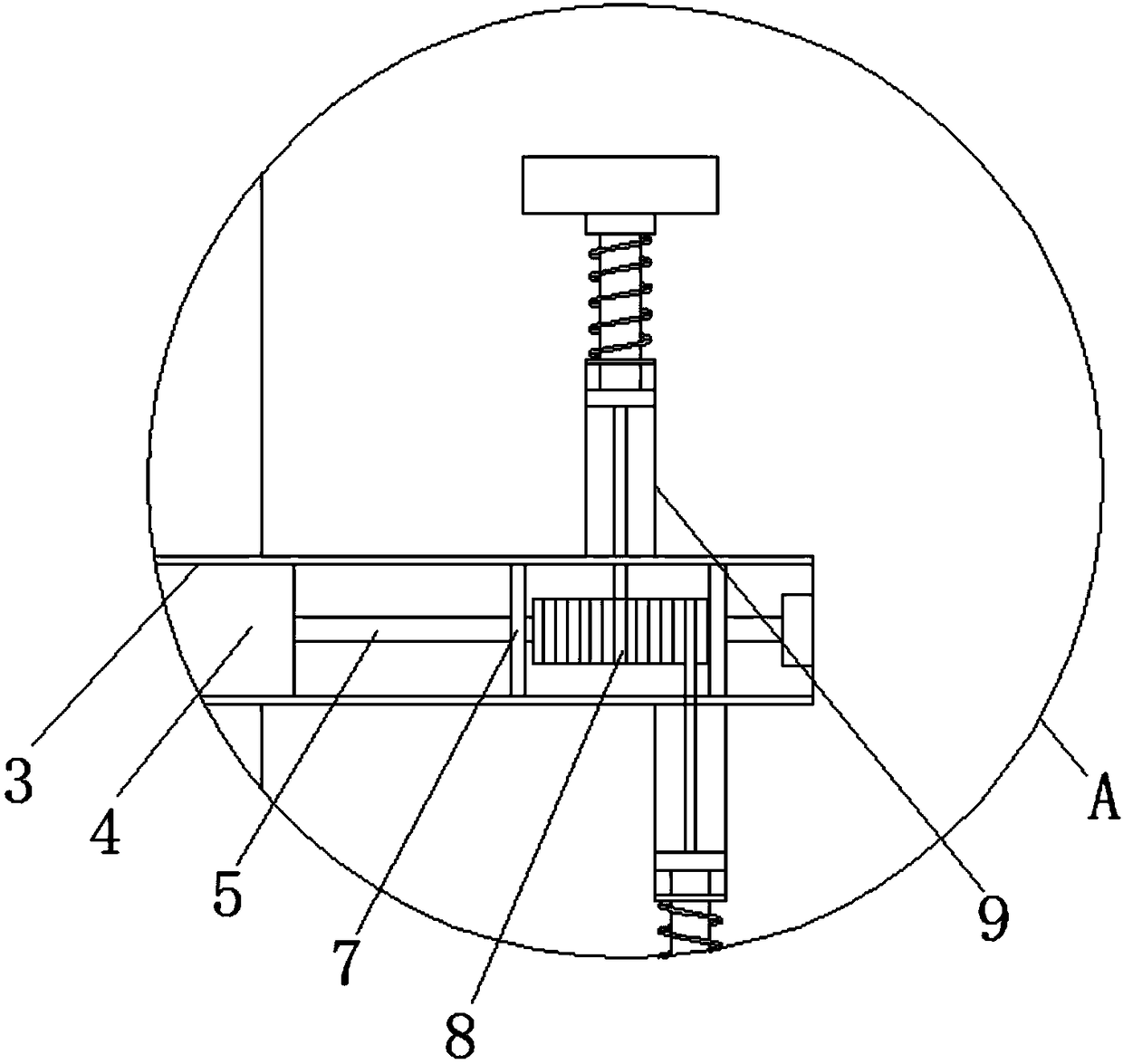

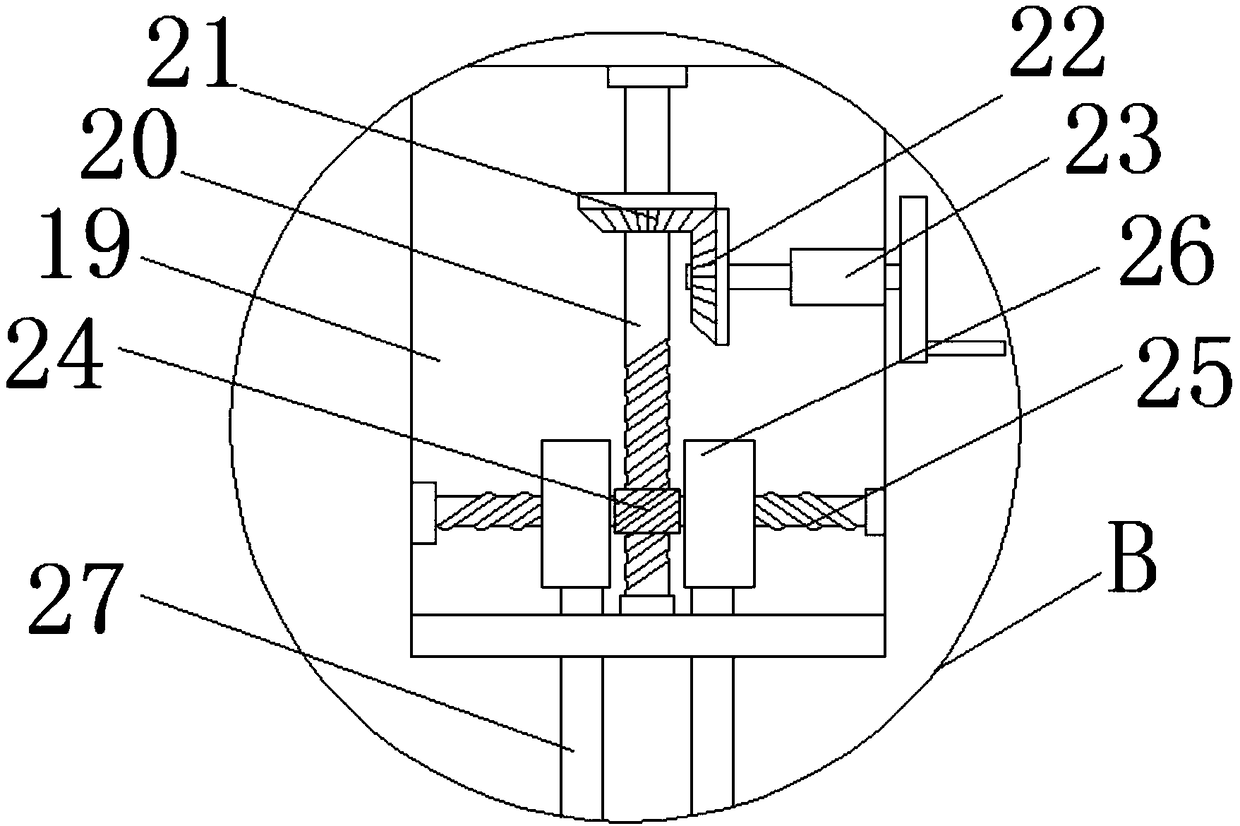

Building decoration plate grinding device

PendingCN108466127AConvenient positioning and processingAvoid affecting your healthEdge grinding machinesGrinding carriagesArchitectural engineeringDust collector

The invention discloses a building decoration plate grinding device which comprises a base. The top end of the base is fixedly connected with a top plate through four supporting rods. The middle of the top end of the top plate is fixedly connected with a dust collector. A dust collection hood is arranged in the middle of the bottom end of the top plate. The two sides of the dust collection hood are fixedly connected with electric air cylinders. The middle of the top end of the base is connected with a rotary table through a bearing. Grinding equipment tables are in sliding connection with thebase through two second guide rods. Each grinding equipment table is in sliding connection with a moving seat. A second stepping motor is arranged at one end of the inner top of each grinding equipment table. The moving seats are in transmission connection with the second stepping motors through ball screws. The top end of each moving seat is fixedly connected with a motor. The output end of eachmotor is fixedly connected with a grinding disc. According to the building decoration plate grinding device, through the arrangement of the overall structure, building plates are conveniently locatedand machined, manpower is saved, and the grinding effect is improved; and through the arrangement of the dust collection hood and the dust collector, machining dust can be absorbed.

Owner:贵州泓耀科技装饰材料有限公司

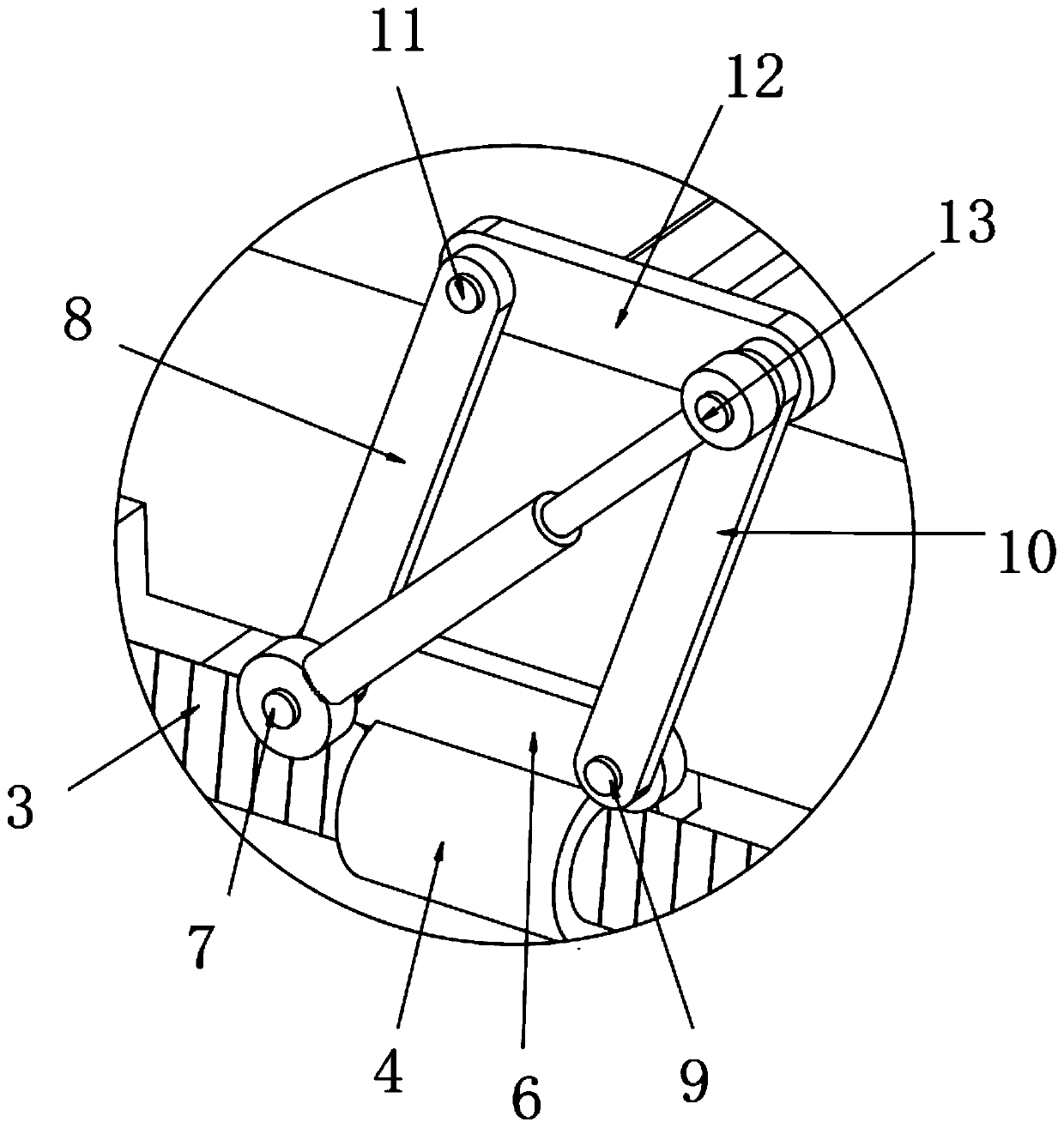

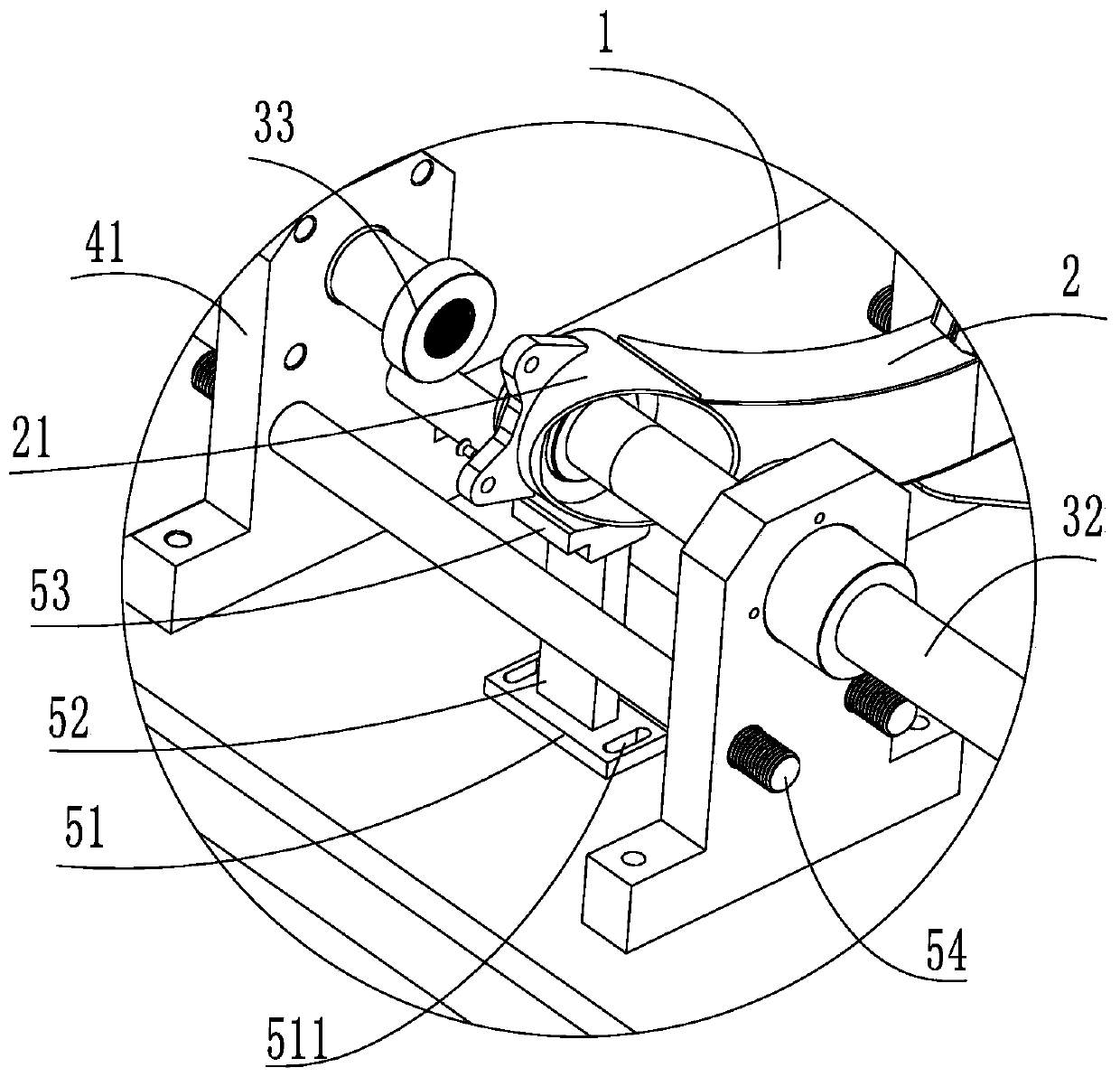

Clamp for welding of processing joints of spiral air pipes

InactiveCN108372382AImprove practicalityImprove timeliness and practicalityWelding/cutting auxillary devicesAuxillary welding devicesExternal fixationDrive shaft

The invention relates to the technical field of processing equipment of spiral air pipes, and discloses a clamp for welding of processing joints of spiral air pipes. The clamp comprises a base, wherein a positioning plate is fixedly arranged at the top part of the base; a fixed cylinder is fixedly arranged at the top part of the side surface of the positioning plate; a positioning shaft sleeve isfixedly arranged in the middle part of an inner cavity of the fixed cylinder; a drive shaft is movably sheathed at the middle part of the positioning shaft sleeve; one end of the drive shaft extends to the exterior of the side surface of the positioning plate, and is fixedly provided with a rotary disc II; the other end of the drive shaft is fixedly sheathed with a bearing at the inner wall of thefixed cylinder. The clamp for the welding of the processing joints of the spiral air pipes has the advantages that the inclining angle of a fixed column corresponding to the fixed cylinder is adjusted by using the bolt and the clamping plate, and the distance between the second spiral air pipe fixed on the fixed and the first spiral air pipe on the fixed cylinder is limited by a limiting plate, so as to conveniently adjust the welding angel and position of the two spiral air pipes; the practicality and timeliness in re-processing of the spiral air pipes are improved.

Owner:潘世健

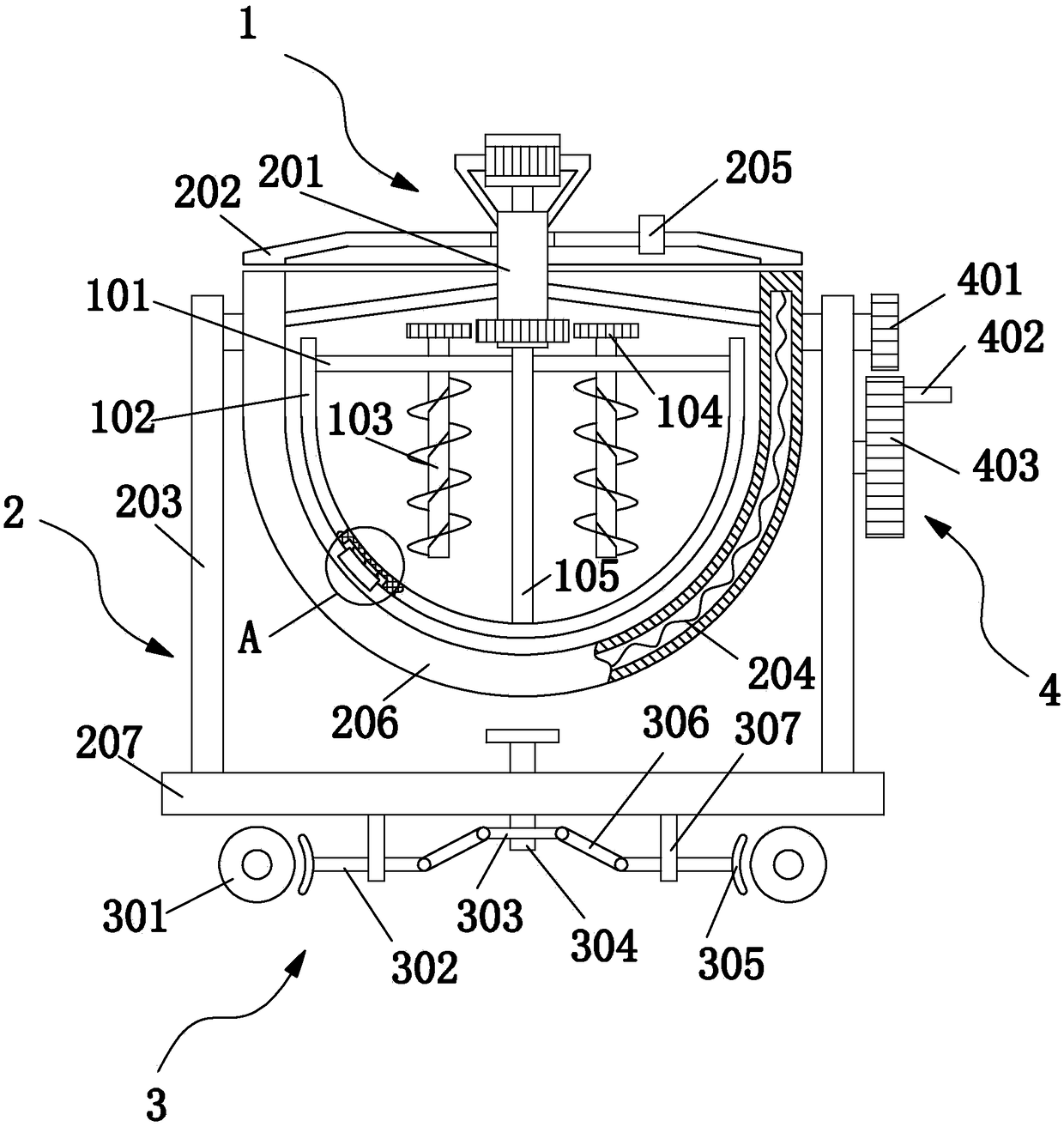

Anti-burn sugar boiler for sweet production

InactiveCN108902424AEvenly heatedImprove uniformityConfectionerySweetmeatsInternal pressureSpiral blade

The invention discloses an anti-burn sugar boiler for sweet production. The anti-burn sugar boiler comprises a boiler. The boiler comprises a base. The bottom of the base is connected to a mobile device. A top cover covers the boiler body so that a closed space is formed. An air pump is used for feeding gas so that pressure in the boiler is improved and sugar is fast molten. Rollers are used for moving the boiler. Through the friction between a blocking plate and the rollers, the rollers are fixed so that the boiler is fixed and positioning and processing are convenient. A spiral blade shaft rotates to bring lower sugar to the upper part, and continuously stirs so that the heat is more uniform and the uniformity is high. A bow scraper plate and scraper sheets can scrap syrup adhered to theinner wall of the boiler so that long-term heating is avoided and burnt phenomenon is avoided.

Owner:HOLEYWOOD FUJIAN FOODS

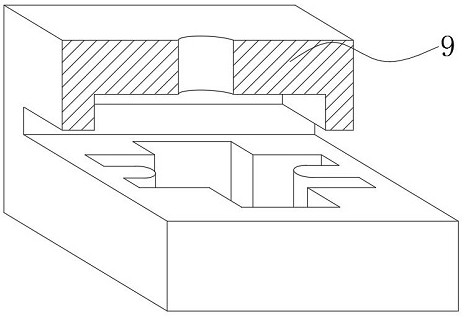

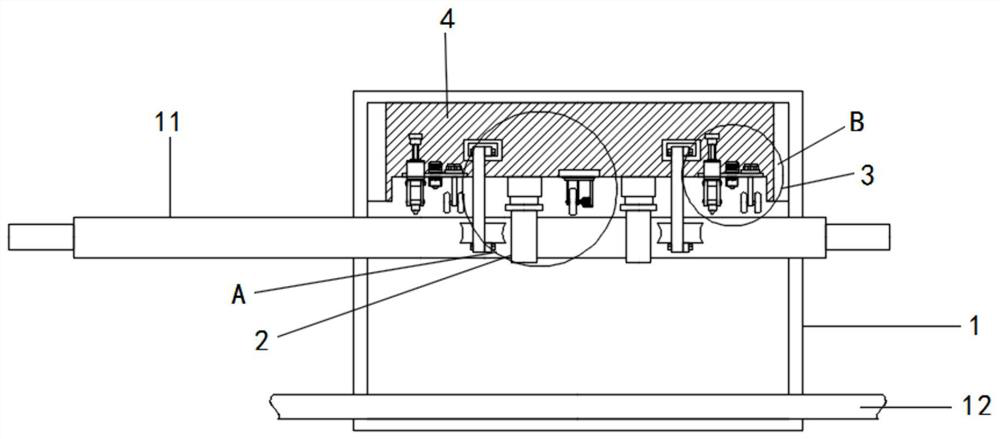

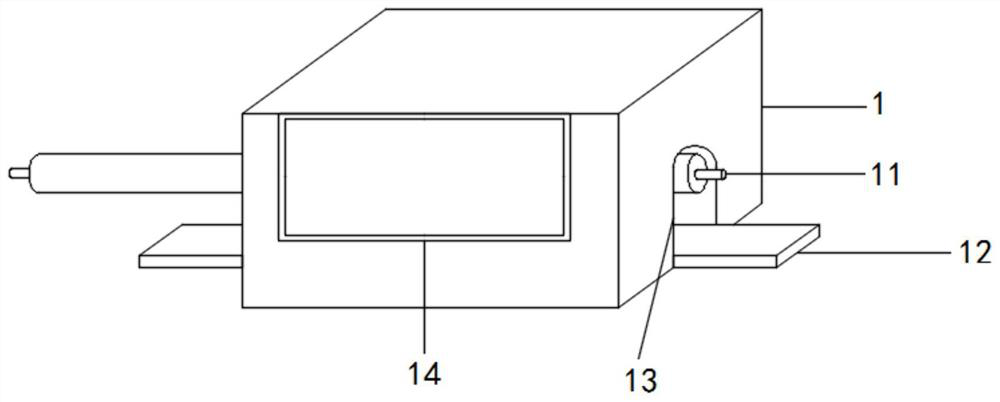

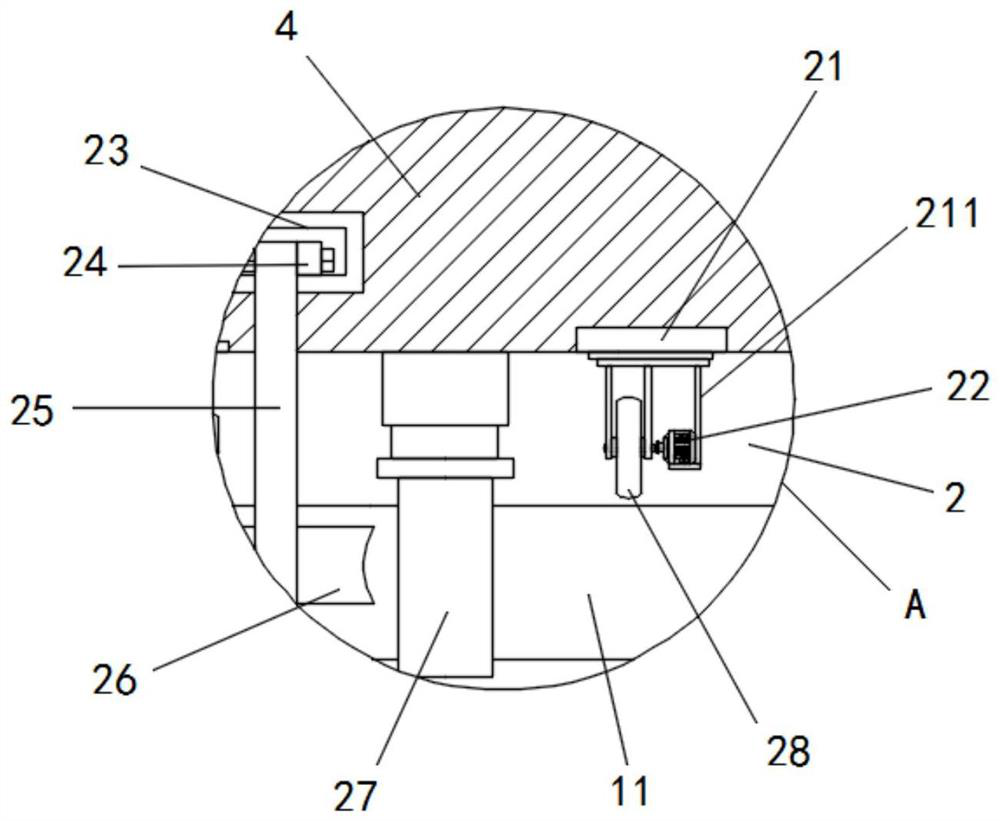

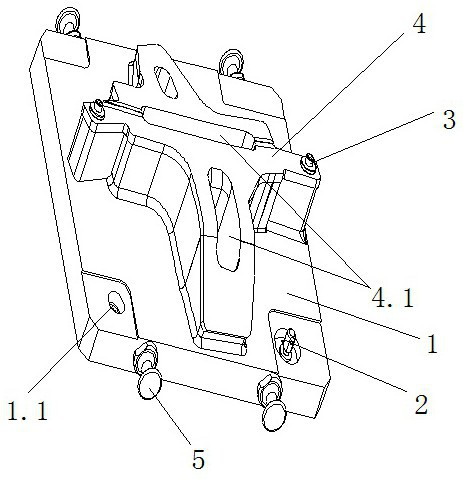

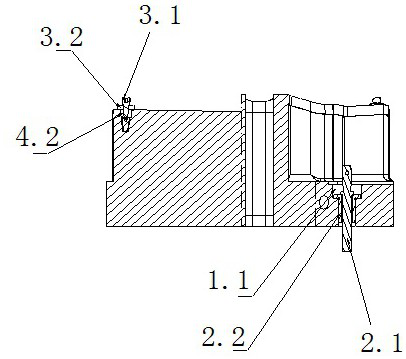

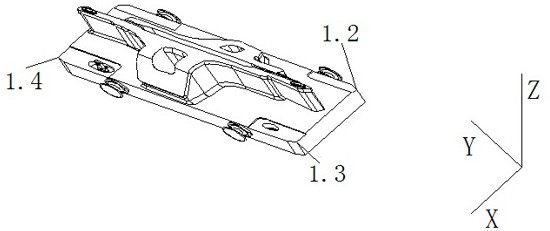

Clamp special for double-face machining of engine cylinder body

PendingCN108907780AWith rotatable angle functionMultiple processing methodsAutomatic control devicesFeeding apparatusEngineeringCylinder block

The invention discloses a clamp special for double-face machining of an engine cylinder body. The clamp comprises a base box. A supporting rotating shaft is connected in the base box in a rotating manner. A hollow supporting box is fixedly connected to the top end of the supporting rotating shaft. A sliding rail is fixedly connected to the top of the hollow supporting box. A lead screw shaft is connected to the surface of the hollow supporting box in a rotating manner. One end of the lead screw shaft penetrates through the hollow supporting box and extends to one side of the hollow supportingbox. A hand wheel is fixedly connected to one end of the lead screw shaft. A moving frame is connected to the surface of the lead screw shaft in a thread manner. The surface of the moving frame is connected with the sliding rail in a sliding manner. The invention relates to the technical field of engine cylinder body machining. The clamp special for double-face machining of the engine cylinder body has a function of clamping the engine cylinder body, the engine cylinder body can be located and machined on an engine cylinder body double-face machining tool conveniently, the angle can be adjusted, use is convenient, more machining means are possessed, the machining range is widened, and the machining ability is improved.

Owner:ZHEJIANG LINGBEN MACHINERY & ELECTRONICS

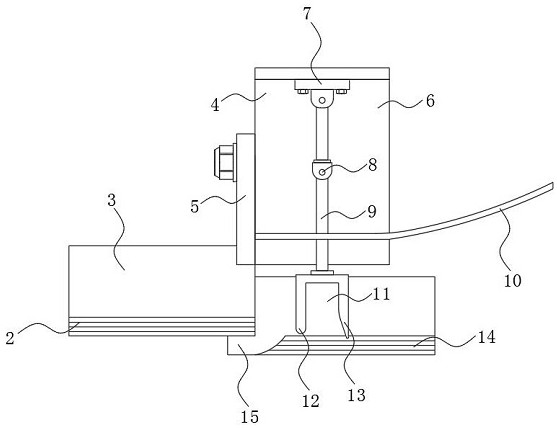

Processing equipment with contact reed having positioning production detection function

InactiveCN111986955AEasy to move toEasy to foldMaterial analysis by optical meansElectromagnetic relay detailsHydraulic cylinderPunching

The invention discloses processing equipment with a contact reed having a positioning production detection function. Case frame, a heightening base is mounted on the left side of the upper surface ofthe case frame; the right side surface of the feeding device is connected with a punching case; a transmission seat is arranged at the bottom of the punching case; a rotary base is mounted above the controller; the conveying base and the bending base are symmetrically arranged on the two sides of the bending mechanism; transmission seat, the microphone sheet can be conveniently moved into the inner cavity of the bending mechanism; then, a bending hydraulic cylinder and a bending block are arranged; the two sides of the brass sheet can be conveniently folded downwards; a motor and a connectingrod are arranged; according to the brass sheet folding device, the folded brass sheet can be conveniently moved to the bending base, meanwhile, through the arrangement of the bending base and the clamping end cover, the brass sheet is prevented from moving on the bending base when the brass sheet is folded upwards, and therefore the brass sheet is prevented from being manually turned over and machined, and the working efficiency of brass sheet folding is improved.

Owner:深圳市康瑞龙数控科技有限公司

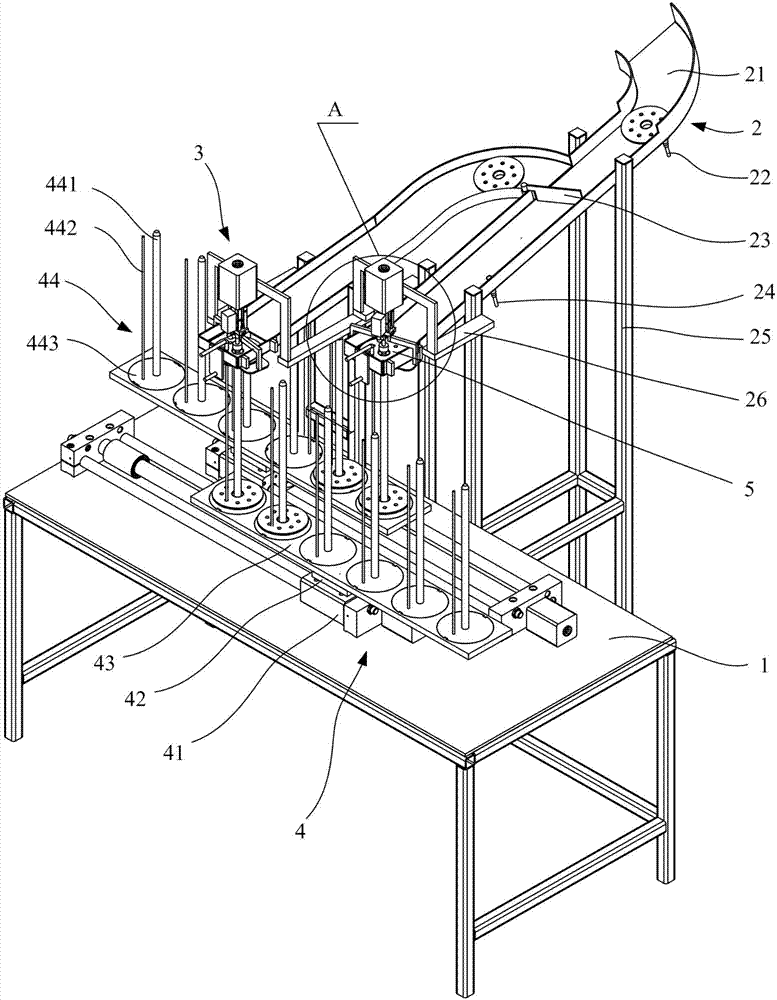

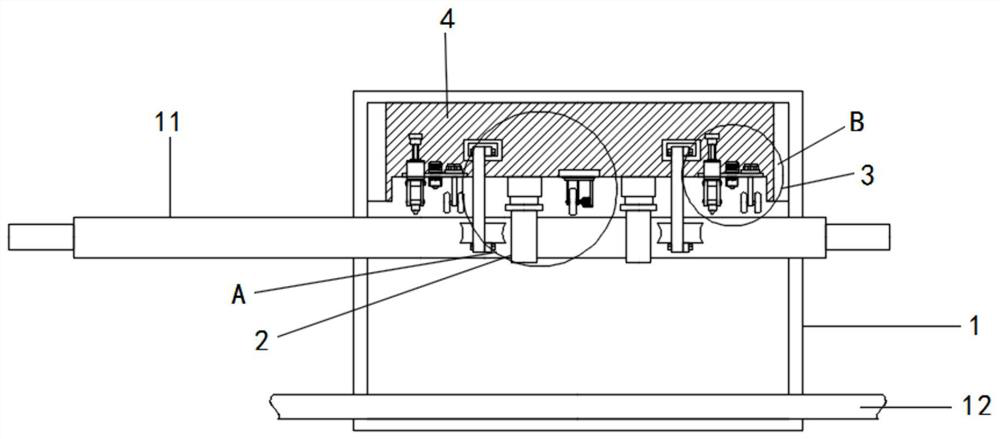

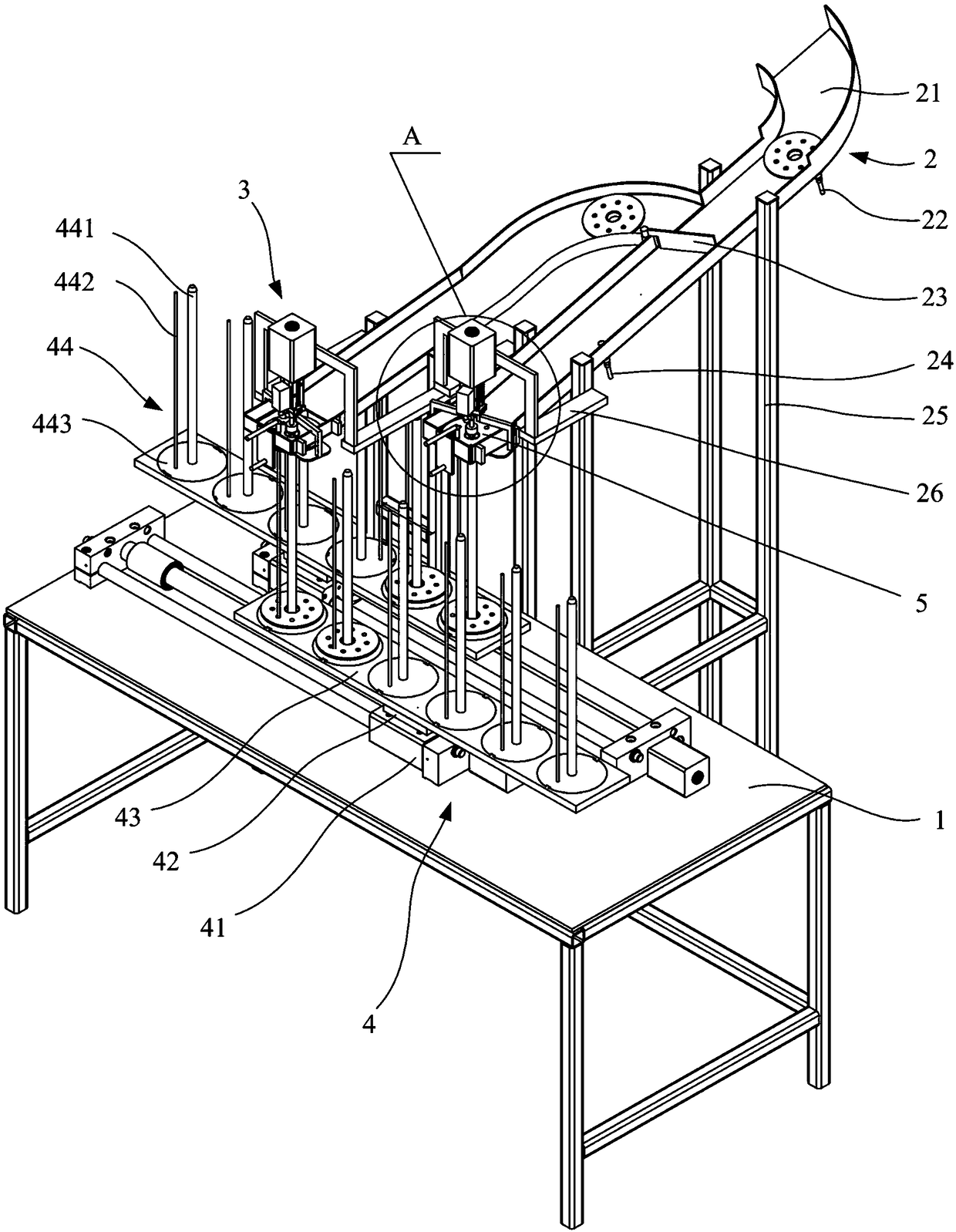

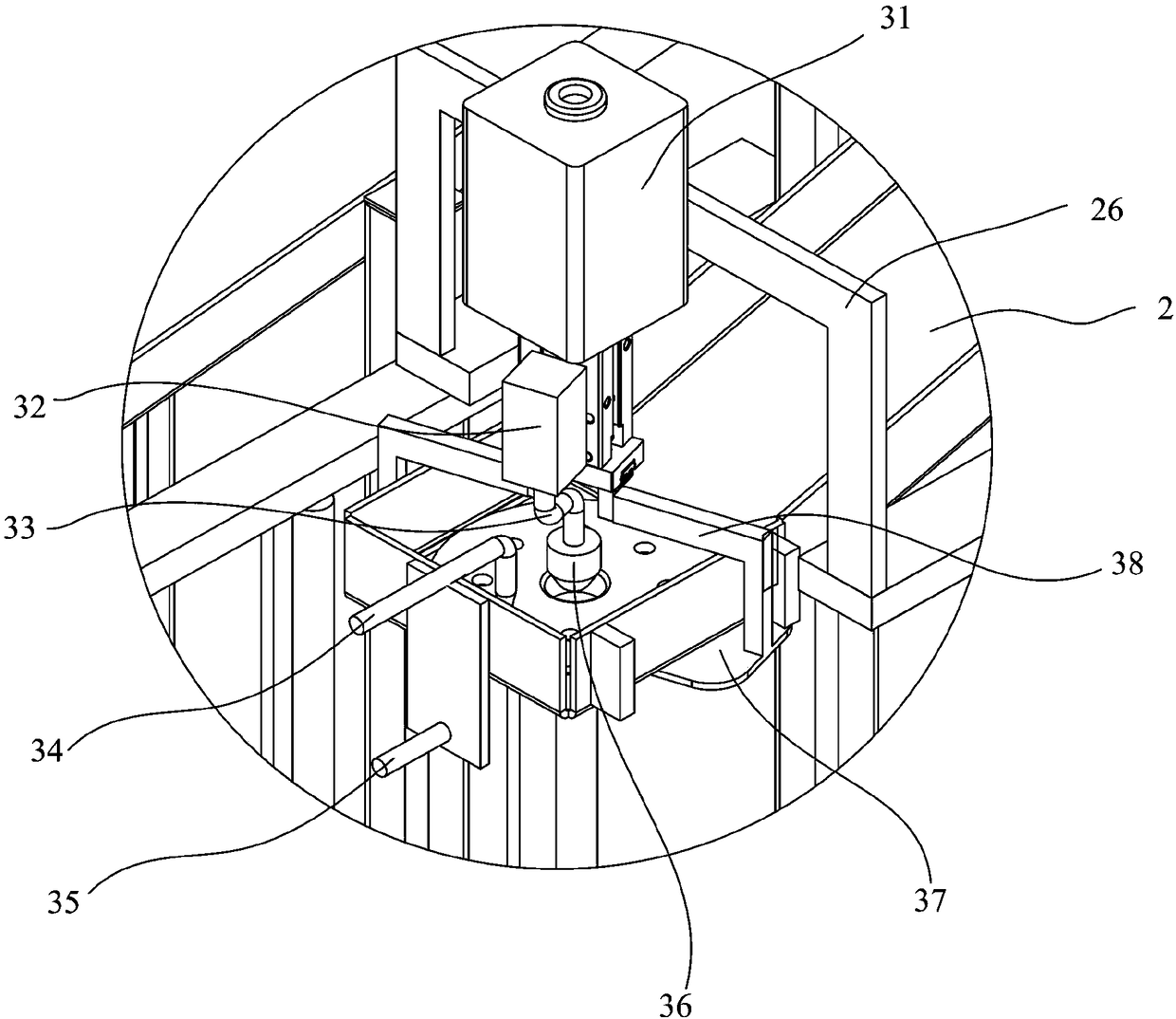

Automatic discharging and positioning device for punching and control method

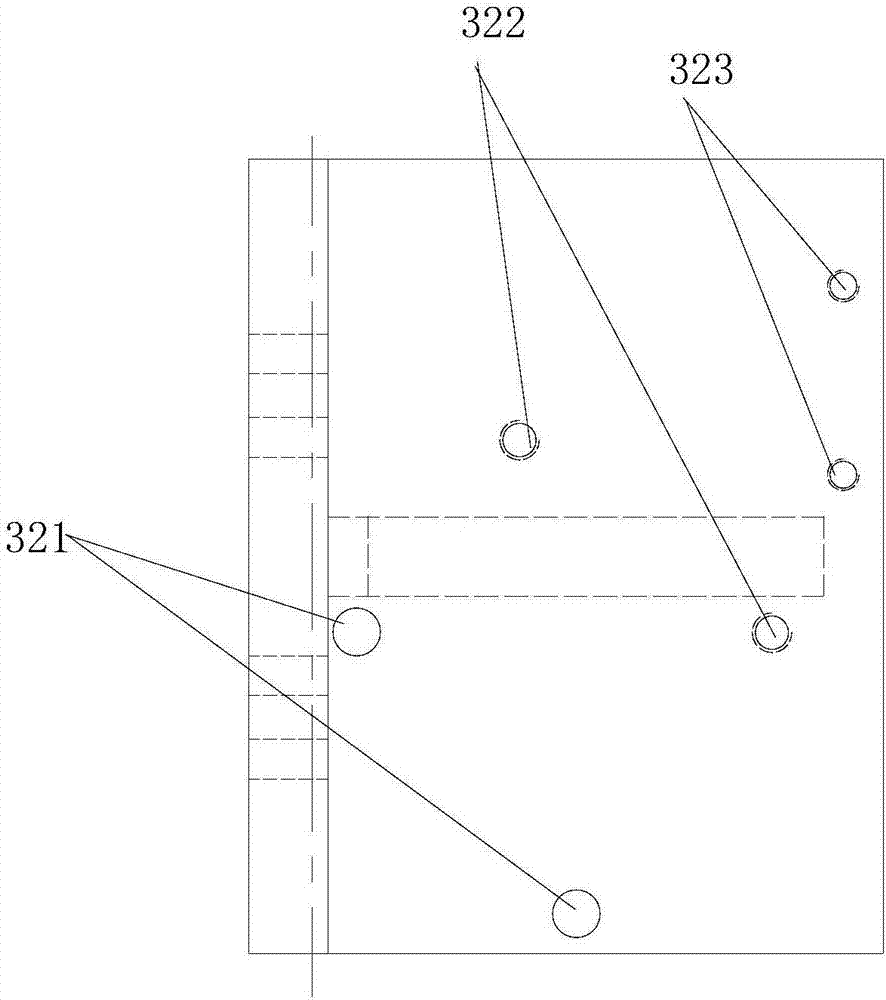

ActiveCN106862413ARealize the liberation of part of the labor forceRelieve pressureMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses an automatic discharging and positioning device for punching. The automatic discharging positioning device comprises a material receiving table, a material receiving mechanism, a detection positioning mechanism, a feeding mechanism and a main system circuit. The material receiving mechanism is installed on the top face of the material receiving table. The detection positioning mechanism is arranged above the material receiving mechanism. One end of the feeding mechanism is closed to a punching machine, and the other end of the feeding mechanism is close to the detection positioning mechanism. The invention further provides a control method. The feeding mechanism conveys workpieces to the detection positioning mechanism through the perpendicular height difference of the two ends, and the detection positioning mechanism and the material receiving mechanism are matched to position and stack the workpieces. According to the technical scheme, operation workers can be reduced for a production line, labor force is liberated, and enterprise management pressure and labor cost are reduced; meanwhile, a feeding groove is adopted for conducting directional conveying and stacking the workpieces through a stacking frame in a concentrated manner according to a certain rule, surface damage of the workpieces can be reduced, and the production quality of the products is improved; and in addition, the workpiece are stacked in the same direction, and the workpieces can be positioned and machined rapidly in the subsequent processes.

Owner:广东佛智芯微电子技术研究有限公司

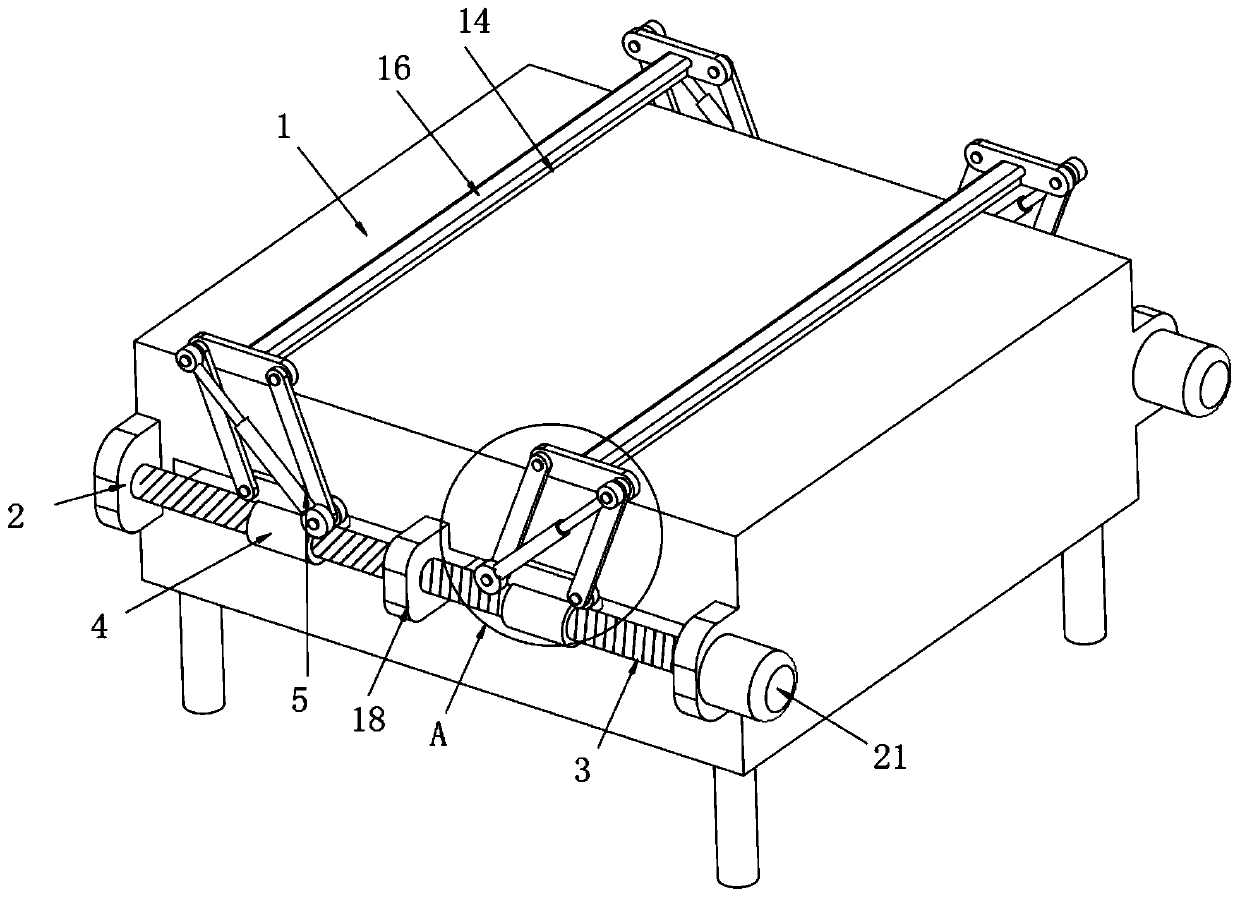

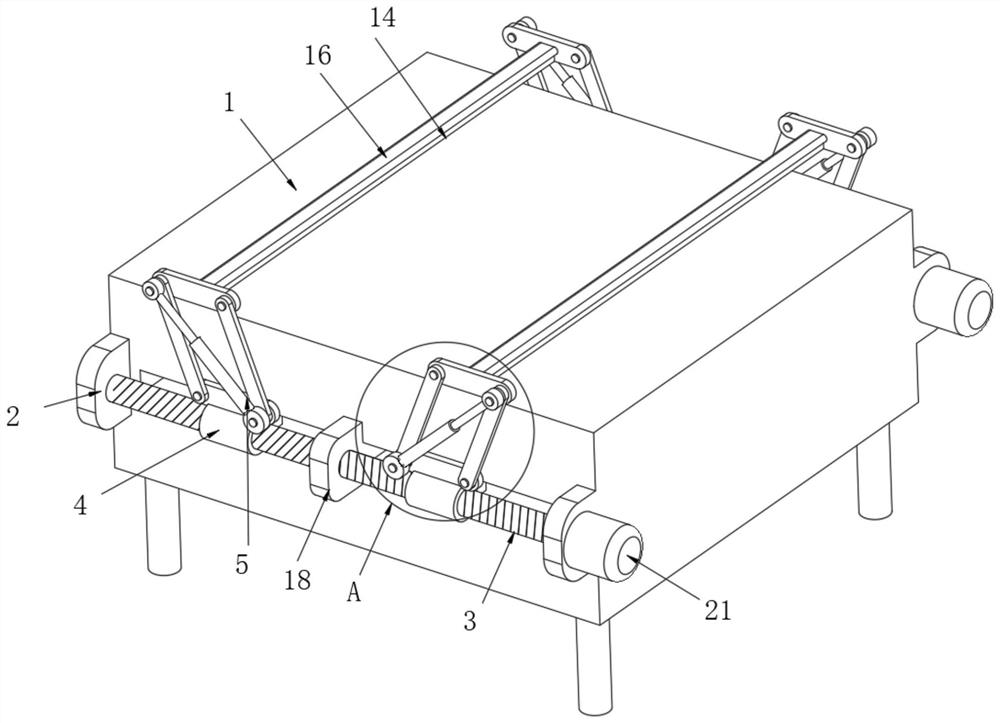

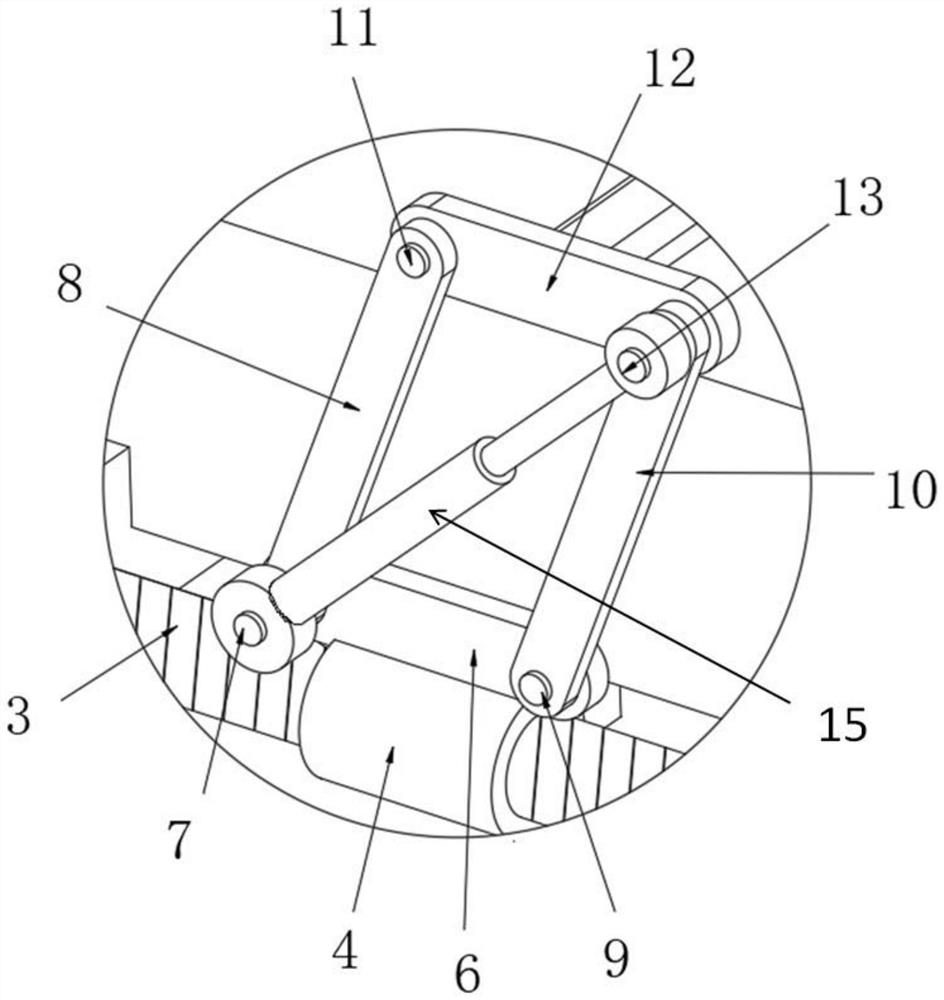

Positioning and clamping device for garment processing

The invention discloses a positioning and clamping device for garment processing. The positioning and clamping device comprises a workbench, wherein mounting seats are symmetrically fixed on two corresponding sides of the workbench; a threaded rod is arranged between the two mounting seats on the same side of the workbench; the rotating directions of two ends of the threaded rod are opposite; a motor is fixed on one side of each mounting seat; an output shaft of each motor is fixedly connected with one end of the threaded rod; two ends of the threaded rod are in threaded connection with threaded sleeves; a driving device is mounted on each threaded sleeve; each driving device comprises a bottom plate, a first rotating shaft, a first connecting rod, a second rotating shaft, a second connecting rod, a third rotating shaft, a top plate, a fourth rotating shaft, an air cylinder and a pressing plate; the bottom plate is fixed on the outer side wall of each threaded sleeve; and one end of each bottom plate is hinged with the corresponding first connecting rod through the corresponding first rotating shaft. The positioning and clamping device for garment processing can provide an outwarddragging force for cloth, so that the flatness of the cloth can be guaranteed, and later positioning processing is facilitated.

Owner:沧州明珠服装服饰科技有限公司

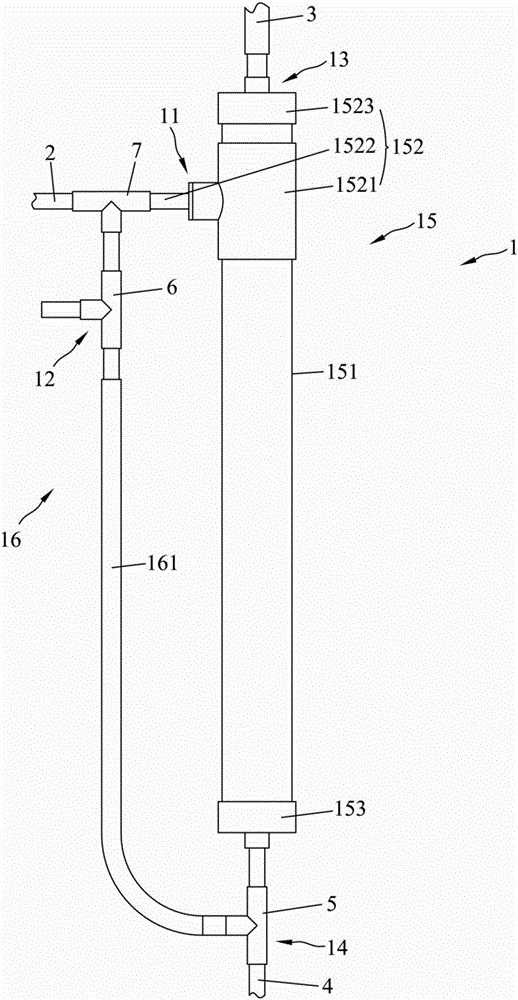

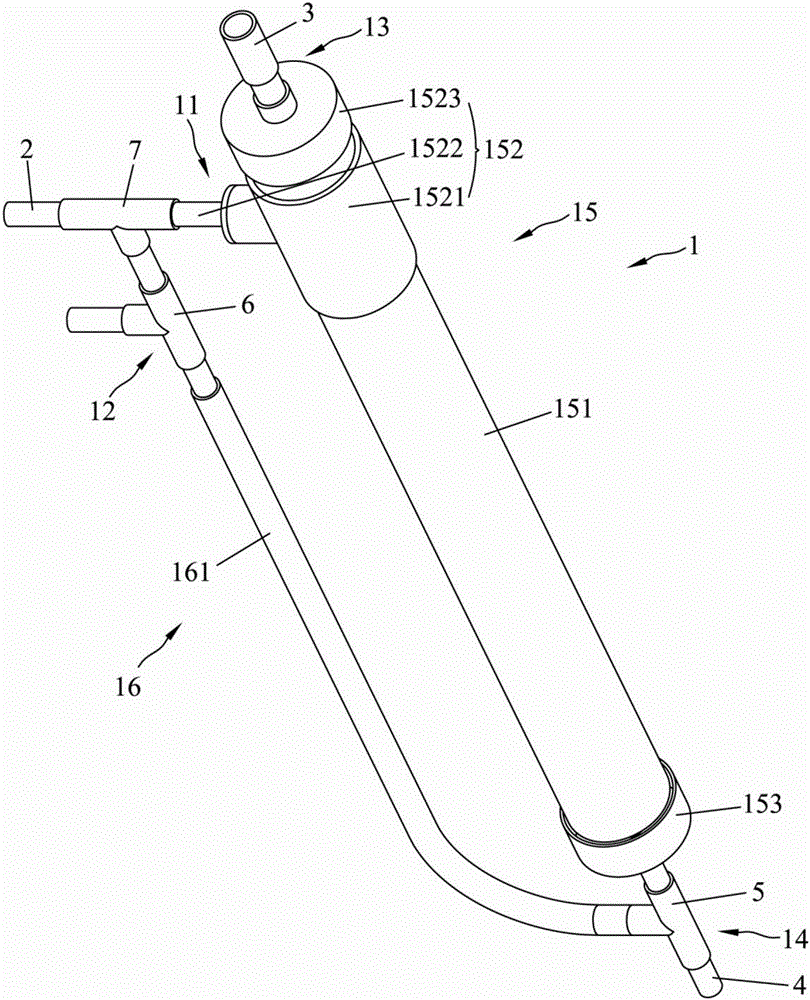

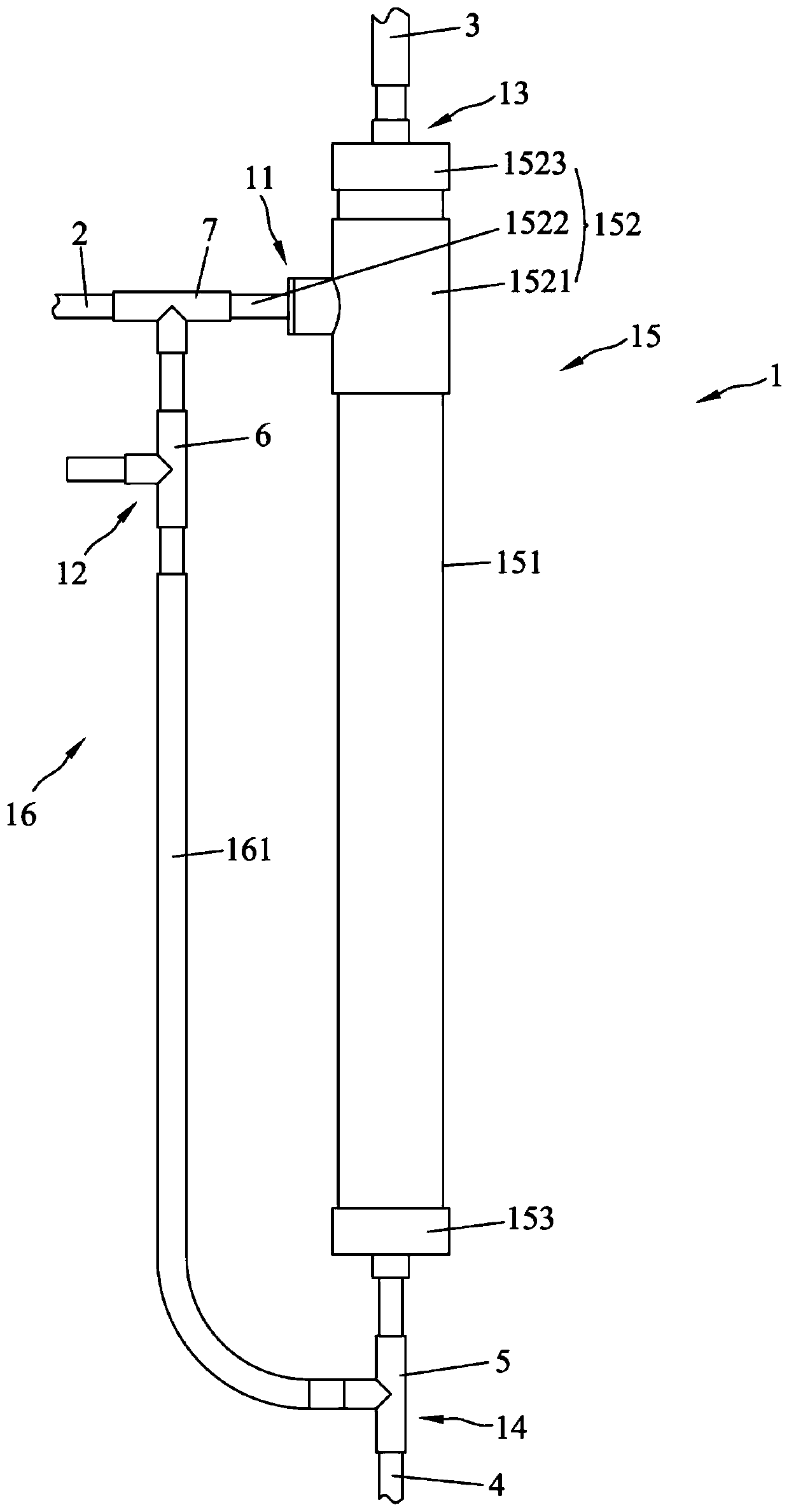

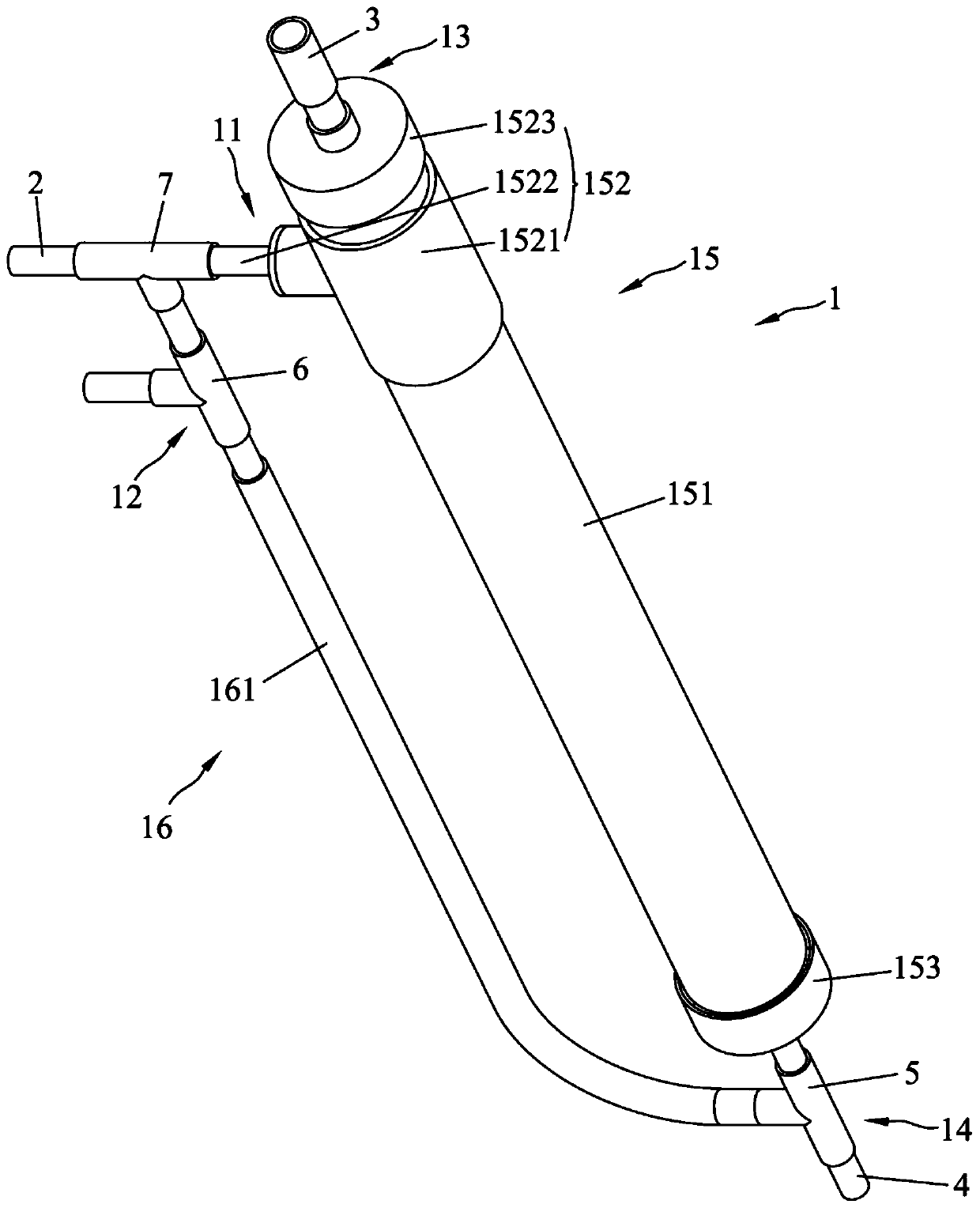

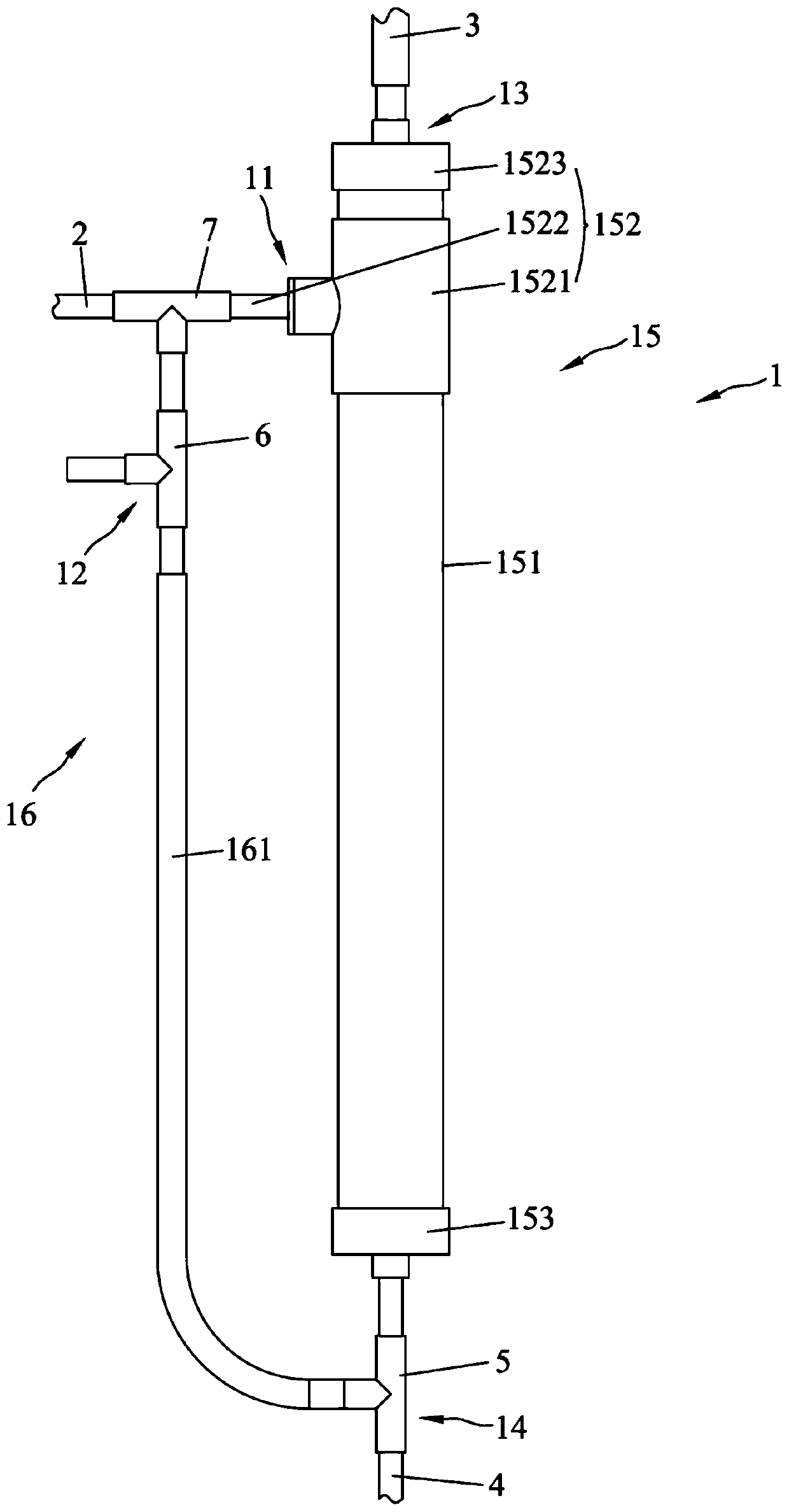

Solution recovery device for machine tool and machine tool

ActiveCN106392754AConvenient positioning and processingPositioning apparatusMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a solution recovery device for a machine tool and the machine tool. The solution recovery device comprises a container, a first switch valve and a second switch valve. A containing space for containing a solution is hollowly formed in the container. A first gas inlet, a second gas inlet, a gas outlet and a liquid outlet, all of which communicate with the containing space are formed in the container. The first gas inlet is connected with a vacuum fixture in a communicating manner. The gas outlet is connected with a vacuum generator in a communicating manner. The gas outlet and the second gas inlet are higher than the liquid outlet. The first switch valve is used for controlling connection and disconnection of the liquid outlet. The second switch valve is used for controlling connection and disconnection of the second gas inlet. According to the solution recovery device for the machine tool and the machine tool, when the solution stored in the containing space needs to be recovered, vacuumizing operation on the containing space by the vacuum generator can be stopped firstly, the first switch valve and the second switch valve are opened, then external air enters the containing space from the second gas inlet quickly, the solution flows out of the container from the liquid outlet due to the gravity for recovery and reutilization, the waste of the solution is avoided, and therefore the cost of the solution resource is lowered.

Owner:GUANGDONG EVERWIN PRECISION TECH

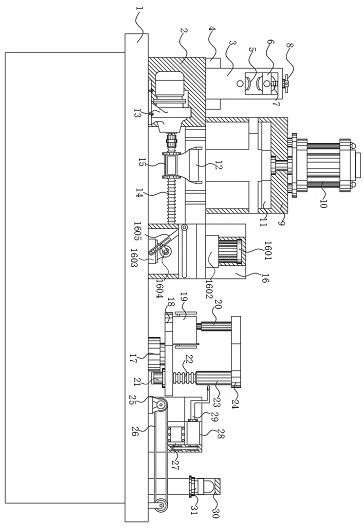

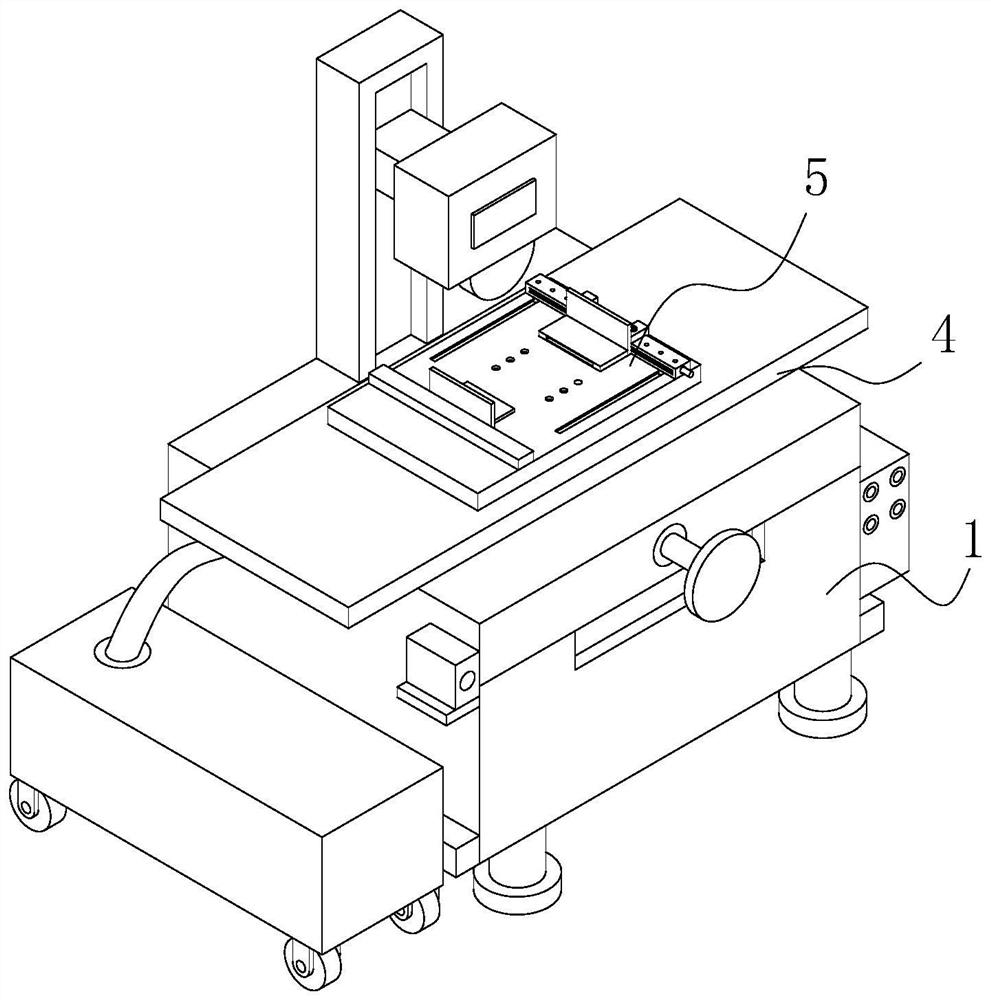

Glass punching device facilitating locating and machining

ActiveCN112976351AConvenient positioning and processingEasy to processWorking accessoriesStone-like material working toolsPunchingStructural engineering

The invention relates to the technical field of glass punching devices, and discloses a glass punching device facilitating locating and machining. The glass punching device facilitating locating and machining comprises a main plate and a punching device, wherein a support block I and a support block II are fixedly installed on the upper wall surface of the main plate, and the punching device is fixedly connected with the lower wall surface of the support block I; and a main body is arranged at the position, corresponding to the punching device, above the support block I. According to the invention, when a functional block is driven by a threaded rod to move downwards, four connecting blocks move downwards in corresponding sliding holes, and meanwhile, the four connecting blocks pull corresponding ropes to move downwards, so that four fixing rods move towards the sides close to each other along with pulling of the corresponding ropes; and when the inner concave portions of the four fixing rods and the outer wall surface of a functional ring are clamped together, four reinforcing blocks extrude downwards a glass piece on the main body, so that a secondary fixing effect on the glass piece is achieved, and the problems that the glass piece shakes in a punching process, and then is punched and broken, resources are wasted, and the production efficiency is affected are solved.

Owner:福建灿丰玻璃有限公司

Milling tool with multifunctional blade compensation

InactiveCN108747481AEasy maintenanceConvenient positioning and processingFeeding apparatusOther manufacturing equipments/toolsEngineeringMachine tool

The invention discloses a milling tool with multifunctional blade compensation. The milling tool comprises a machine tool, and a power machine body arranged on the top end face of the machine tool; the left end face of the power machine body is internally provided with a circular groove with an opening leftward; the interior of the circular groove is connected to a firmware sleeve in a running fitmanner, and the firmware sleeve extends right and left; the left end of the firmware sleeve extends out of the circular groove; the firmware sleeve is internally provided with a firmware hole with anopening leftward, and the right end face of the firmware sleeve is in power connection with a first motor of which the outside surface is embedded in and fixedly connected to the inner wall of the right end of the circular groove; the circumferential inner wall of the firmware hole is provided with bilaterally symmetrical grooves in a communicating manner, and a ring groove is arranged between the two grooves in the communicating manner; and the top of the ring groove is provided with a first cavity in the communicating manner. The milling tool has the advantages of the simple structure, easyoperation, convenient fixation and chambering, and stable machining.

Owner:邓聪迪

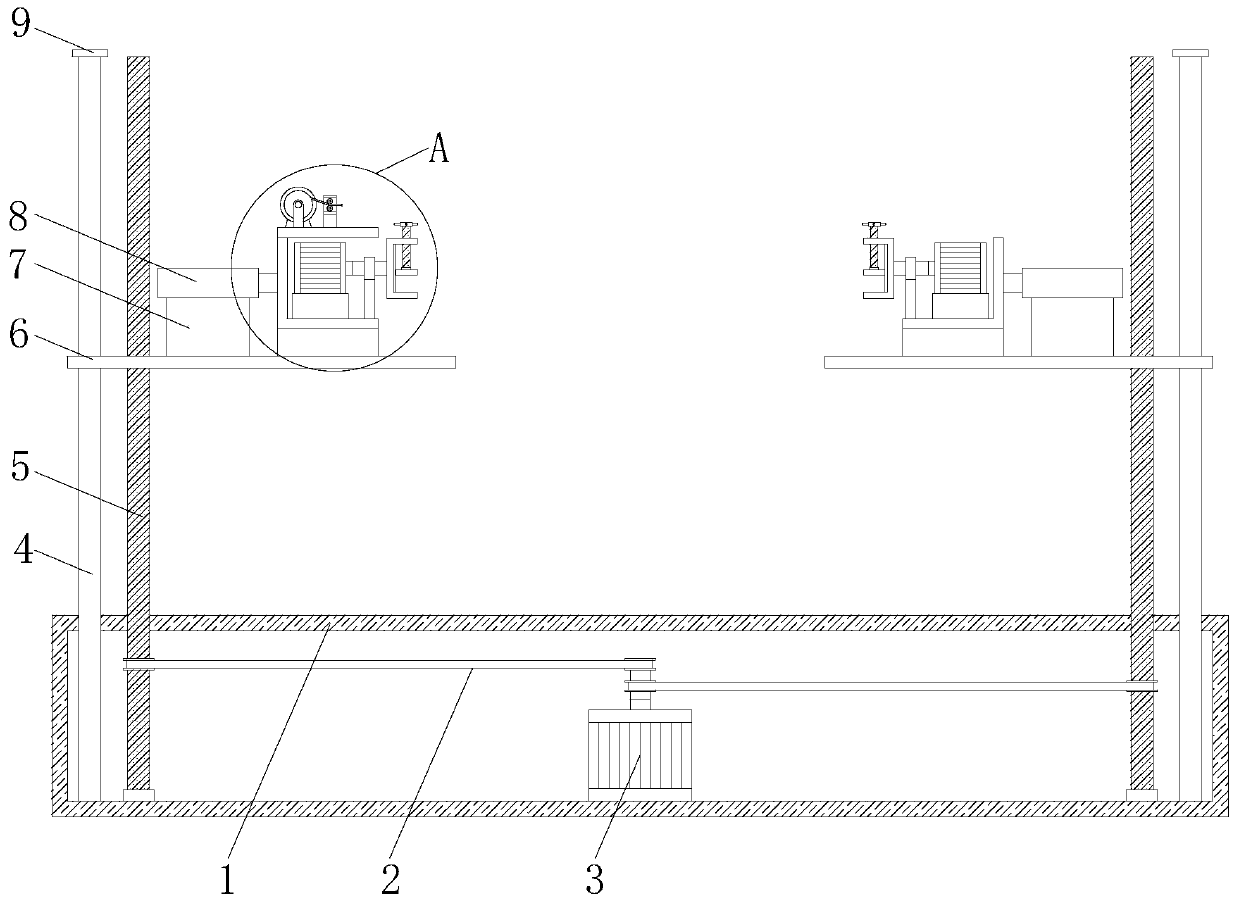

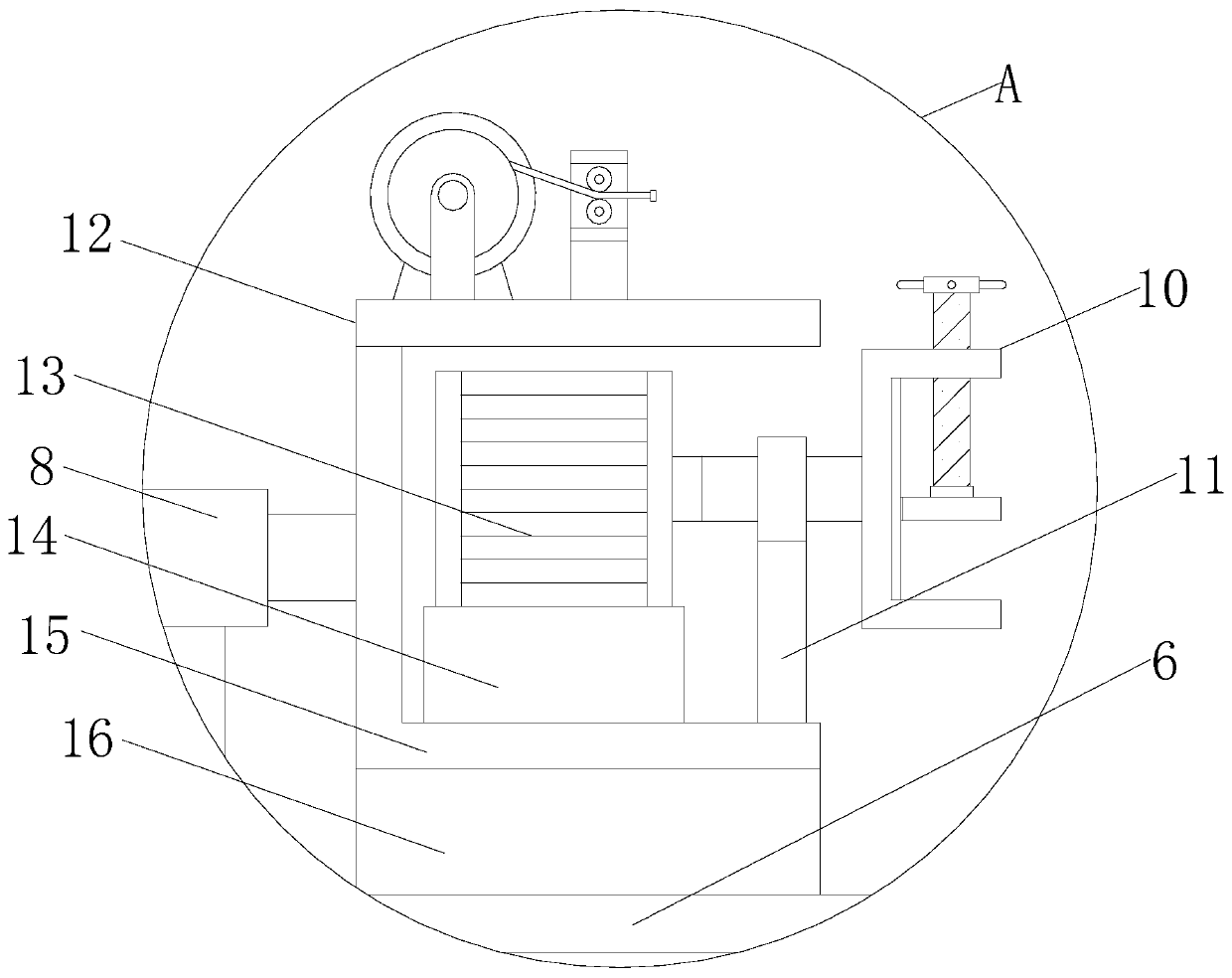

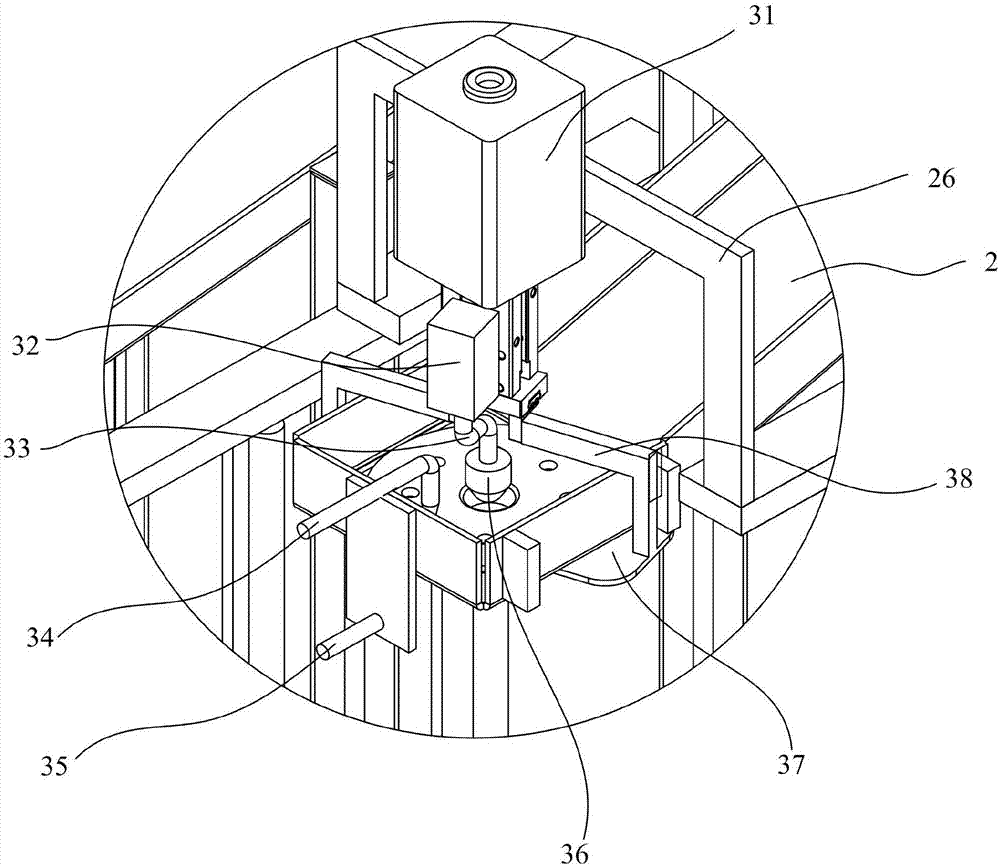

Pu alloy furnace roller production device and production process thereof

ActiveCN112975686AConvenient positioning and processingEasy to lift and processGrinding drivesGrinding machinesHydraulic cylinderEngineering

The invention discloses a pu alloy furnace roller production device and a production process thereof, particularly relates to the technical field of furnace roller production, and adopts the technical scheme that the pu alloy furnace roller production device comprises a machining shell, a transmission device and a combined machining device. A control bed is fixedly installed on the inner wall of the machining shell; the transmission device is fixedly installed at the lower end of the control bed; the transmission device comprises a first hydraulic cylinder; the first hydraulic cylinder is fixedly installed at the side end of the control bed; the left end of the first hydraulic cylinder is connected with a first supporting arm through a pin; the lower end of the first supporting arm is connected with a second supporting arm through a pin; a transmission wheel is fixedly installed at the right end of the second supporting arm; a lock catch is fixedly installed on the inner wall of the transmission wheel; a rotating rod is fixedly installed on the inner wall of the lock catch; and a fixing seat is installed on the outer wall of the second supporting arm through a screw. The pu alloy furnace roller production device provided by the invention has the beneficial effects that grinding and polishing of an alloy furnace roller are combined, and rotary transmission machining is conducted on the alloy furnace roller, so that original operation steps are simplified, and the production cost is reduced.

Owner:托普工业(江苏)有限公司

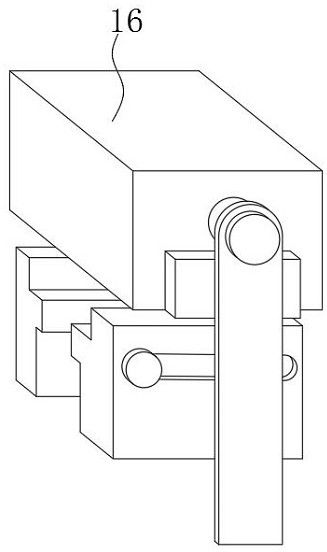

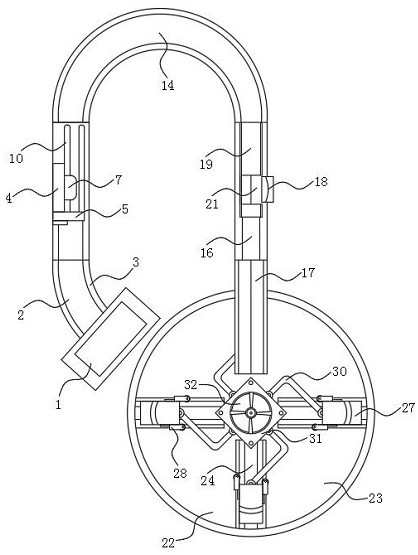

Knife-shaped hairpin chamfering facility with screening and feeding functions

PendingCN112607383AWith screening functionIncrease productivityConveyor partsManufacturing engineeringIndustrial engineering

The invention discloses a knife-shaped hairpin chamfering facility with screening and feeding functions, and relates to the technical field of ornament processing. The facility specifically comprises a feeding end, a reverse material screening mechanism, a directional feeding mechanism, a synchronous chamfering mechanism and a cam divider, wherein a lifting rail is arranged on one side of the feeding end. According to the knife-shaped hairpin chamfering facility with the screening and feeding functions, due to the fact that the reverse material screening mechanism is arranged, the known track distance of the lifting track only allows blanks in the vertical direction to pass through, and the reverse material screening mechanism only needs to identify and screen the direction of the large diameter or the small diameter when the blanks pass through the mechanism. In a traditional manufacturing technology, when visual inspection equipment and other equipment or the manual screening mode is used, the production cost of an enterprise can be undoubtedly and greatly increased, and the traditional manufacturing technology is not suitable for large-batch low-cost workpiece production, and therefore the knife-shaped hairpin reverse material recognition screening which is achieved through a simple mechanical structure and a simple physical principle has the irreplaceable advantages of low cost, accuracy, efficiency, easy and convenient maintenance and the like.

Owner:重庆德森诺科技有限公司

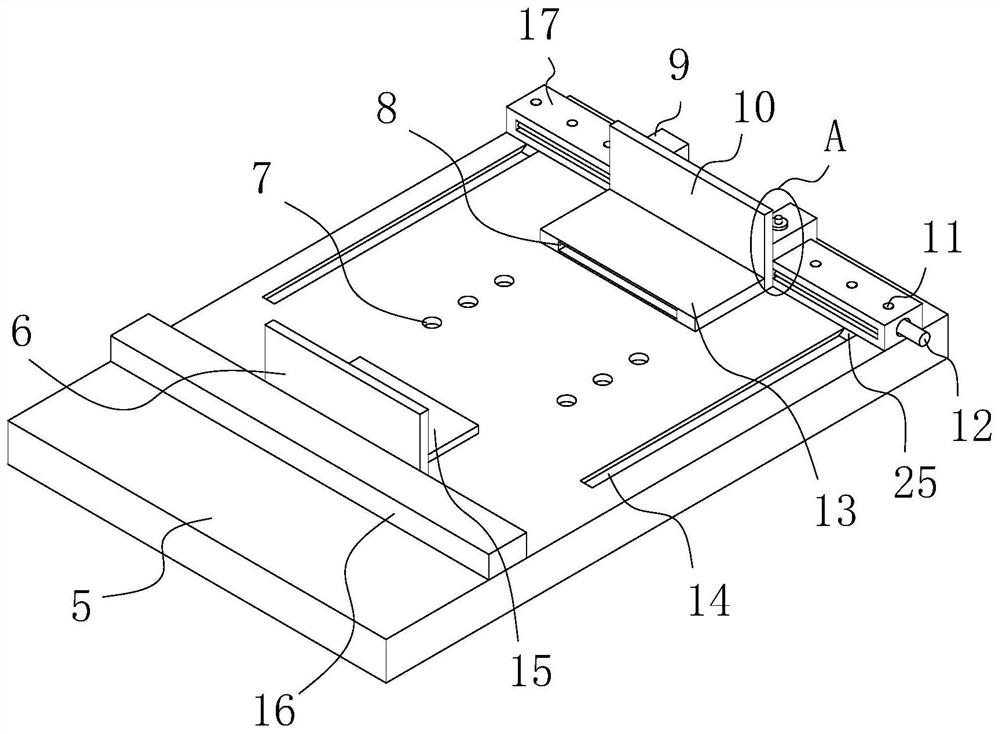

Positioning device of surface grinding machine for photo-cured ceramic slurry precision forming of and using method thereof

PendingCN112536658AAchieve positioningPrevent movementGrinding carriagesGrinding drivesEngineeringSlurry

The invention discloses a positioning device of a surface grinding machine for photo-cured ceramic slurry precision forming and a using method thereof. The positioning device of the surface grinding machine for photo-cured ceramic slurry precision forming comprises a grinding machine body, wherein a machining plate is fixedly connected to the top of the grinding machine body, a top plate is fixedly connected to the top of the machining plate, and a fixed plate is fixedly connected to the left side of the top of the top plate. According to the positioning device of the surface grinding machinefor photo-cured ceramic slurry precision forming, through cooperative use of the grinding machine body, a positioning mechanism, buckling mechanisms, the machining plate, the top plate, a first limiting block, positioning grooves, an inserting groove, a connecting block, a second limiting block, clamping grooves, a push rod, a supporting plate, dovetail grooves, an inserting plate, the fixed plate, a movable plate, sliding rods, sliding sleeves, a handle, transmission holes, a stabilizing plate, a moving hole, stabilizing rods and dovetail blocks, the problems that according to an existing positioning device of the surface grinding machine for photo-cured ceramic slurry precision forming, positioning of ceramic is inconvenient, the using method is complex, movable grinding cannot be conducted on the ceramic after positioning, grinding is incomplete, and using is inconvenient for a user are solved.

Owner:江苏薄荷新材料科技有限公司

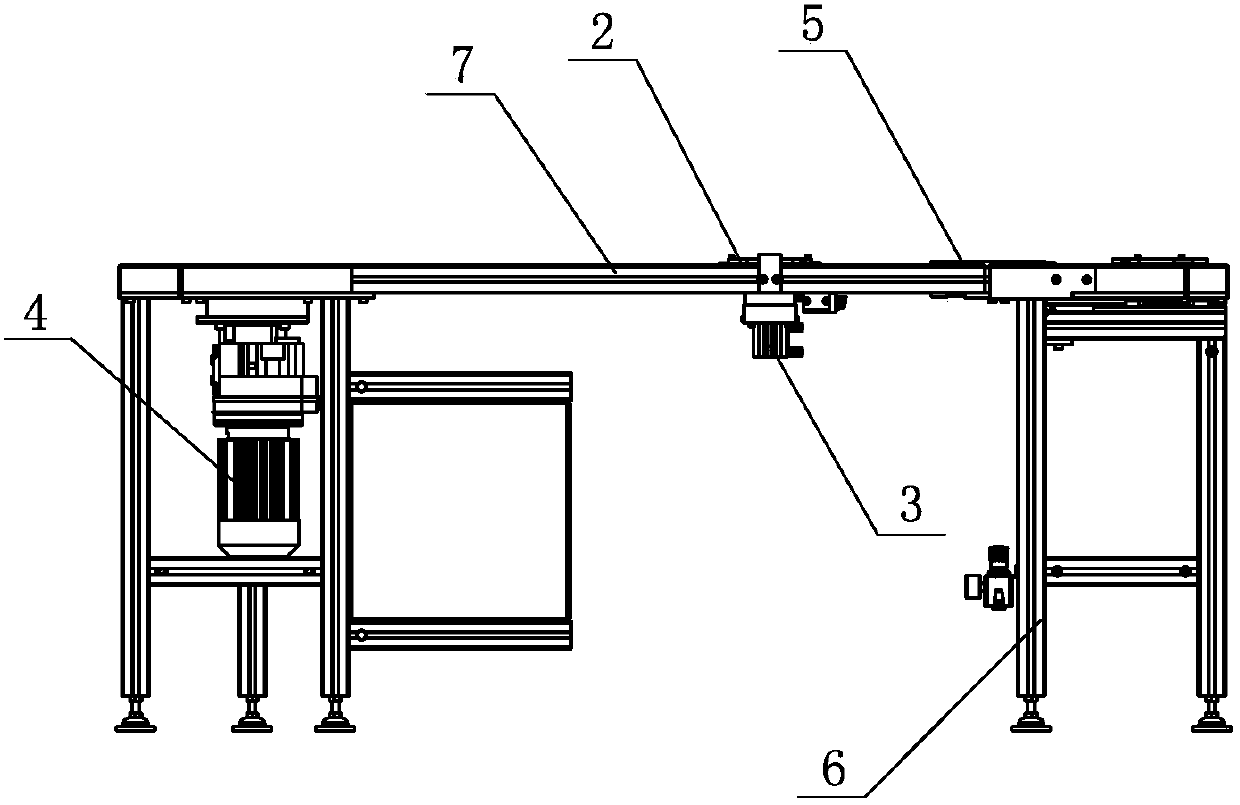

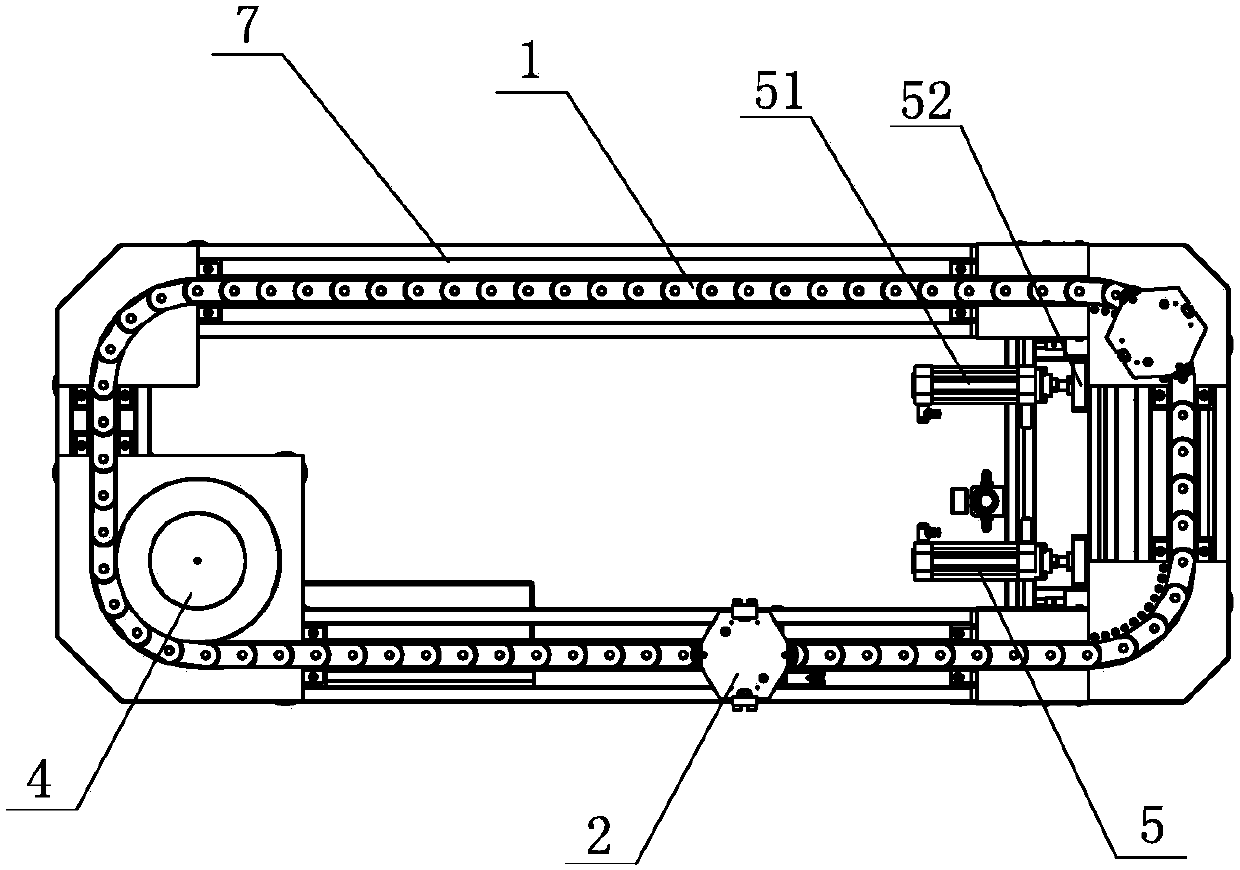

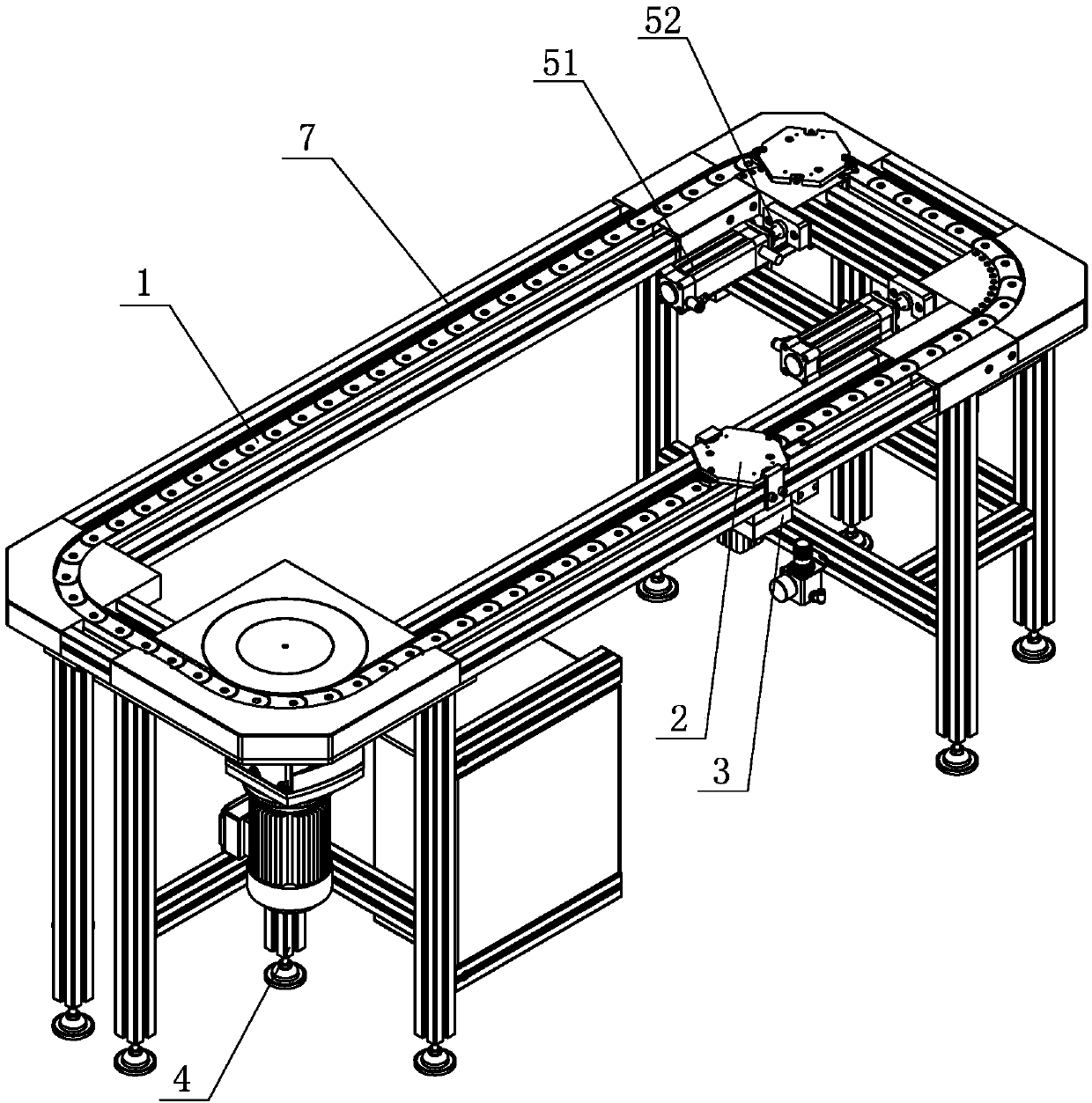

a transmission system

ActiveCN105775603BIncreased load-bearing capacityEasy to cornerConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a transmission system. The transmission system is characterized by comprising a rack as well as a chain mechanism, a drive mechanism, a jacking mechanism, a tensioning mechanism and a tray device which are arranged on the rack, wherein the chain mechanism comprises a chain rail arranged on the rack and a conveying chain arranged in the chain rail; the jacking mechanism is mounted on the bottom of the chain rail; the tray device is arranged in the chain rail; the bottom of the tray device is adhered to the top surface of the conveying chain; the drive mechanism is arranged at one side of the rack; the tensioning mechanism is arranged at the other side of the rack; the conveying chain is driven by the drive mechanism; and the tension degree is regulated through the tensioning mechanism. The service life of the transmission system is effectively prolonged, the use cost is reduced, and the turning flexibility of the transmission system is improved.

Owner:SUZHOU ITS IND TRANSFER SYST CO LTD

A positioning and clamping device for garment processing

Owner:沧州明珠服装服饰科技有限公司

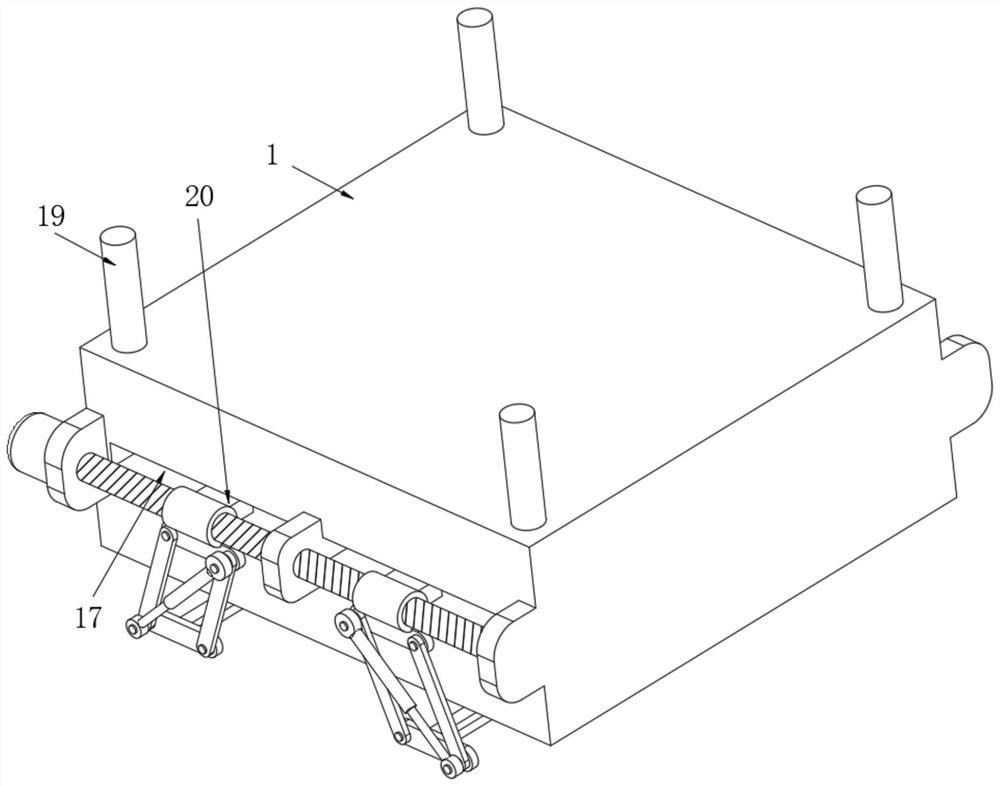

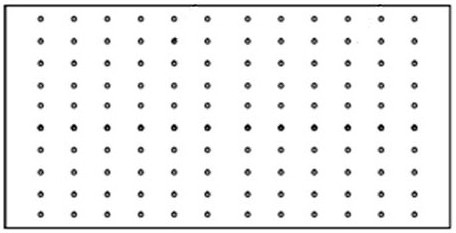

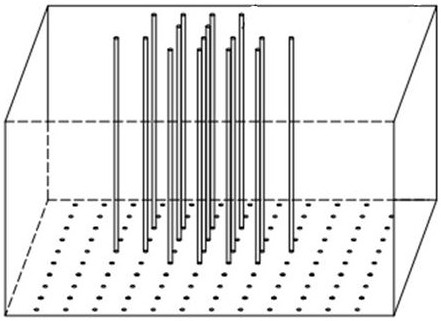

Light-transmitting energy-storage concrete block and preparation method thereof

InactiveCN114656226ALow costImprove work performanceCeramic shaping apparatusHeat-exchange elementsAluminateFiber

The invention belongs to the technical field of constructional engineering, and particularly relates to a light-transmitting energy-storage concrete building block and a preparation method thereof.The preparation method includes the steps that 1, light-transmitting fibers penetrate through through holes of a building block forming mold, and the two ends of the light-transmitting fibers are fixed; 2, preparing a phase-change energy-storage microcapsule, namely performing vacuum adsorption on a core material paraffin by taking the fly ash floating beads as an adsorption carrier to obtain the phase-change energy-storage microcapsule; 3, stirring 60 parts of Portland cement, 3 parts of sulphoaluminate cement, 12.5 parts of fly ash, 12.5 parts of slag powder, 17.5 parts of quartz powder, 3.5 parts of anhydrous sodium sulfate, 2 parts of a water reducing agent, 40 parts of phase change energy storage microcapsules and 40 parts of water in a cement mortar stirrer to obtain phase change energy storage cement mortar, and 4, pouring the phase change energy storage cement mortar into a building block forming mold, after curing and hardening, removing the mold, taking out and grinding to obtain the phase change energy storage building block. The light-transmitting energy-storage concrete block is obtained. And the light-transmitting conductor is combined with the phase change energy storage mortar, so that the light transmission is ensured, and meanwhile, the good heat storage performance of the phase change energy storage mortar is utilized to improve the indoor heat comfort.

Owner:NORTHEAST GASOLINEEUM UNIV

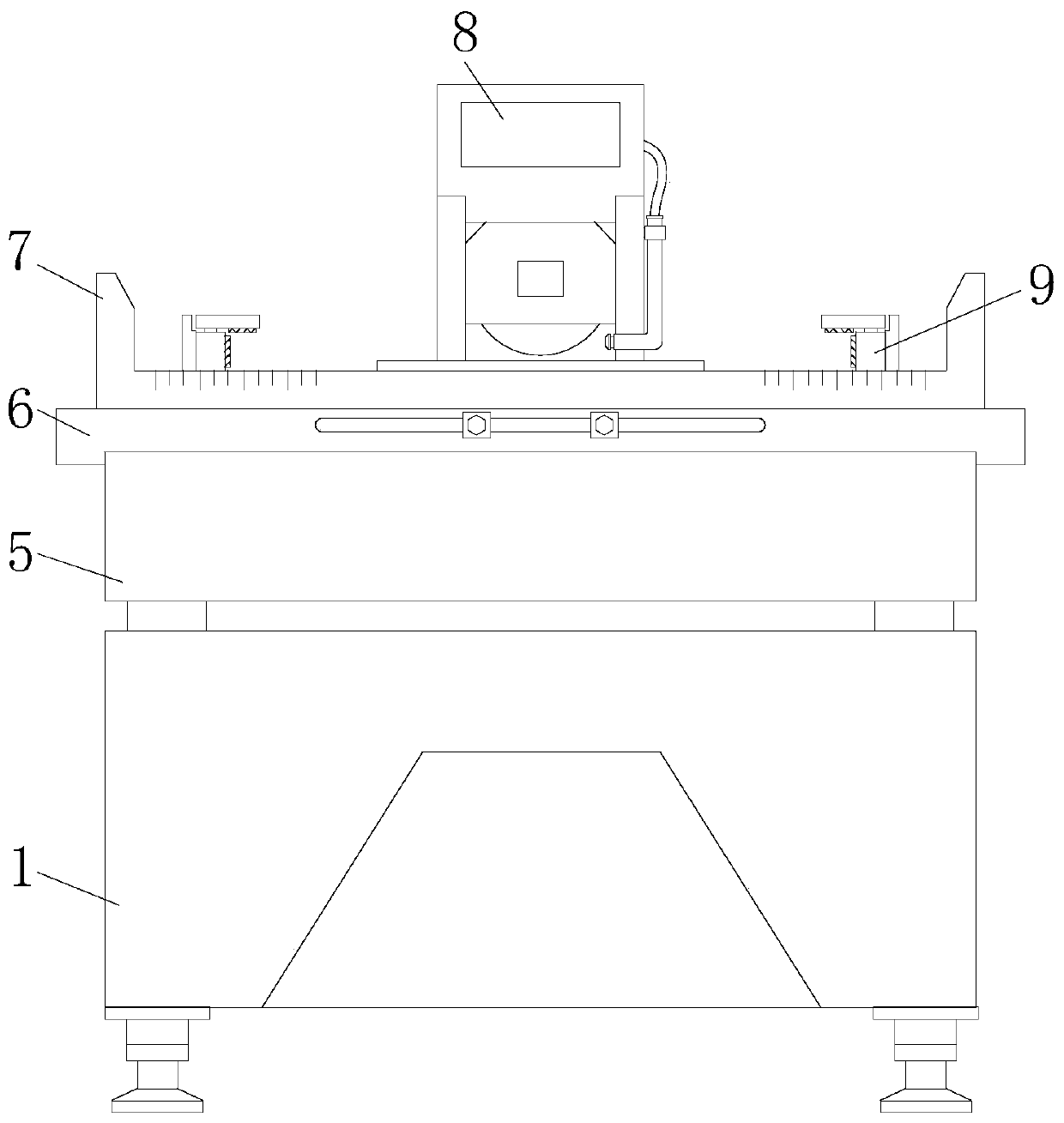

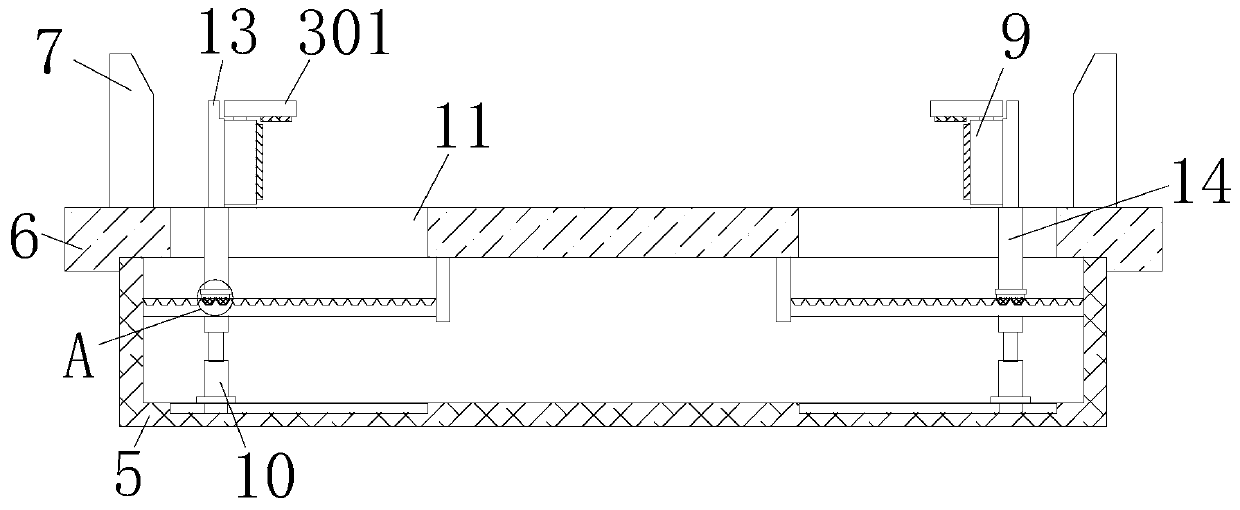

Workpiece stabilizing and fixing mechanism for machining grinding machine

ActiveCN110000701AEasy to useConvenient positioning and processingGrinding work supportsSlide plateMachining

The invention discloses a workpiece stabilizing and fixing mechanism for a machining grinding machine. The workpiece stabilizing and fixing mechanism comprises a bottom box. The top of the bottom boxis fixedly connected with a fixed shell. The top of the fixed shell is fixedly connected with a top plate. The top of the top plate is fixedly connected with a grinding device. The two sides of the top of the top plate are both movably connected with movable plates. The opposite sides of the two movable plates are both fixedly connected with positioning shells. The top of each positioning shell ismovably connected with a positioning mechanism. The workpiece stabilizing and fixing mechanism for the machining grinding machine is provided with the bottom box, limiting mechanisms, the positioningmechanisms, fixing mechanisms, the fixed shell, the top plate, protection plates, the grinding device, the positioning shells, telescopic rods, first ports, springs, the movable plates, sliding plates, connecting plates, vertical plates, fixing grooves, second ports and pull rings to be used cooperatively. The problems that a user cannot conduct positioning on different sizes of workpieces conveniently through an existing machining grinding tool workpiece stabilizing and fixing mechanism and the positioning effect of the workpieces is poor are solved.

Owner:河南工学院

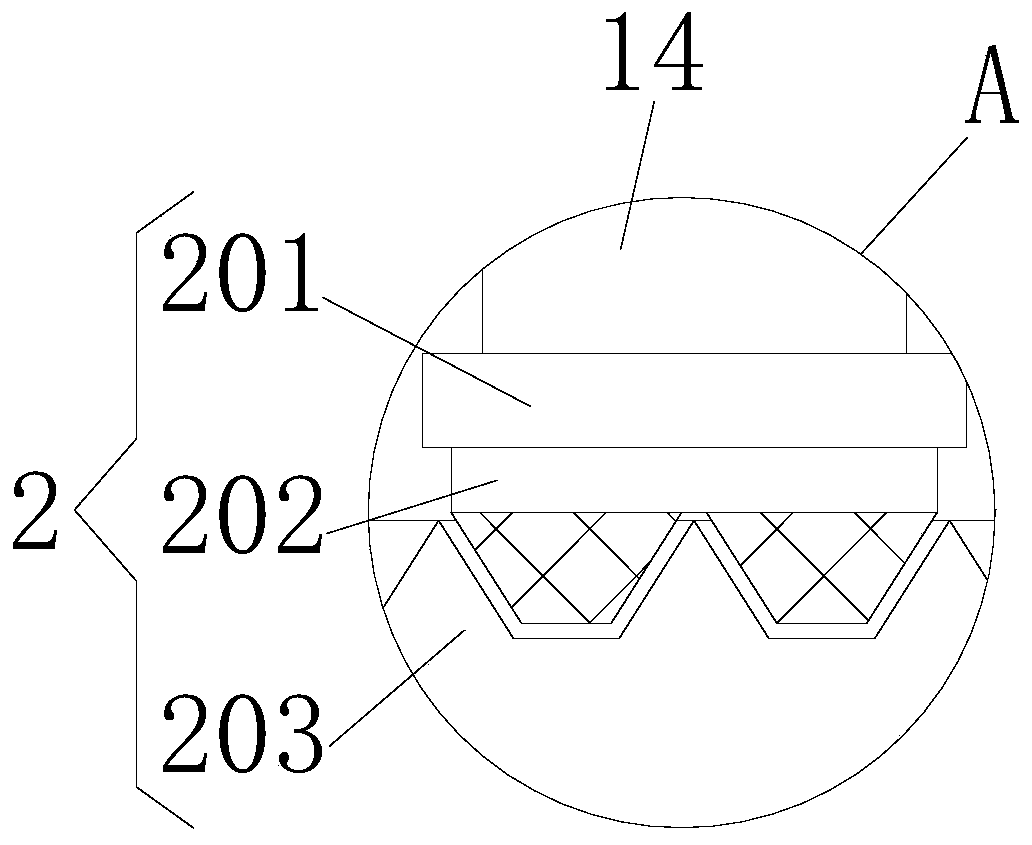

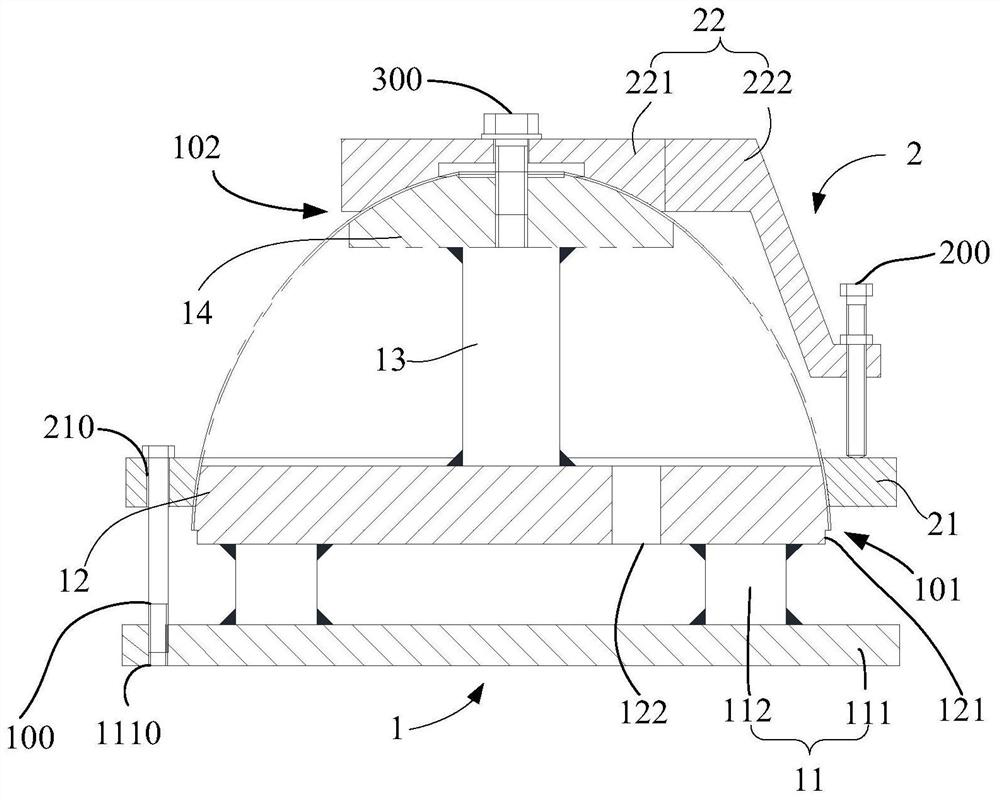

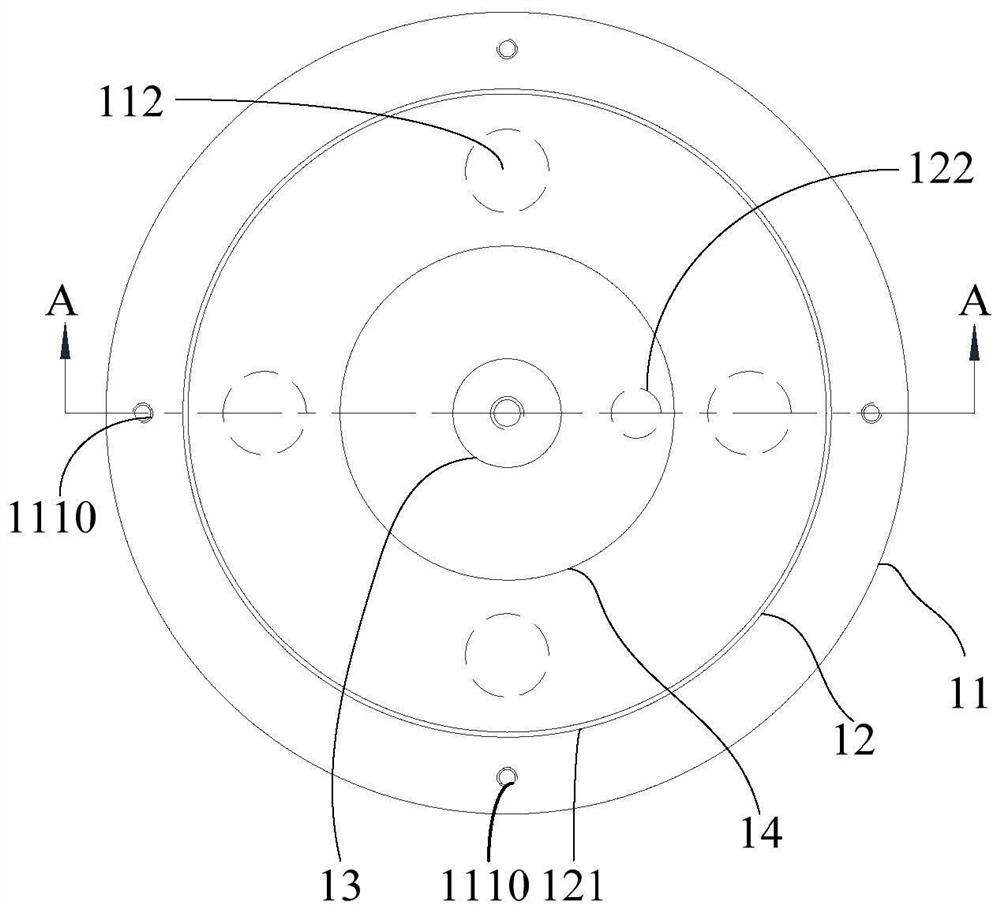

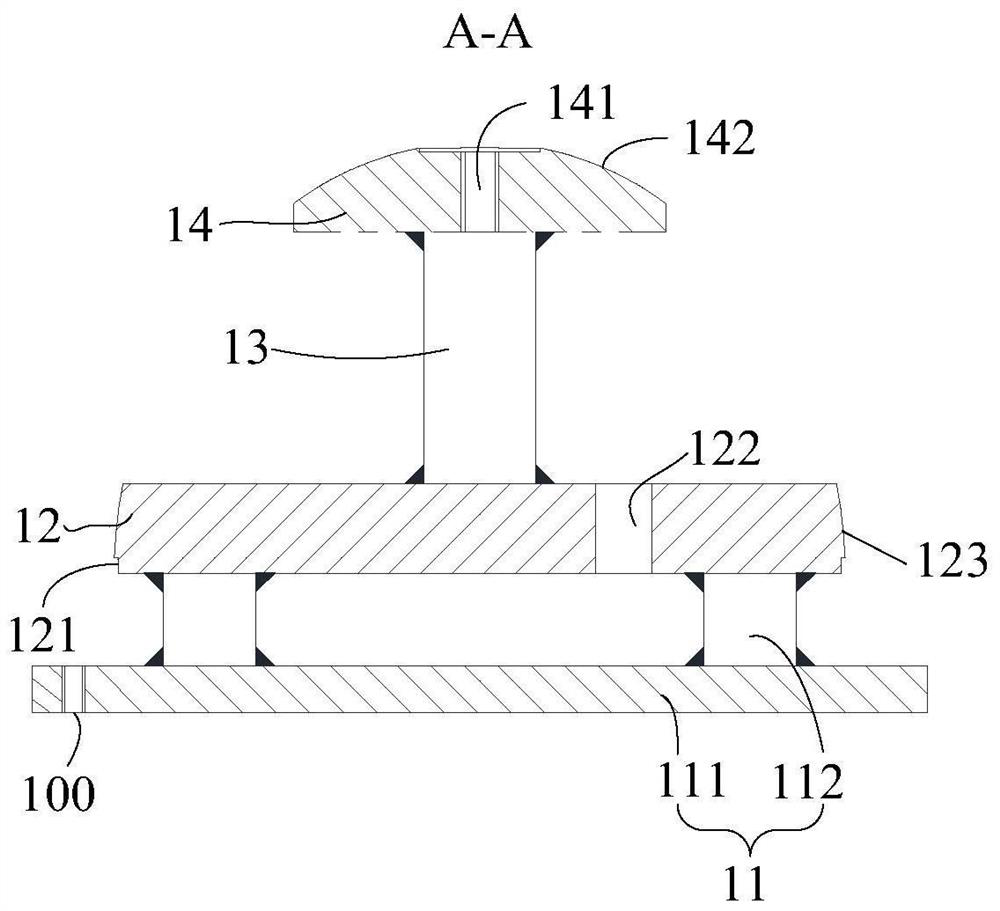

Fixtures for processing hemispherical parts

ActiveCN111015270BGuaranteed deformationPrecise positioningPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a fixture for processing hemispherical parts. The fixture for processing hemispherical parts includes a positioning assembly and a pressing assembly; the positioning assembly includes a base, a first support plate, a connecting shaft, a second support plate, and a first support The plate is fixed on the base, one end of the connecting shaft is vertically fixed at the center of the first support plate, and the other end of the connecting shaft is vertically fixed at the center of the second support plate; the compression assembly includes a compression ring plate and a compression bracket, The compression ring plate is detachably installed on the base, and the compression ring plate is coaxially sleeved on the first support plate, and a hemisphere is arranged between the inner side wall of the compression ring plate and the outer side wall of the first support plate. In the first clamping space of the part, the compression bracket is detachably installed on the side of the second support plate facing away from the connecting shaft, and the second clamp for clamping the hemispherical parts is arranged between the compression bracket and the second support plate load space. In the present invention, through the cooperation of the positioning component and the pressing component, the hemispherical parts can be precisely positioned.

Owner:WUHAN MARINE MACHINERY PLANT

Car pipe piece clamping apparatus

InactiveCN107081623AQuick positioning clampingPrecise positioningPositioning apparatusMetal-working holdersMachiningBolt connection

The invention discloses a car pipe piece clamping apparatus. The car pipe piece clamping apparatus comprises a flange plate and a positioning plate installed at the flange plate. A supporting board is installed on the positioning plate. The supporting board comprises a trapezoid connecting board and a rectangular board perpendicularly connected with the trapezoid connecting board. The trapezoid connecting board is pasted on the positioning plate and connected with the positioning plate through a bolt. The rectangular board is connected with an L-shaped pipe piece pipe opening positioning plate through a connecting bolt. The L-shaped pipe piece pipe opening positioning plate is used for positioning and fixing the pipe opening end of a pipe piece to be machined. The lower portion of the rectangular board is provided with a positioning pin nail hole used for installing a pin nail positioning the bottom of the pipe piece. The middle of the rectangular board is connected with a rotatable pressing board used for tightly pressing a bent pipe through a screw rod. one end of the pressing board is provided with a bent hook. A locking screw rod matched with the bending hook and used for being hooked by the bending hook to fix the pressing board is installed on the rectangular board. According to the car pipe piece clamping apparatus, rapid positioning clamping for the bending pipe is achieved, the positioning effect is good, positioning is accurate, and positioning machining of bending pipe workpieces is convenient.

Owner:天津市中马骏腾精密机械制造有限公司

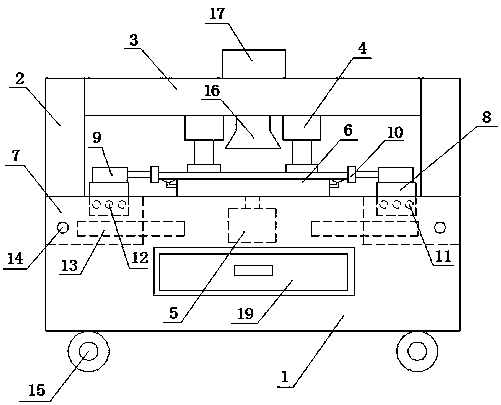

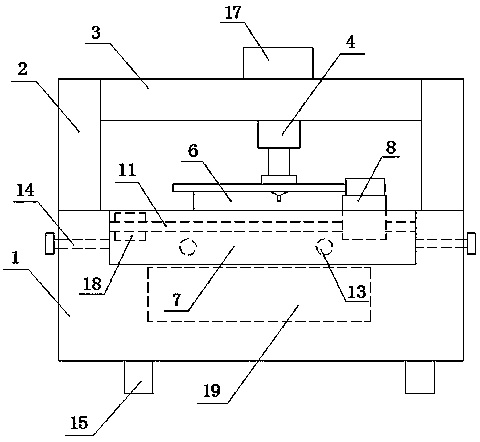

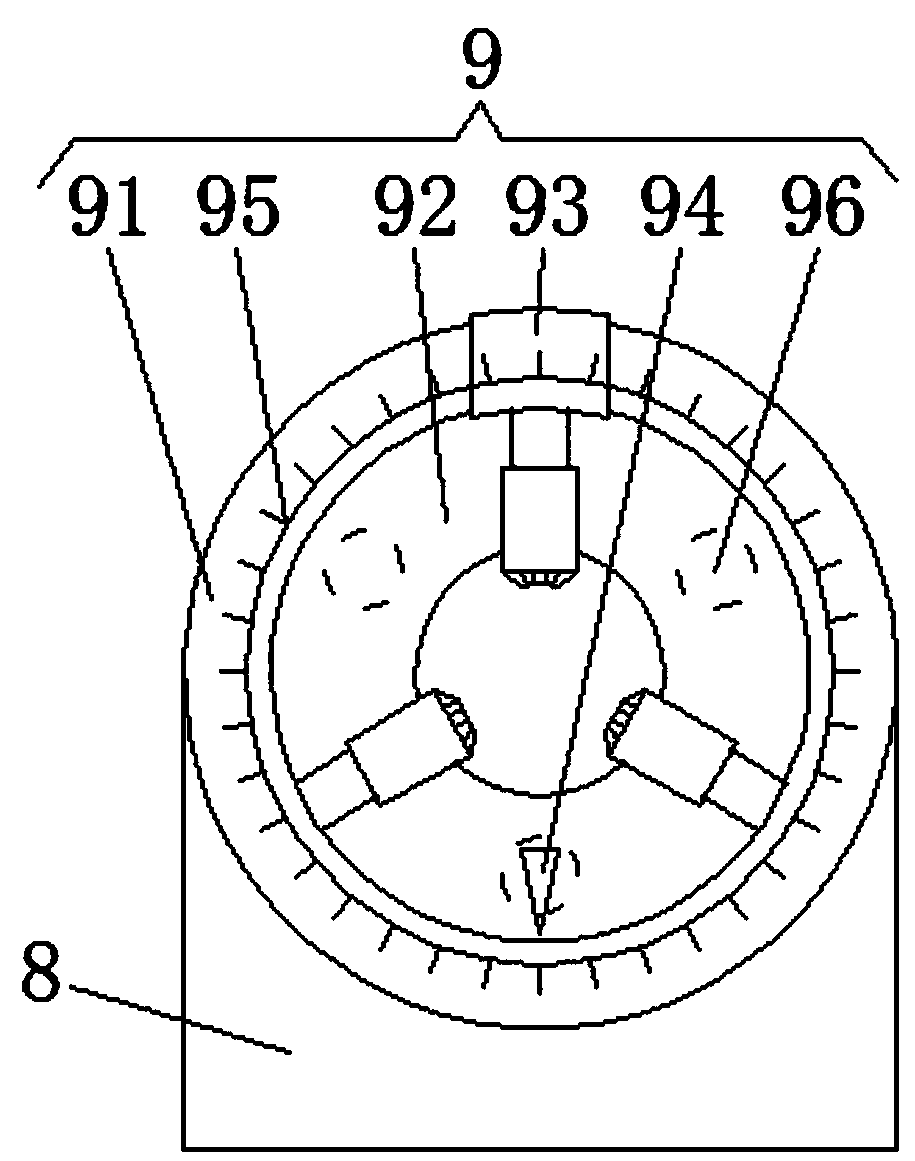

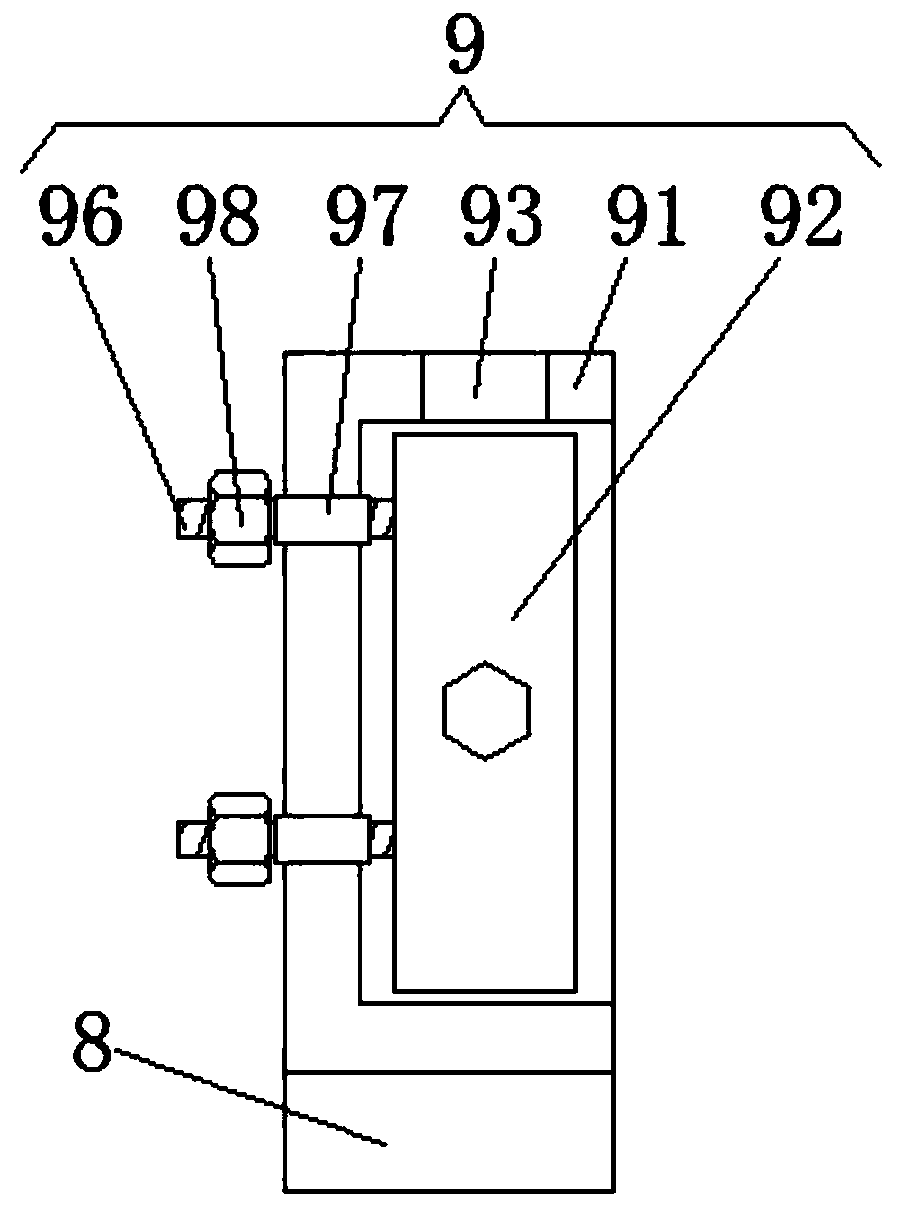

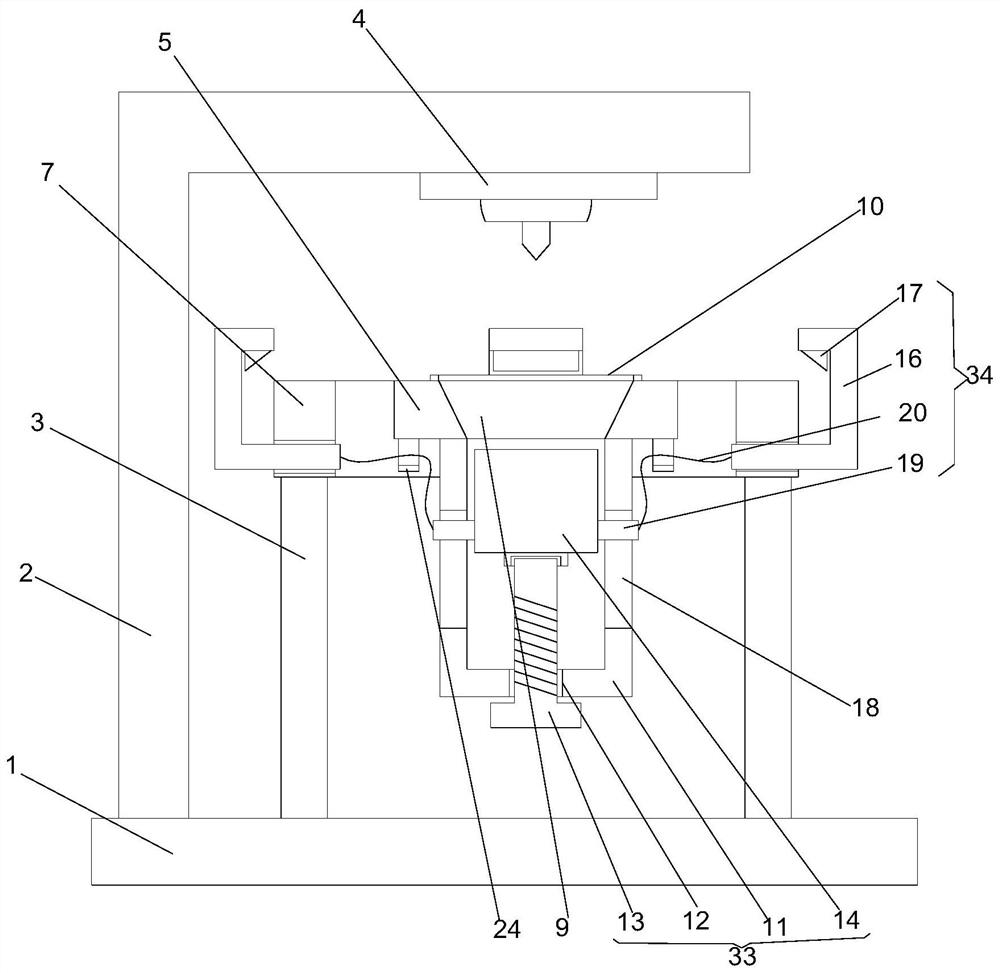

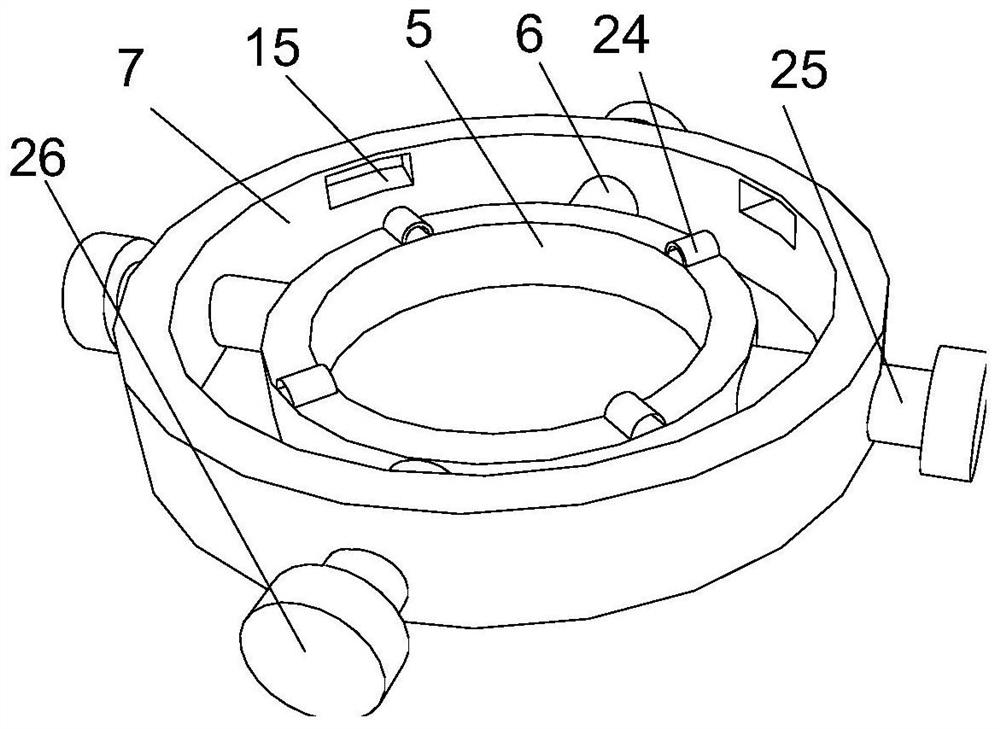

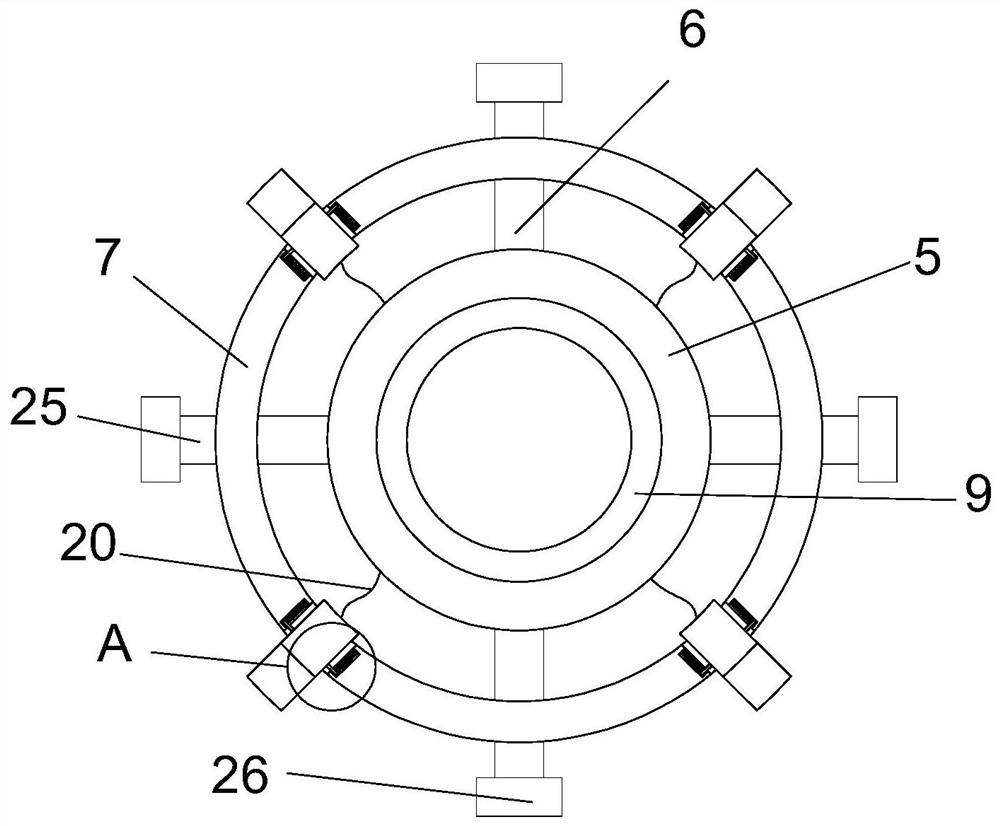

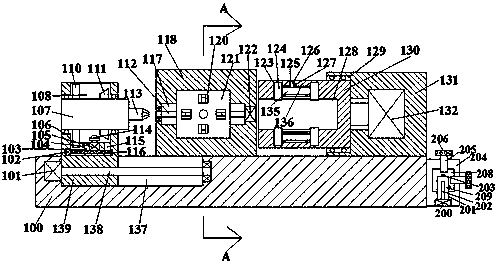

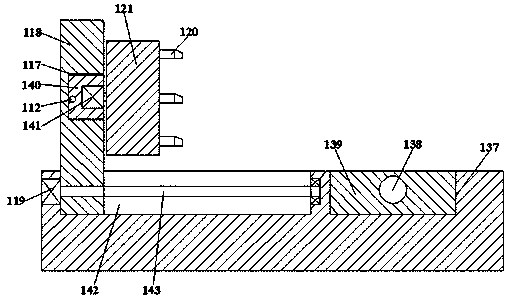

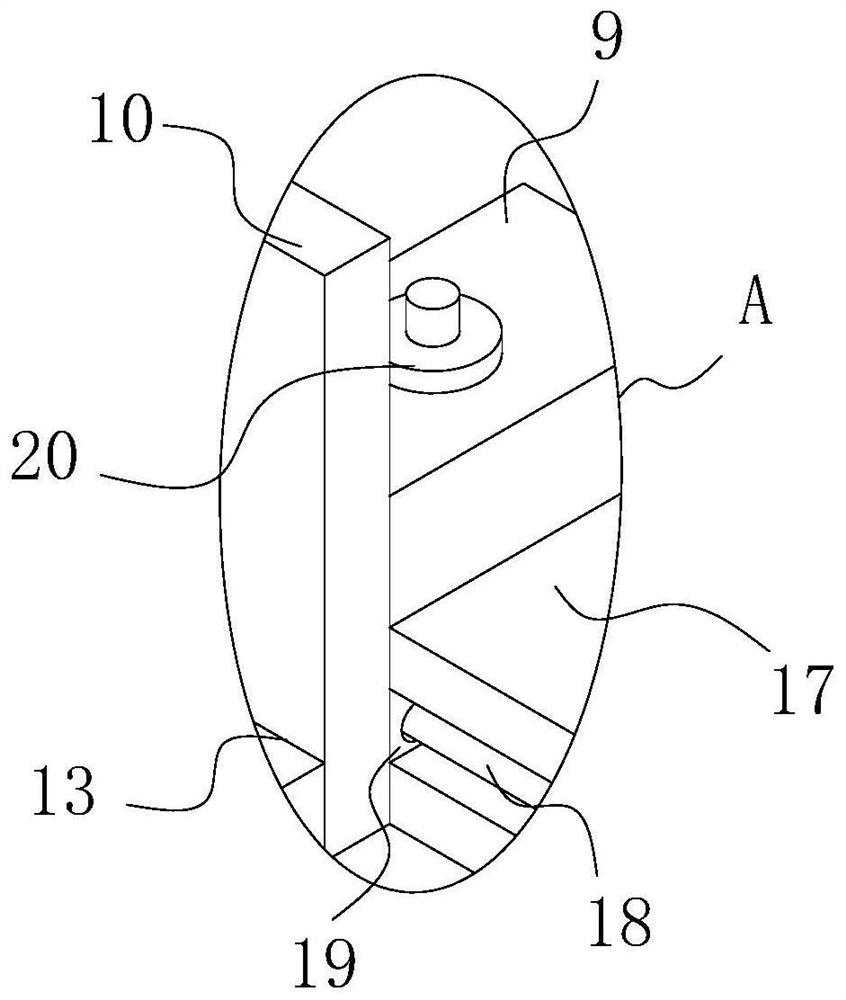

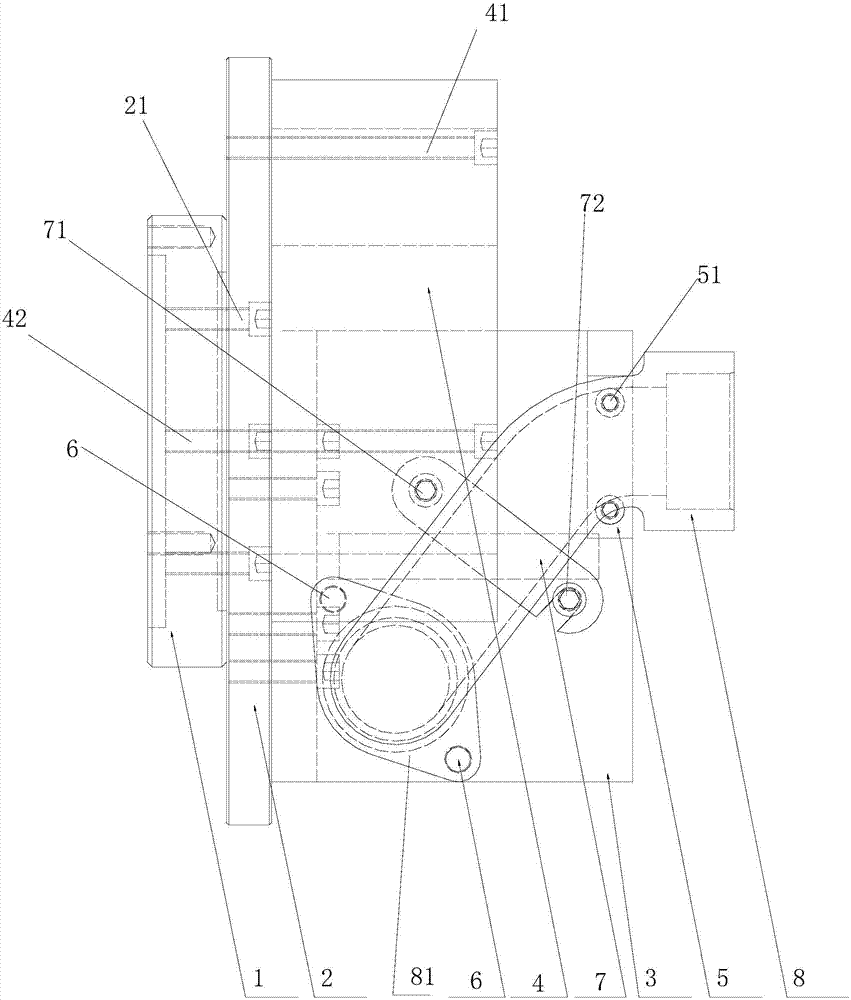

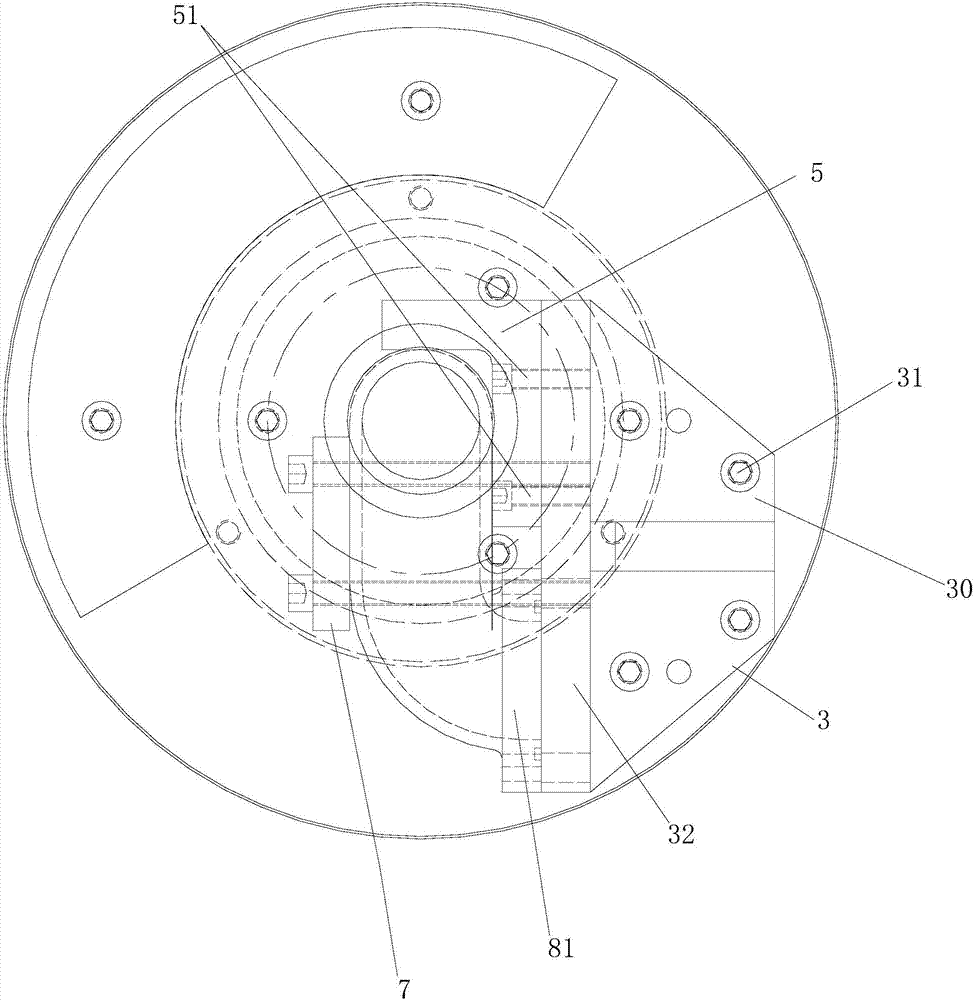

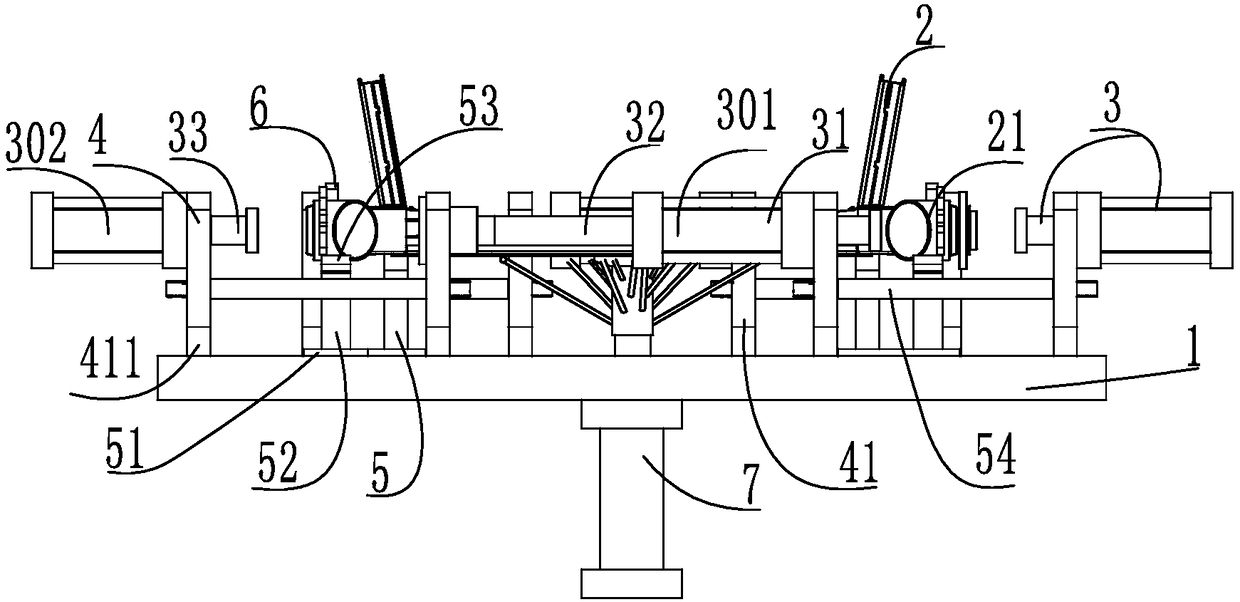

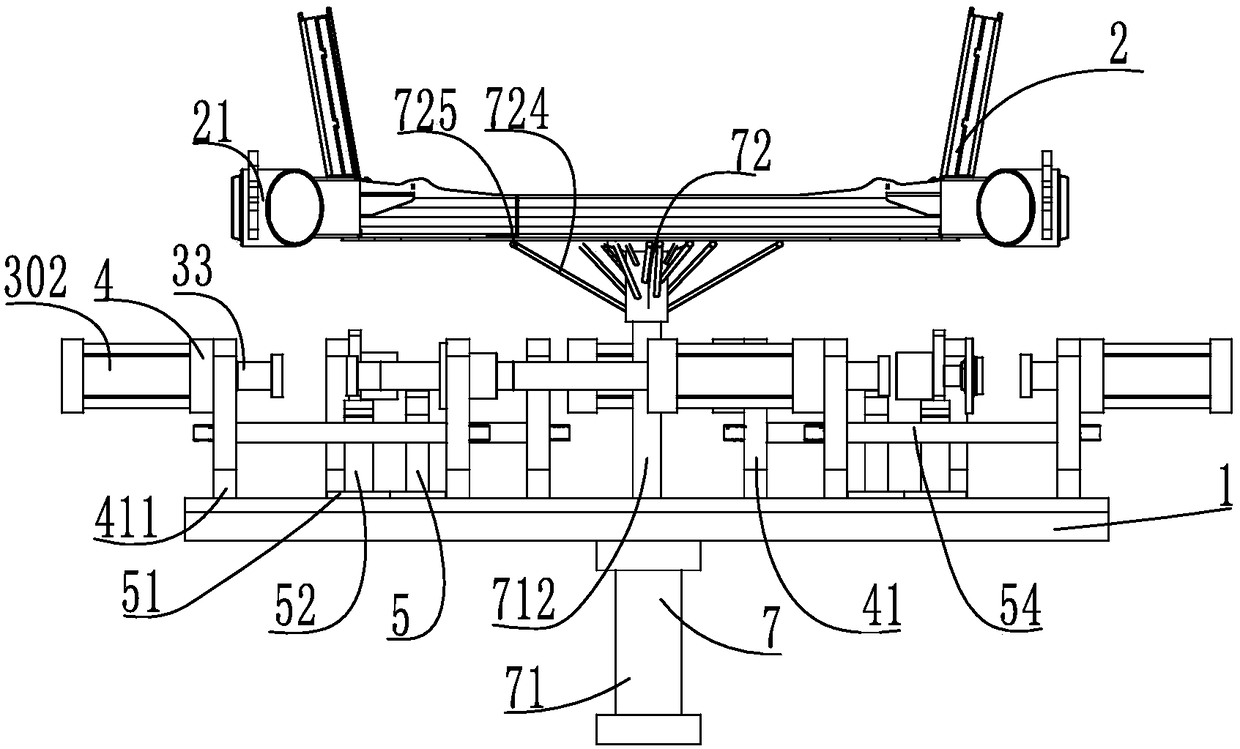

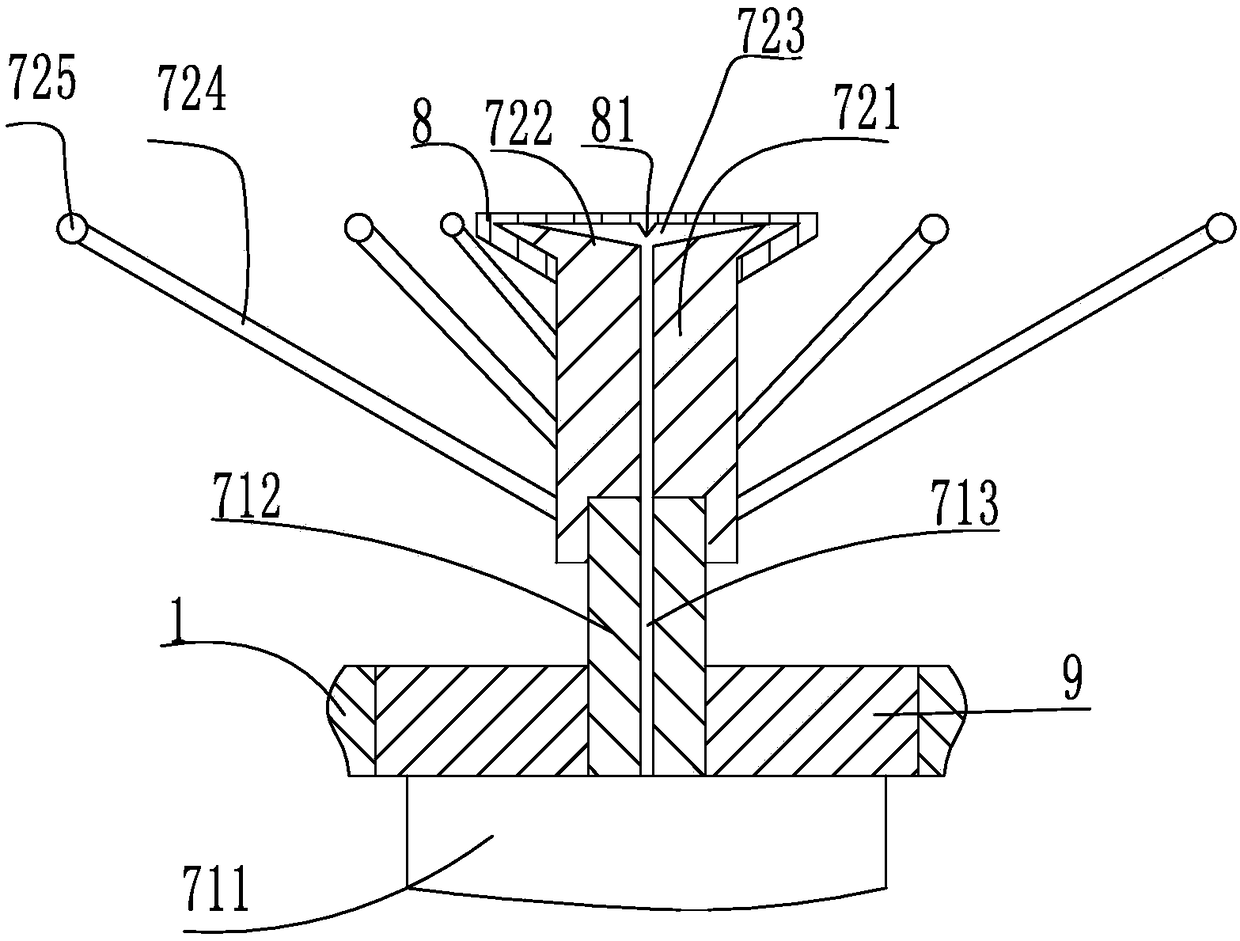

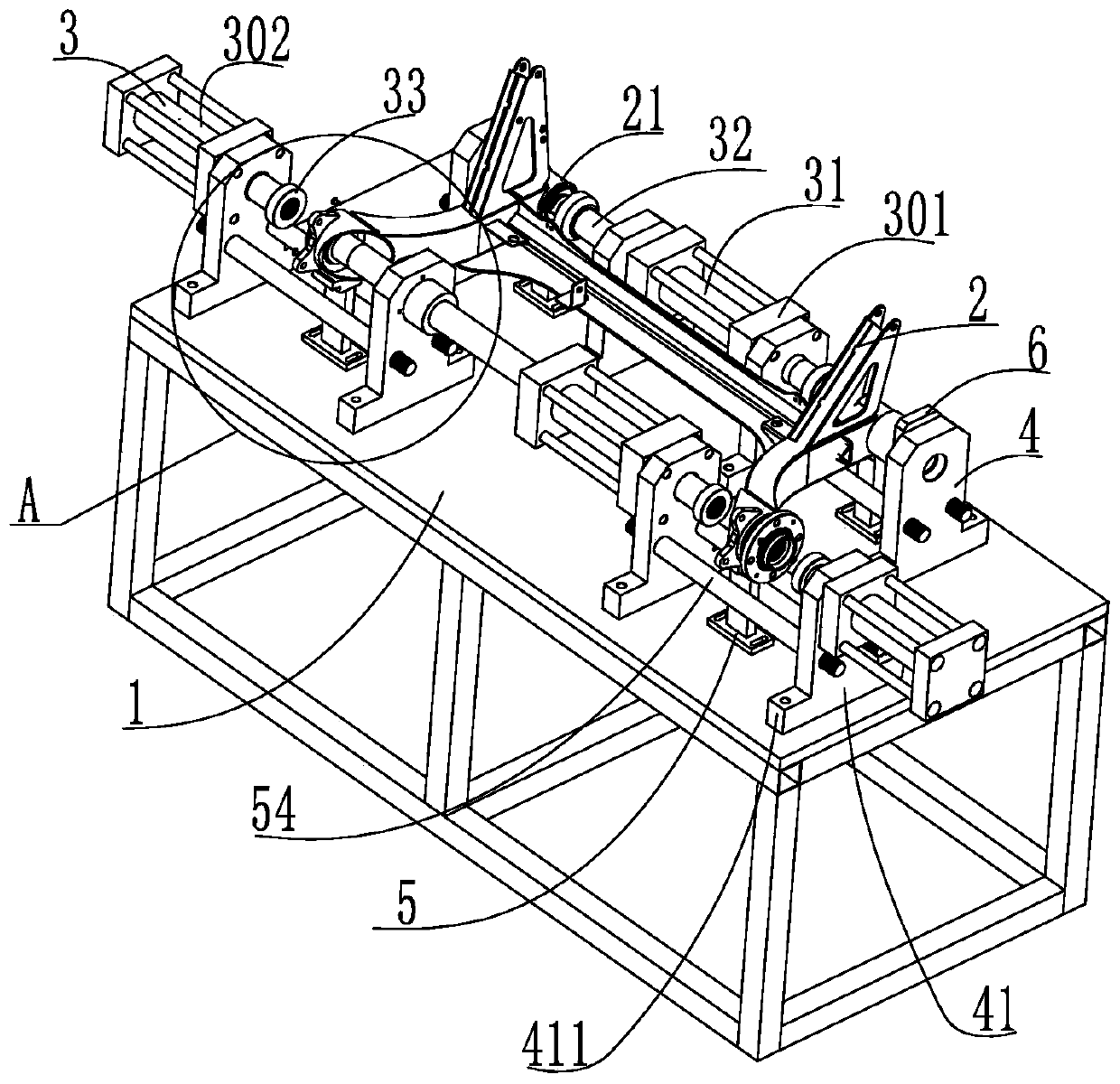

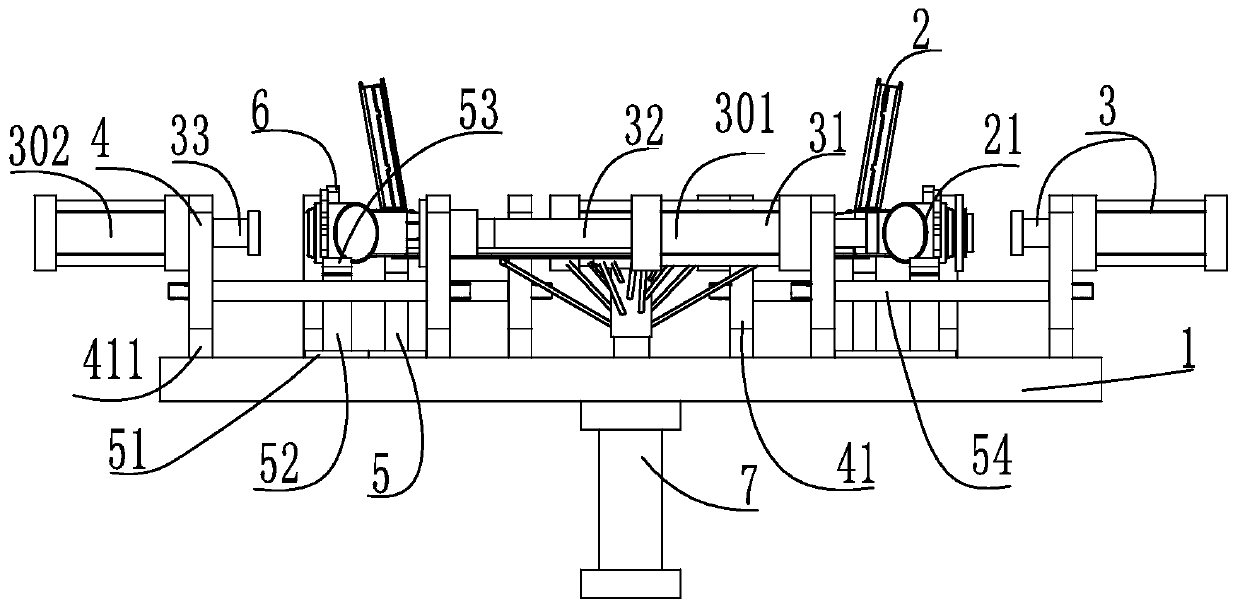

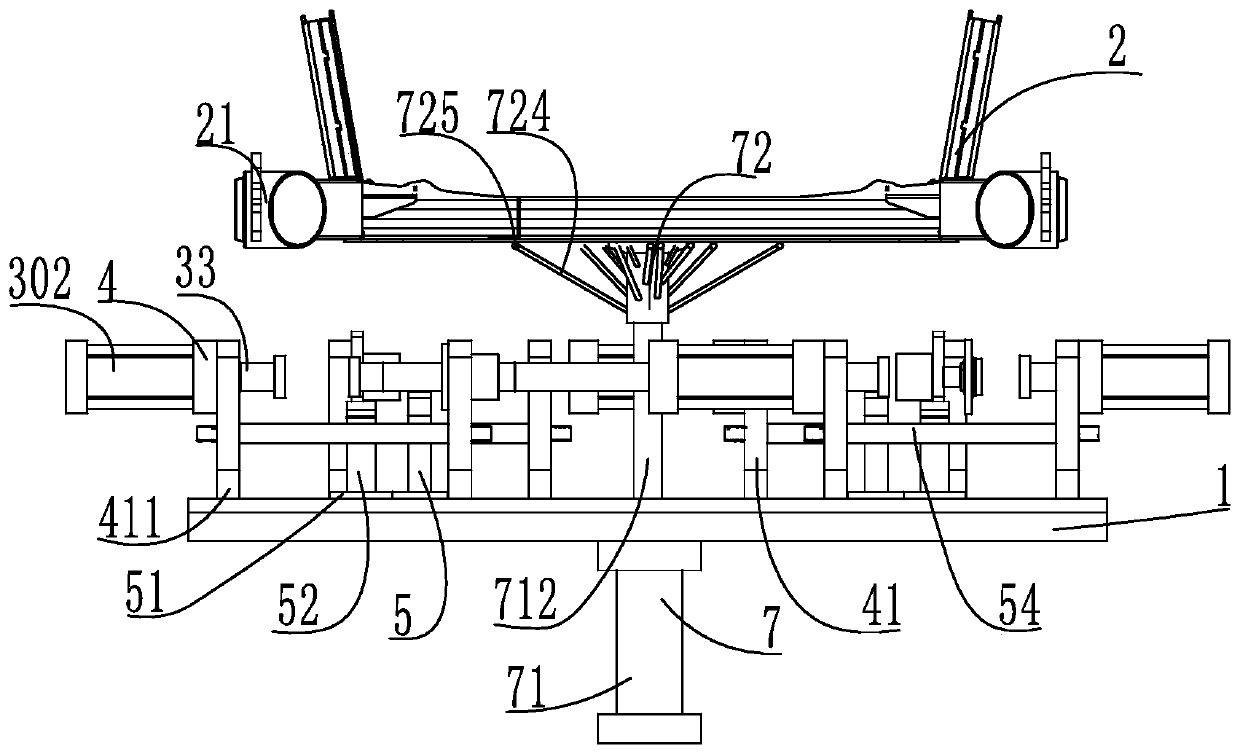

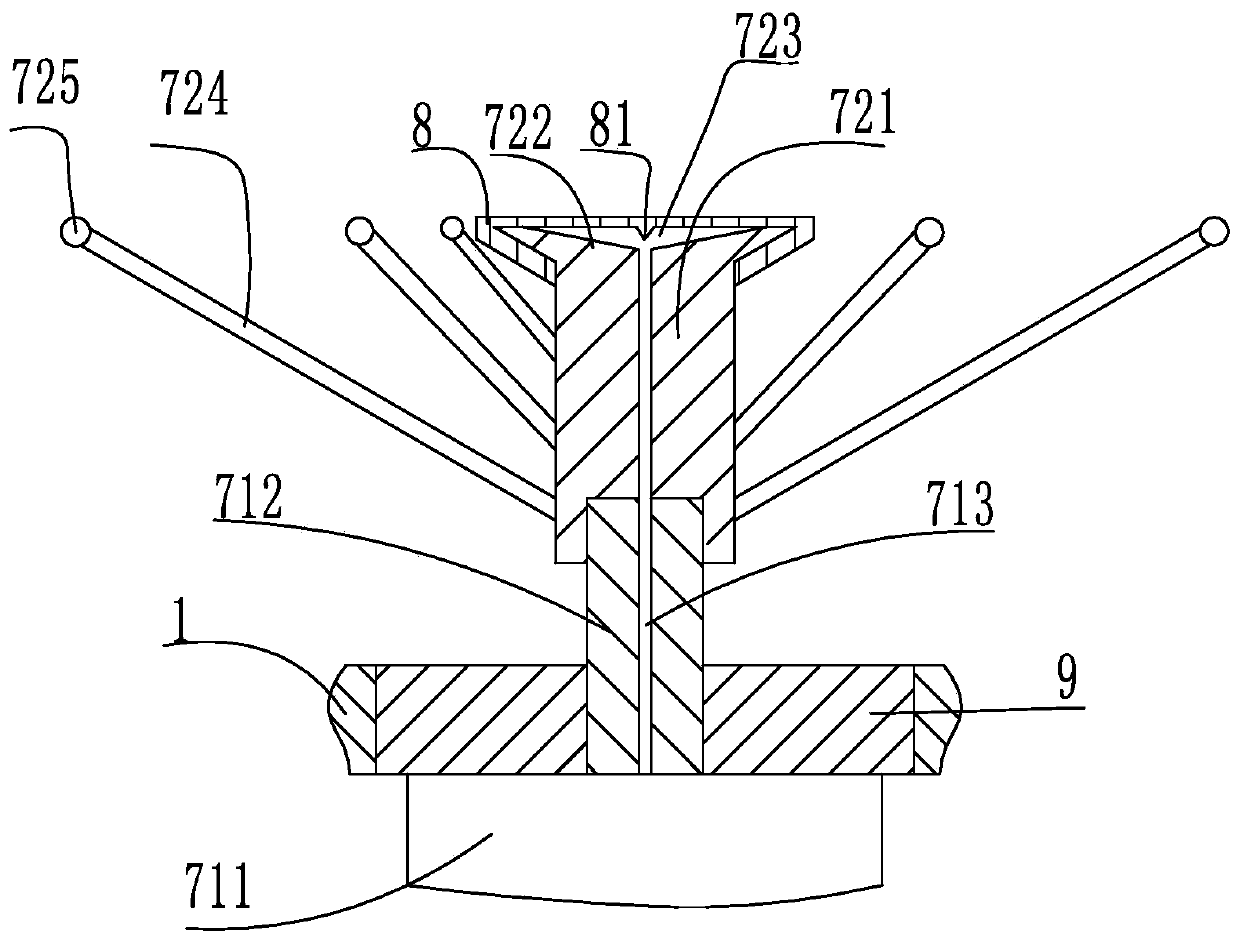

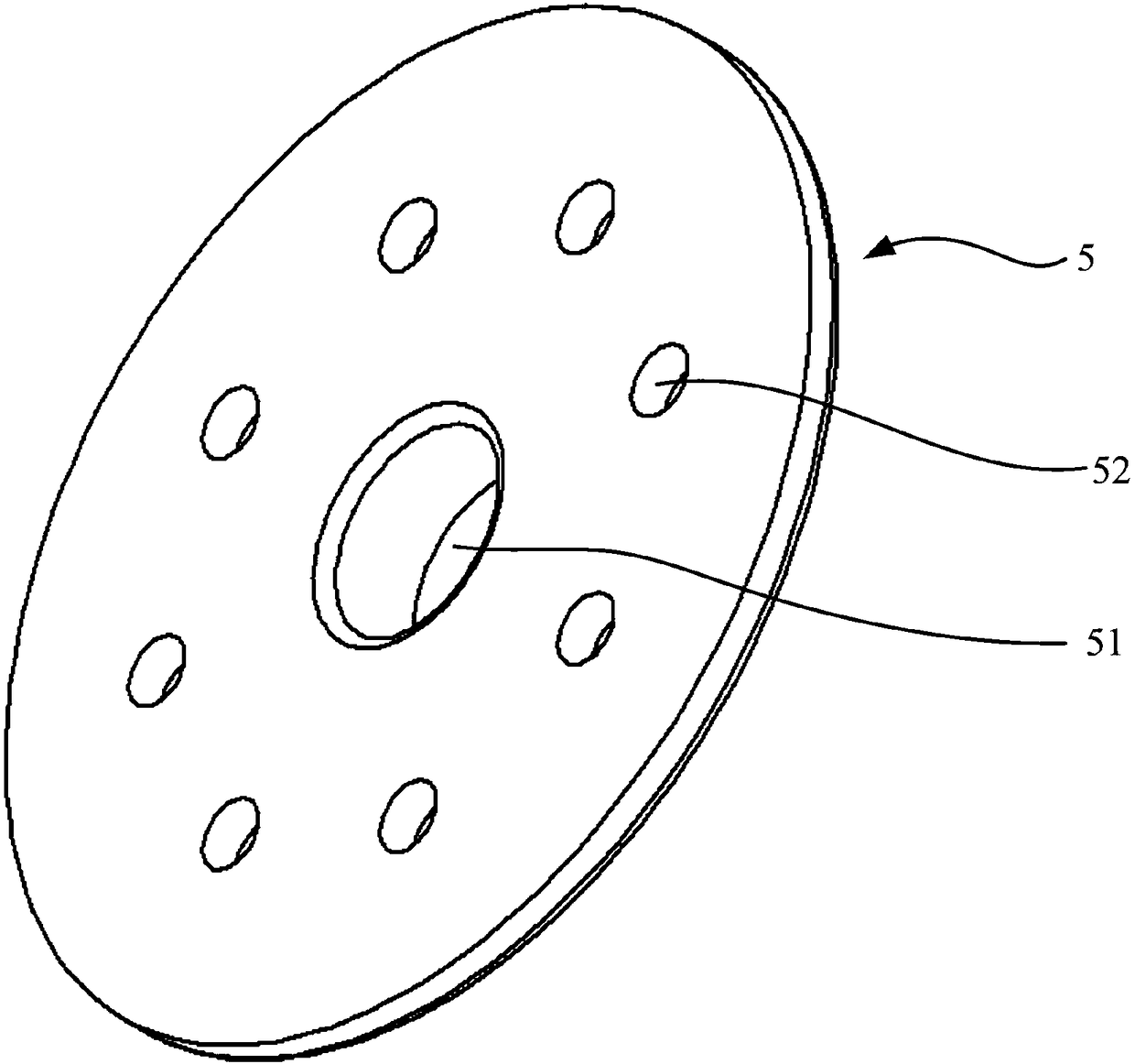

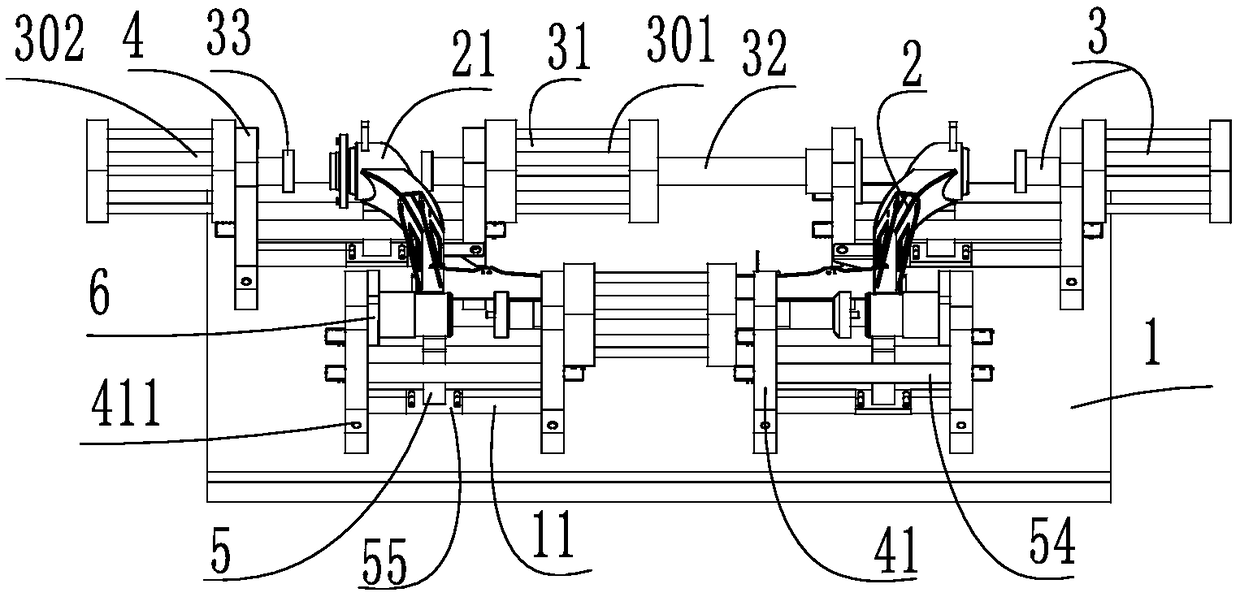

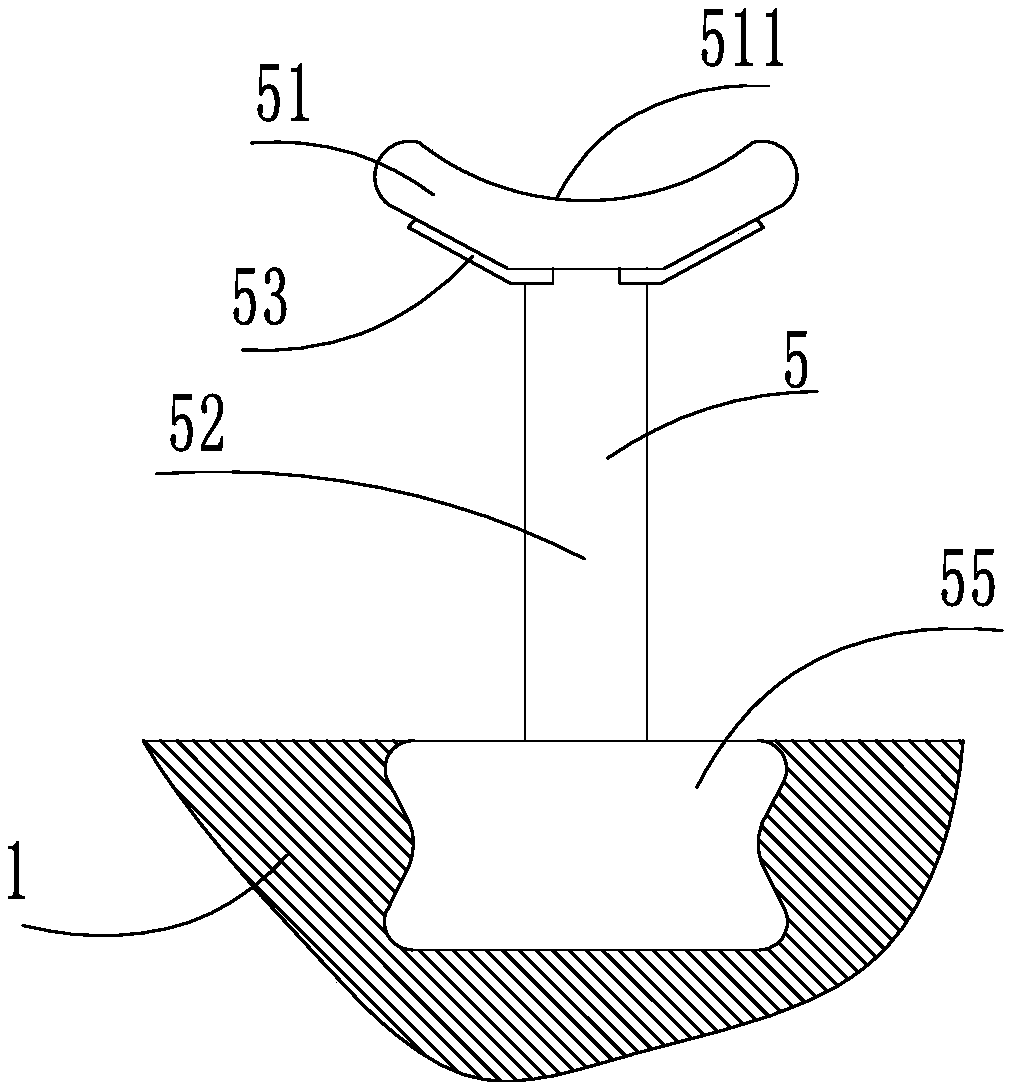

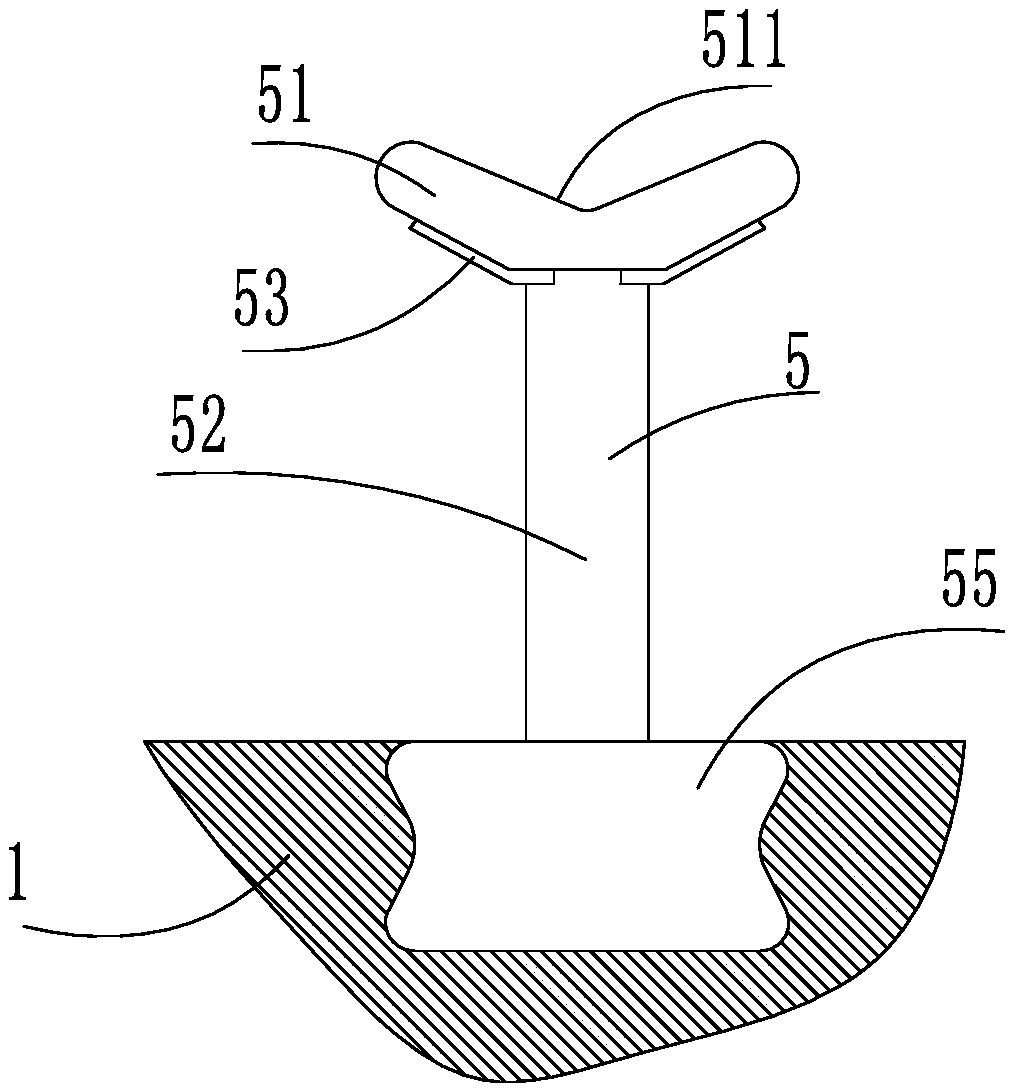

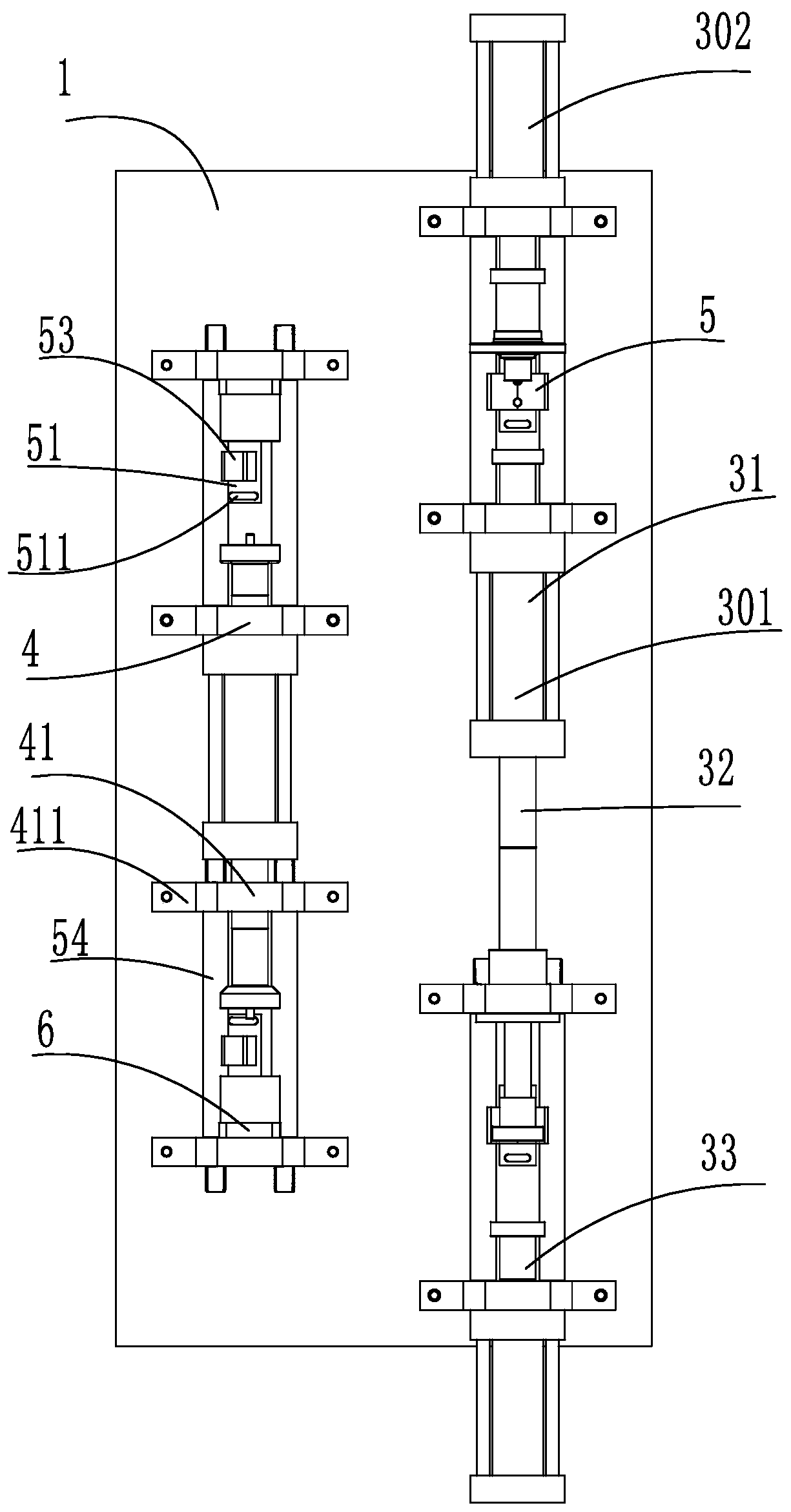

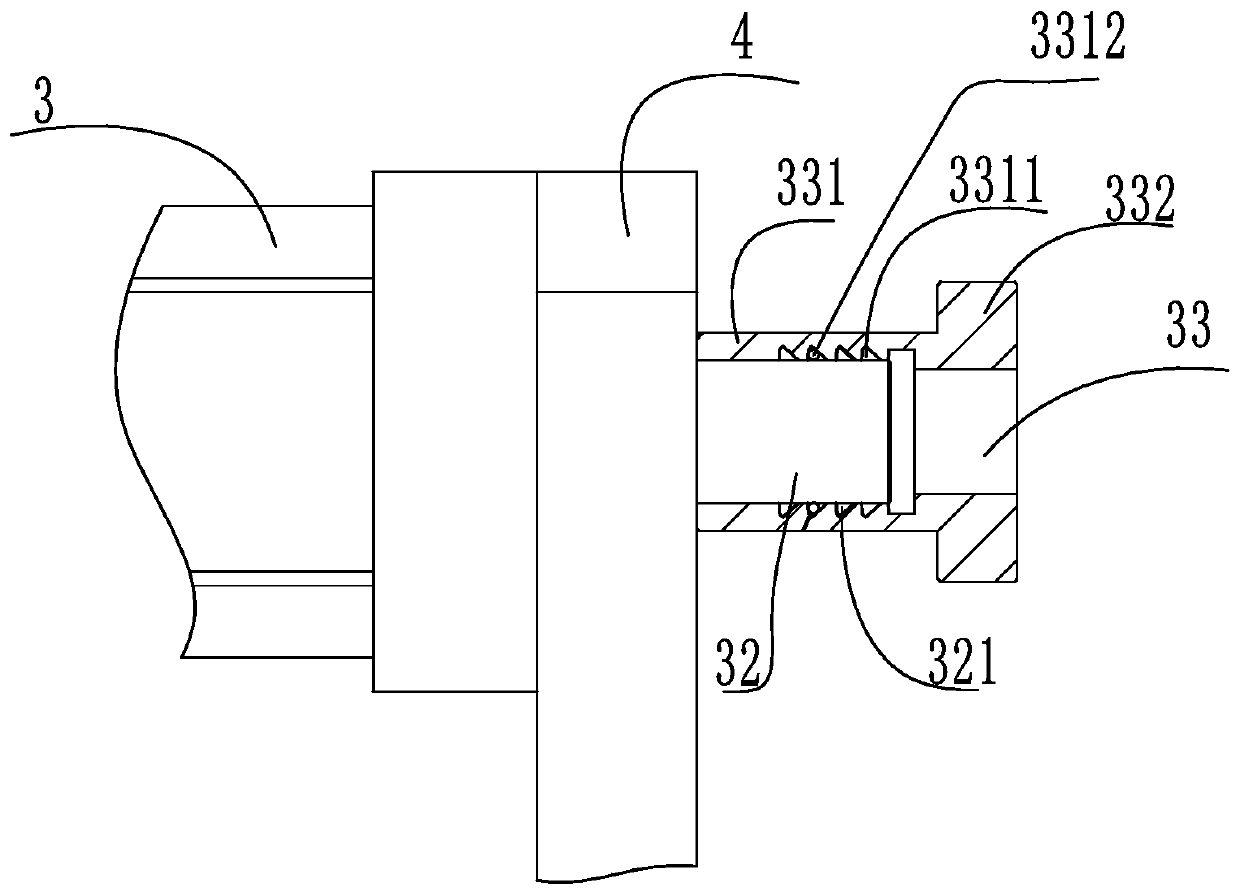

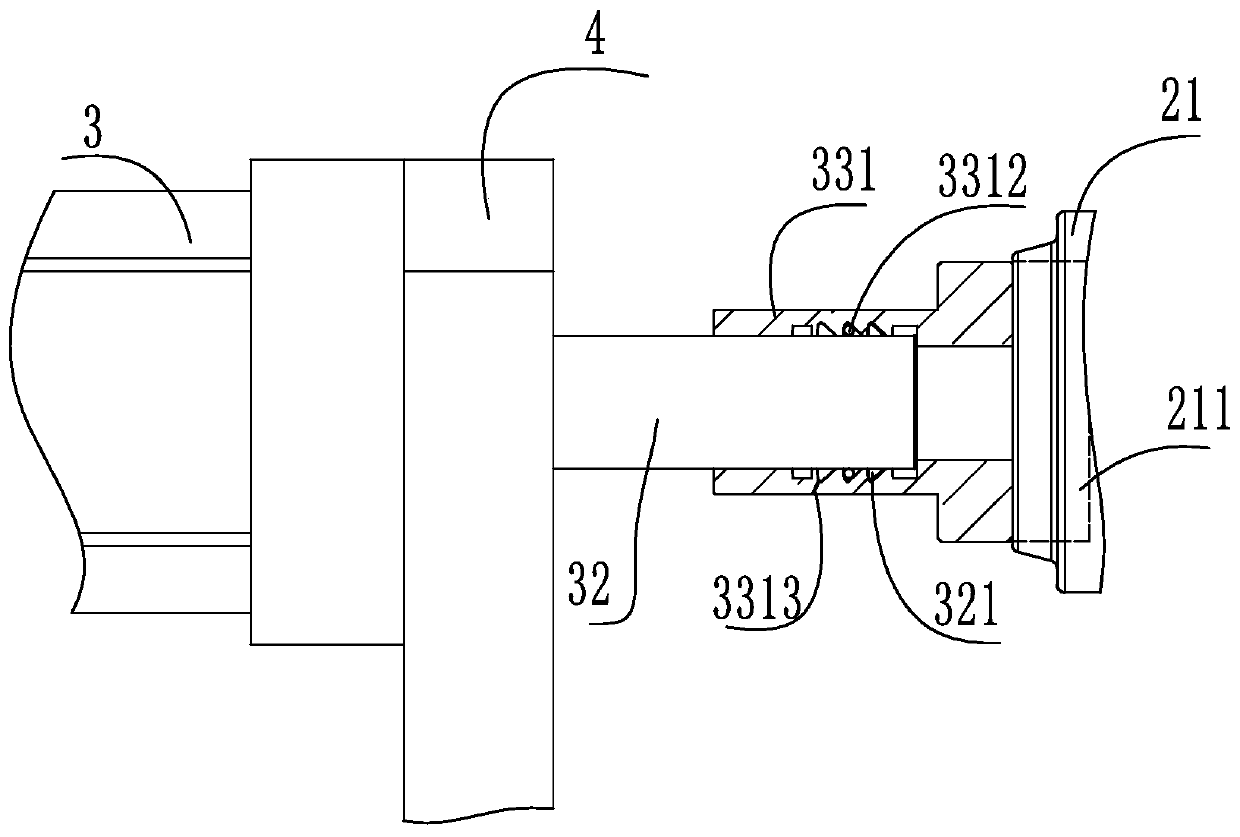

Synchronous positioning and press-fitting device for multi-station rear axle bearing

ActiveCN108544208AEasy to pre-locateImprove installation efficiencyVehicle componentsMetal working apparatusTransverse planeMechanical engineering

The invention discloses a synchronous positioning and press-fitting device for a multi-station rear axle bearing. The synchronous positioning and press-fitting device for the multi-station rear axle bearing comprises a working table and a rear axle mold, wherein the rear axle mold comprises a plurality of bearing seats; bearings to be pressed are arranged in the bearing seats; pressurizing oil cylinders are arranged at least one side of two side surfaces in the axial direction of each bearing seat; each pressurizing oil cylinder comprises an oil cylinder shell and a pressurizing piston rod; apressurizing block is arranged at one outward end of each pressurizing piston rod; a positioning assembly is arranged under each bearing seat; a feeding and blanking mechanism is arranged on the upperside surface of the working table, and comprises a power mechanism; and a positioning mold capable of supporting the rear axle mold is arranged above the power mechanism. The synchronous positioningand press-fitting device for the multi-station rear axle bearing provided by the invention has the advantages that the rear axle mold is convenient and safe to feed and blank; the bearing is pressed in a horizontal plane, so that the processing space is large, no repetitive positioning is needed, the positioning times is less, and the pressing-fit efficiency is high; and the feeding and blanking mechanism can be used for pre-positioning the rear axle mold, so that the bearing can be processed and positioned conveniently and can be quickly pressed.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

A jig and method for laser cutting of aerospace titanium alloy

ActiveCN113059289BReduce weightHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingTitanium alloy

The invention belongs to the technical field of parts processing, and in particular relates to a jig and method for laser cutting of aviation titanium alloys, comprising a bottom plate base, at least two fixture positioning parts and at least two part positioning parts; the bottom plate base is provided with a jig and The positioning parts correspond to the fixture positioning holes one by one, and the top of the bottom plate base is provided with profile protrusions for supporting titanium alloy parts, and the profile protrusions are provided with part positioning holes corresponding to the part positioning parts one-to-one. This technical solution can be based on the simple composition structure of the cutting jig, and adopts cast aluminum as the manufacturing material of the cutting jig, which makes the cutting jig lighter in weight and better in strength and fatigue limit; After grinding, it can have a smooth surface structure. Under the conditions of supporting the titanium alloy plate, the convex surface of the profile will not be deformed, and it can also effectively avoid surface quality problems such as scratches on the surface of titanium alloy parts.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

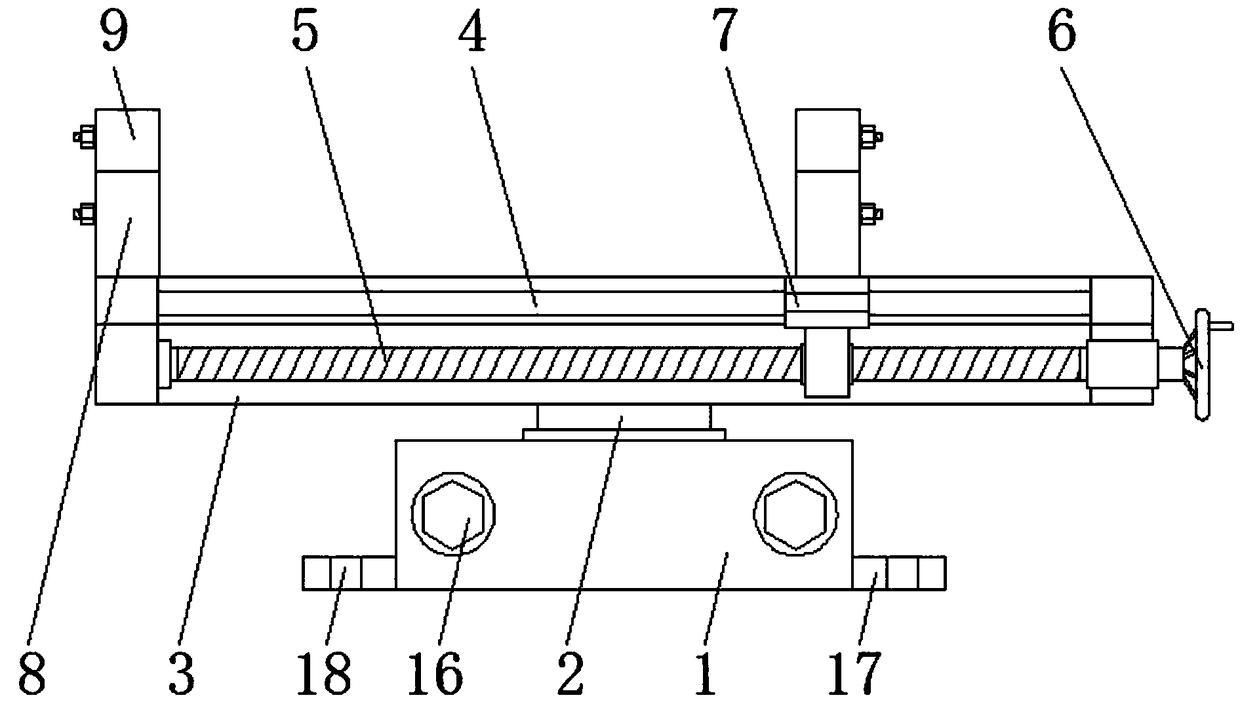

A multi-station synchronous rear axle bearing pressing equipment

ActiveCN108637645BImprove processing efficiencyImprove work efficiencyVehicle componentsMetal working apparatusPillow block bearingStructural engineering

The invention discloses a multi-station synchronous rear axle bearing press-fitting device. The device comprises a workbench and a rear axle die, the rear axle die comprises a plurality of bearing seats, the bearing seats are internally provided with to-be-pressed bearings, at least one side of the two axial side faces of each bearing seat is provided with a pressure applying oil cylinder, each pressure applying oil cylinder comprises an oil cylinder shell and a piston rod, pressure applying blocks attached to the side faces of the to-be-pressed bearings are arranged at the ends, facing outwards, of the piston rods, the piston rods are coaxial with the to-be-pressed bearings, the axis of each to-be-pressed bearing is parallel to the working upper plane of the workbench, a limiting assemblyand a positioning assembly for positioning the rear axle die are arranged on the workbench, and the pressure applying oil cylinders are fixed on the limiting assembly. The device has the advantages that when re-machining is carried out after pre-positioning, fixing of the rear axle die is completed by the pressure applying oil cylinders and the pressure applying blocks, the machining space is enlarged, positioning and machining are convenient, the machining precision of the to-be-pressed bearings and the bearing seats is improved, the to-be-pressed bearings are prevented from being eccentricto the bearing seats, the plurality of to-be-pressed bearings can be synchronously machined through the pressure applying oil cylinders, so that the working efficiency of bearing press-fitting is improved.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

A solution recovery device for a machine tool and the machine tool

ActiveCN106392754BConvenient positioning and processingPositioning apparatusMaintainance and safety accessoriesMachine toolSolution flow

The invention discloses a solution recovery device for a machine tool and the machine tool. The solution recovery device comprises a container, a first switch valve and a second switch valve. A containing space for containing a solution is hollowly formed in the container. A first gas inlet, a second gas inlet, a gas outlet and a liquid outlet, all of which communicate with the containing space are formed in the container. The first gas inlet is connected with a vacuum fixture in a communicating manner. The gas outlet is connected with a vacuum generator in a communicating manner. The gas outlet and the second gas inlet are higher than the liquid outlet. The first switch valve is used for controlling connection and disconnection of the liquid outlet. The second switch valve is used for controlling connection and disconnection of the second gas inlet. According to the solution recovery device for the machine tool and the machine tool, when the solution stored in the containing space needs to be recovered, vacuumizing operation on the containing space by the vacuum generator can be stopped firstly, the first switch valve and the second switch valve are opened, then external air enters the containing space from the second gas inlet quickly, the solution flows out of the container from the liquid outlet due to the gravity for recovery and reutilization, the waste of the solution is avoided, and therefore the cost of the solution resource is lowered.

Owner:GUANGDONG EVERWIN PRECISION TECH

A multi-station rear axle bearing synchronous positioning and pressing equipment

ActiveCN108544208BEasy accessEasy to installVehicle componentsMetal working apparatusControl theoryMechanical engineering

The invention discloses a synchronous positioning and press-fitting device for a multi-station rear axle bearing. The synchronous positioning and press-fitting device for the multi-station rear axle bearing comprises a working table and a rear axle mold, wherein the rear axle mold comprises a plurality of bearing seats; bearings to be pressed are arranged in the bearing seats; pressurizing oil cylinders are arranged at least one side of two side surfaces in the axial direction of each bearing seat; each pressurizing oil cylinder comprises an oil cylinder shell and a pressurizing piston rod; apressurizing block is arranged at one outward end of each pressurizing piston rod; a positioning assembly is arranged under each bearing seat; a feeding and blanking mechanism is arranged on the upperside surface of the working table, and comprises a power mechanism; and a positioning mold capable of supporting the rear axle mold is arranged above the power mechanism. The synchronous positioningand press-fitting device for the multi-station rear axle bearing provided by the invention has the advantages that the rear axle mold is convenient and safe to feed and blank; the bearing is pressed in a horizontal plane, so that the processing space is large, no repetitive positioning is needed, the positioning times is less, and the pressing-fit efficiency is high; and the feeding and blanking mechanism can be used for pre-positioning the rear axle mold, so that the bearing can be processed and positioned conveniently and can be quickly pressed.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

A kind of PU alloy furnace roller production device and its production process

ActiveCN112975686BConvenient positioning and processingEasy to lift and processGrinding drivesGrinding machinesHydraulic cylinderEngineering

Owner:托普工业(江苏)有限公司

A stamping automatic blanking positioning device and control method

ActiveCN106862413BRealize the liberation of part of the labor forceRelieve pressureMetal-working feeding devicesStripping-off devicesPunchingHeight difference

The invention discloses an automatic discharging and positioning device for punching. The automatic discharging positioning device comprises a material receiving table, a material receiving mechanism, a detection positioning mechanism, a feeding mechanism and a main system circuit. The material receiving mechanism is installed on the top face of the material receiving table. The detection positioning mechanism is arranged above the material receiving mechanism. One end of the feeding mechanism is closed to a punching machine, and the other end of the feeding mechanism is close to the detection positioning mechanism. The invention further provides a control method. The feeding mechanism conveys workpieces to the detection positioning mechanism through the perpendicular height difference of the two ends, and the detection positioning mechanism and the material receiving mechanism are matched to position and stack the workpieces. According to the technical scheme, operation workers can be reduced for a production line, labor force is liberated, and enterprise management pressure and labor cost are reduced; meanwhile, a feeding groove is adopted for conducting directional conveying and stacking the workpieces through a stacking frame in a concentrated manner according to a certain rule, surface damage of the workpieces can be reduced, and the production quality of the products is improved; and in addition, the workpiece are stacked in the same direction, and the workpieces can be positioned and machined rapidly in the subsequent processes.

Owner:广东佛智芯微电子技术研究有限公司

Rapid positioning rear axle bearing press mounting equipment

ActiveCN108655697AImprove work efficiencyImprove machining accuracyVehicle componentsMetal working apparatusEngineeringBlock match

The invention discloses rapid positioning rear axle bearing press mounting equipment. The equipment comprises a workbench and a rear axle mold. The rear axle mold comprises a plurality of sets of coaxial bearing seats. To-be-pressed bearings are arranged in the bearing seats. Pressing power assemblies and limiting assemblies are arranged on the upper portion of the workbench. The pressing power assemblies are located on the limiting assemblies. Each bearing seat is arranged on one side of the corresponding pressing power assembly. Sliding rails are arranged between the pressing power assemblies corresponding to the coaxial bearing seats. Sliding blocks matched with the sliding rails are arranged in the sliding rails. Positioning assemblies are fixed to the upper portions of the sliding blocks. Each positioning assembly comprises a positioning wall; a calibration plane is arranged on the upper side face of each positioning wall; and each bearing seat is located on the upper portion of the corresponding calibration plane. The rapid positioning rear axle bearing press mounting equipment has the advantages that the bearings can be simultaneously positioned and pressed when being subjected to press mounting, and the press mounting efficiency is improved; a machining space is enlarged, positioning and machining are convenient, and the bearing press mounting operation efficiency is high; the machining precision of the to-be-pressed bearings and the bearing seats is high; and the multiple to-be-pressed bearings can be synchronously machined through the pressing power assemblies, and thus the bearing press mounting operation efficiency is improved.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

A high-efficiency press-fitting equipment for rear axle bearings

ActiveCN108637646BImprove work efficiencyLarge processing spaceMetal working apparatusPillow block bearingClassical mechanics

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com