Patents

Literature

35results about How to "Easy to pre-locate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

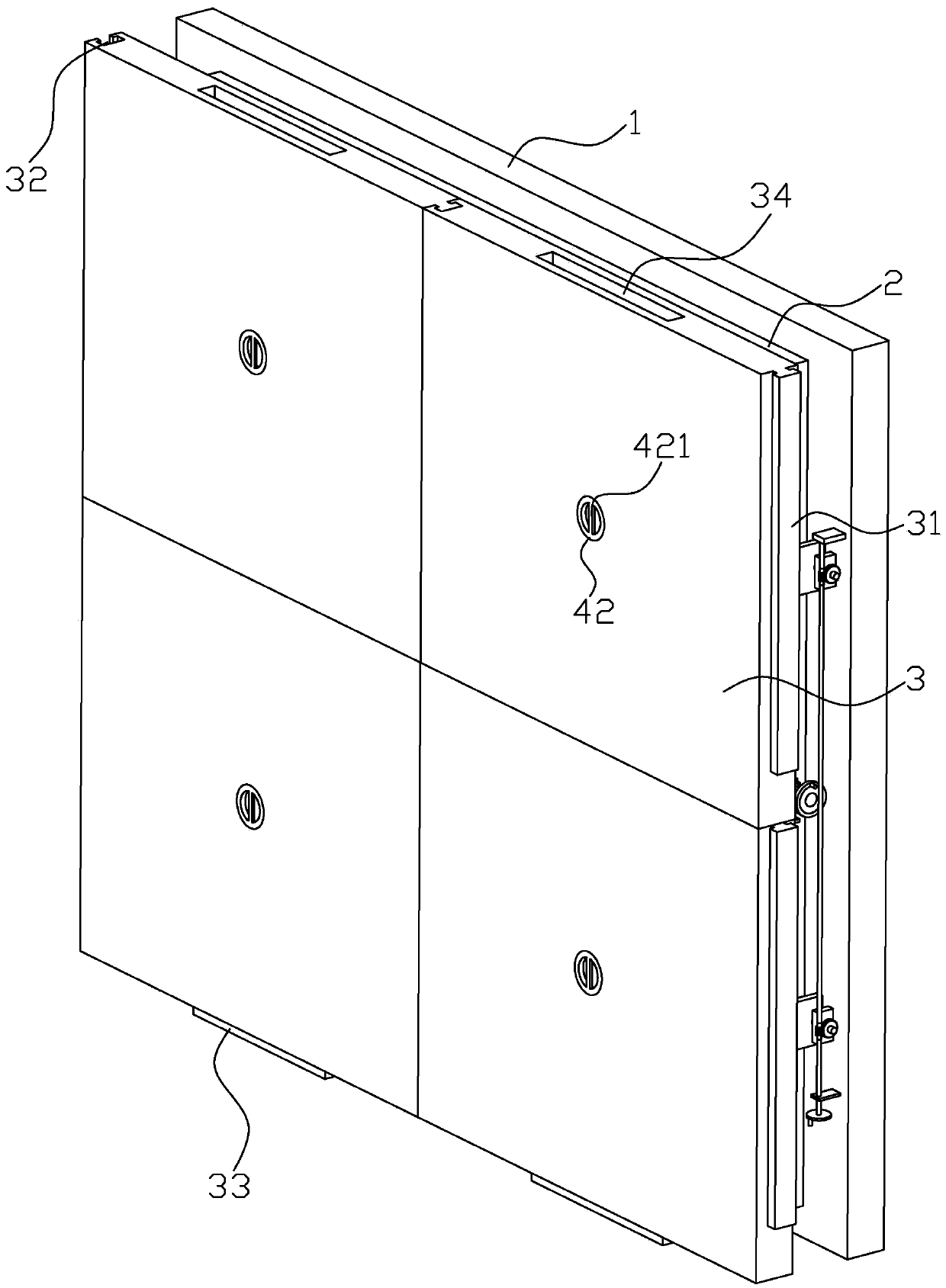

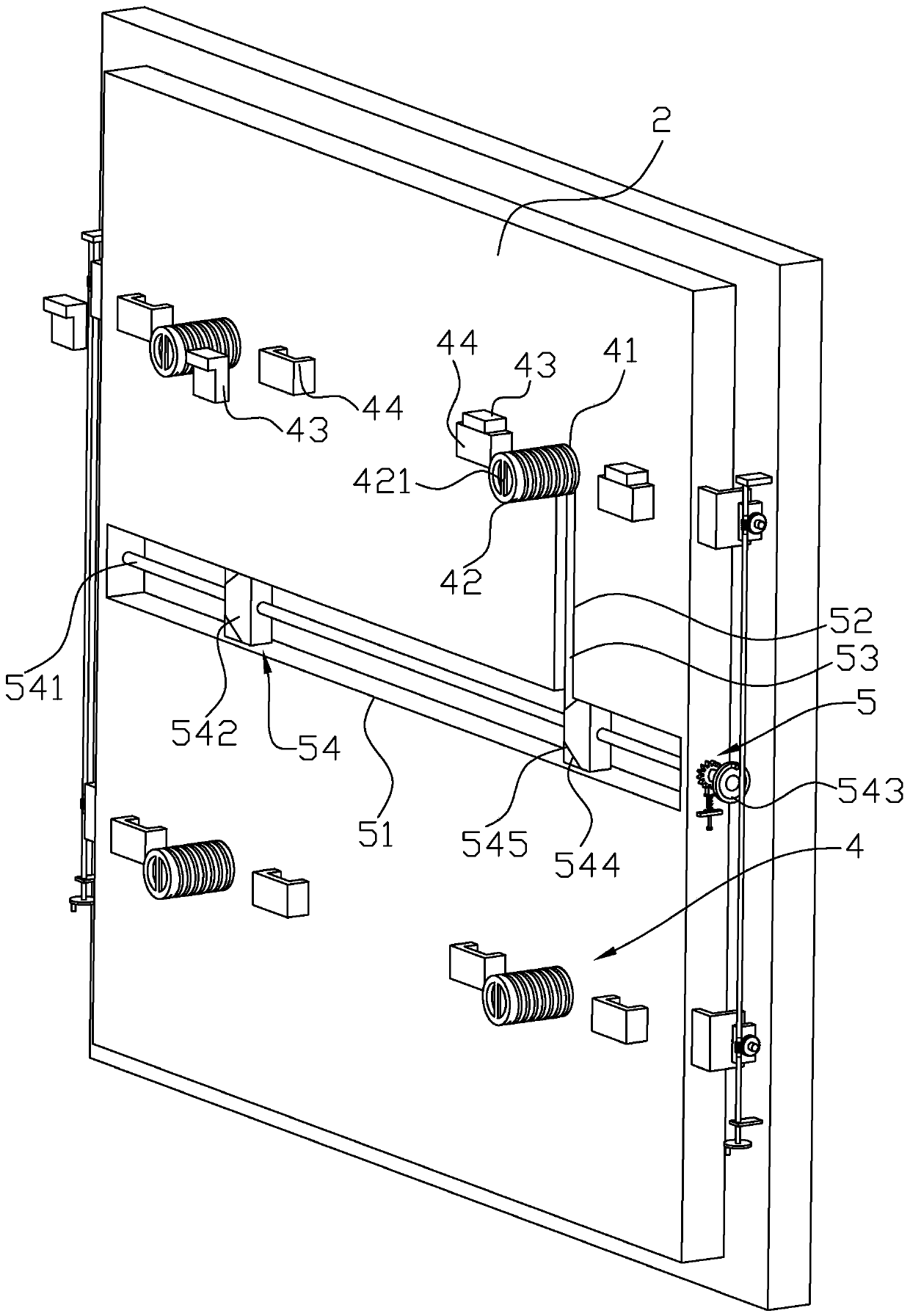

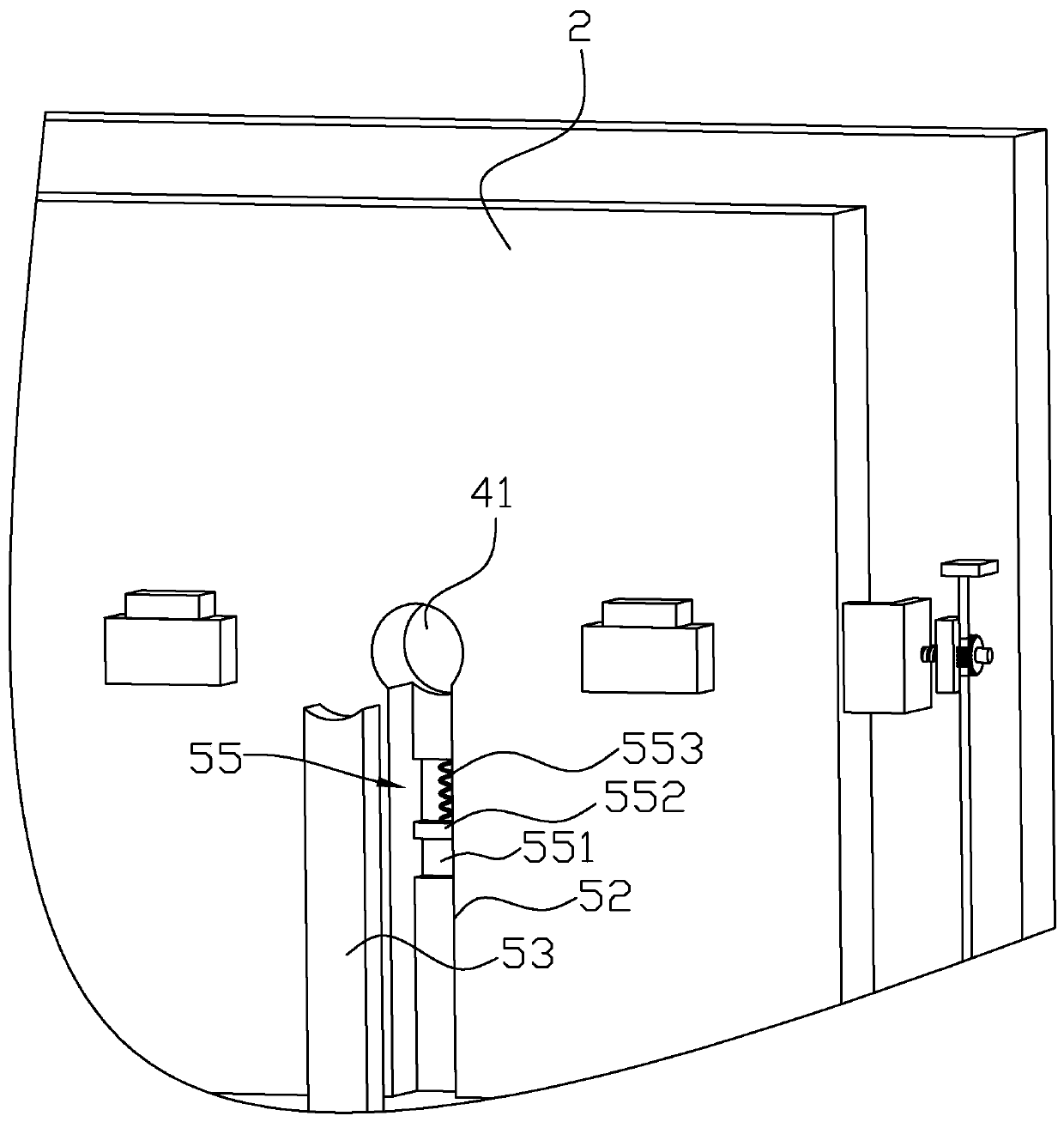

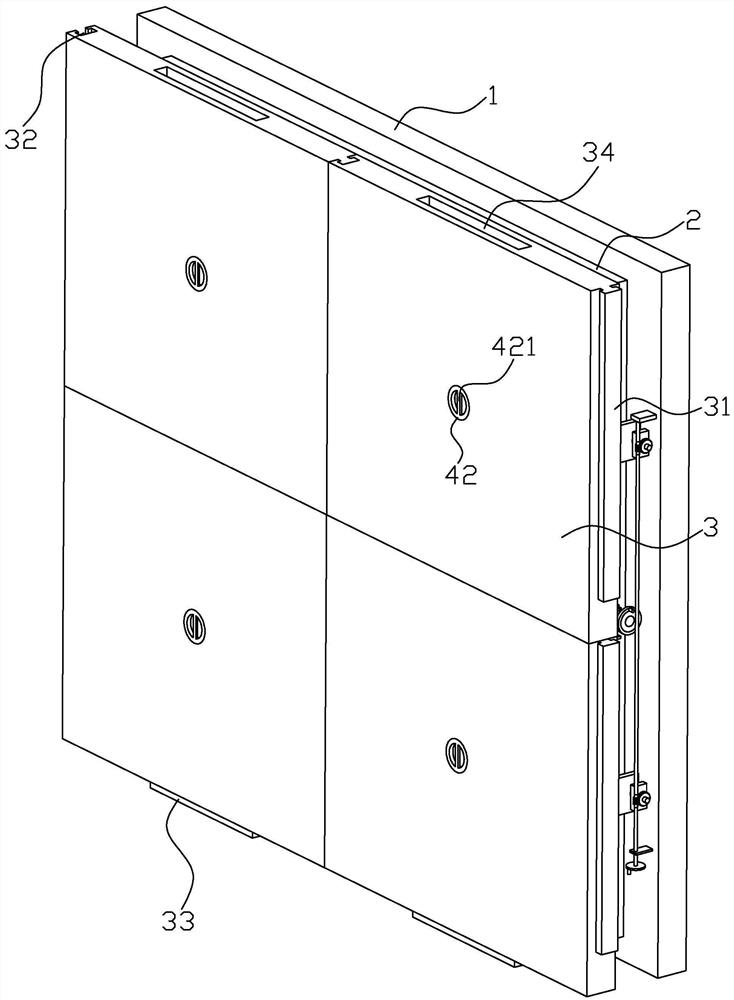

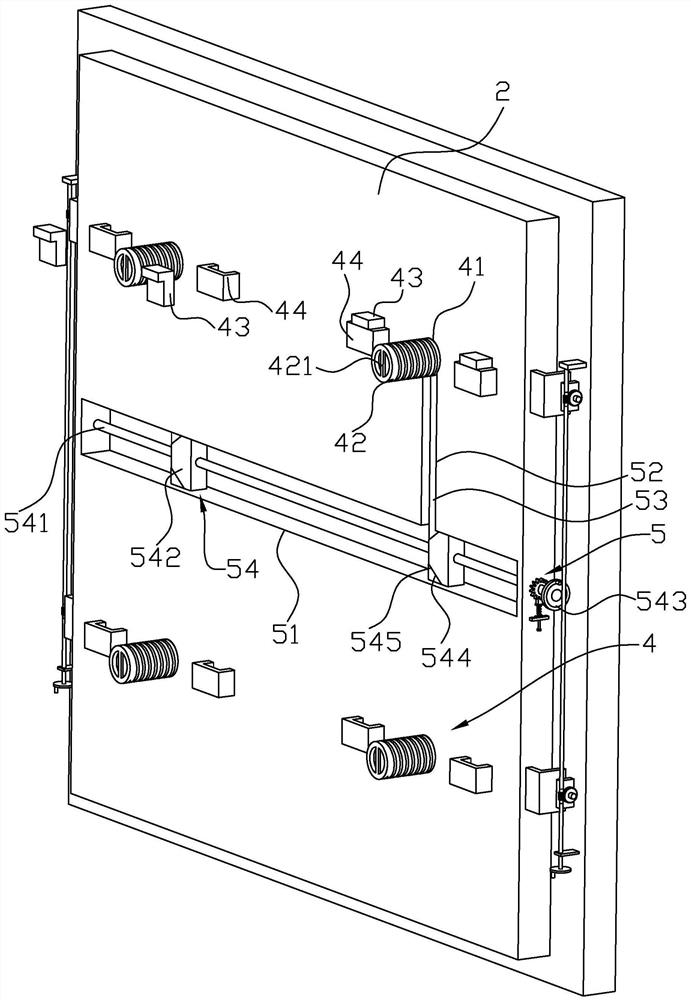

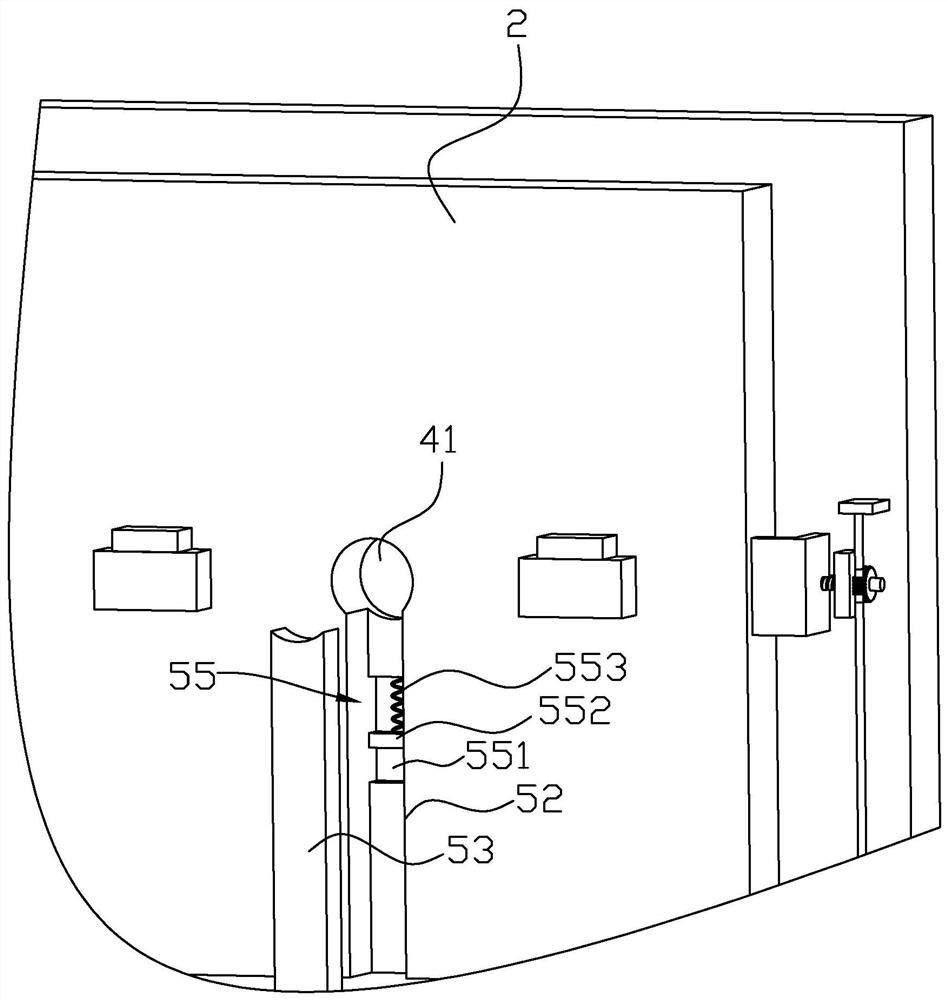

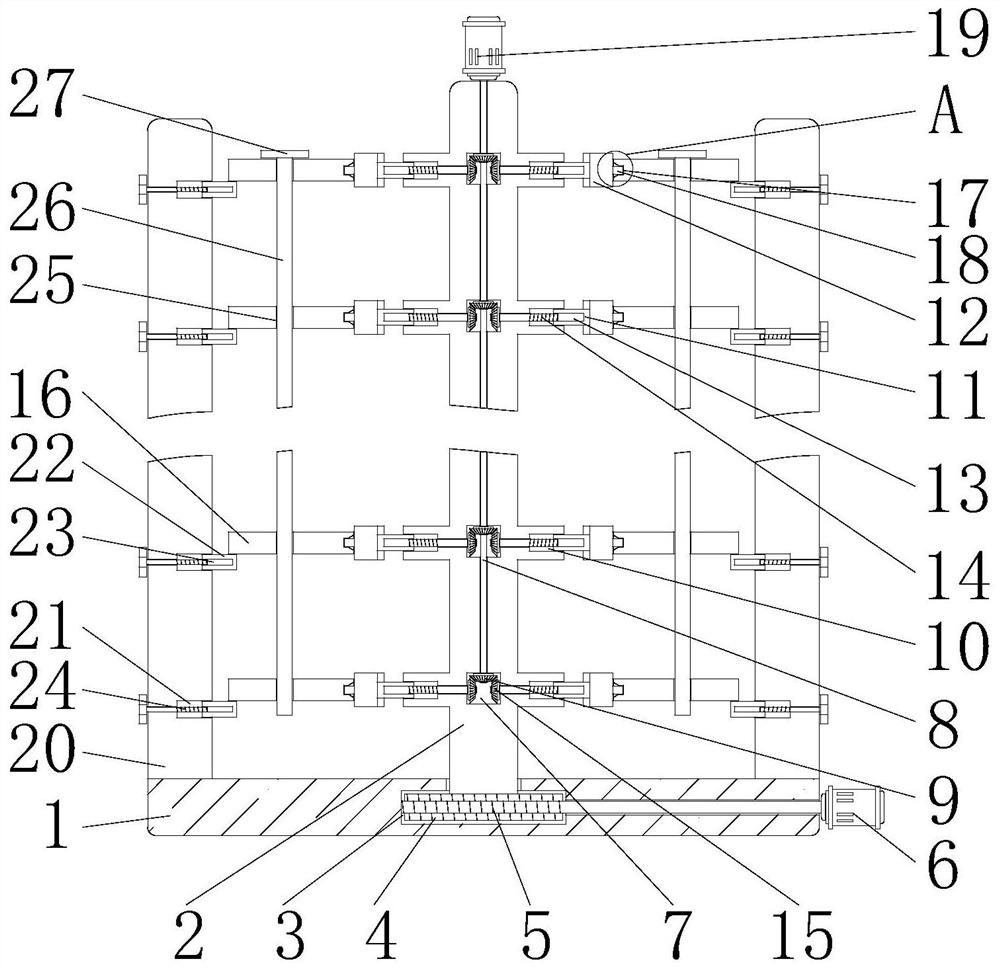

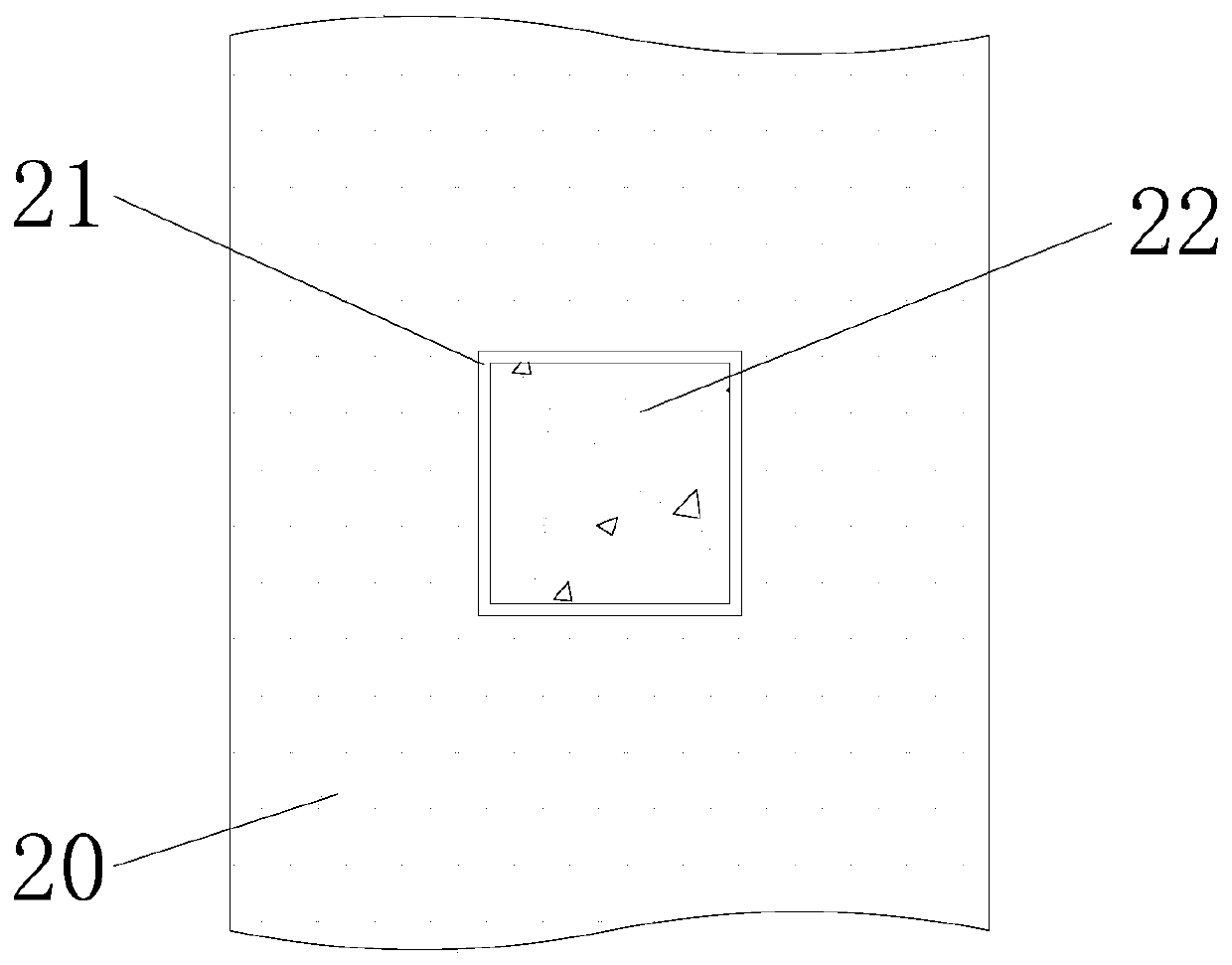

Curtain wall structure and installation method thereof

The invention discloses a curtain wall structure and an installation method thereof, and relates to the technical field of curtain walls. The curtain wall structure is characterized by comprising a keel frame, a fixed plate and a plurality of curtain wall plates, and further comprising a mounting device, wherein the mounting device comprises two rows of first slots, a plurality of first insertionblocks and a first limiting mechanism; the plurality of first insertion blocks are correspondingly inserted into the plurality of first slots one by one; hooks are fixedly connected to the two ends ofthe side, close to the fixed plate, of each curtain wall plate, and two annular blocks are fixedly connected to the side, away from the wall body, of the fixed plate; two hooks are respectively hungon the two annular blocks; the first limiting mechanism comprises a horizontal groove, a plurality of vertical grooves and a corresponding plurality of abutting blocks which are vertically and slidably connected to the plurality of vertical grooves; and the abutting blocks can abut against the first insertion blocks, a driving assembly used for driving the plurality of abutting blocks to move is installed in the horizontal groove, and a reset assembly used for resetting the abutting blocks is installed in each vertical groove. By arranging the mounting device, the curtain wall plates can be conveniently mounted.

Owner:江苏诺米新材料科技有限公司

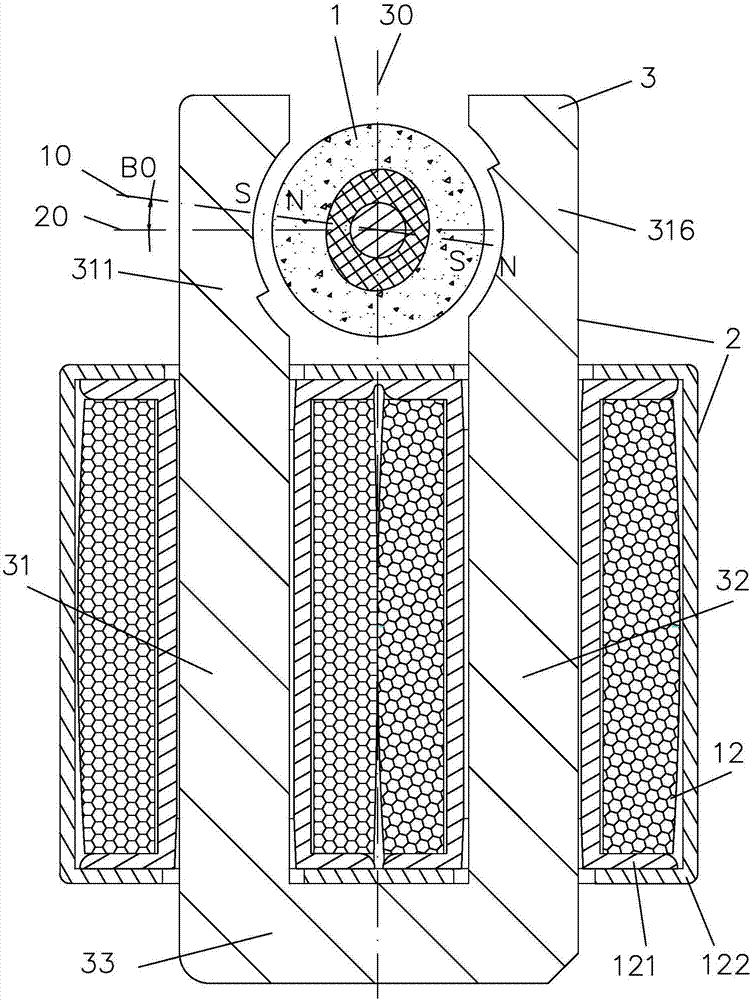

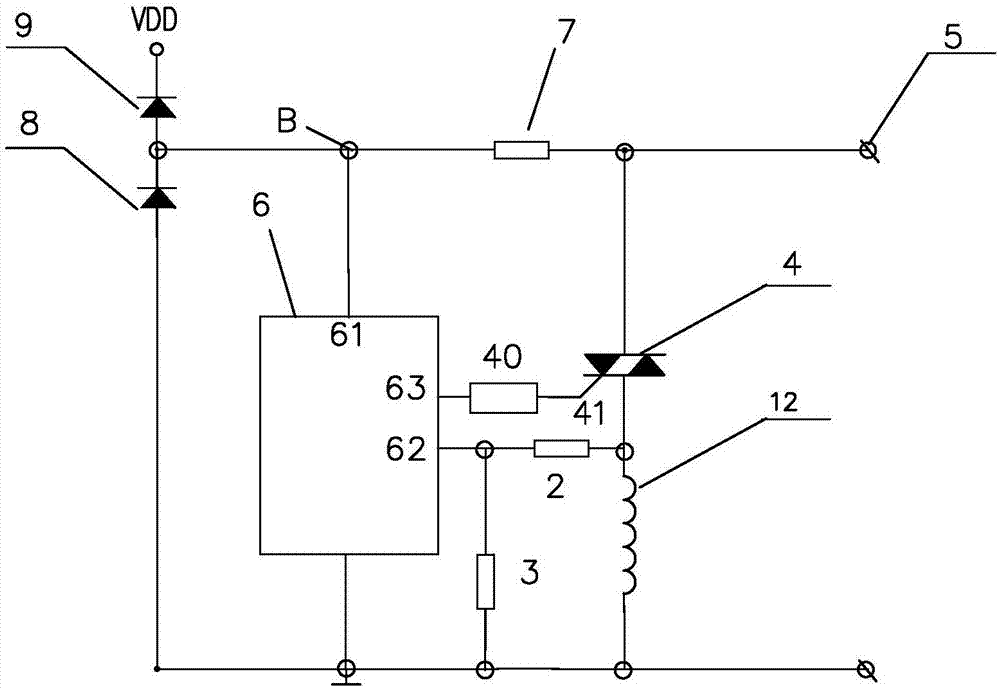

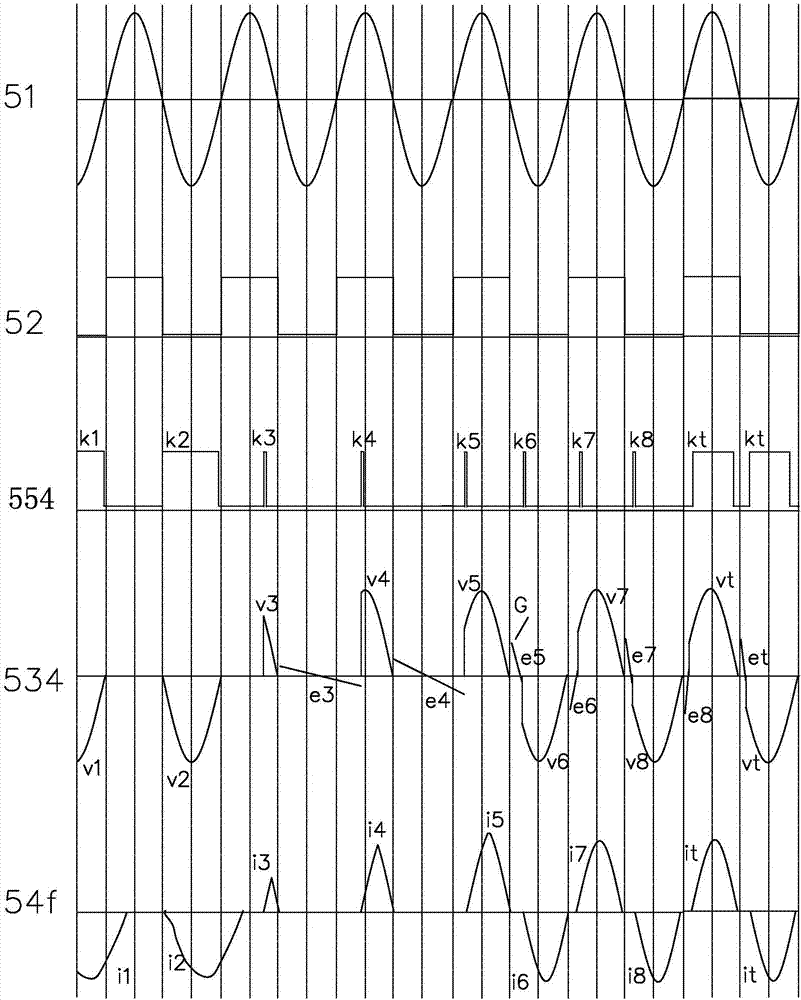

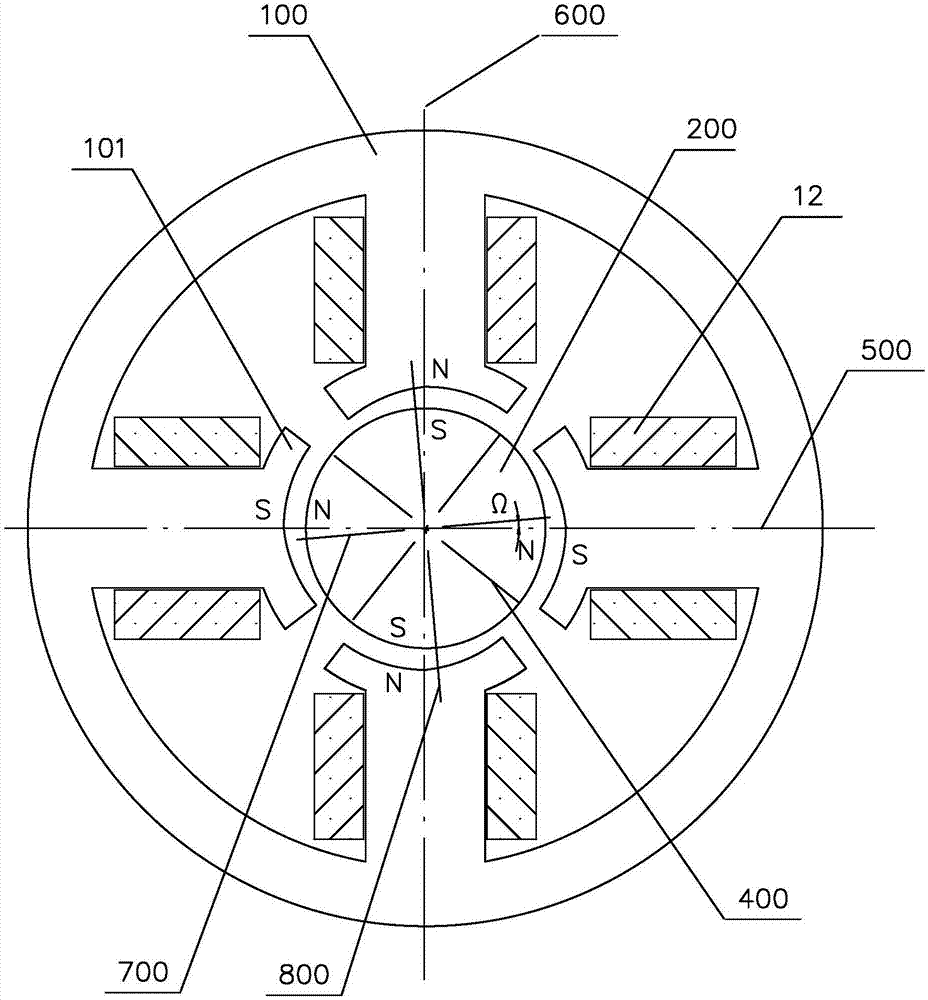

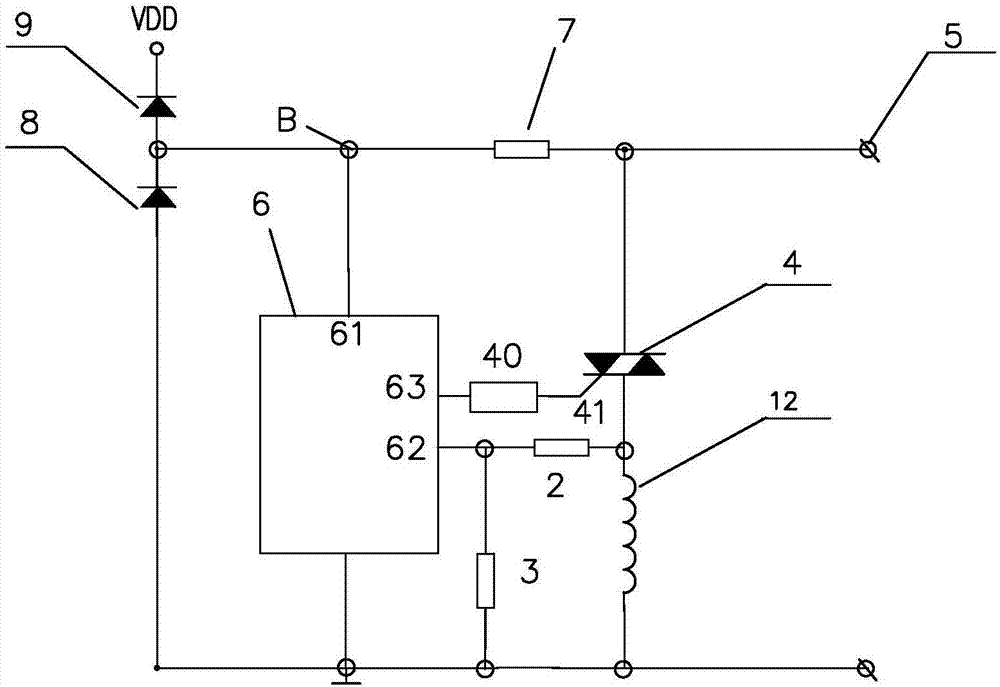

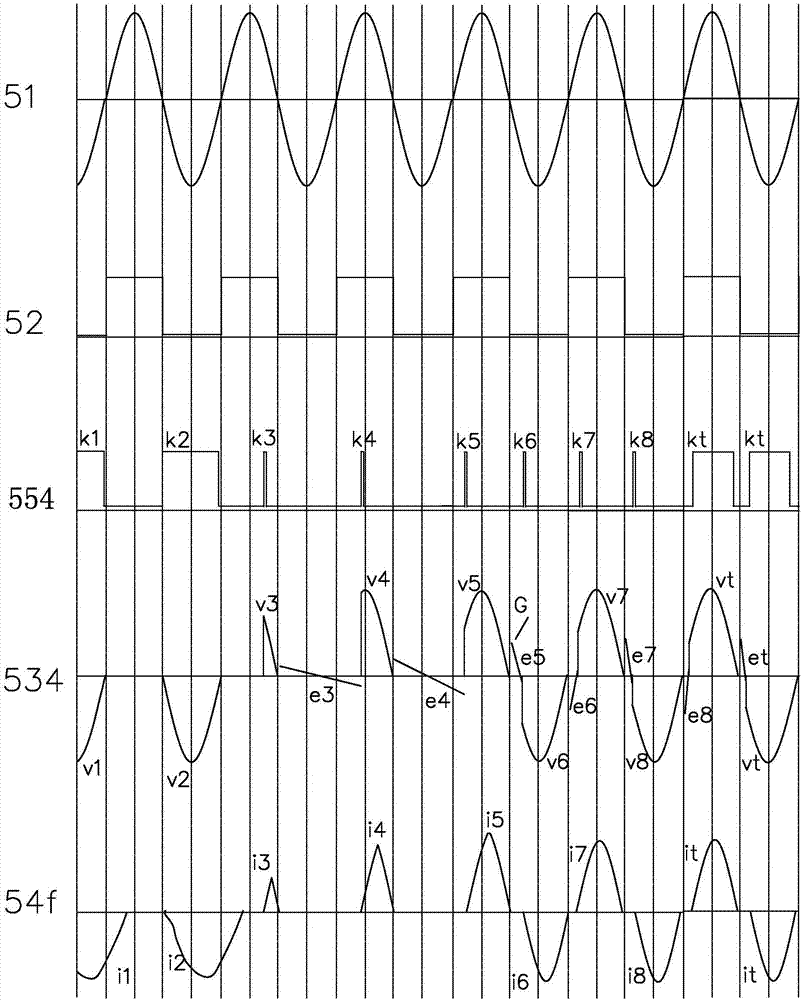

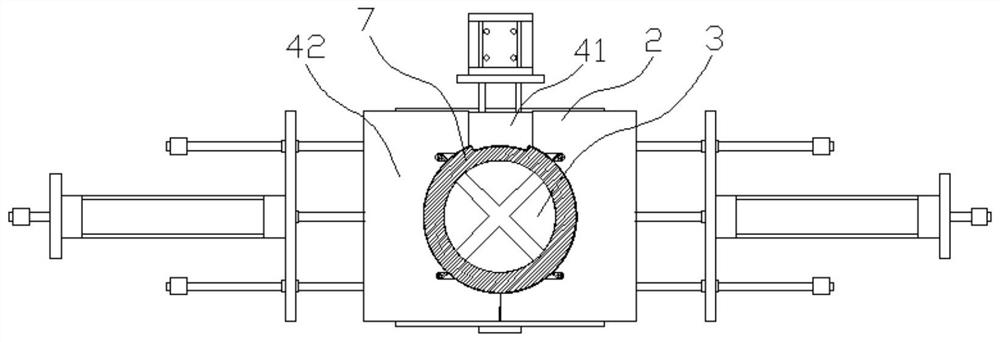

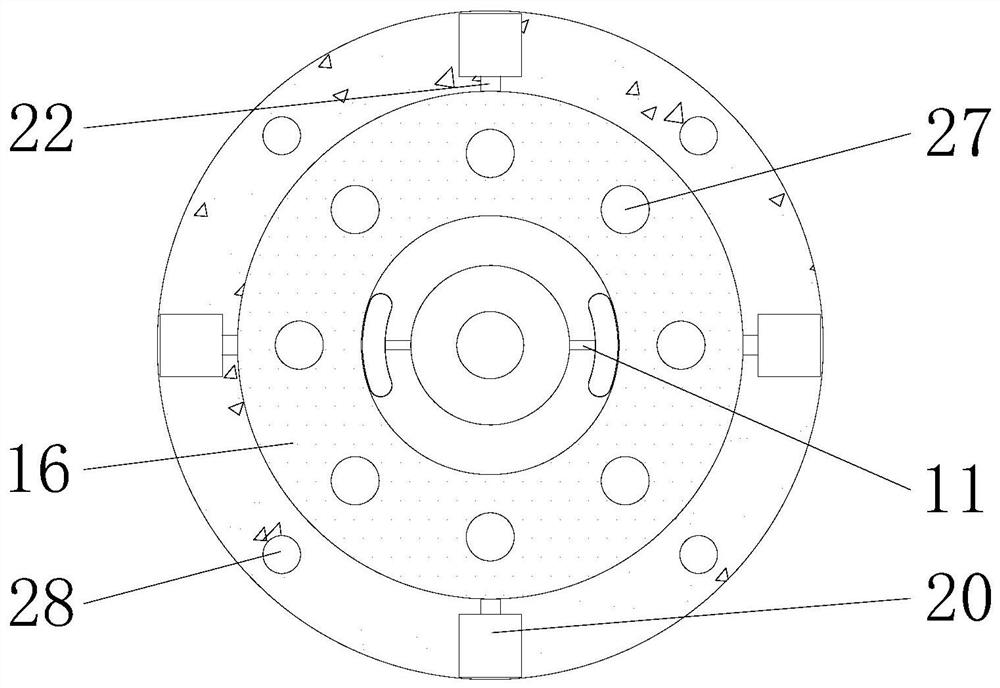

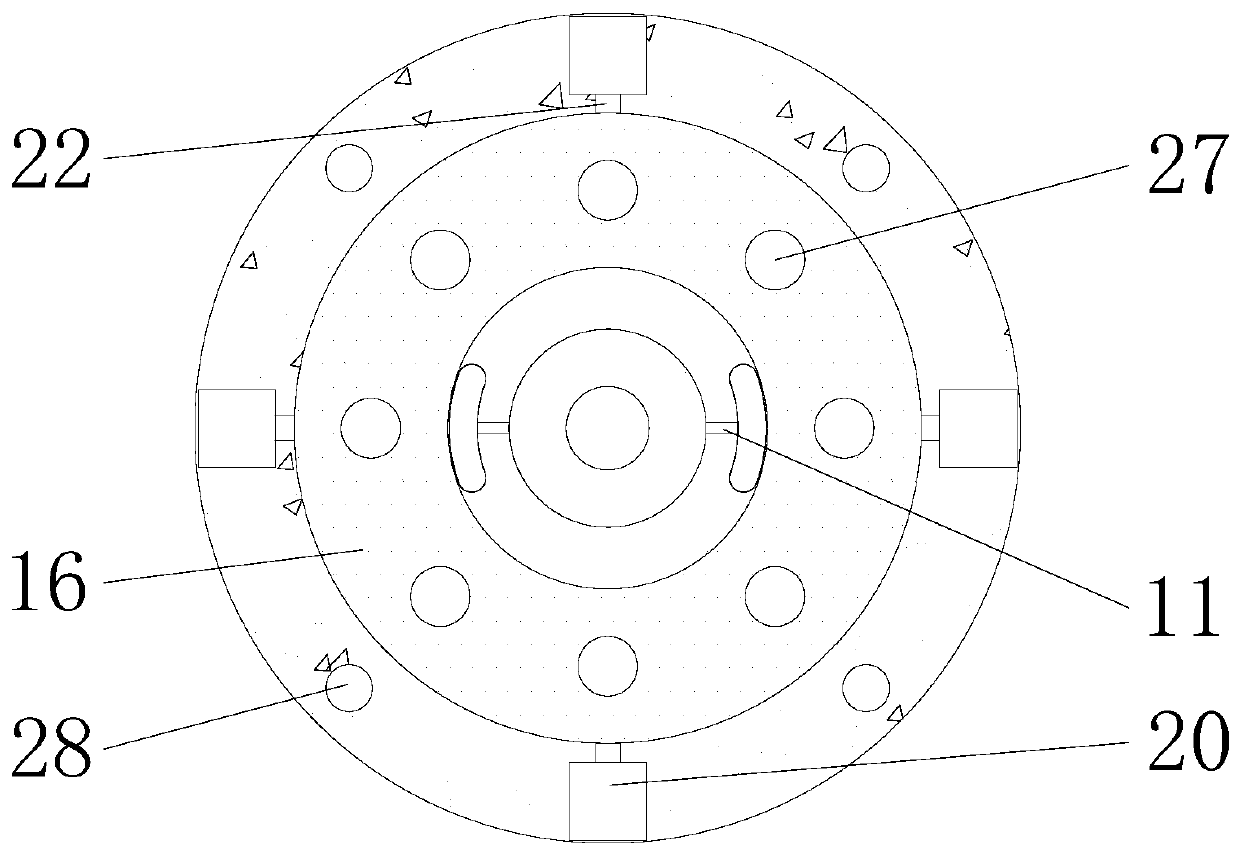

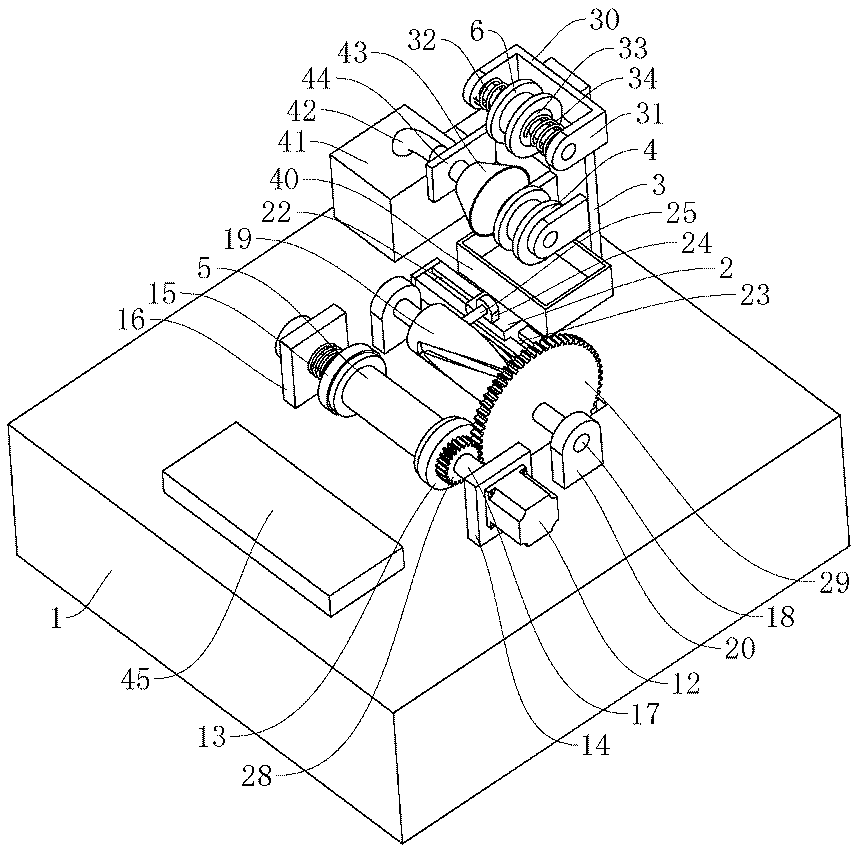

Low-power centrifugal pump directly driven by permanent-magnet synchronous motor

ActiveCN107355390ALow costEasy to pre-locateAC motor controlPump componentsPermanent magnet rotorSynchronous motor

A low-power centrifugal pump directly driven by a permanent-magnet synchronous motor comprises a centrifugal impeller and the motor, wherein the centrifugal impeller rotates in a fixed direction; the motor drives the impeller coaxially, a stator winding of the motor is connected with an alternating-current power supply in a specified winding direction, a rotor is a permanent-magnet rotor, and the number of poles of the rotor is the same as that of a stator; and in the free state, the axes of all the poles of the rotor deflect by certain acute angles in a preset deflection direction with the axis of the pole closest to the stator as the reference. The alternating-current power supply supplies power to the stator winding through a switch controlled by a control circuit. The number of the poles of the stator is two, and the diameter of the impeller is not larger than 70 mm; or the number of the poles of the stator is four, and the diameter of the impeller is not larger than 100 mm. A program set in the control circuit comprises the step that the switch is driven according to a detected signal to control the alternating-current power supply to supply power to the stator winding. Before the centrifugal pump starts, one pole surface of a stator core has the magnetism with the specified polarity. Through the design, the process of pre-positioning detection when a centrifugal pump starts in the prior art is omitted, the performance is improved, and the cost is reduced.

Owner:HANYU GRP CO LTD

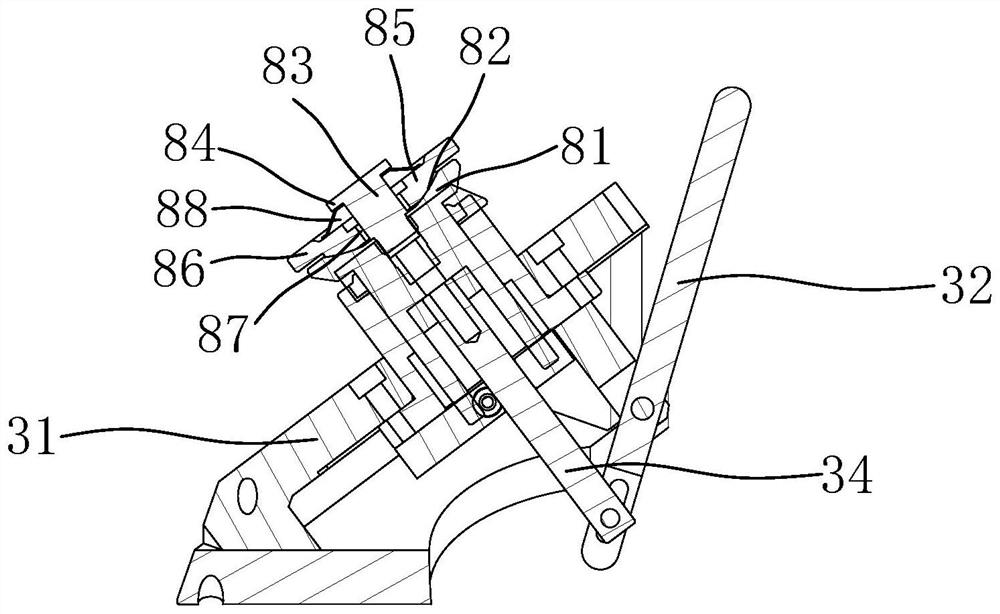

Rubber shell rotatable wiring terminal shell pre-inserting method and device

PendingCN109361132AReasonable structural designGuaranteed uptimeContact member assembly/disassemblyEngineeringSupport point

The invention discloses a rubber shell rotatable wiring terminal shell pre-inserting method and device. The method includes the steps: firstly, obliquely placing an inserting port of the tail end of arubber shell upwards; secondly, overlapping the inner bottom wall of the inserting port of the tail end of a rubber shell at the bottom of a wiring terminal; thirdly, rotating a head of the rubber shell upwards by taking an overlapping portion of the tail of the rubber shell and the wiring terminal as a rotatable supporting point, and enabling the wiring terminal to be pre-inserted into the rubber shell. The wiring terminal is pre-positioned in the rubber shell by a shell pre-inserting step. The shell pre-inserting method is implemented by an 'overlapping-rotating' mode, so that the wiring terminal can be excellently pre-positioned in the rubber shell, and smooth subsequent shell inserting steps can be facilitated.

Owner:东莞市超日自动化设备科技有限公司

Hole-opening equipment capable of opening hole stably used for lamp shell

The invention relates to the technical field of lamp processing, and discloses a hole-opening equipment capable of opening the a hole stably used for a lamp shell. The hole-opening equipment used forthe lamp shell comprises an operation table, a sliding block is movably connected to the top of the operation table through a supporting frame, and an inserting plate is fixedly connected with the bottom of the sliding block through a hydraulic rod; a punching machine is fixedly connected to the bottom of the inserting plate, and a threaded rod is in threaded connection with the top of the slidingblock; the bottom of the threaded rod is fixedly connected with the supporting frame through a fixing block, an inserting rod is connected to the bottom of the side face of the inserting plate in aninserting mode, and the bottom of the inserting rod is fixedly connected with the top of the operation table; a fixing sleeve is fixedly connected with the top of the operation table through a fixingplate, and a shell body is connected in the fixing sleeve in a clamping mode; and the top of the fixing plate is fixedly connected with the shell body through a telescopic rod. According to the hole-opening equipment capable of opening the hole stably used for the lamp shell, the sliding block and the supporting frame are fixed through the fixing block by adjusting the threaded rod, and fixing ofthe position of the punching machine is convenient; stability of punching is enhanced by pre-positioning of the inserting plate by the inserting rod and fixing of the telescopic rod and the shell body.

Owner:江苏大浪电气集团有限公司

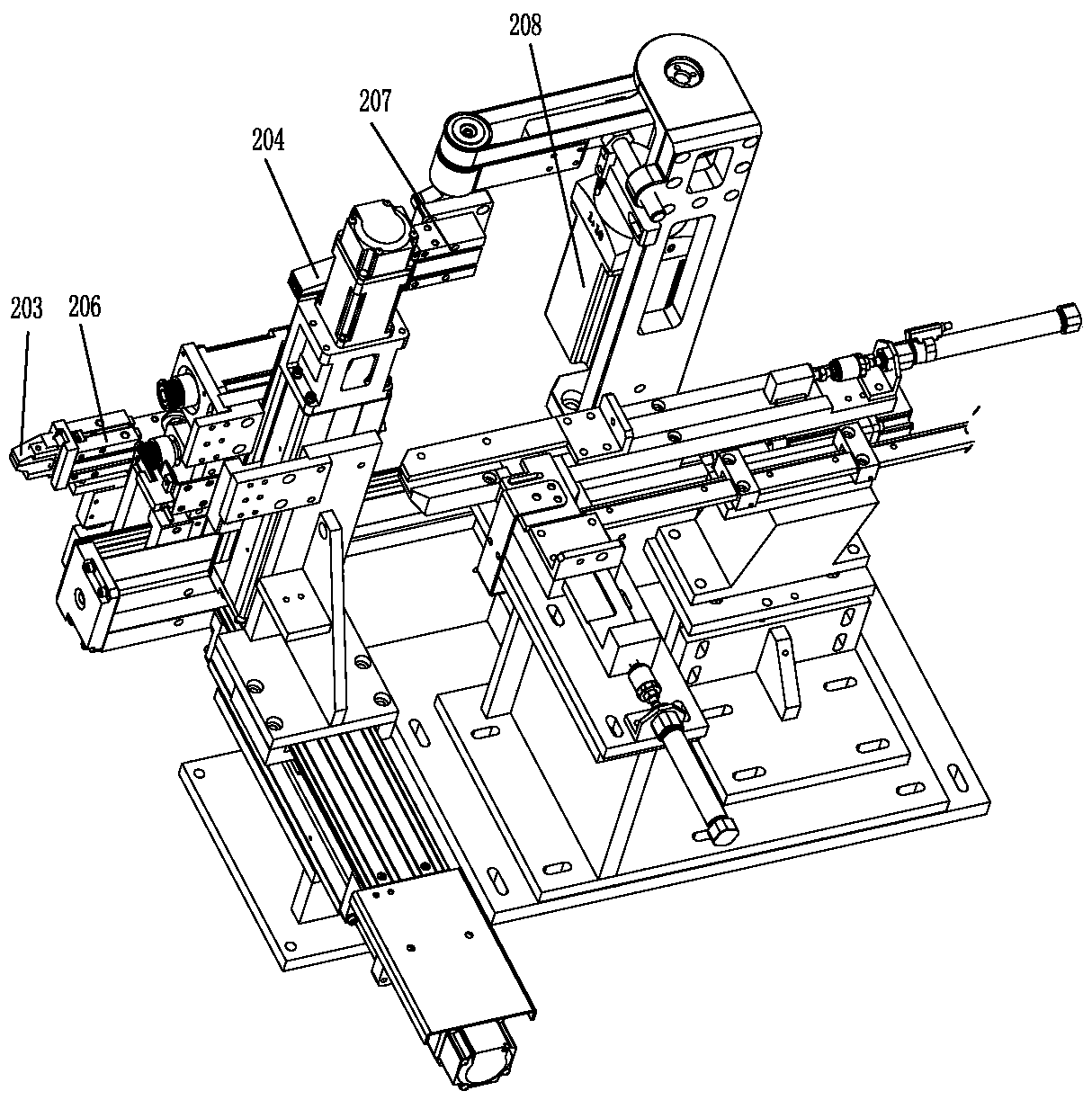

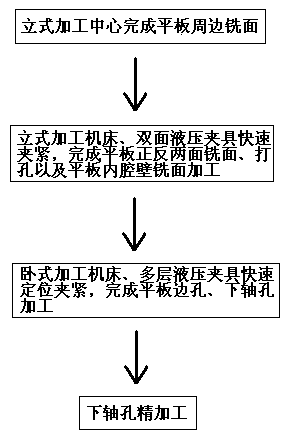

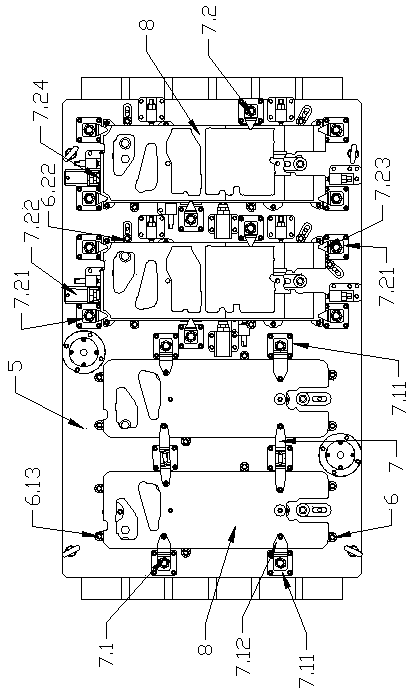

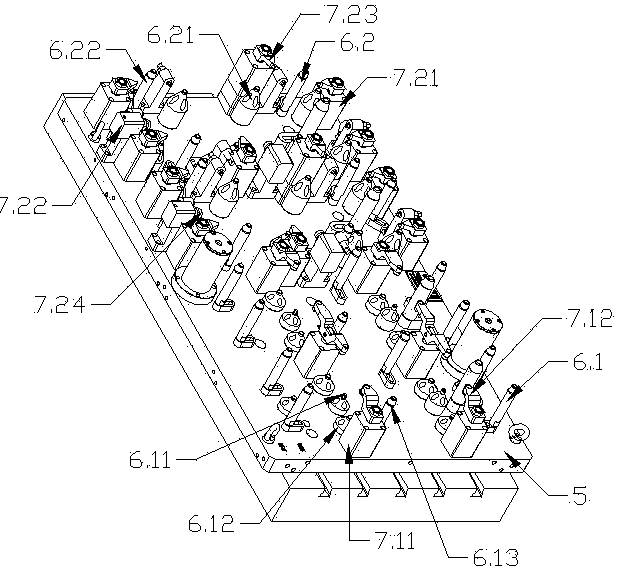

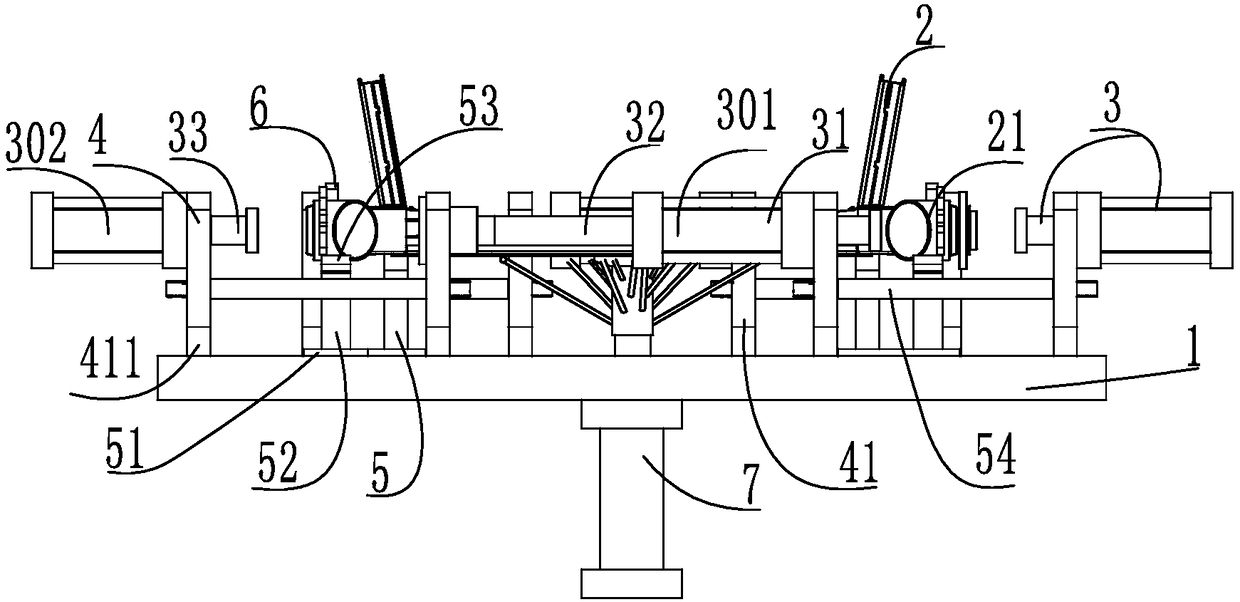

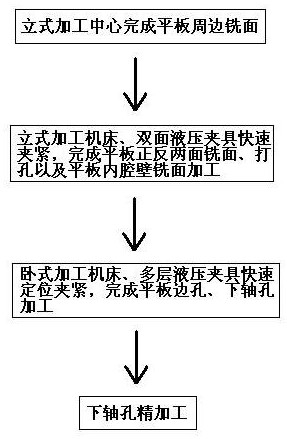

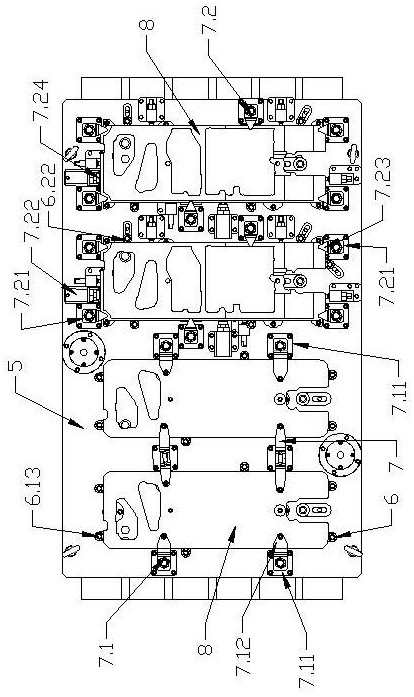

Process for quickly machining sewing machine flat plates

ActiveCN109352290ARapid positioningQuick clampingWork clamping meansPositioning apparatusPunchingRapid processing

The invention discloses a process for quickly machining sewing machine flat plates. The process comprises the following steps of finishing milling of the peripheries of the flat plates through a vertical machining center; quickly clamping the plurality of flat plates through a double-side hydraulic clamp on a vertical machining machine tool to finish milling and punching of the front surfaces andback surfaces of the flat plates and milling of inner cavity walls of the flat plates; quickly positioning and clamping the plurality of flat plates through a multi-layer hydraulic clamp on a horizontal machining machine tool so as to finish the machining of edge holes of the flat plates and lower shaft holes in the middle; and carrying out four working procedures including fine machining on mainholes of the flat plates. By means of the process, the machining of the flat plates can be completed by just the four working procedures, quick positioning and quick clamping are realized, the efficacy and the yield per unit time are improved, and the machining precision is ensured.

Owner:湖南凯斯机械股份有限公司

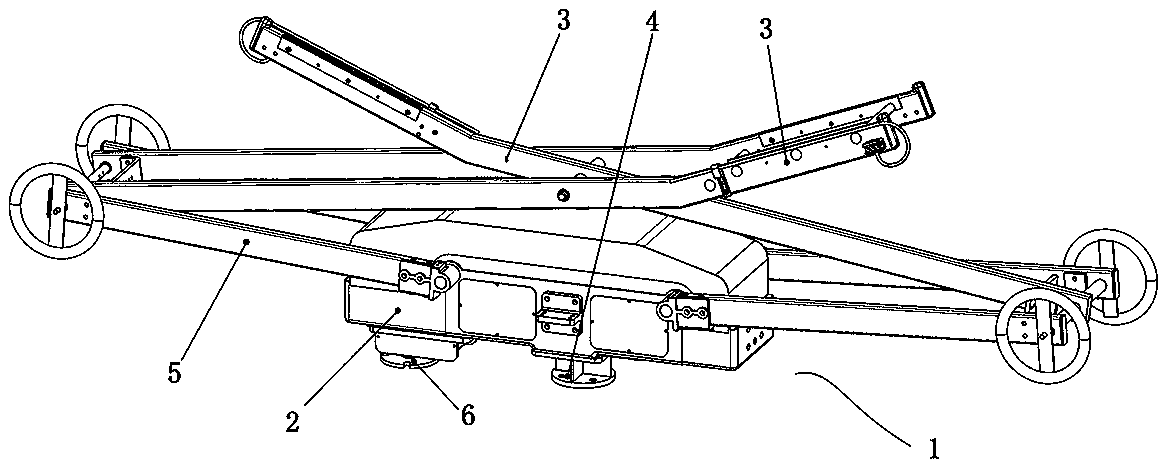

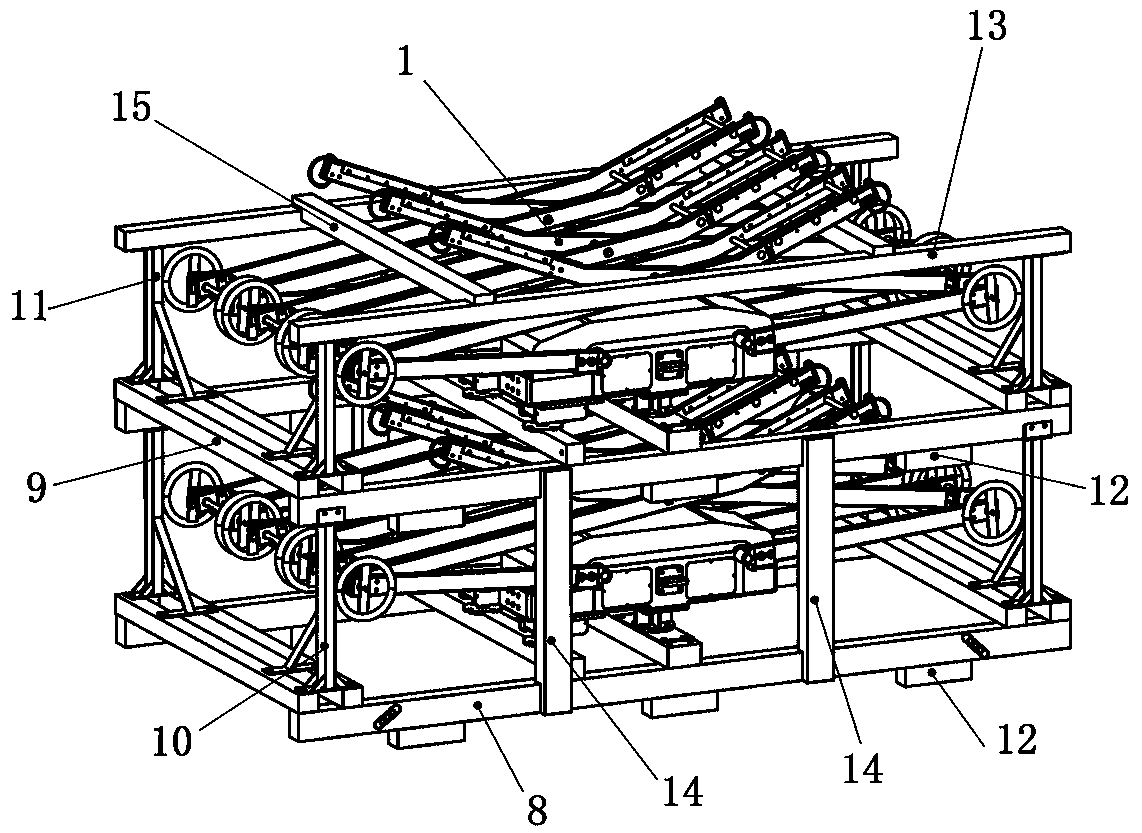

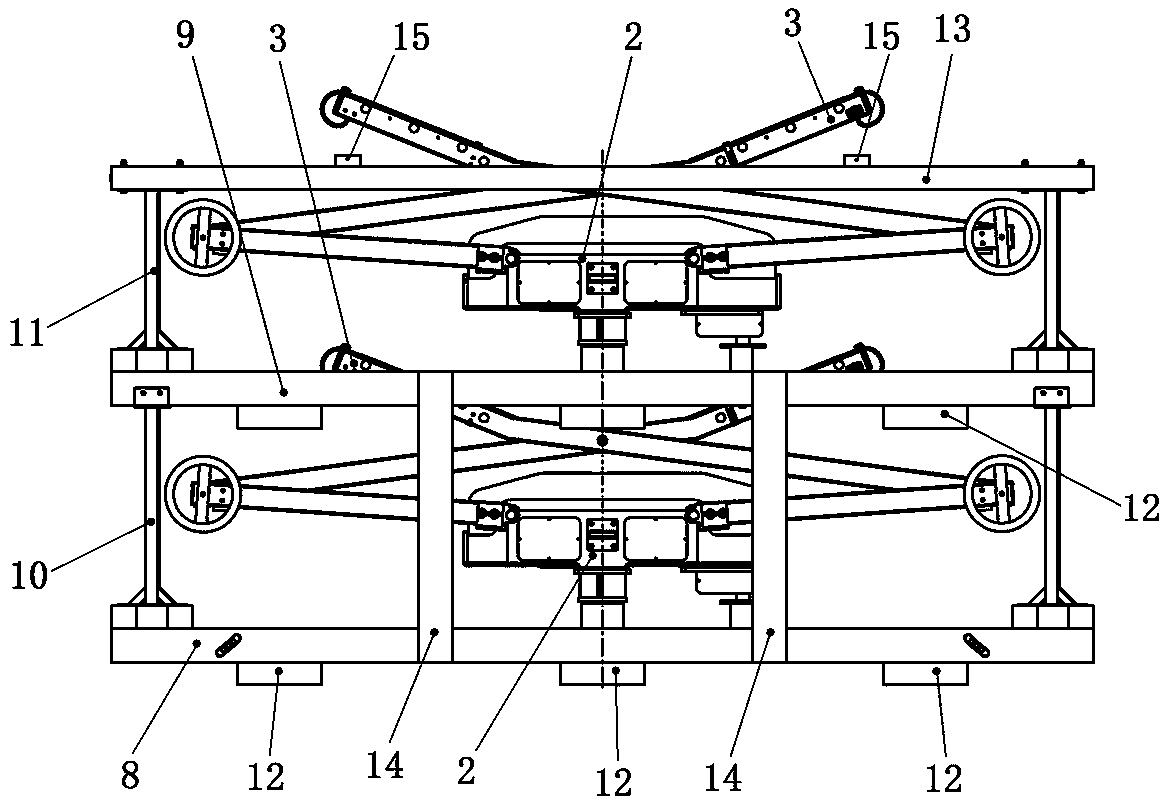

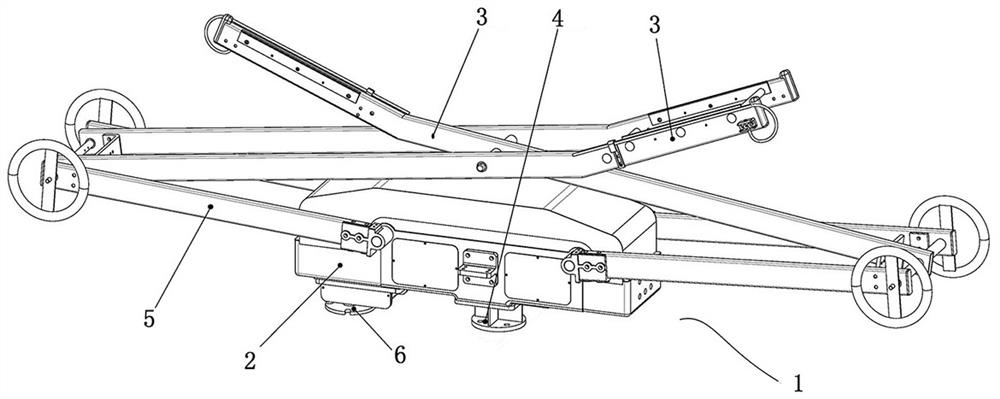

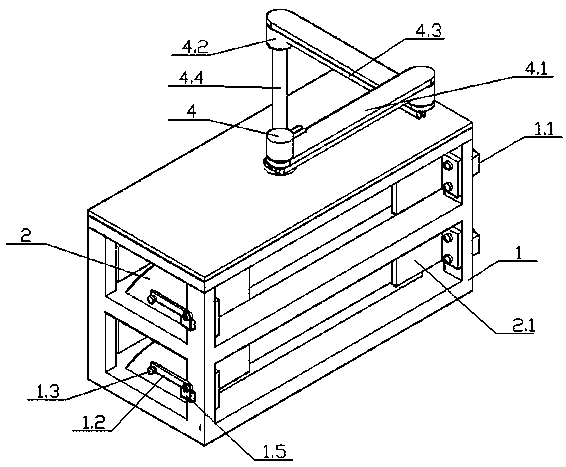

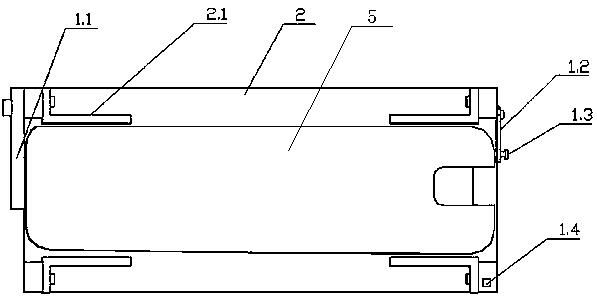

Scissor-type isolating switch packaging structure

ActiveCN110155458ASmall footprintImprove transportation efficiencyPackaging vehiclesContainers for machinesEngineering

The invention relates to a scissor-type isolating switch packaging structure. The scissor-type isolating switch packaging structure comprises at least two layers of brackets which are arranged up anddown, and the two adjacent layers of brackets cooperate with each other in a supporting mode; each bracket comprises a bottom frame which is used for supporting and fixing scissor-type isolating switches, and each bottom frame comprises a fixing part which is used for fixing the scissor-type isolating switches and enabling the hinge axes of conductive tubes of the scissor-type isolating switches to extend in the front-back direction; and the upper layer bracket comprises containing spaces which are located on the left side and the right side of the corresponding fixing part and used for allowing the tops of the conductive tubes of the scissor-type isolating switches supported by the lower layer bracket to stretch into the upper layer bracket. In the bracket stacking process, parts of the conductive tubes of the scissor-type isolating switches located on the bottom frame of the lower layer bracket stretch into the upper layer bracket, thus, the scissor-type isolating switches on the upper layer bracket and the lower layer bracket are partially overlapped in the vertical direction, compared with the mode that in the prior art, scissor-type isolating switches are completely separated,the occupied space is decreased, and the conveying efficiency is improved.

Owner:HENAN PINGGAO ELECTRIC +2

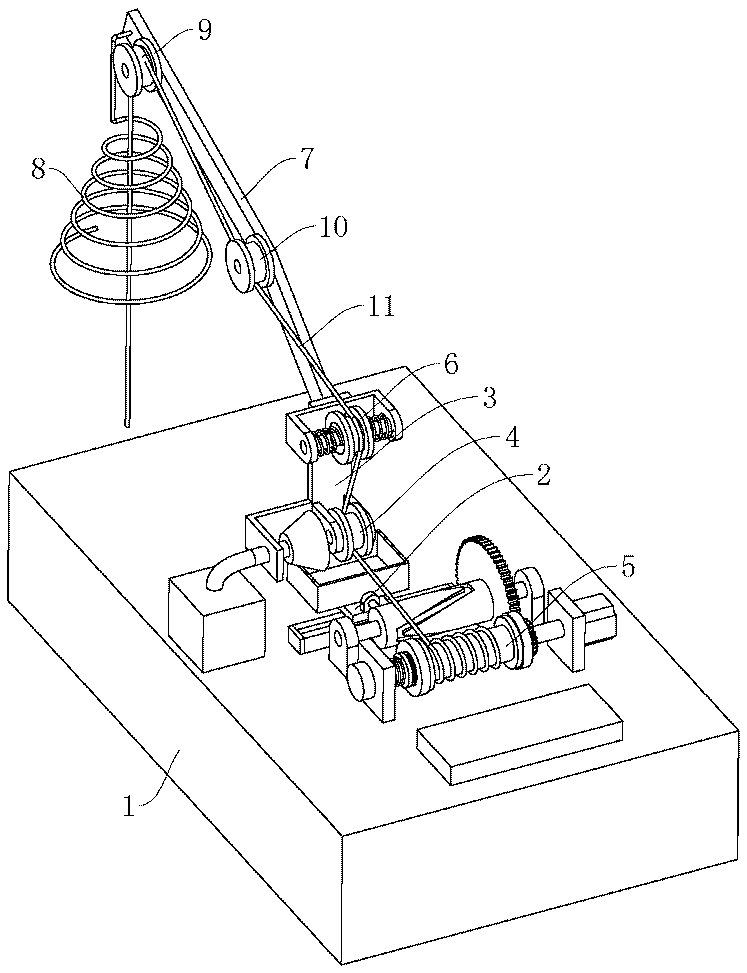

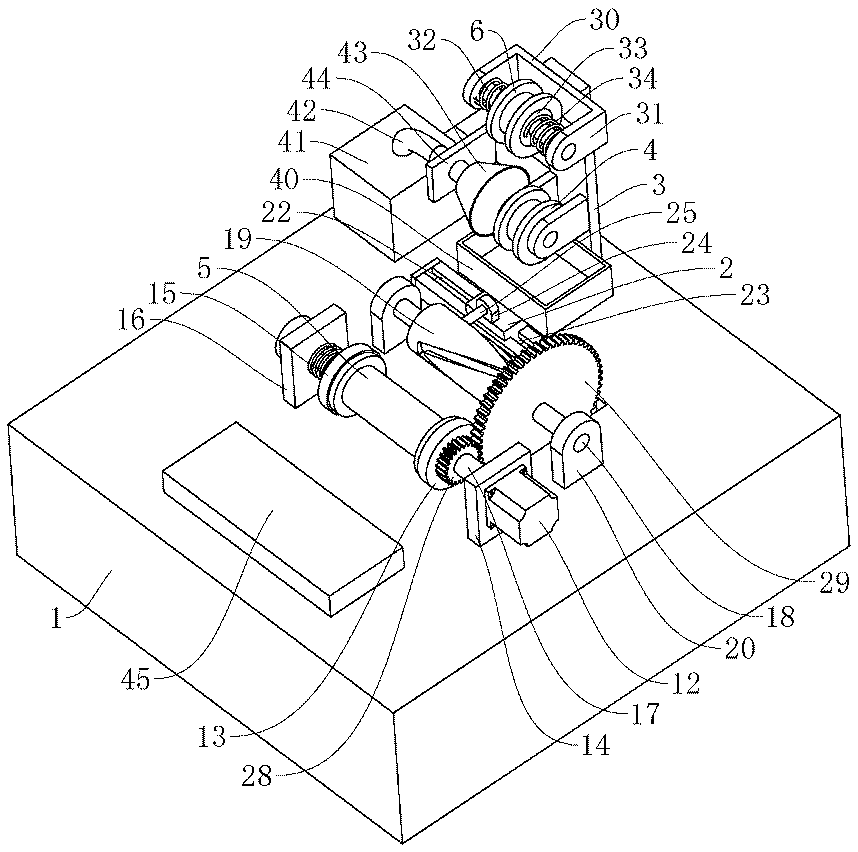

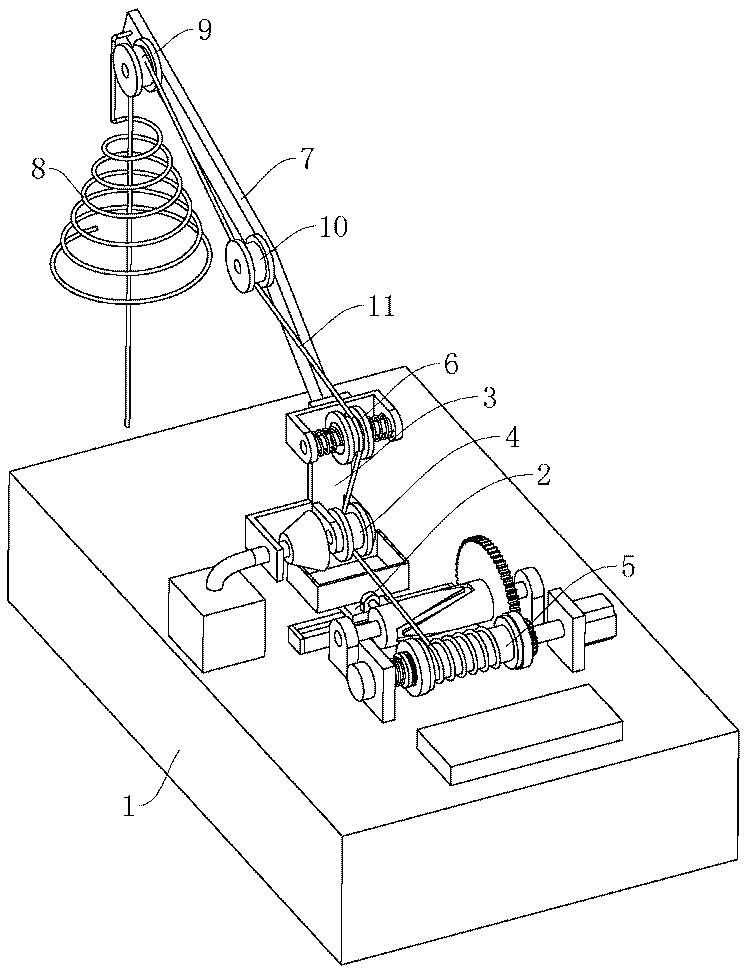

Automatic winding device for tin welding wire and winding method thereof

The invention relates to an automatic winding device for a tin welding wire and a winding method thereof, and relates to the field of tin welding material processing equipment. The automatic winding device comprises a workbench, a winding assembly arranged on the workbench and used for driving an I-shaped cylinder to rotate, a sliding strip horizontally sliding on the workbench, a connecting striparranged on the sliding strip, a lower guide wheel rotationally connected to the connecting strip and used for guiding the tin wire, and a linkage assembly arranged on the workbench, wherein the linkage assembly drives the sliding strip to do reciprocating motion in the length direction of the I-shaped cylinder. According to the automatic winding device, the winding assembly, the lower guide wheel and the linkage assembly are arranged on the workbench, the winding assembly drives the I-shaped cylinder to rotate, the tin wire can be wound on the I-shaped cylinder, the linkage assembly drives the lower guide wheel to do reciprocating motion in the length direction of the I-shaped cylinder through the connecting strip, so that the lower guide wheel can guide the tin wire, and the tin wire isuniformly wound on the I-shaped cylinder.

Owner:GUANGDONG ANSON SOLED & TIN PROD MADE

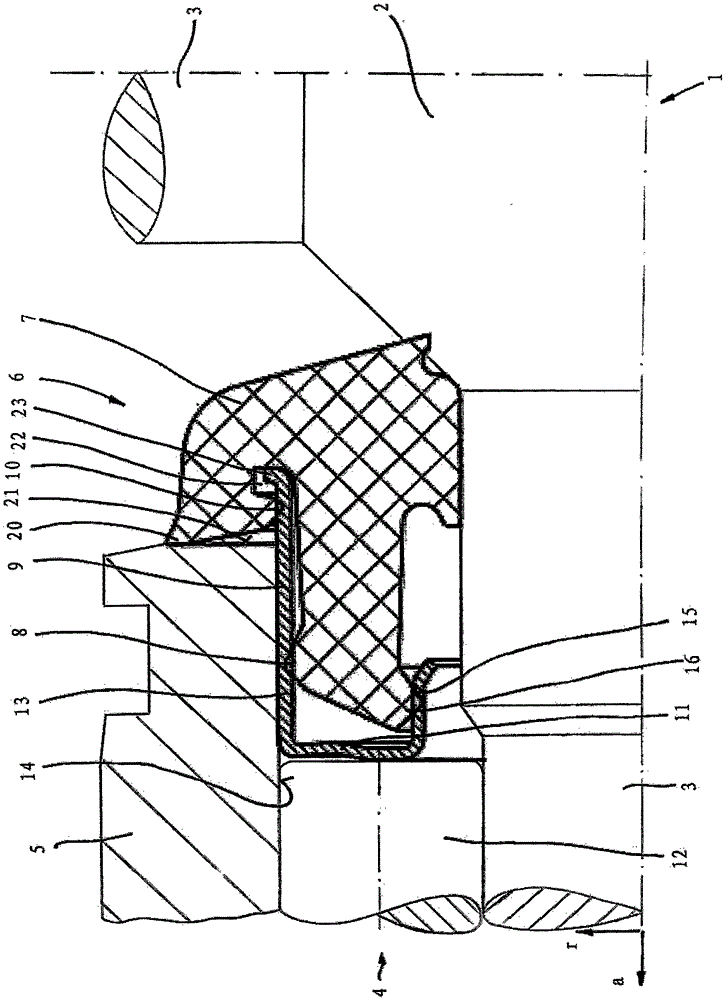

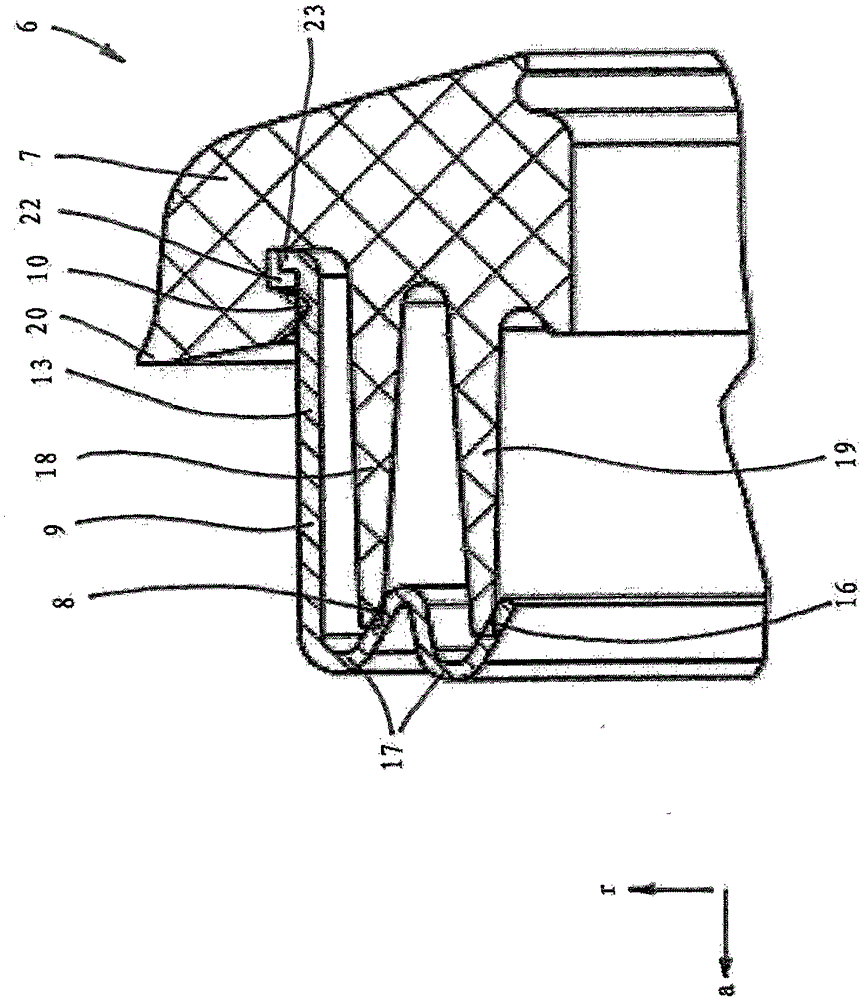

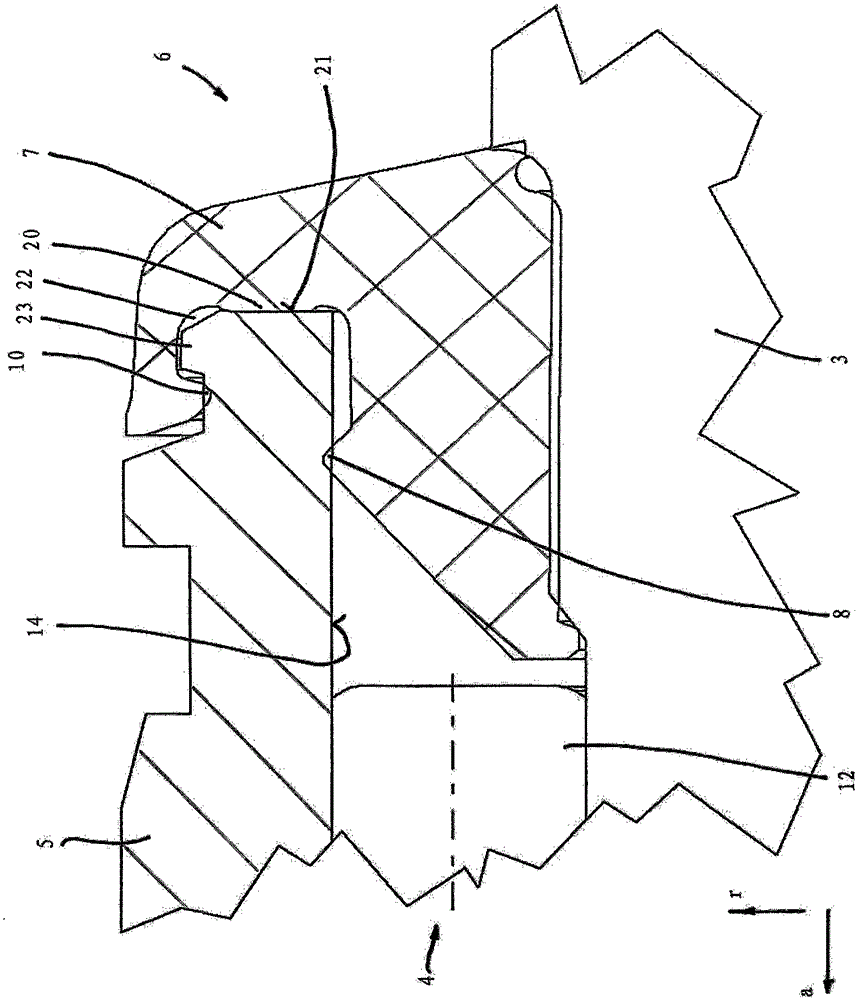

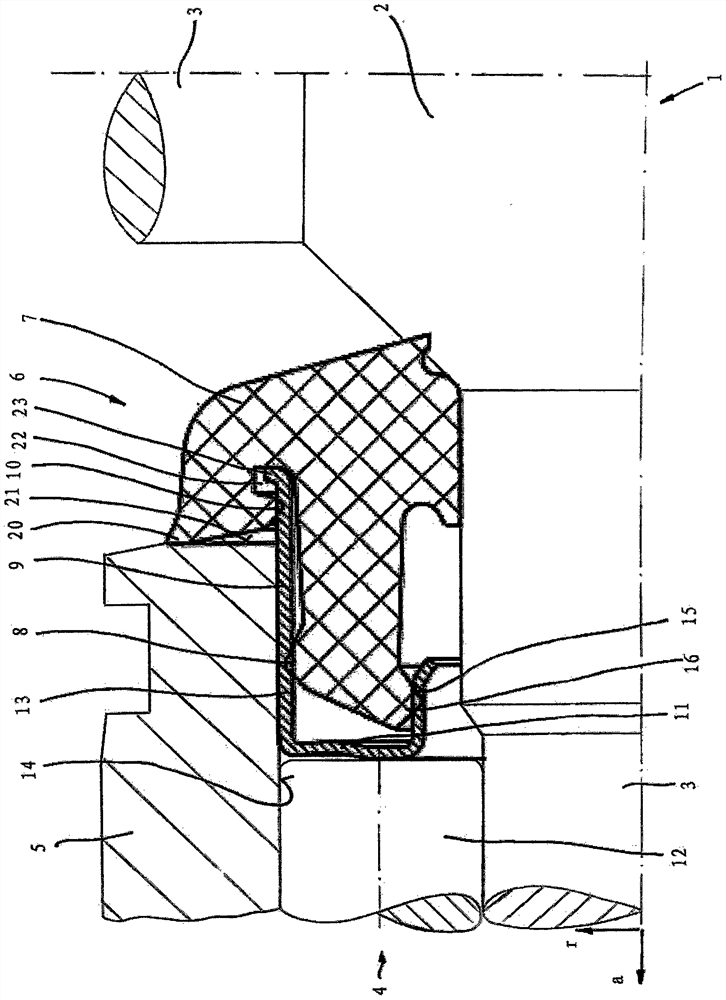

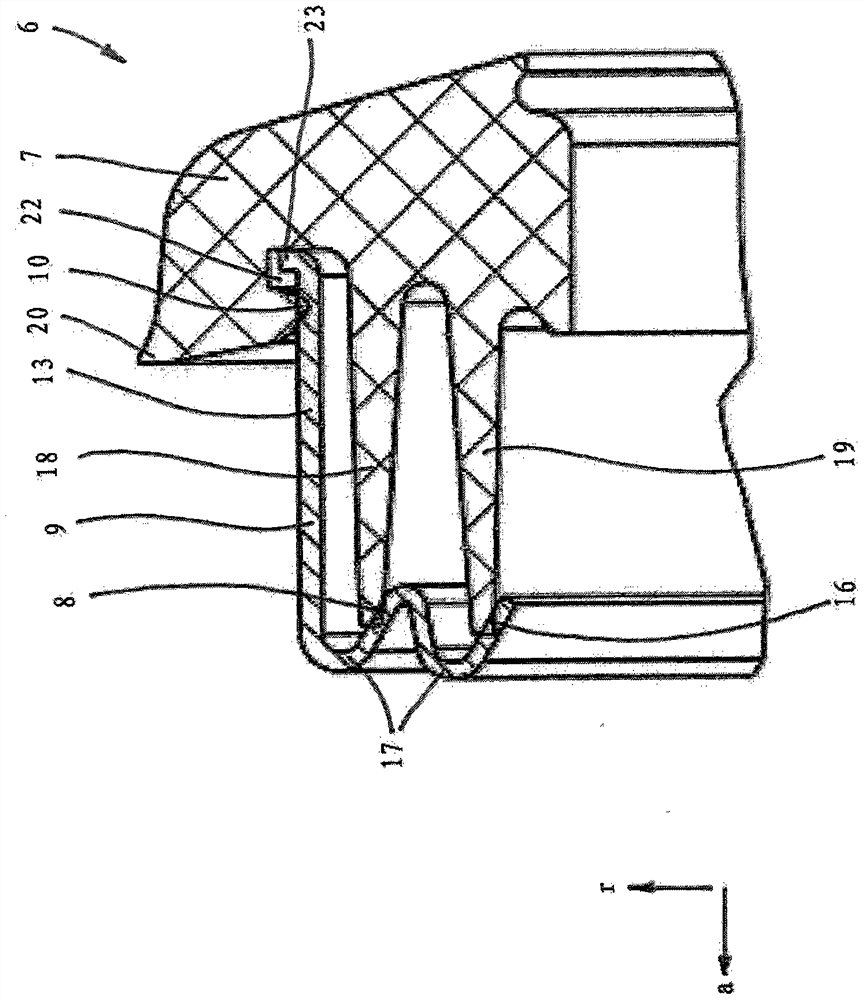

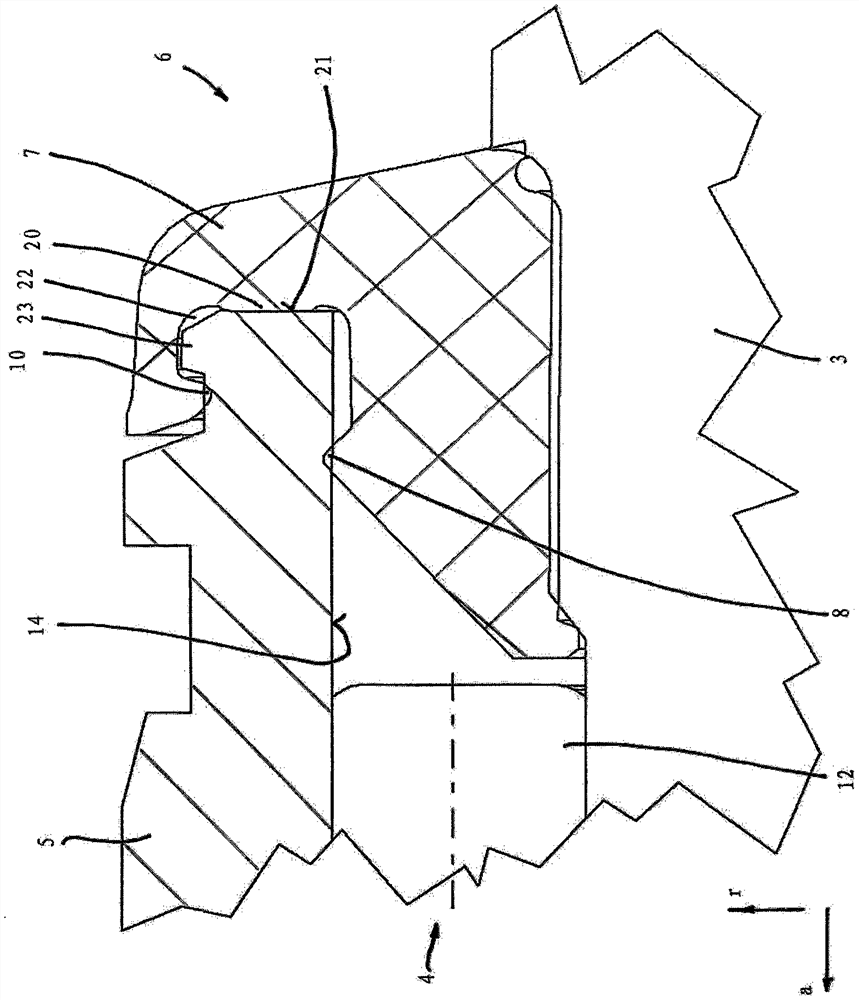

Universal joint

ActiveCN105465204AReduce or prevent biasCheap manufacturingClutchesYielding couplingUniversal jointEngineering

A universal joint including a joint cross has a plurality of bearing journals supported in a trunnion bearing having a bearing bushing and a seal assembly including a one-piece seal body sealing the journal cross against the bearing bushing, the seal body having a first lip configured to form a dynamic seal on the bearing bushing or on a U-shaped sleeve connected to the bearing bushing, a second lip configured to form a dynamic seal on the bearing bushing or on the sleeve, a first arm of the sleeve being press-fit in a cylindrical receiving surface of the bearing bushing, or the sleeve having a section that is rounded or doubly corrugated in radial section, or wherein between the seal body and rolling elements of the trunnion bearing a separate ring part is disposed and pressed towards the rolling elements by at least one elastic element projecting from the seal body.

Owner:AB SKF

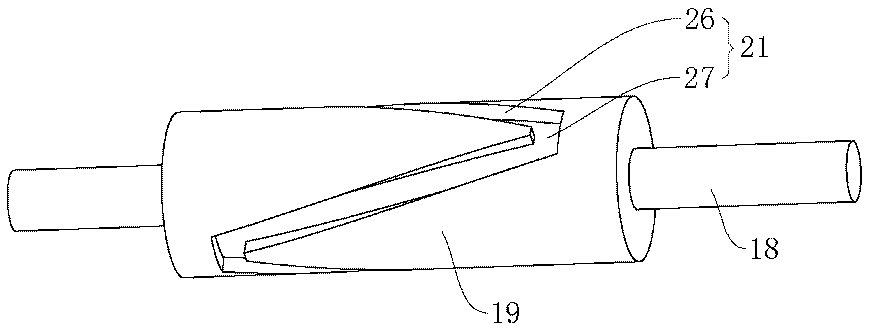

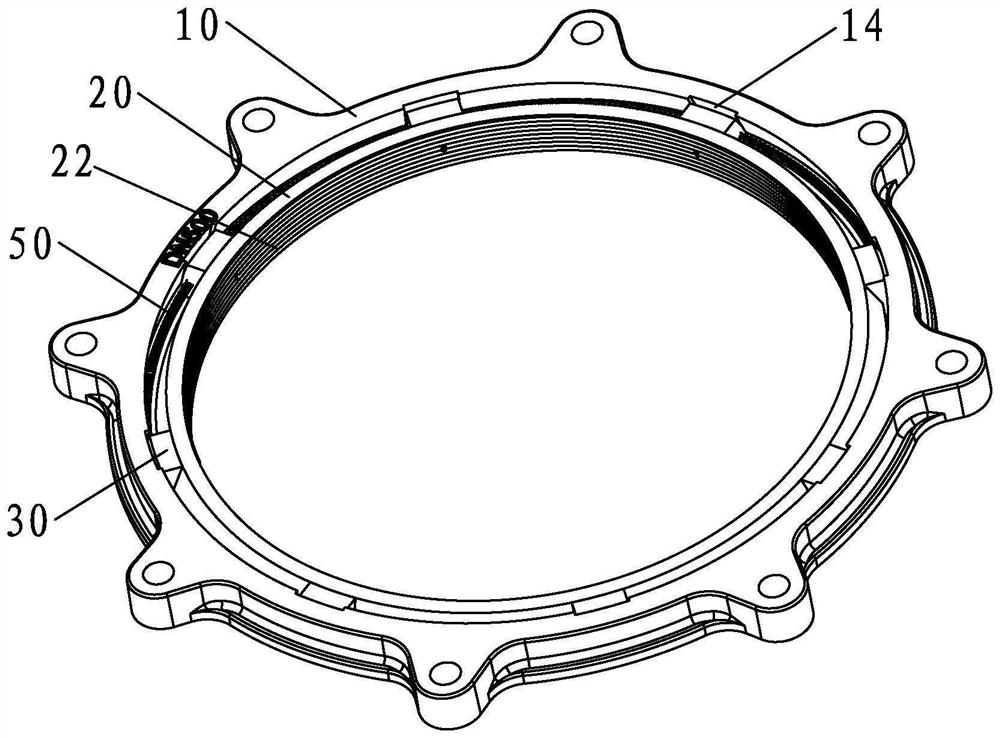

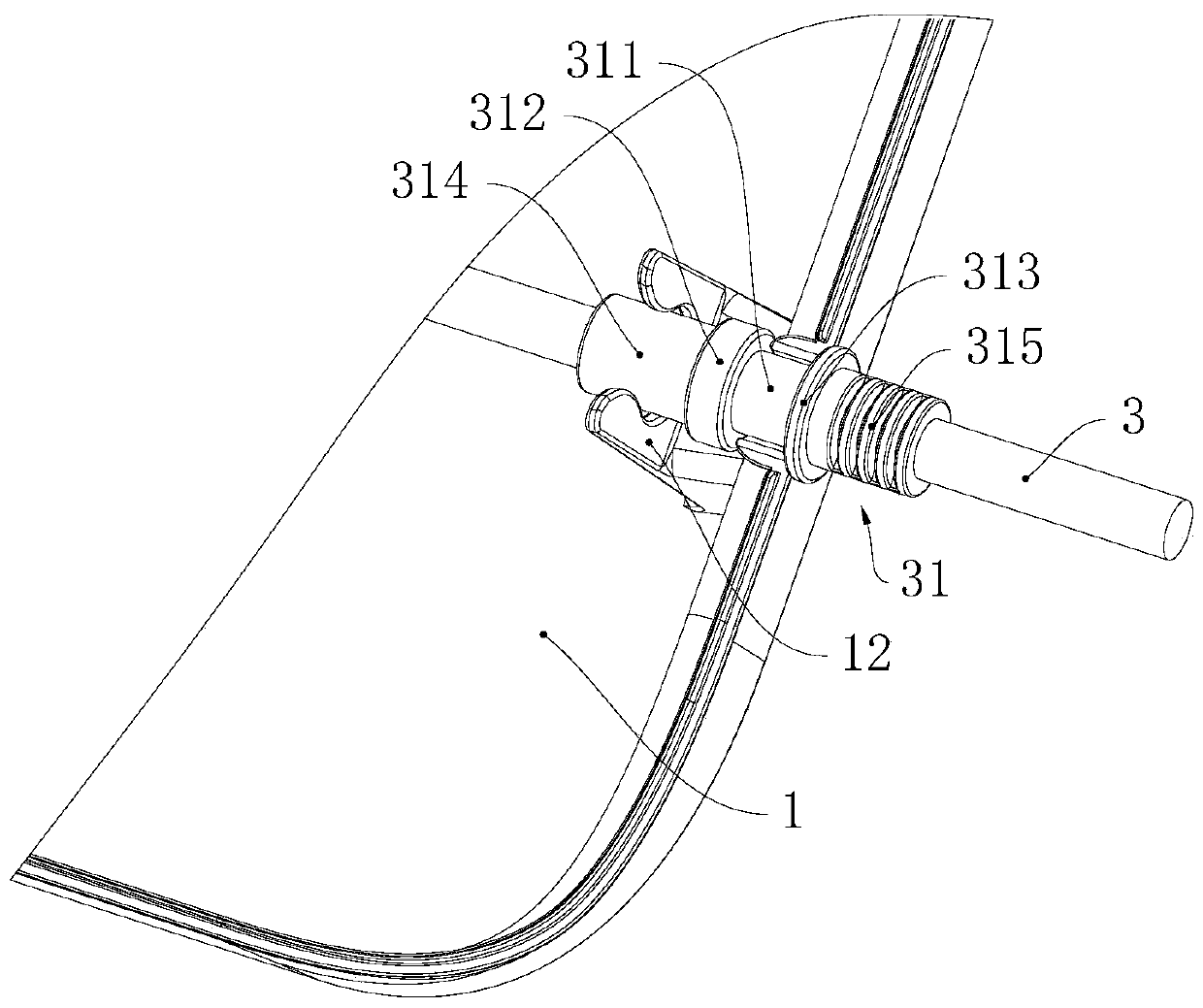

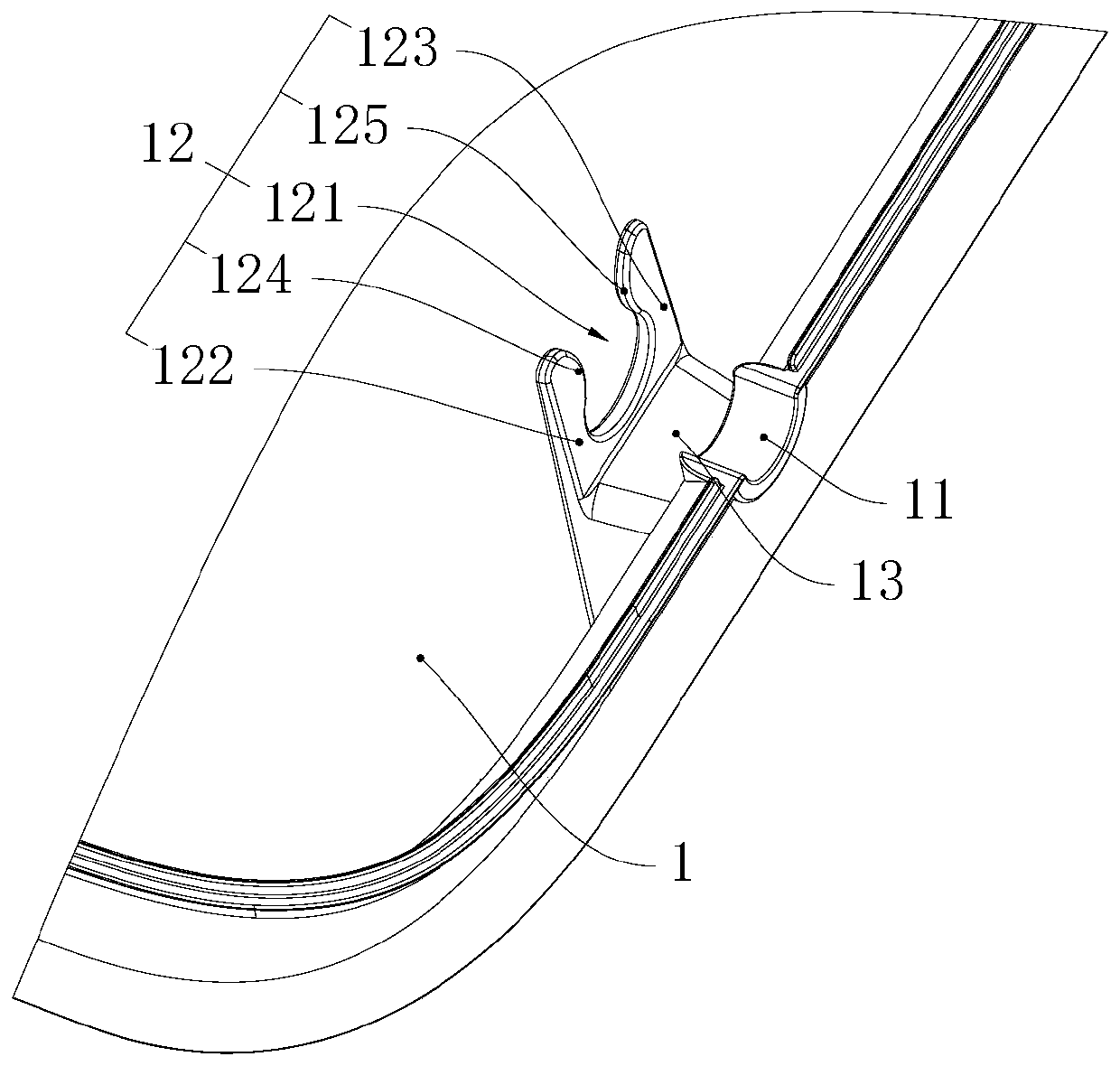

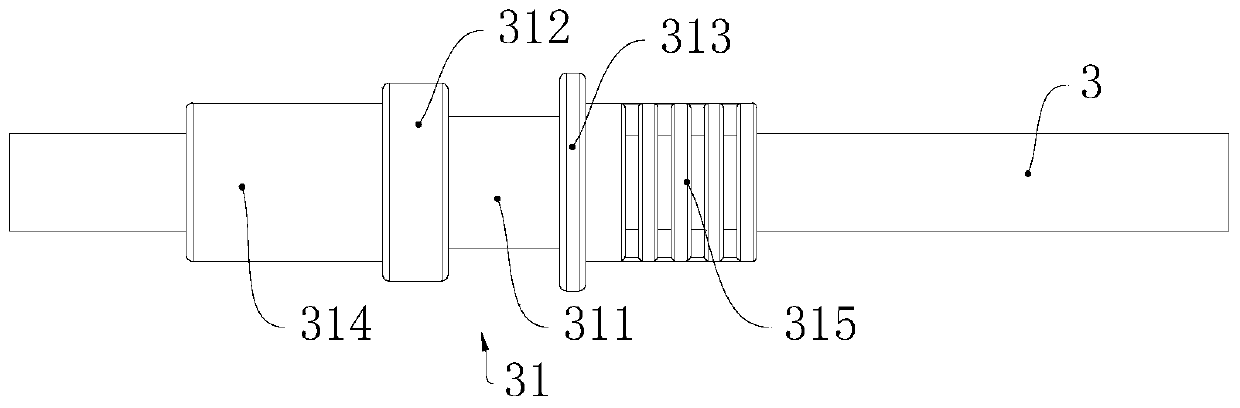

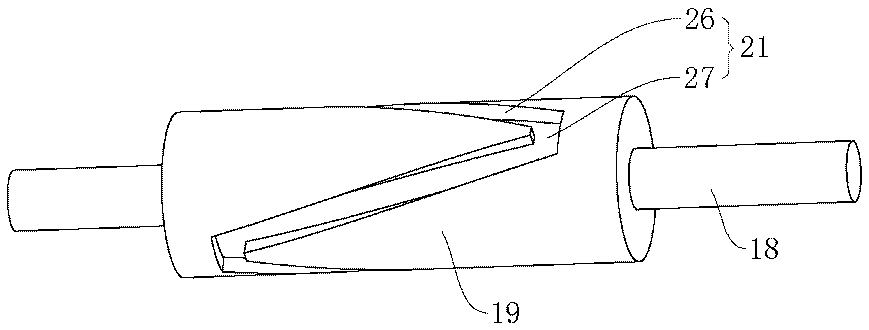

Small-power ventilator directly driven by permanent-magnet synchronous electromotor

PendingCN107165843ALow costEasy to pre-locatePump componentsPump controlPermanent magnet rotorAcute angle

The invention provides a small-power ventilator directly driven by a permanent-magnet synchronous electromotor. The small-power ventilator comprises an impeller and the electromotor directly driving the impeller, wherein the impeller performs directional rotation and is formed through injection moulding, a stator winding of the electromotor is connected with an alternating-current power source according to the stipulated winding direction, a rotor is a permanent magnet rotor and is of the same number of poles as that of a stator, and in a free state, the axes of all poles of the rotor are deviated by an acute angle in the predetermined rotation direction with the axis of the closest pole of the stator being the reference. The alternating-current power source supplies power to the stator winding through a switch controlled by a control circuit. When the number of poles of the stator is four, the diameter of the impeller is smaller than or equal to 100 mm, or when the number of poles of the stator is six, the diameter of the impeller is smaller than or equal to 130 mm, or when the number of poles of the stator is eight, the diameter of the impeller is smaller than or equal to 150 mm; a built-in program of the control circuit comprises the step that the switch is driven according to the detected signal so as to control the alternating-current power source to supply power to the stator winding; and before the ventilator is started, one pole face of a stator iron core represents magnetism of the stipulated polarity. By means of the design, the prepositioning detection process performed when a ventilator of the traditional technology is started is omitted, performance is improved, and the cost is lowered.

Owner:广州市先河技术工程有限公司

Two-time insertion mode flexible circuit board terminal shell insertion method and device

PendingCN109449718AReduce defective rateImprove assembly qualityContact member assembly/disassemblyFlexible circuitsEngineering

The invention discloses a two-time insertion mode flexible circuit board terminal shell insertion method and device. A first flexible circuit board clip and a second flexible circuit board clip are set in sequence from a terminal end of a flexible circuit board along an extension direction of the flexible circuit board. The first flexible circuit board clip is located between a flexible circuit board terminal and the second flexible circuit board clip. Shell insertion steps comprise the fact that S1, the first flexible circuit board clip is opened, the second flexible circuit board clip positions the flexible circuit board, and a plastic shell is displaced towards the extension direction of the flexible circuit board from the terminal end of the flexible circuit board, so first soft insertion is formed; and S2, the first flexible circuit board clip is closed to position the flexible circuit board, and the plastic shell is displaced towards the extension direction of the flexible circuit board from the terminal end of the flexible circuit board, so second soft insertion is formed. Through the first soft insertion and the second soft insertion, flexible circuit board terminal shell insertion is realized; and in a two-time insertion mode, the shell insertion is relatively precise, the flexible circuit board terminal and / or the plastic shell is prevented from being damaged, a shellinsertion reject ratio is reduced, and flexible circuit board terminal shell insertion assembly quality is improved.

Owner:东莞市超日自动化设备科技有限公司

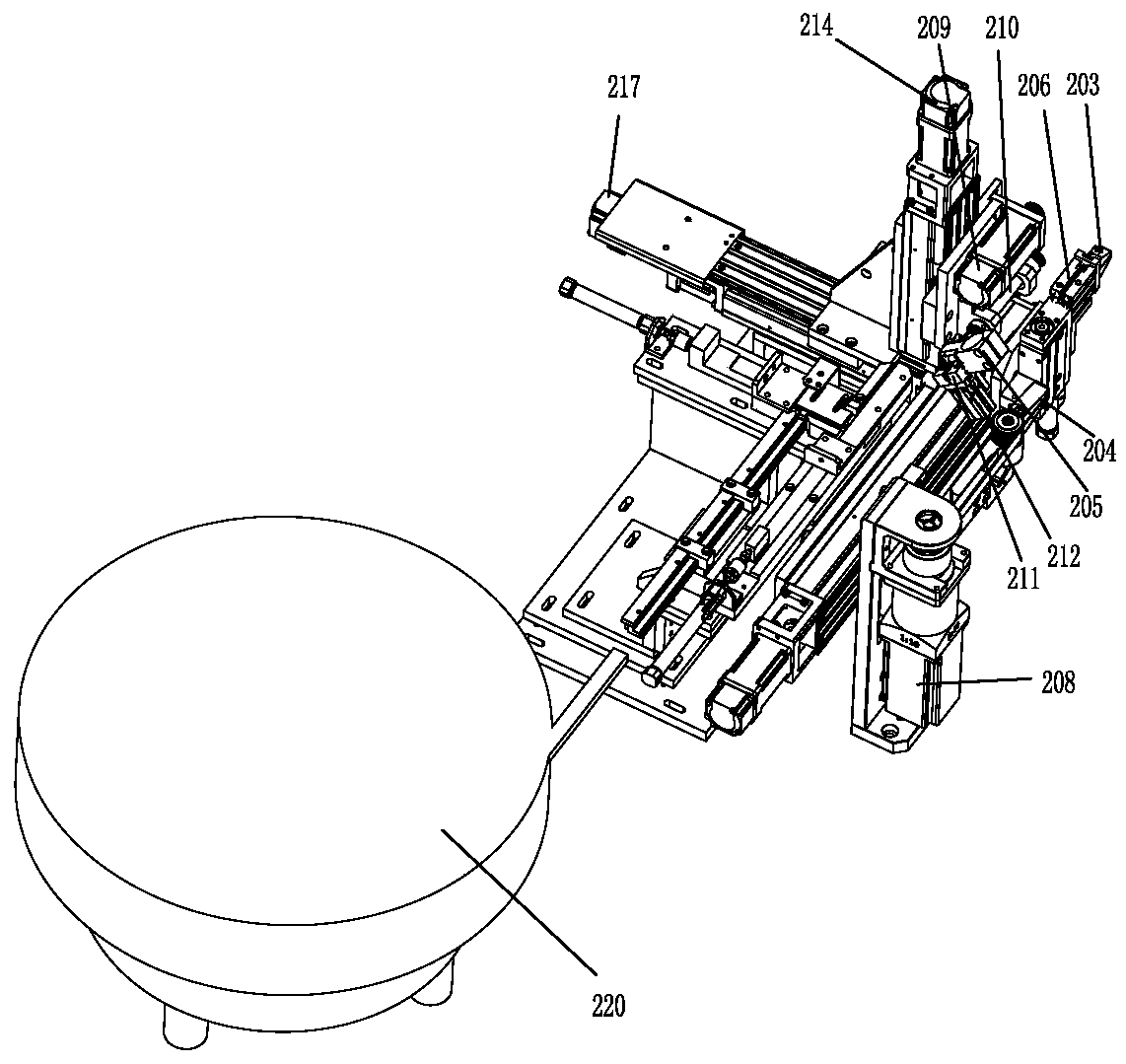

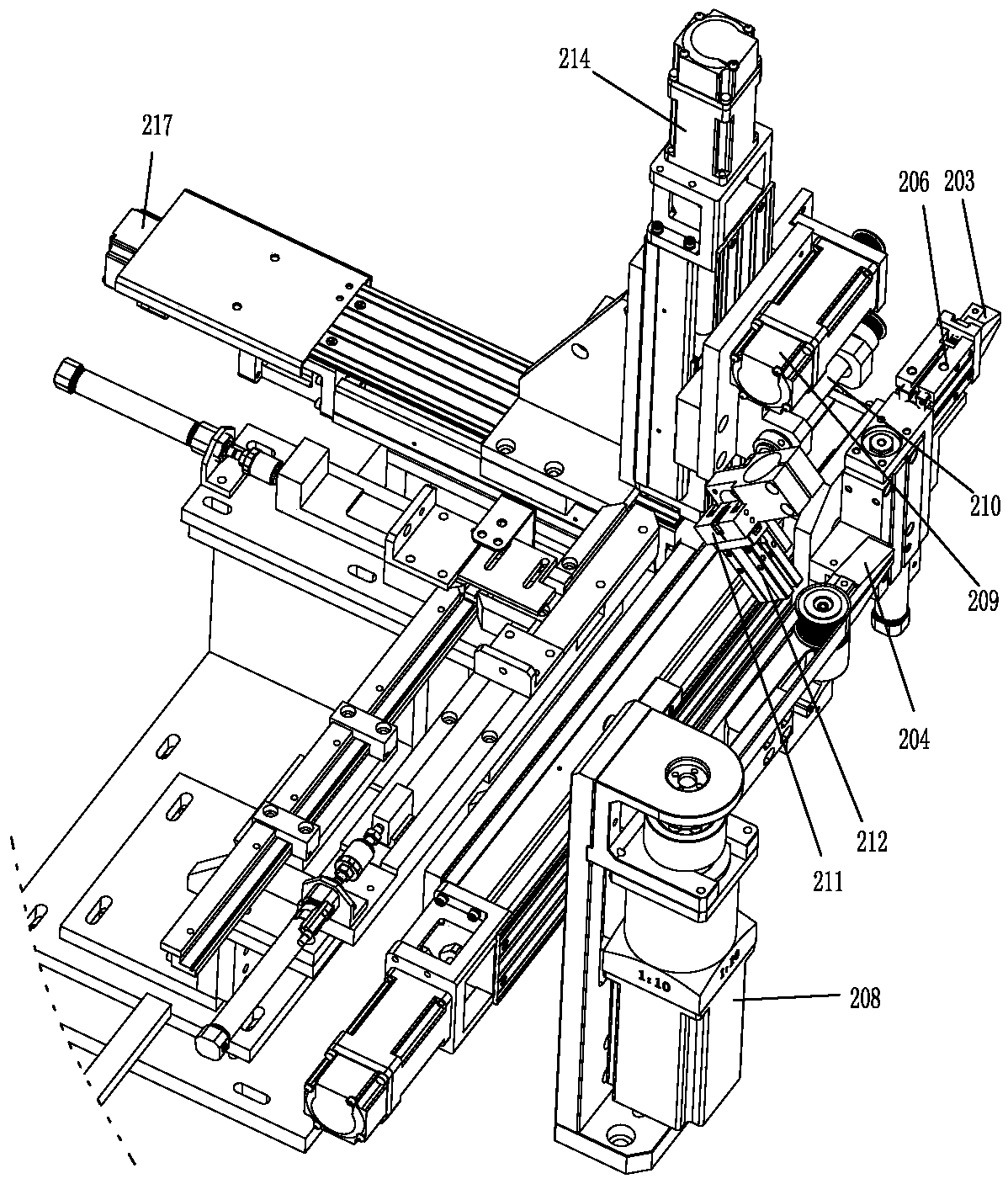

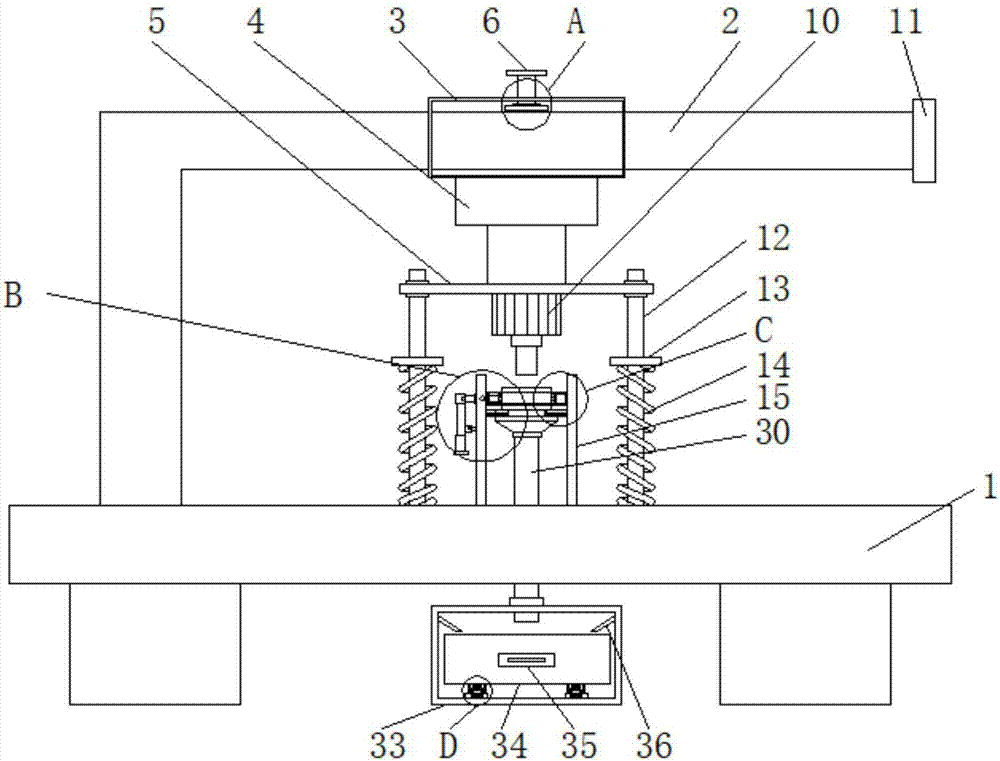

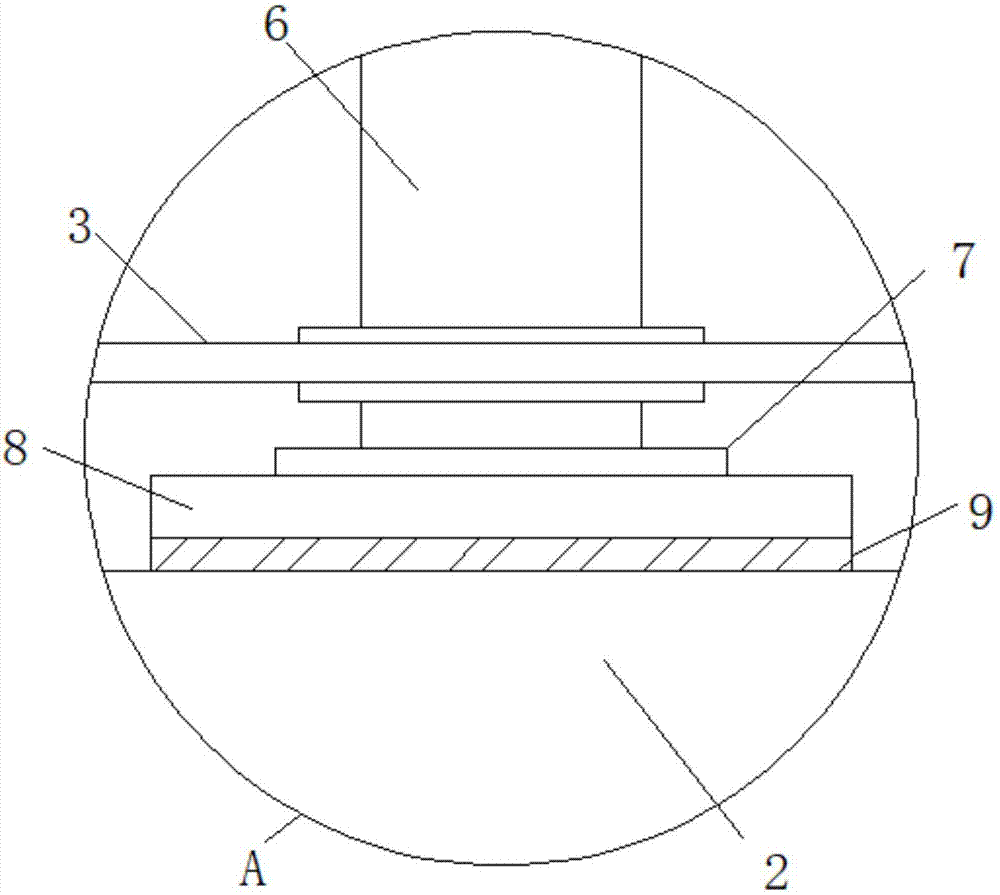

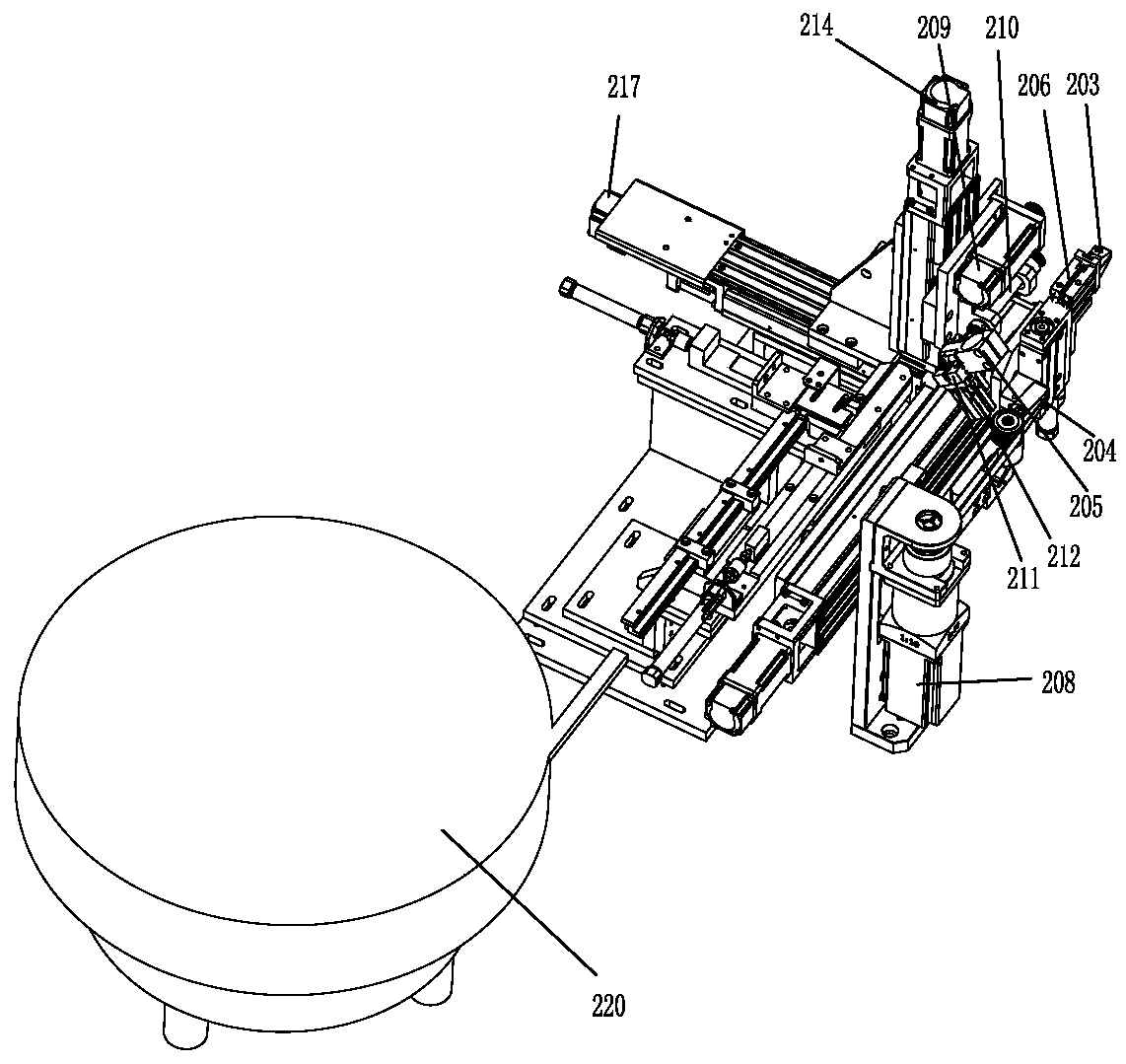

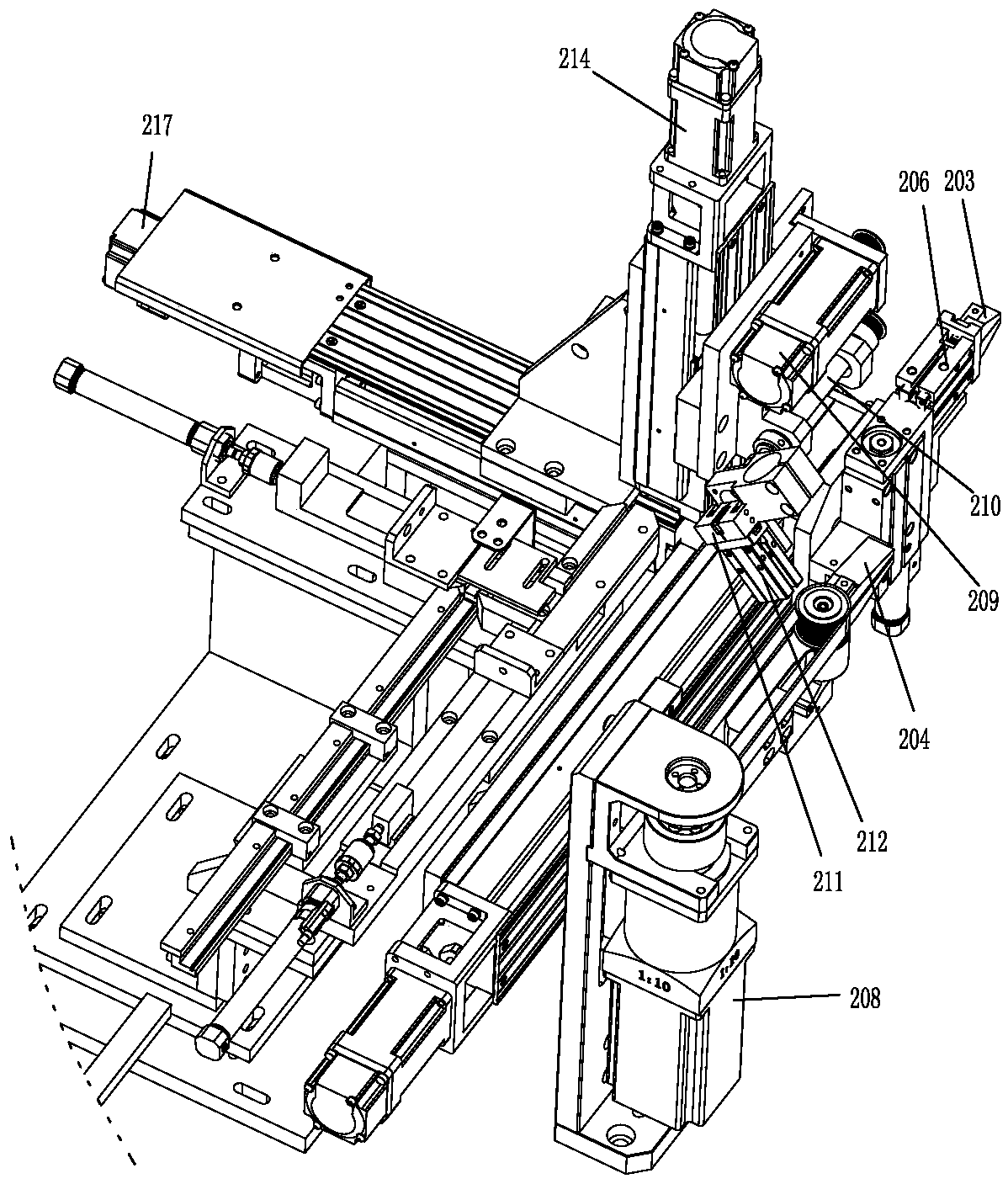

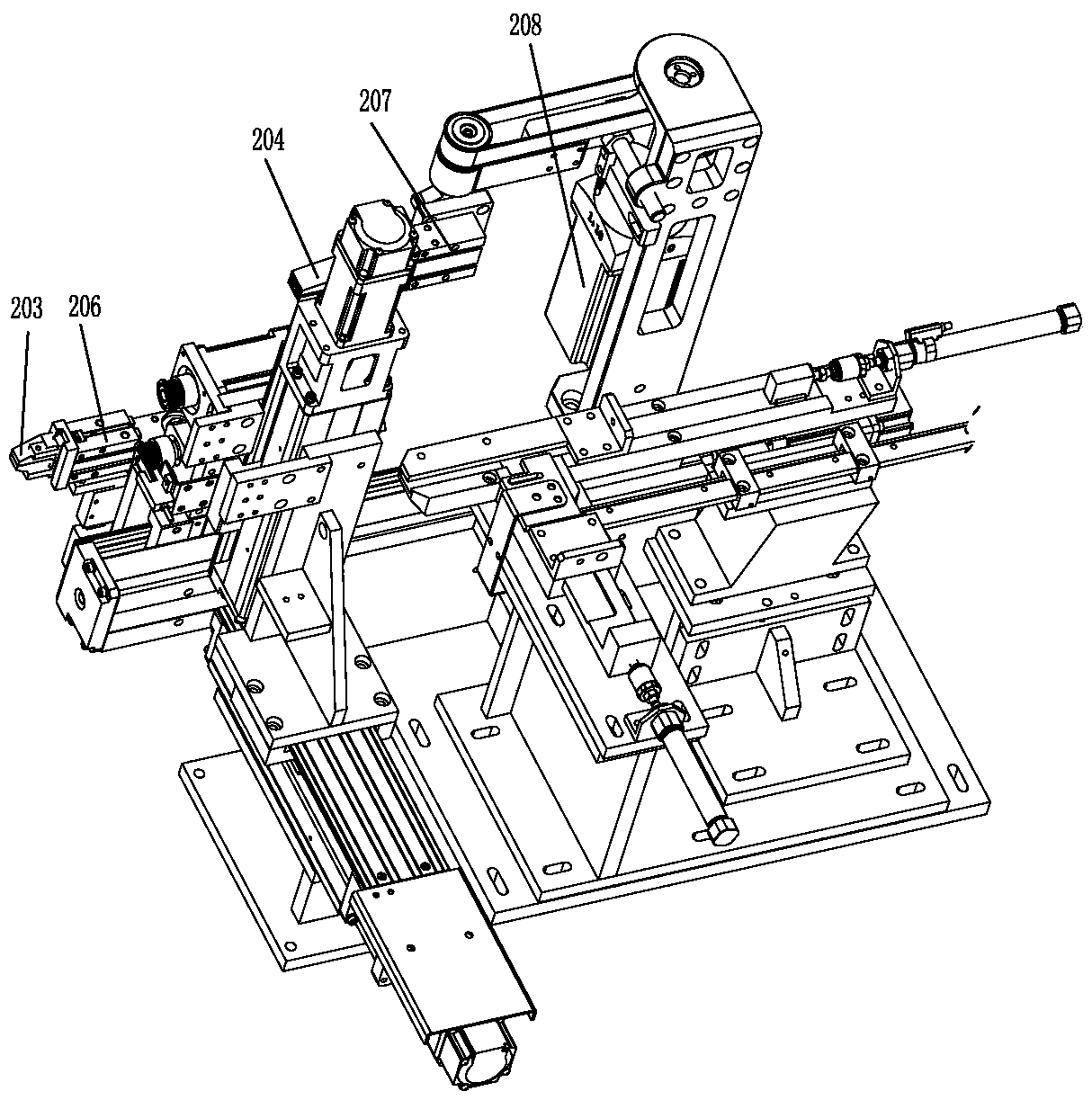

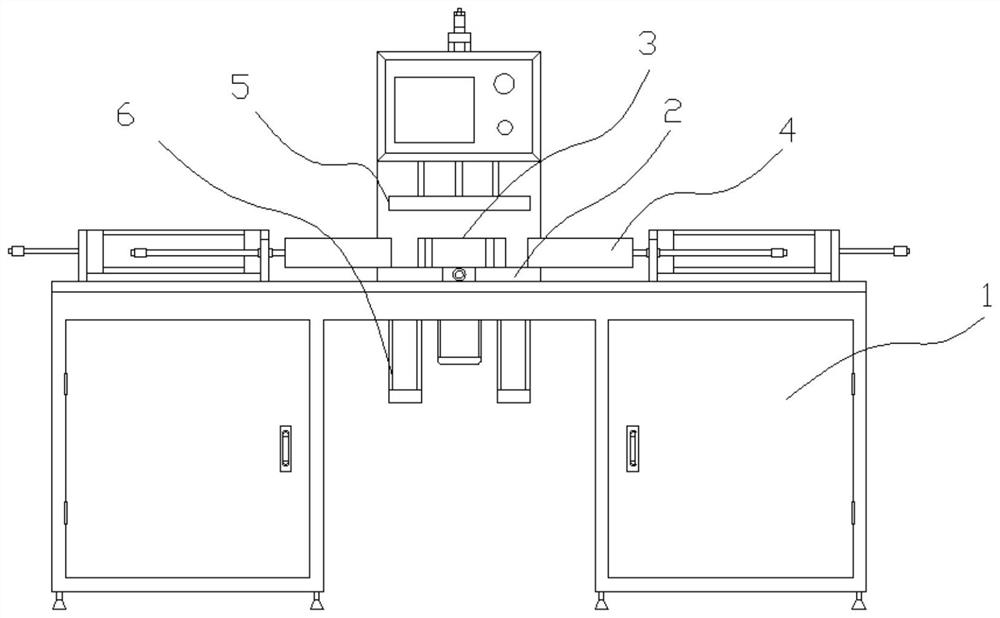

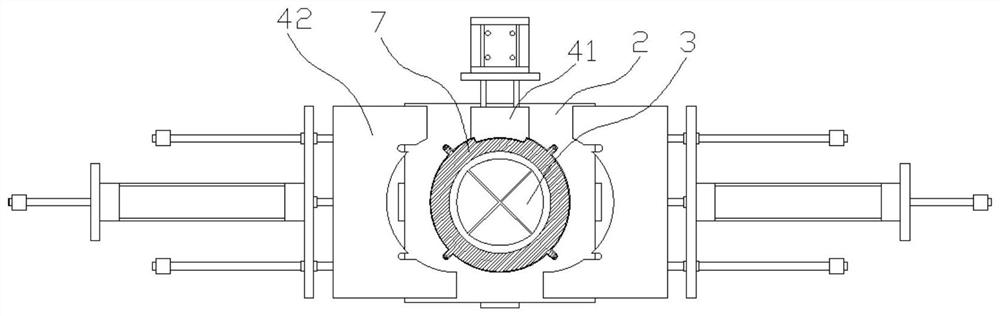

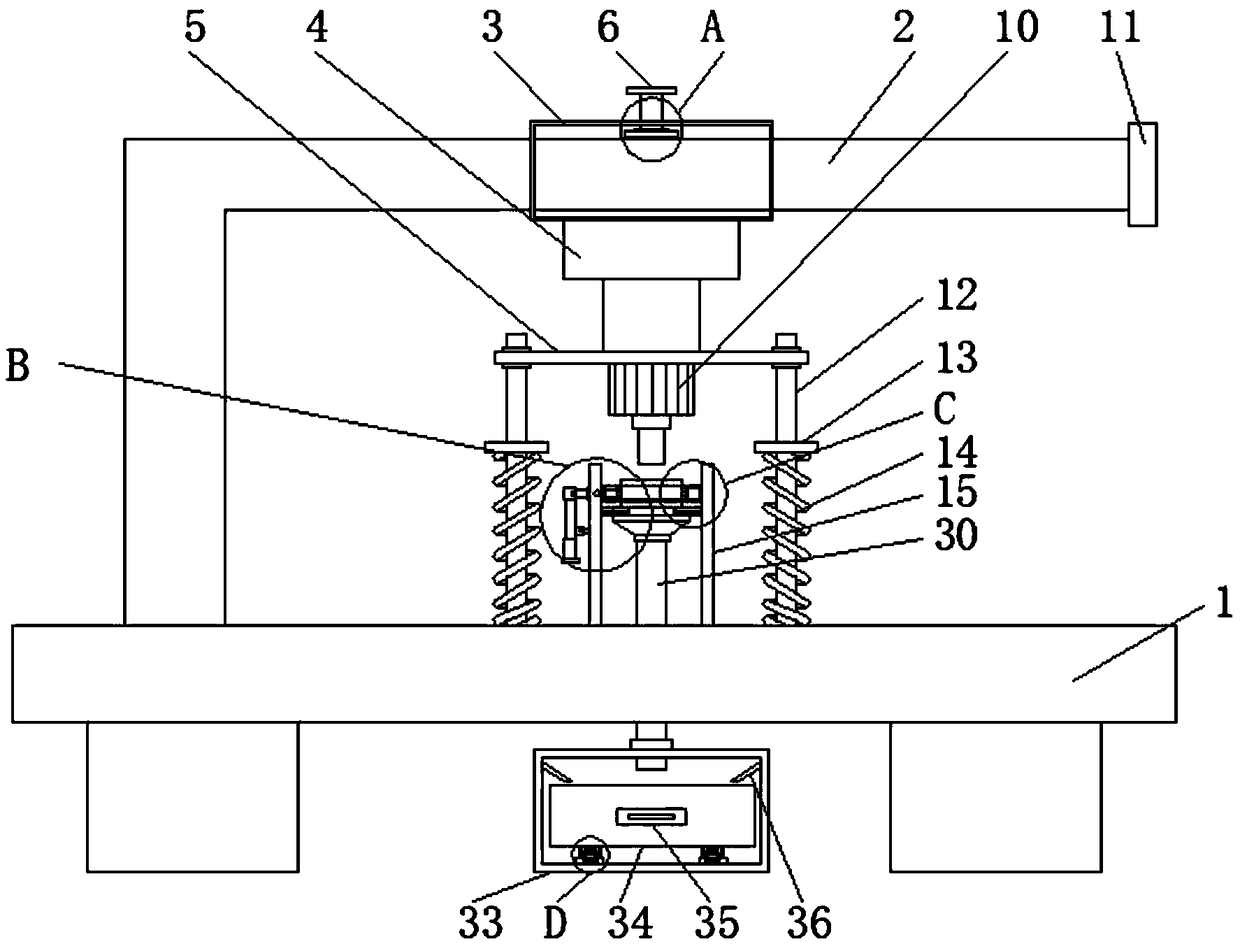

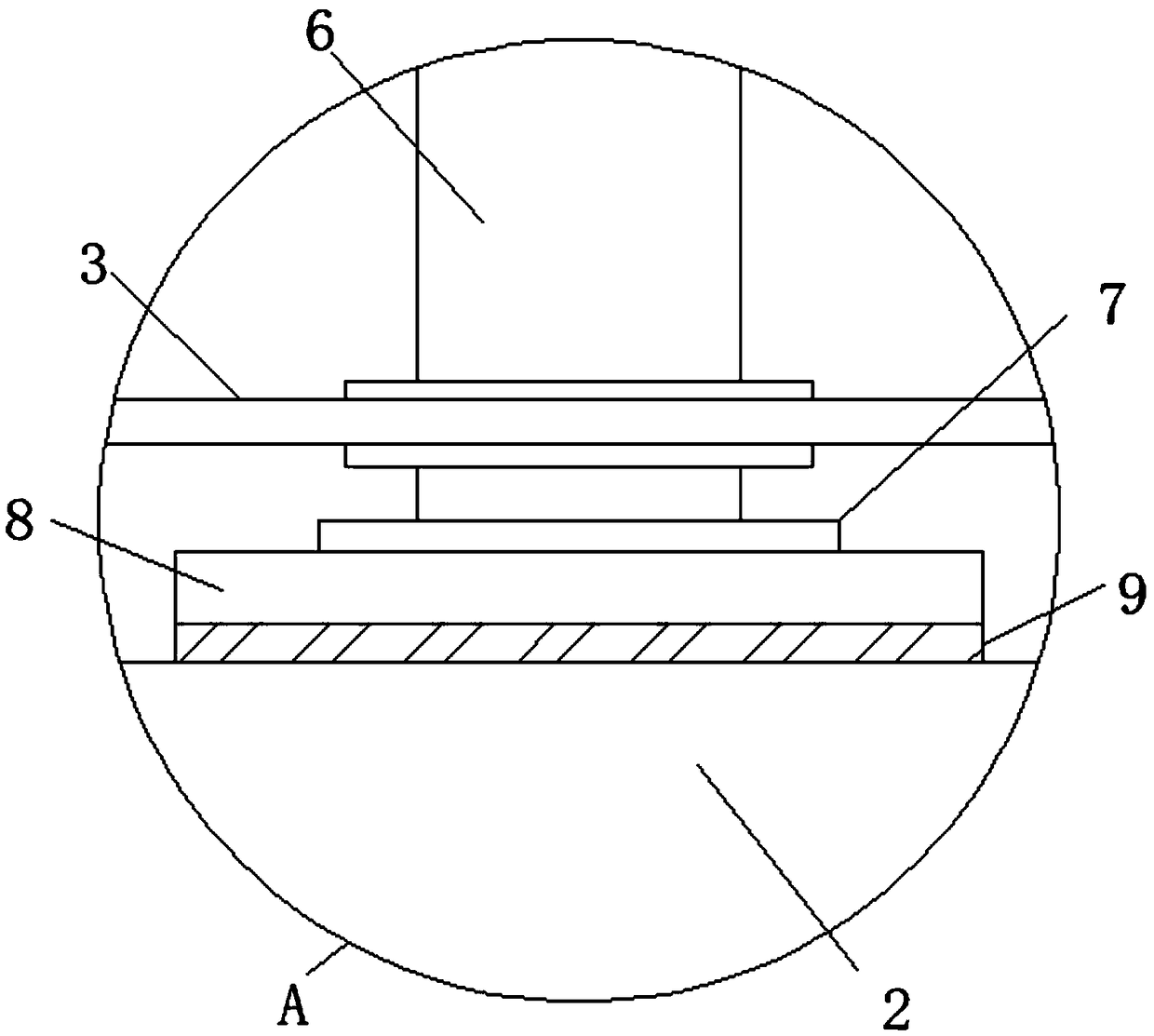

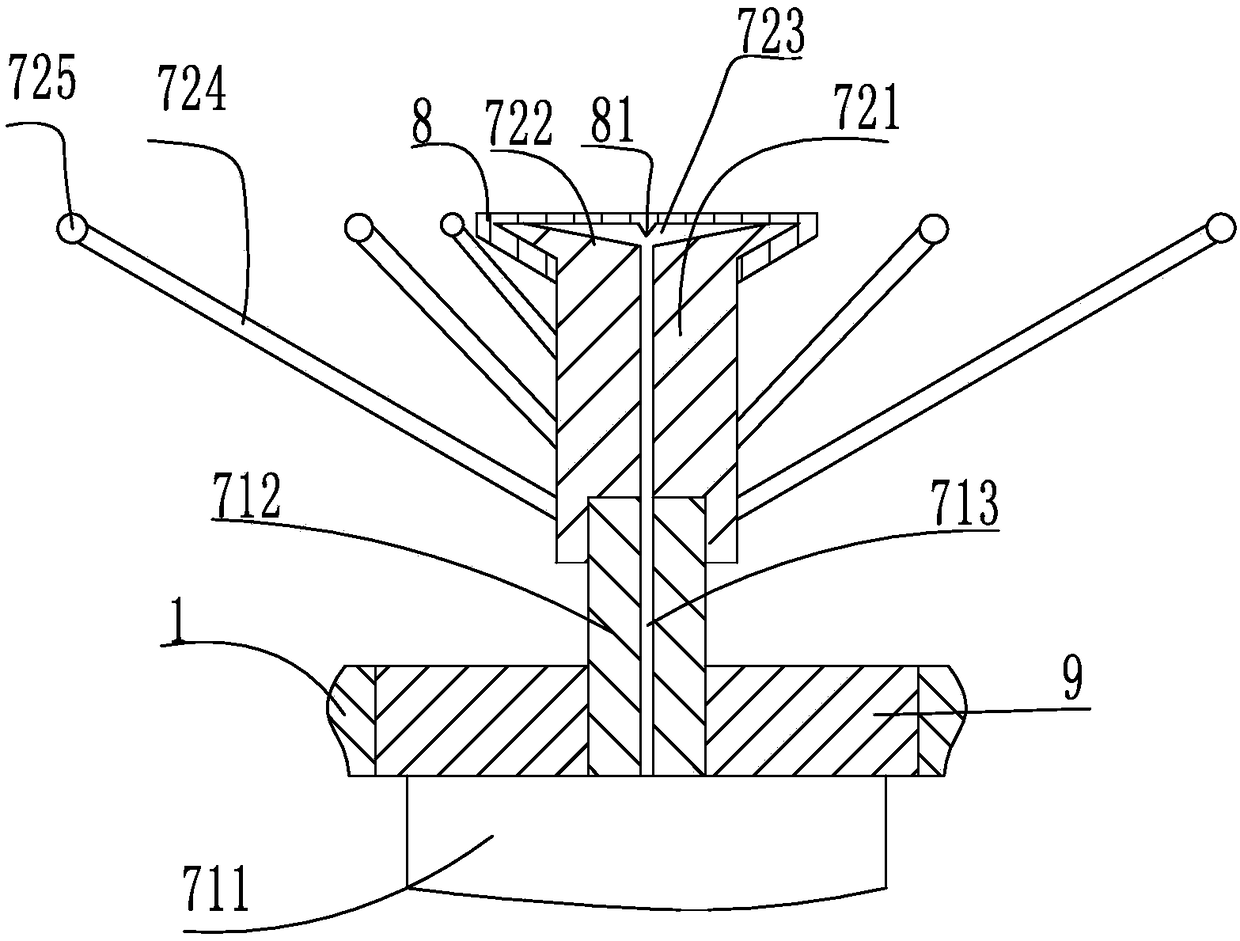

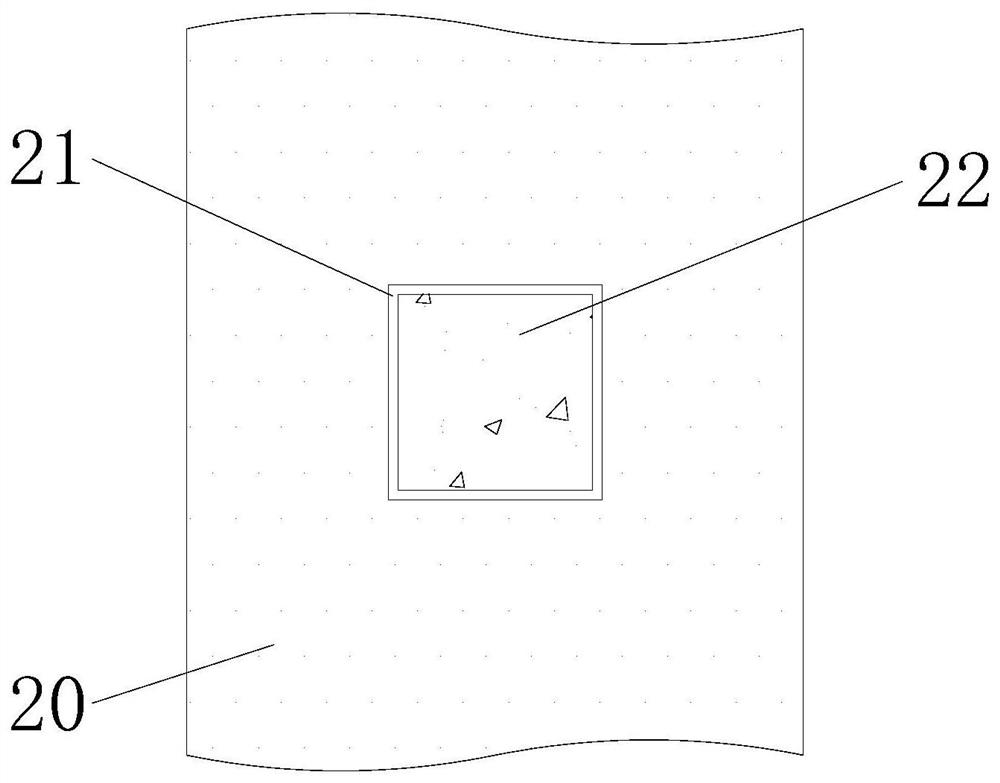

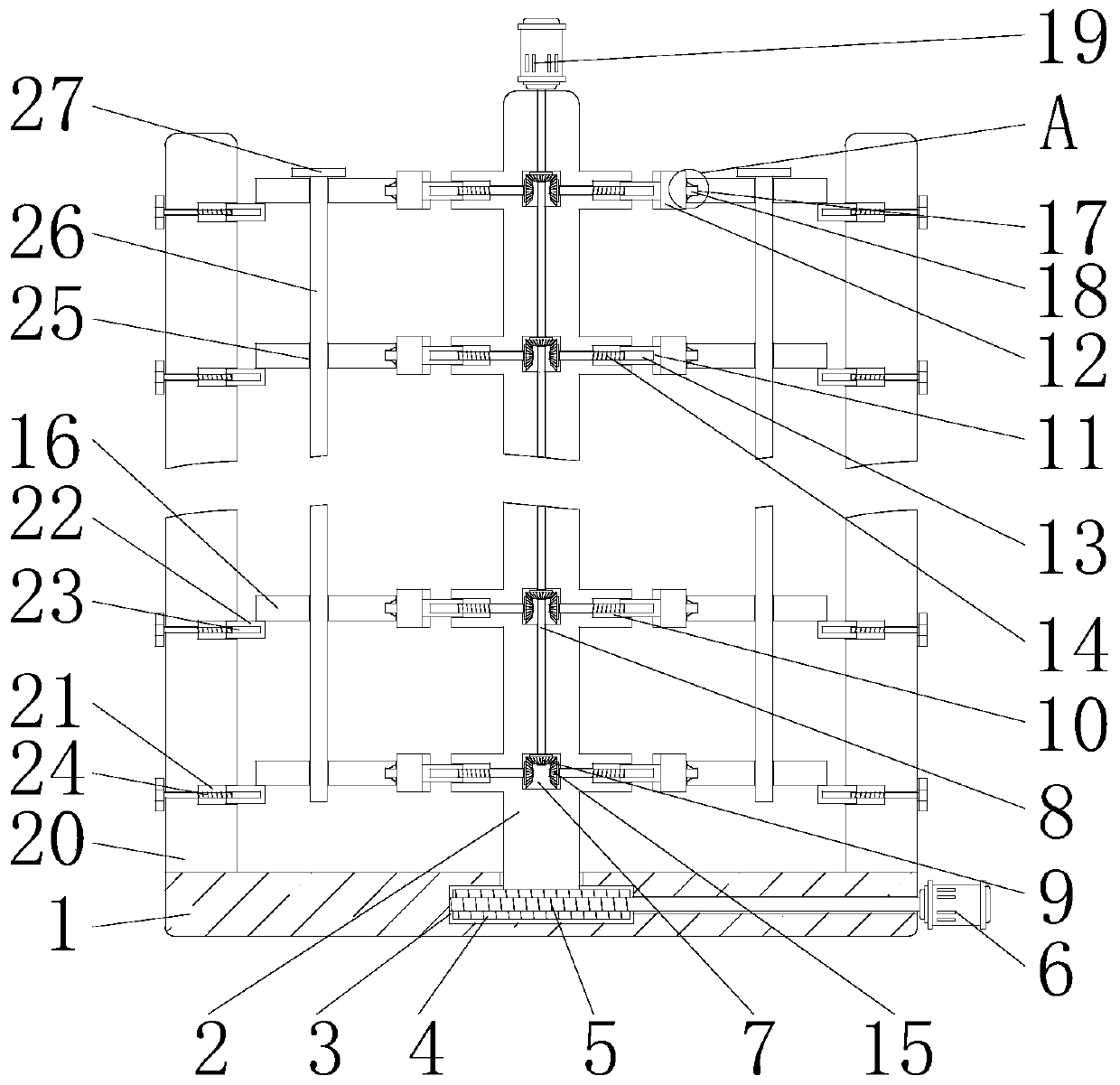

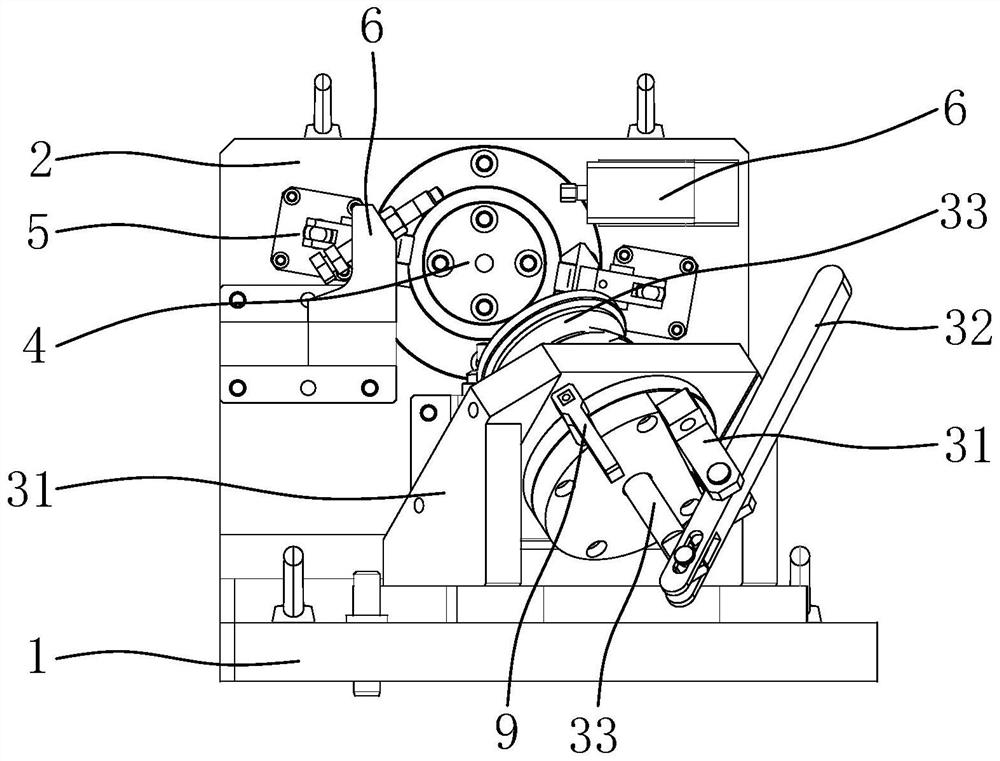

Oil cooler assembling machine and assembling method

InactiveCN111805206AEasy to pre-locateGuarantee lamination accuracyMetal working apparatusPhysicsEngineering

The invention relates to an oil cooler assembling machine. The machine comprises an electric control cabinet, a lamination platform, a fixed mandrel, a positioning device, a pressing device and an ejection device, wherein the lamination platform is provided with a clamp placing groove; the fixed mandrel is vertically arranged on the lamination platform; the positioning device is arranged at the periphery of the fixed mandrel and used for positioning an oil cooler; the pressing device is arranged above the lamination platform and used for pressing the oil cooler; and the ejection device is arranged below the lamination platform and used for separating the oil cooler from the fixed mandrel. The invention also discloses an assembling method of the oil cooler assembling machine, an oil coolerchip can be conveniently preset through a preset assembly and the fixed mandrel, and the oil cooler chip lamination efficiency is improved; and the fixed mandrel, the preset assembly and the positioning assembly are used for positioning the inner side and the outer side of the oil cooler chip at the same time, the oil cooler chip is pressed through the pressing device, the lamination accuracy of the oil cooler can be guaranteed, and the lamination yield of the oil cooler is improved.

Owner:盐城海荣炉业科技有限公司

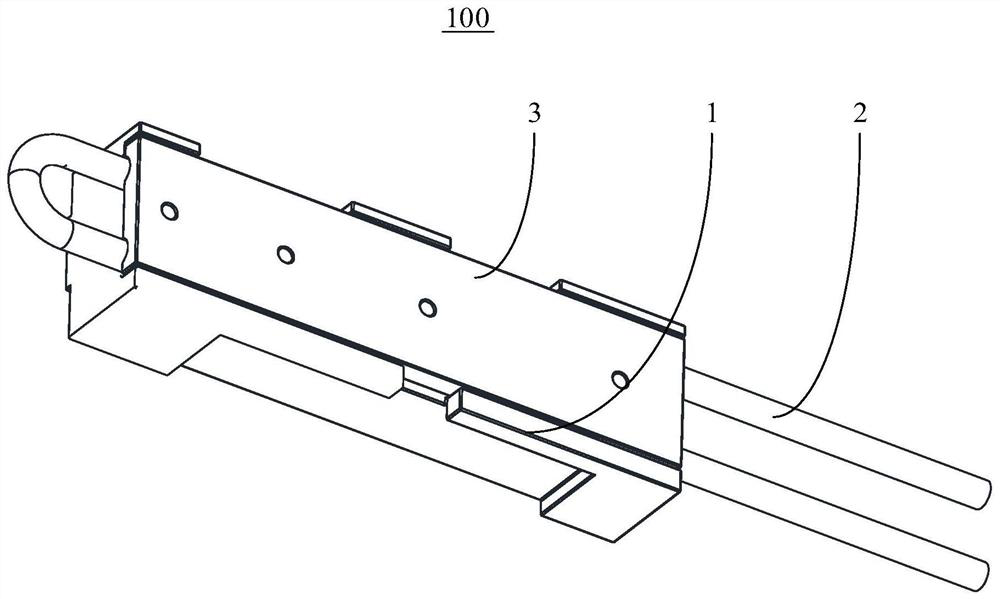

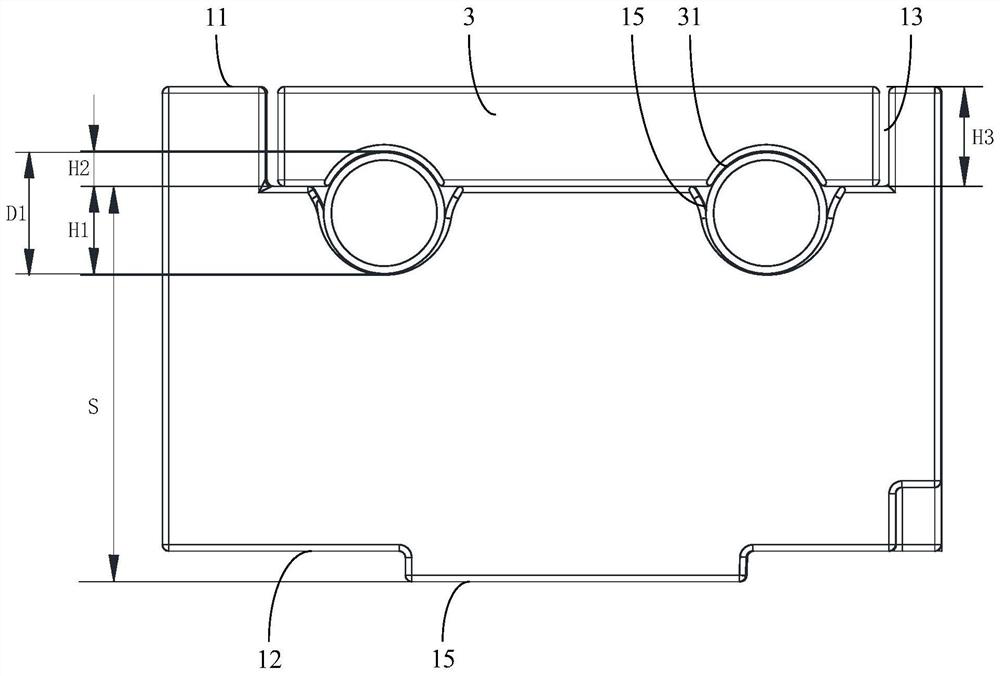

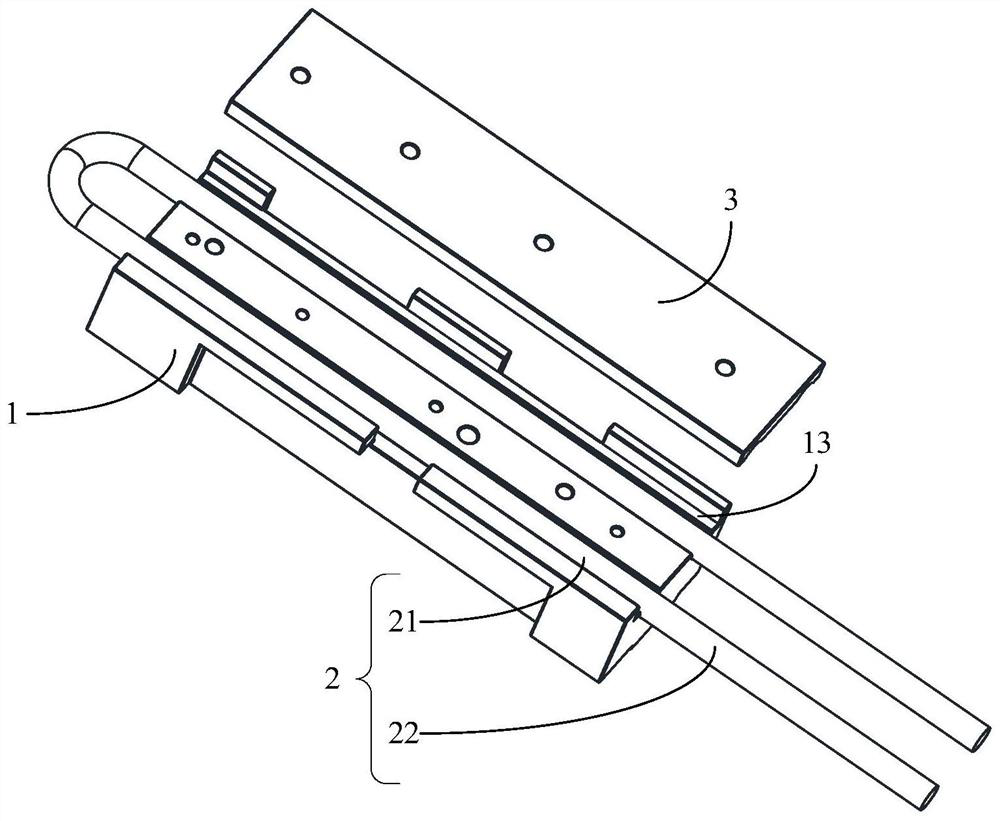

Electric control heat dissipation structure, air conditioner outdoor unit and air conditioner

ActiveCN113970135AQuick installationEasy to pre-locateLighting and heating apparatusAir conditioning systemsEngineeringElectric control

The invention discloses an electric control heat dissipation structure, an air conditioner outdoor unit and an air conditioner. The electric control heat dissipation structure comprises a heat dissipation piece, a refrigerant pipe and a cover plate, wherein the heat dissipation piece is provided with a mounting side and a heat conduction side which are opposite, and a leading-in end and a leading-out end which are located between the mounting side and the heat conduction side and are oppositely arranged; the mounting side is provided with a mounting groove; the mounting groove penetrates through the leading-in end and / or the leading-out end; a first containing groove is formed in the bottom wall of the mounting groove; the heat conduction side is used for being in heat conduction connection with an electric control element; the cover plate is arranged in the mounting groove and provided with a second containing groove; a mounting hole is defined by the second containing groove and the first containing groove jointly; and the refrigerant pipe is arranged in the mounting hole and used for conducting heat exchange with the heat dissipation piece. The heat of the electric control element is transmitted to the mounting hole through the heat conduction side of the heat dissipation piece, so that the refrigerant pipe exchanges heat with the heat dissipation piece so as to take away the heat of the heat dissipation piece, and meanwhile, the refrigerant pipe is kept in contact with the heat dissipation piece through the cover plate so as to prevent the refrigerant pipe from being separated from the heat dissipation piece.

Owner:MIDEA GRP WUHAN HEATING & VENTILATING EQUIP CO LTD +1

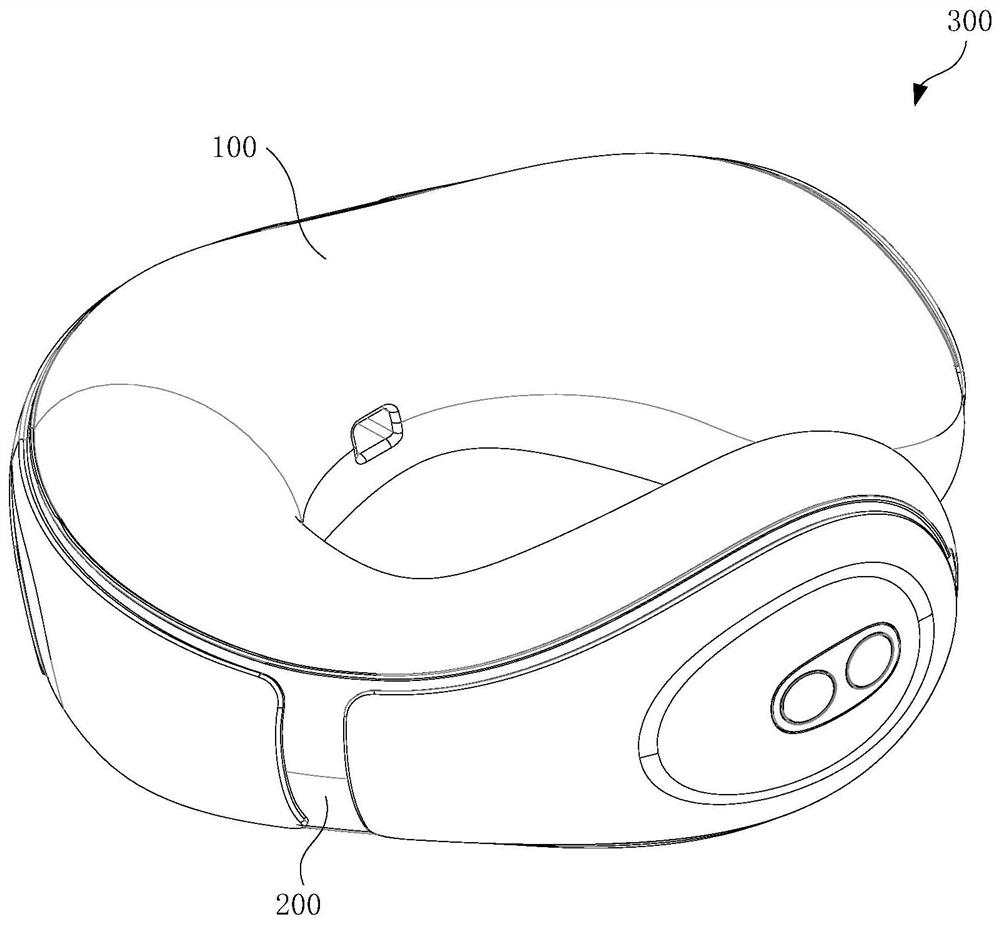

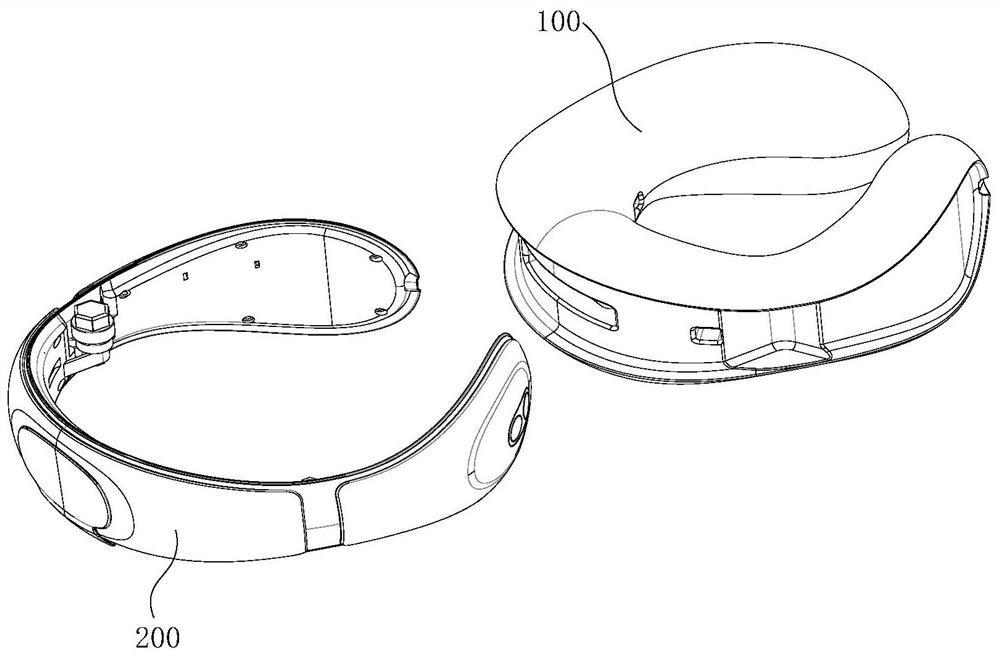

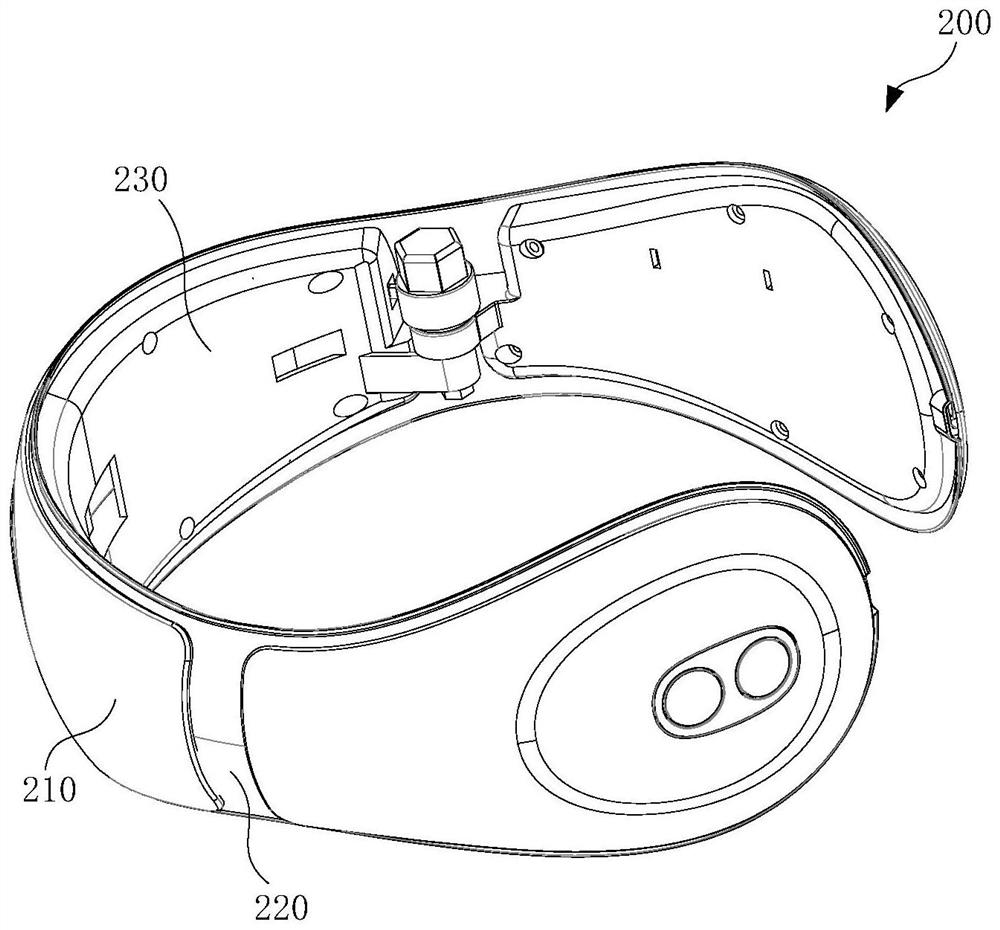

Ergonomic U-shaped pillow

PendingCN112842030ALow costImprove installation efficiencyPillowsStoolsStructural engineeringMechanical engineering

The embodiment of the invention discloses an ergonomic U-shaped pillow, and the ergonomic U-shaped pillow comprises a U-shaped pillow mounting assembly and a U-shaped pillow body; the U-shaped pillow body comprises a U-shaped sleeve, and the U-shaped sleeve is detachably connected with the U-shaped pillow mounting assembly. The U-shaped pillow solves the problems that an ergonomic U-shaped pillow is of an integrally-formed structure, especially a cloth cover and a lining are integrally formed, and cleaning, dismounting and replacement are inconvenient.

Owner:NINGBO YONGSHUN PROD DESIGN CO LTD

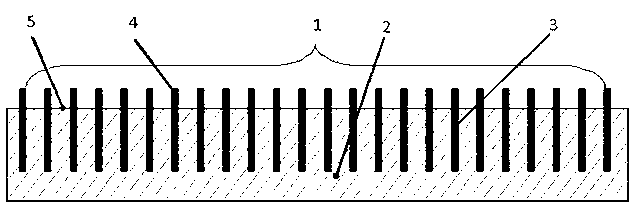

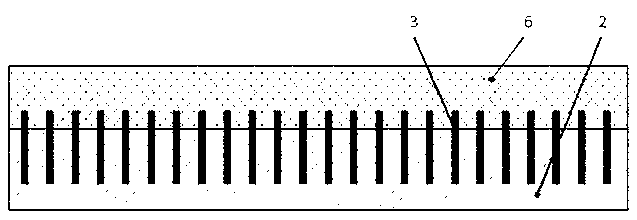

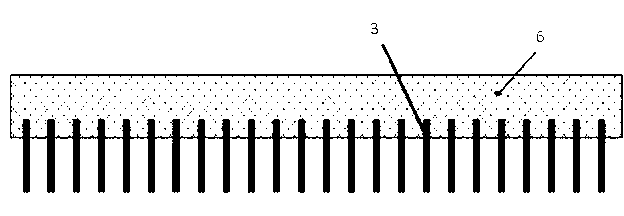

Method for fixing small column-shaped metal body arrays

InactiveCN103302446ATo achieve electrical conductionLow melting removalMetal working apparatusChemical platingElectroplating

The invention discloses a method for fixing small column-shaped metal body arrays. The method comprises the steps as follows: (a) regularly inserting the small column-shaped metal body arrays (1) into a paraffin layer (2) and exposing root parts (4) of small column-shaped metal bodies (3) to the surface of the paraffin layer (2); (b) plating the surface (5) of the paraffin layer, to which the root parts (4) of the small column-shaped metal bodies (3) are exposed, with a metal layer (6) having certain thickness; and (c) removing the paraffin layer (2) by melting. According to the method, low-cost, soft and easily-molten paraffin is taken as an early positioning medium for the small column-shaped metal bodies, the column-shaped bodies are fixed and bonded through low-temperature metal electroplating or chemical plating, the operation is simple, the technological process has small force and heat effects on the small column-shaped metal bodies, the fixing operation is efficient and reliable, the cost is low, and mounting and fixing problems of the small column-shaped metal body arrays are satisfactorily solved.

Owner:HENAN POLYTECHNIC UNIV

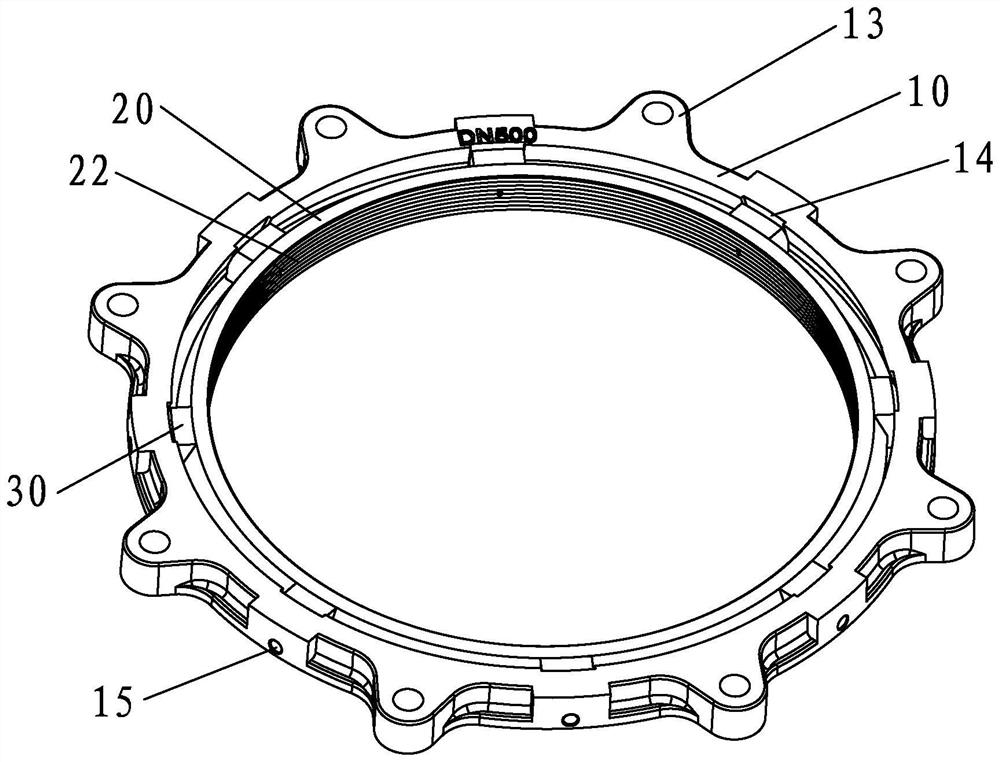

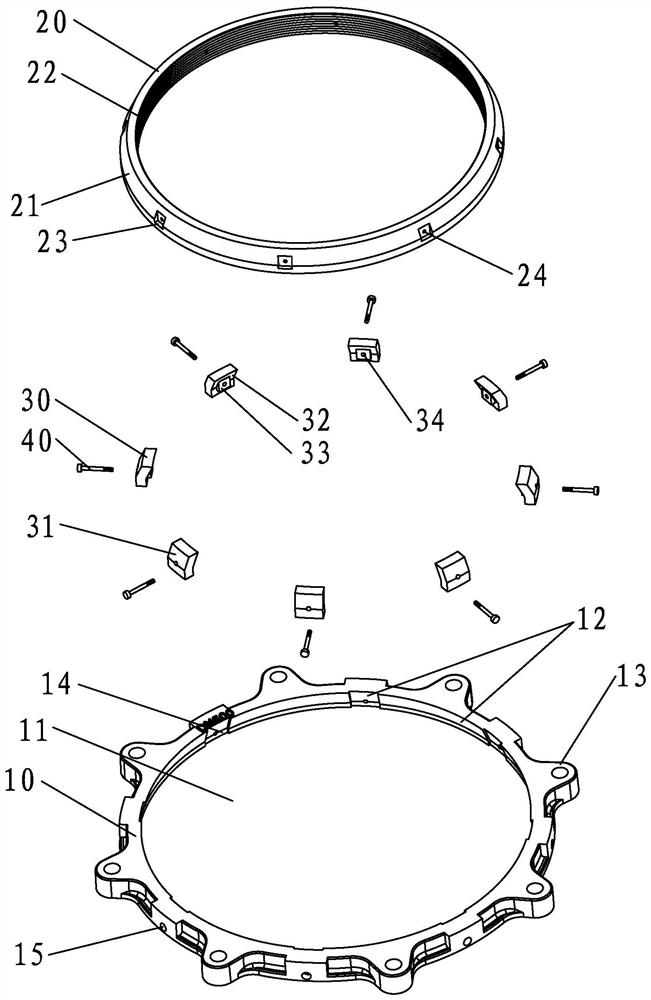

Pipeline anti-disengaging connecting assembly

PendingCN113983251AReduce maintenance costsAvoid affecting the anti-shedding effectSleeve/socket jointsEngineeringStructural engineering

The invention provides a pipeline anti-disengaging connecting assembly which comprises a gland; the gland is provided with a penetrating hole, the inner side wall of the penetrating hole is provided with an inclined guide face, an anti-disengaging ring is arranged in the penetrating hole, and a plurality of adjusting blocks are arranged between the anti-disengaging ring and the gland; an inclined pushing surface is arranged on the outer side wall of a ring body; or the anti-disengaging ring comprises a plurality of anti-disengaging blocks, and each anti-disengaging block is provided with an inclined pushing surface; and the inclined guide face and an inclined push face incline in the same direction relative to the axis of the gland, the side, facing the gland, of each adjusting block is provided with an outer inclined face, and the side, facing the anti-disengaging ring, of each adjusting block is provided with an inner inclined face. According to the pipeline anti-disengaging connecting assembly, the adjusting blocks are arranged between the anti-disengaging ring and the gland, the pipeline anti-disengaging connecting assembly can be suitable for connection of pipelines with different diameters only by replacing the anti-disengaging ring and the adjusting blocks, the gland can be matched with the pipelines with different diameters, funds and warehouse space needed when the pipeline anti-disengaging connecting assembly is backed up are relatively small, and the pipeline maintenance cost can be reduced favourably.

Owner:SOUTHEAST PIPE VALVE CO LTD

Power line mounting assembly of fan heater and fan heater

InactiveCN109855309AEasy to installEasy to pre-locateFluid heatersElectrical and Electronics engineeringWater resistance

The invention relates to the technical field of fan heaters, and provides a power line mounting assembly of a fan heater. The power line mounting assembly of the fan heater comprises a first shell, asecond shell and a power line, wherein a line outlet is formed between the first shell and the second shell; lantern rings are fixed to the circumferential wall of the power line, the lantern rings are provided with embedment parts and first positioning bulges which are abutted with each other, the embedment parts of the lantern rings are embedded into the line outlet, and the first positioning bulges are abutted with the inner wall of the first shell and / or the first positioning bulges are abutted with the inner wall of the second shell; and a clamp is arranged on the first shell, the clamp is located on the extension path of the line outlet, and the power line is clamped in a clamping groove of the clamp. The fan heater comprises the power line mounting assembly of the fan heater. The power line mounting assembly of the fan heater has the advantages of stability in installation of the power line, simple and quick installation process, the simple mounting structure and good water resistance.

Owner:GREE ELECTRIC APPLIANCES INC

Hole opening device for lamp housing capable of stably opening holes

The invention relates to the technical field of lamp processing, and discloses a hole-opening equipment capable of opening the a hole stably used for a lamp shell. The hole-opening equipment used forthe lamp shell comprises an operation table, a sliding block is movably connected to the top of the operation table through a supporting frame, and an inserting plate is fixedly connected with the bottom of the sliding block through a hydraulic rod; a punching machine is fixedly connected to the bottom of the inserting plate, and a threaded rod is in threaded connection with the top of the slidingblock; the bottom of the threaded rod is fixedly connected with the supporting frame through a fixing block, an inserting rod is connected to the bottom of the side face of the inserting plate in aninserting mode, and the bottom of the inserting rod is fixedly connected with the top of the operation table; a fixing sleeve is fixedly connected with the top of the operation table through a fixingplate, and a shell body is connected in the fixing sleeve in a clamping mode; and the top of the fixing plate is fixedly connected with the shell body through a telescopic rod. According to the hole-opening equipment capable of opening the hole stably used for the lamp shell, the sliding block and the supporting frame are fixed through the fixing block by adjusting the threaded rod, and fixing ofthe position of the punching machine is convenient; stability of punching is enhanced by pre-positioning of the inserting plate by the inserting rod and fixing of the telescopic rod and the shell body.

Owner:江苏大浪电气集团有限公司

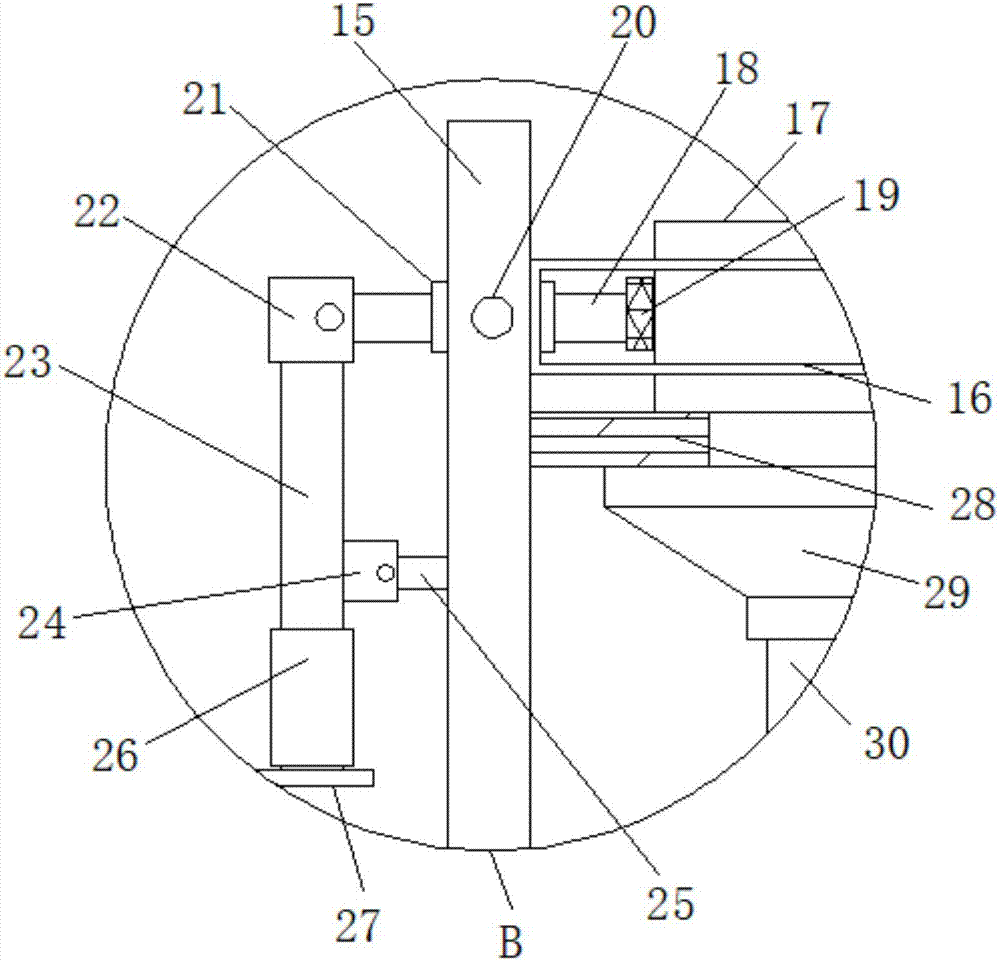

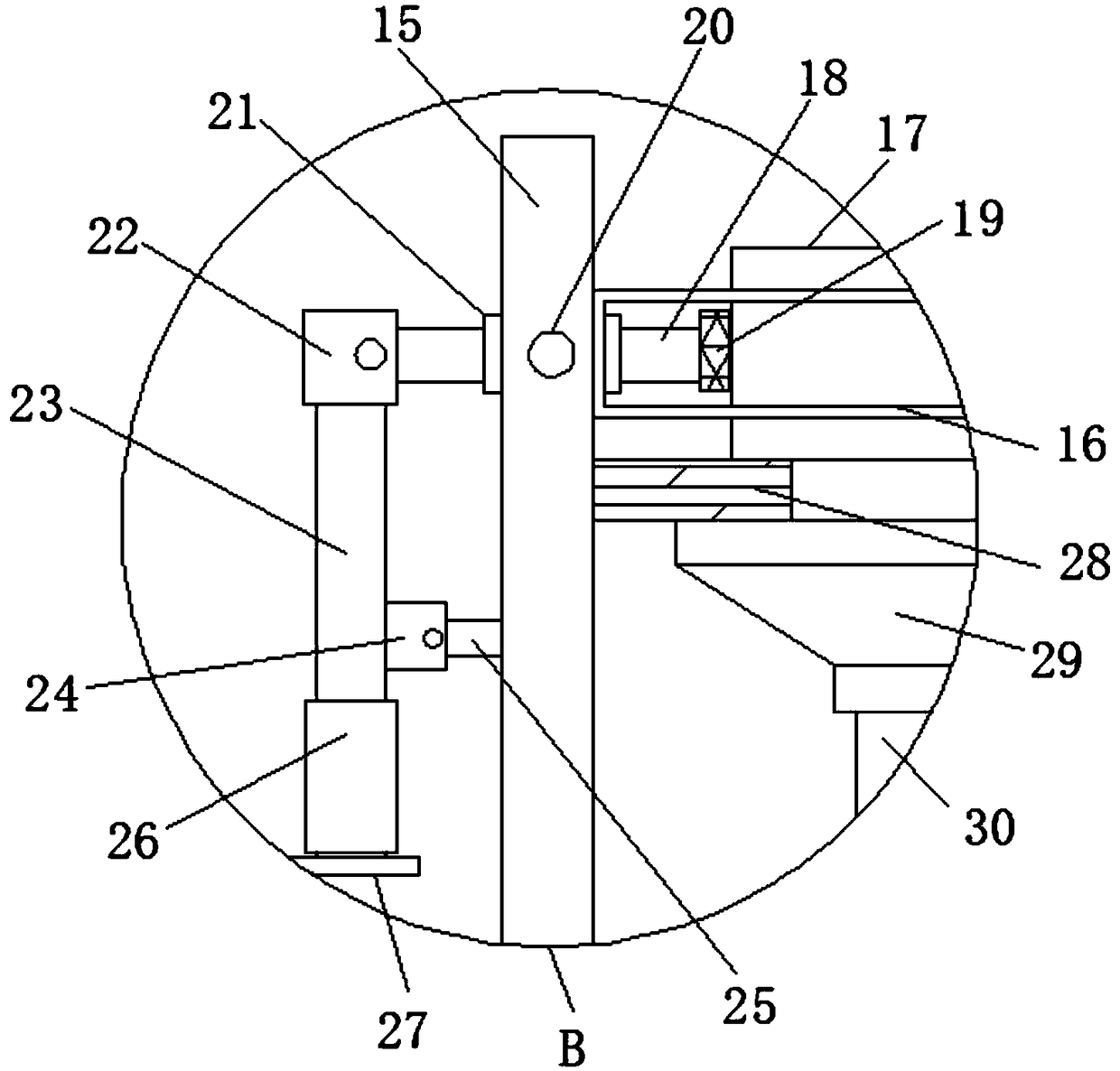

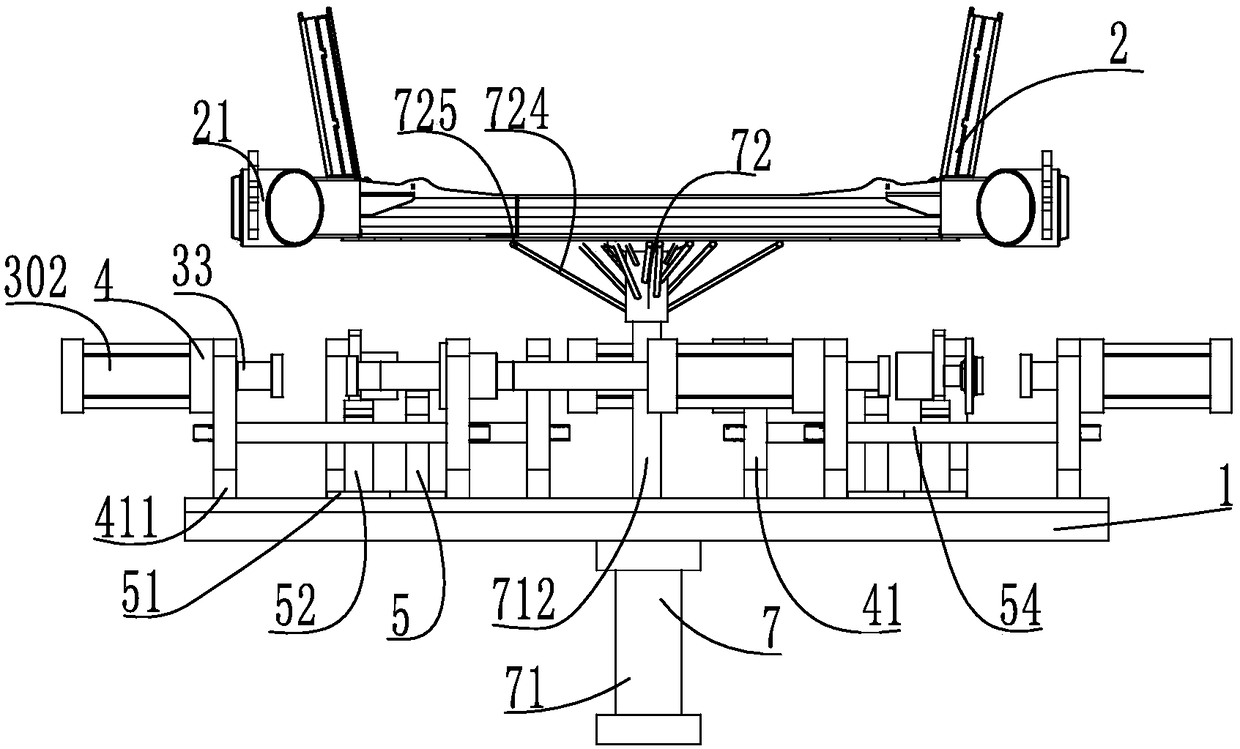

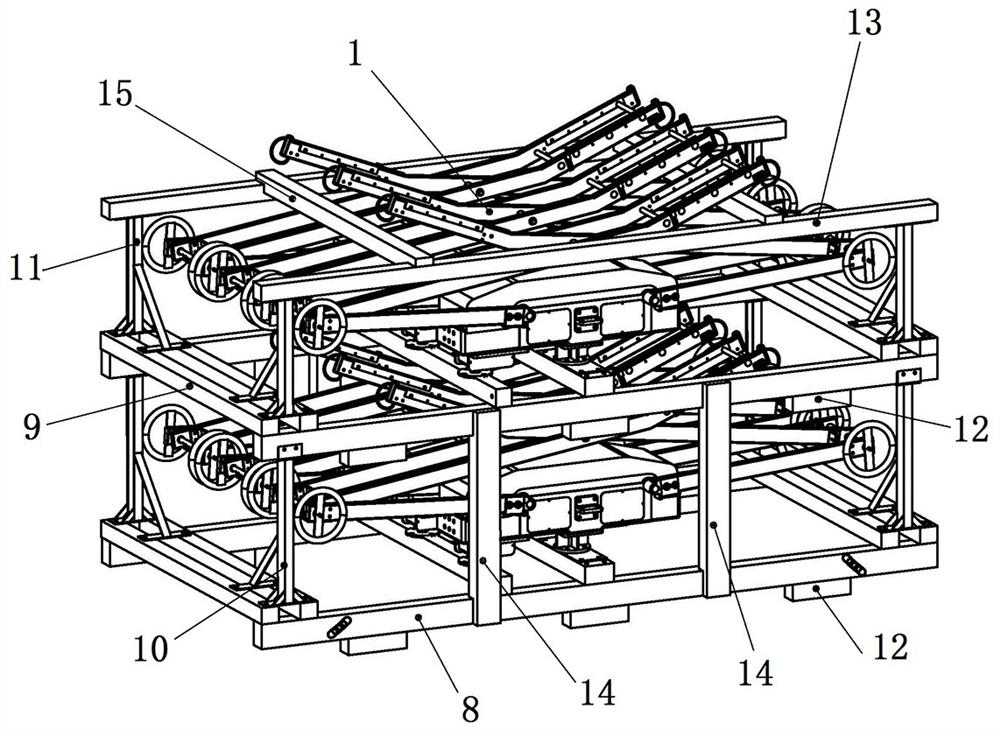

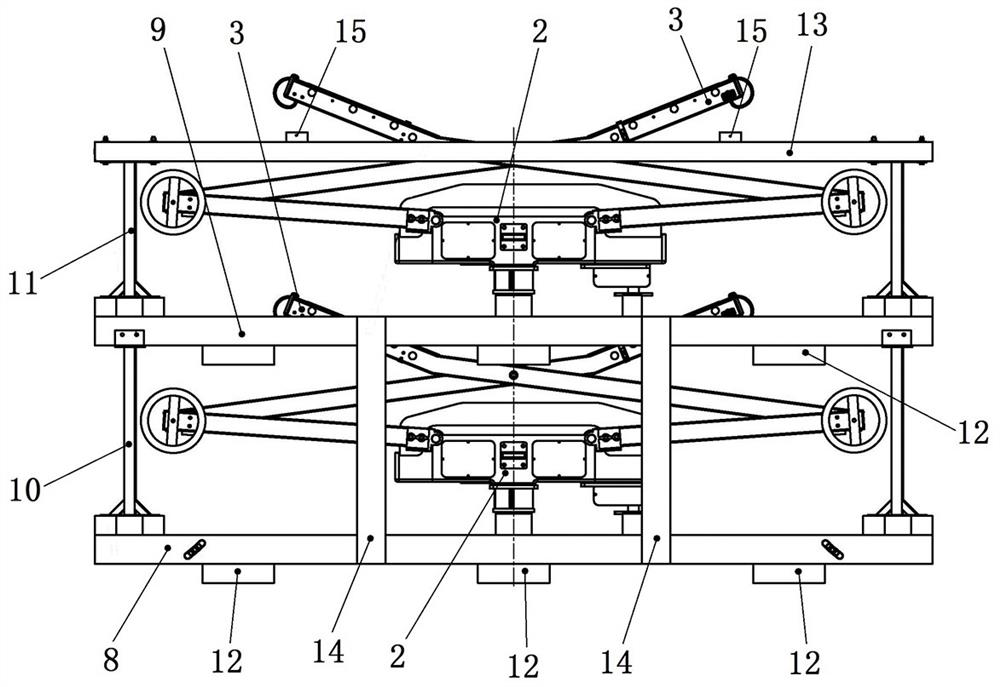

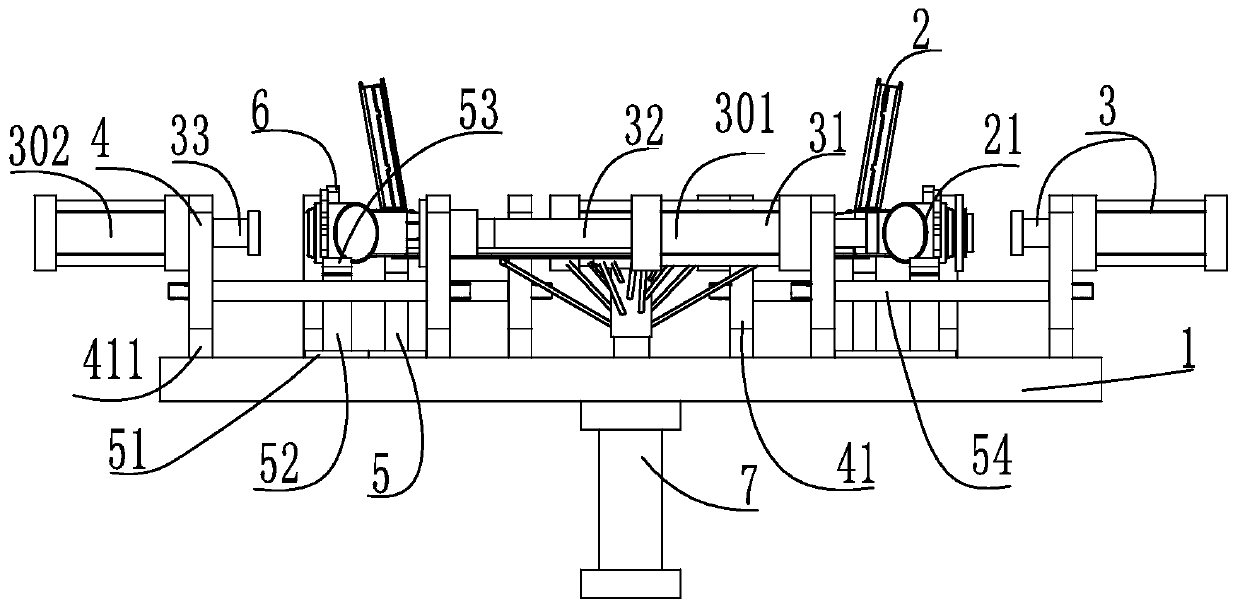

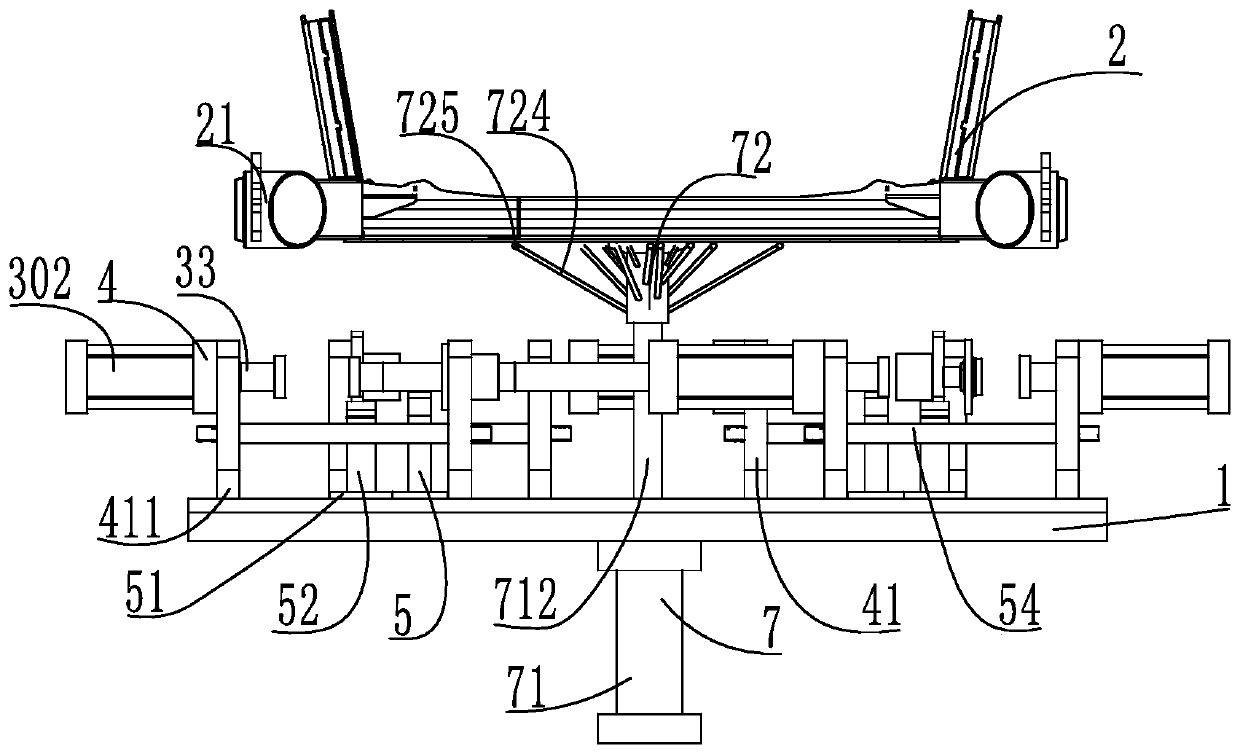

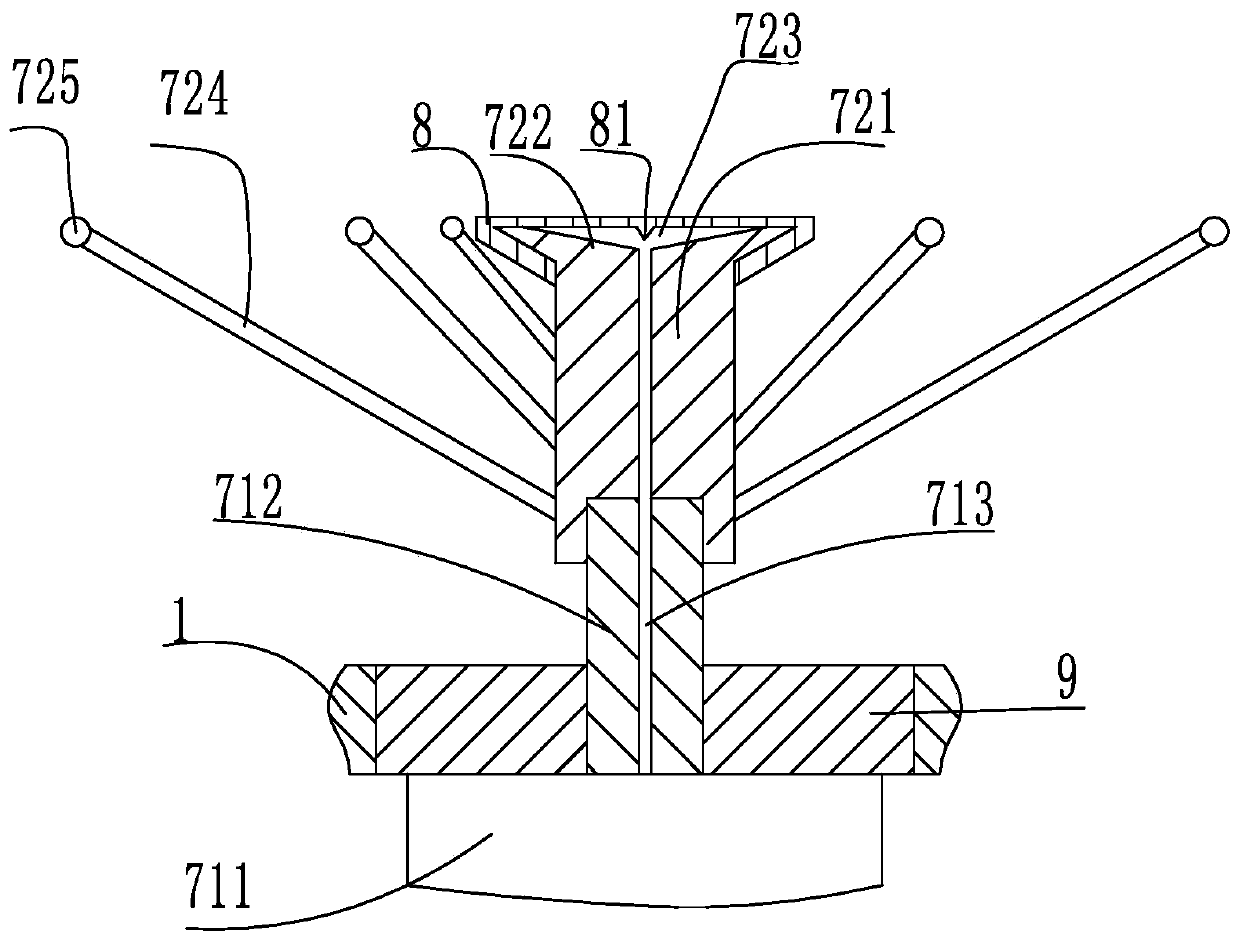

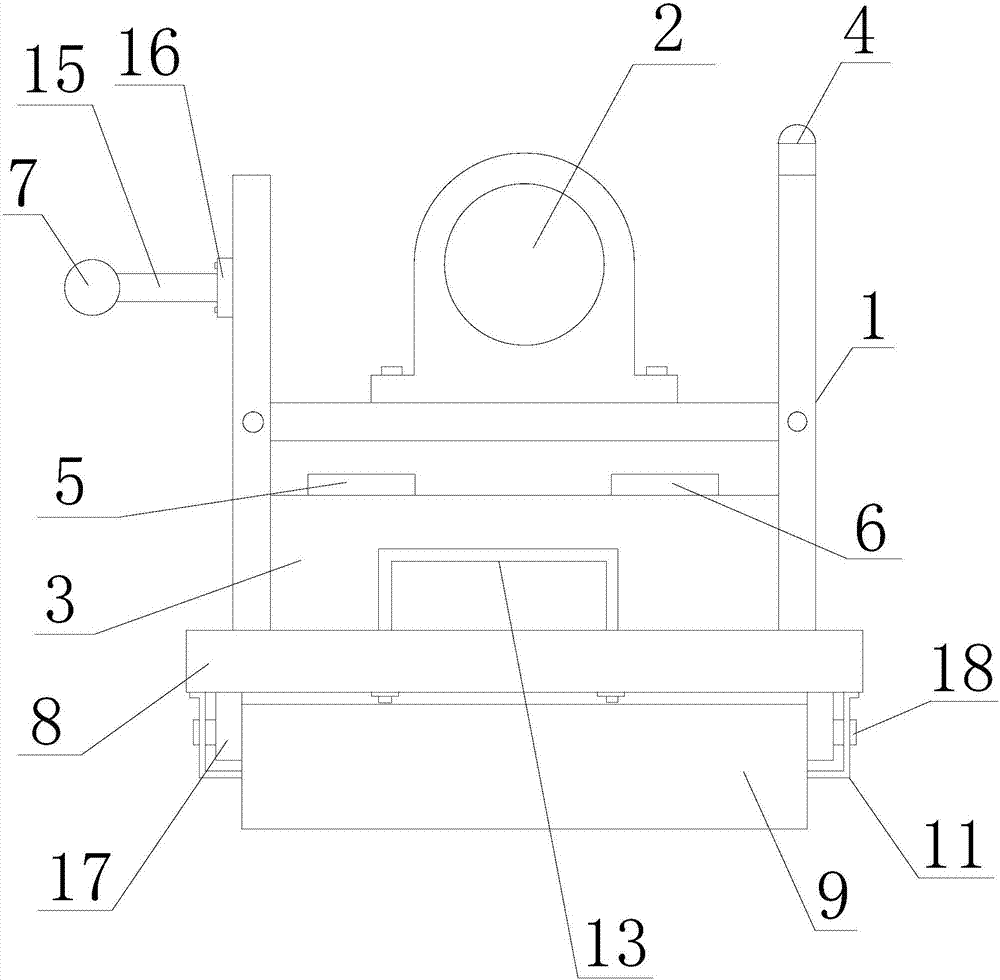

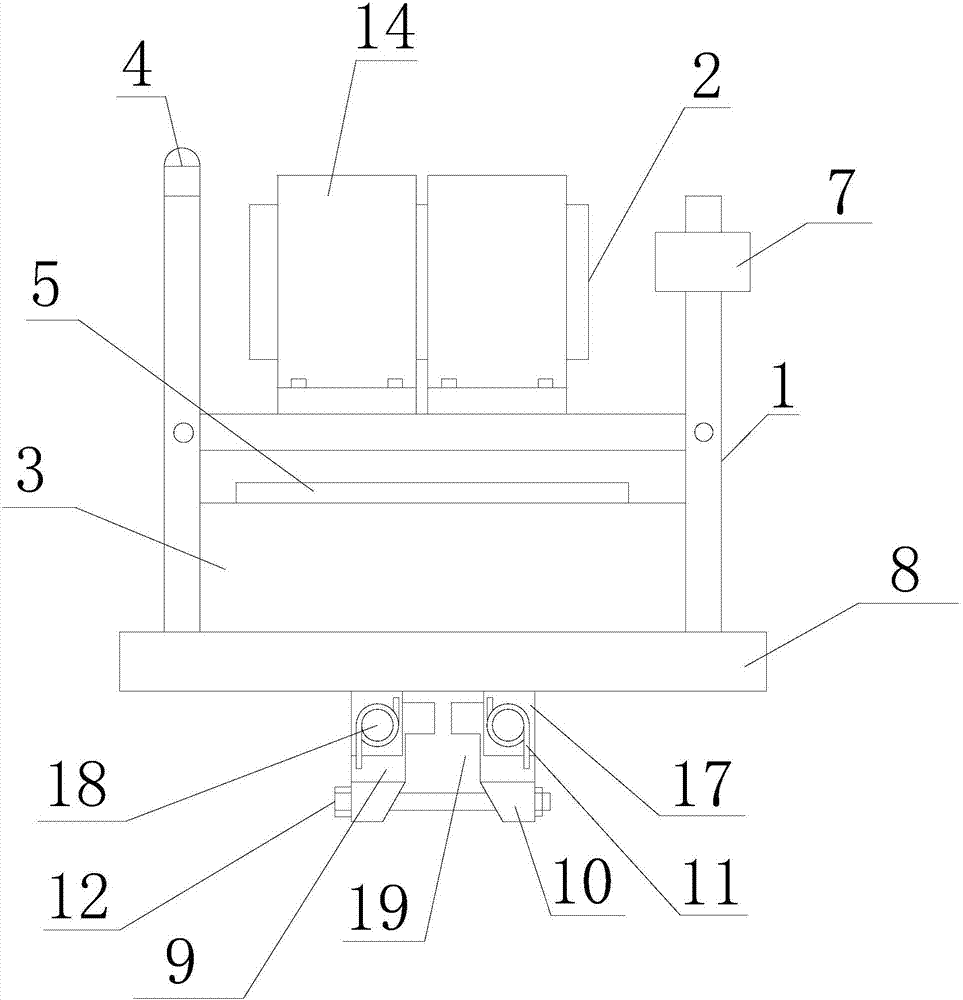

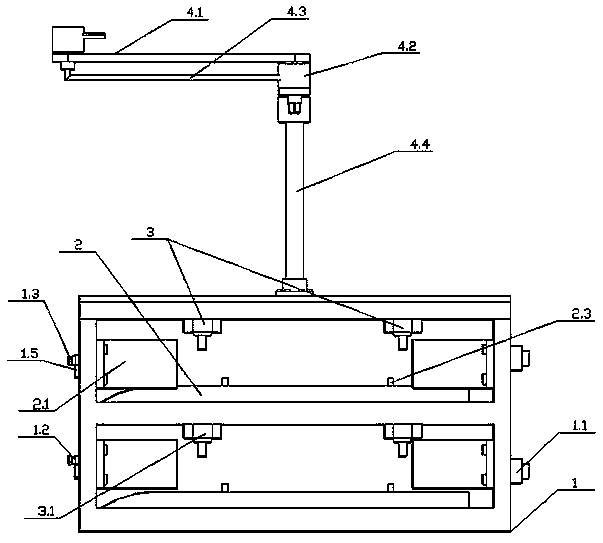

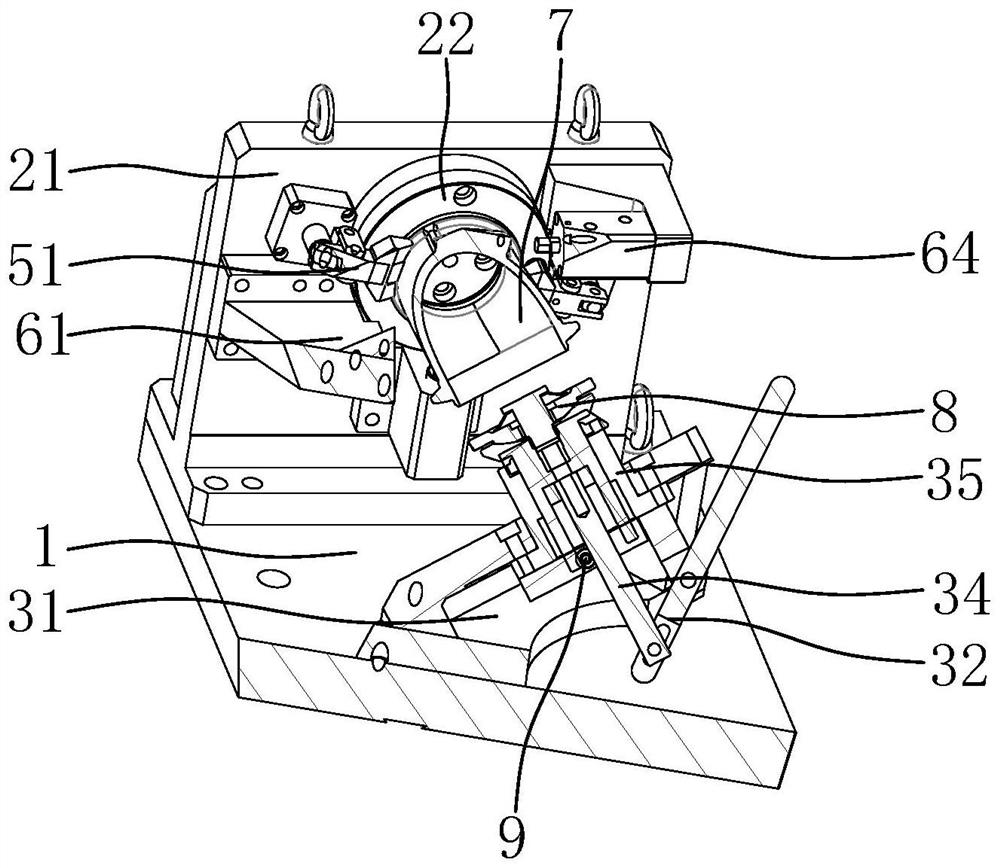

Synchronous positioning and press-fitting device for multi-station rear axle bearing

ActiveCN108544208AEasy to pre-locateImprove installation efficiencyVehicle componentsMetal working apparatusTransverse planeMechanical engineering

The invention discloses a synchronous positioning and press-fitting device for a multi-station rear axle bearing. The synchronous positioning and press-fitting device for the multi-station rear axle bearing comprises a working table and a rear axle mold, wherein the rear axle mold comprises a plurality of bearing seats; bearings to be pressed are arranged in the bearing seats; pressurizing oil cylinders are arranged at least one side of two side surfaces in the axial direction of each bearing seat; each pressurizing oil cylinder comprises an oil cylinder shell and a pressurizing piston rod; apressurizing block is arranged at one outward end of each pressurizing piston rod; a positioning assembly is arranged under each bearing seat; a feeding and blanking mechanism is arranged on the upperside surface of the working table, and comprises a power mechanism; and a positioning mold capable of supporting the rear axle mold is arranged above the power mechanism. The synchronous positioningand press-fitting device for the multi-station rear axle bearing provided by the invention has the advantages that the rear axle mold is convenient and safe to feed and blank; the bearing is pressed in a horizontal plane, so that the processing space is large, no repetitive positioning is needed, the positioning times is less, and the pressing-fit efficiency is high; and the feeding and blanking mechanism can be used for pre-positioning the rear axle mold, so that the bearing can be processed and positioned conveniently and can be quickly pressed.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

A curtain wall structure and its installation method

The invention discloses a curtain wall structure and an installation method thereof, and relates to the technical field of curtain walls. The curtain wall structure is characterized by comprising a keel frame, a fixed plate and a plurality of curtain wall plates, and further comprising a mounting device, wherein the mounting device comprises two rows of first slots, a plurality of first insertionblocks and a first limiting mechanism; the plurality of first insertion blocks are correspondingly inserted into the plurality of first slots one by one; hooks are fixedly connected to the two ends ofthe side, close to the fixed plate, of each curtain wall plate, and two annular blocks are fixedly connected to the side, away from the wall body, of the fixed plate; two hooks are respectively hungon the two annular blocks; the first limiting mechanism comprises a horizontal groove, a plurality of vertical grooves and a corresponding plurality of abutting blocks which are vertically and slidably connected to the plurality of vertical grooves; and the abutting blocks can abut against the first insertion blocks, a driving assembly used for driving the plurality of abutting blocks to move is installed in the horizontal groove, and a reset assembly used for resetting the abutting blocks is installed in each vertical groove. By arranging the mounting device, the curtain wall plates can be conveniently mounted.

Owner:江苏诺米新材料科技有限公司

Scissor type isolating switch packaging structure

ActiveCN110155458BSmall footprintImprove transportation efficiencyPackaging vehiclesContainers for machinesStructural engineeringMechanical engineering

The invention relates to a scissor-type isolating switch packaging structure. The scissor-type isolating switch packaging structure comprises at least two layers of brackets which are arranged up anddown, and the two adjacent layers of brackets cooperate with each other in a supporting mode; each bracket comprises a bottom frame which is used for supporting and fixing scissor-type isolating switches, and each bottom frame comprises a fixing part which is used for fixing the scissor-type isolating switches and enabling the hinge axes of conductive tubes of the scissor-type isolating switches to extend in the front-back direction; and the upper layer bracket comprises containing spaces which are located on the left side and the right side of the corresponding fixing part and used for allowing the tops of the conductive tubes of the scissor-type isolating switches supported by the lower layer bracket to stretch into the upper layer bracket. In the bracket stacking process, parts of the conductive tubes of the scissor-type isolating switches located on the bottom frame of the lower layer bracket stretch into the upper layer bracket, thus, the scissor-type isolating switches on the upper layer bracket and the lower layer bracket are partially overlapped in the vertical direction, compared with the mode that in the prior art, scissor-type isolating switches are completely separated,the occupied space is decreased, and the conveying efficiency is improved.

Owner:HENAN PINGGAO ELECTRIC +2

A multi-station rear axle bearing synchronous positioning and pressing equipment

ActiveCN108544208BEasy accessEasy to installVehicle componentsMetal working apparatusControl theoryMechanical engineering

The invention discloses a synchronous positioning and press-fitting device for a multi-station rear axle bearing. The synchronous positioning and press-fitting device for the multi-station rear axle bearing comprises a working table and a rear axle mold, wherein the rear axle mold comprises a plurality of bearing seats; bearings to be pressed are arranged in the bearing seats; pressurizing oil cylinders are arranged at least one side of two side surfaces in the axial direction of each bearing seat; each pressurizing oil cylinder comprises an oil cylinder shell and a pressurizing piston rod; apressurizing block is arranged at one outward end of each pressurizing piston rod; a positioning assembly is arranged under each bearing seat; a feeding and blanking mechanism is arranged on the upperside surface of the working table, and comprises a power mechanism; and a positioning mold capable of supporting the rear axle mold is arranged above the power mechanism. The synchronous positioningand press-fitting device for the multi-station rear axle bearing provided by the invention has the advantages that the rear axle mold is convenient and safe to feed and blank; the bearing is pressed in a horizontal plane, so that the processing space is large, no repetitive positioning is needed, the positioning times is less, and the pressing-fit efficiency is high; and the feeding and blanking mechanism can be used for pre-positioning the rear axle mold, so that the bearing can be processed and positioned conveniently and can be quickly pressed.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

A technology for rapid processing of sewing machine flat plate

ActiveCN109352290BRapid positioningQuick clampingWork clamping meansPositioning apparatusMachine toolMachining

Owner:湖南凯斯机械股份有限公司

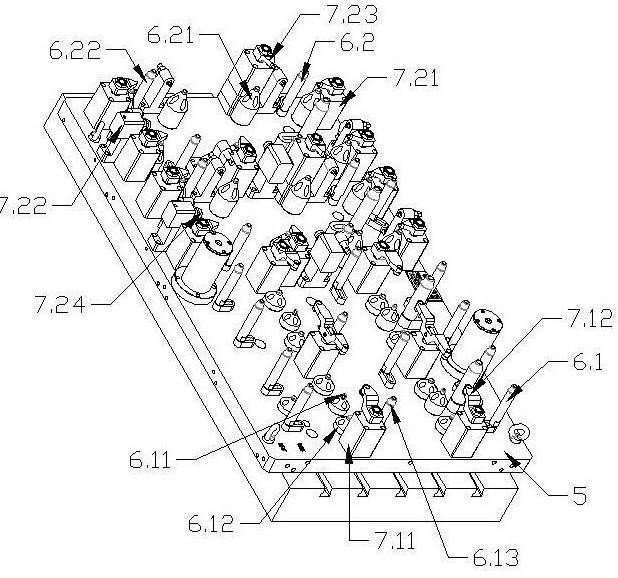

A device for ensuring the concentricity of the assembly and welding of the turbine generator base

ActiveCN111230387BEasy accessFirmly connectedWelding/cutting auxillary devicesAuxillary welding devicesElectric machineStructural engineering

The invention relates to a concentricity guarantee device for assembly and welding of a steam turbine generator base, which includes a base, a first screw rod and a positioning rod. In the transmission slot, a turbine is connected to the inside of the column close to the first transmission slot, wherein a worm is penetrated on a side of the base close to the turbine, and a first motor is fixed on one side of the base. The base of the steam turbine generator is equipped with a welding concentricity guarantee device. After the ring plates are placed in sequence, the first screw rod drives the positioning block to move to the inner side of the ring plate, so that the positioning block drives the positioning rod to enter the interior of the positioning groove. , through the positioning rod and the positioning groove, it is convenient to fix the ring plate and the positioning block, and the positioning block is used to position the ring plate, so that the center of the ring plate coincides with the center of the column, so that the centers of the ring plates of different layers coincide. Position the welding of the ring plate.

Owner:四川双鑫电气股份有限公司

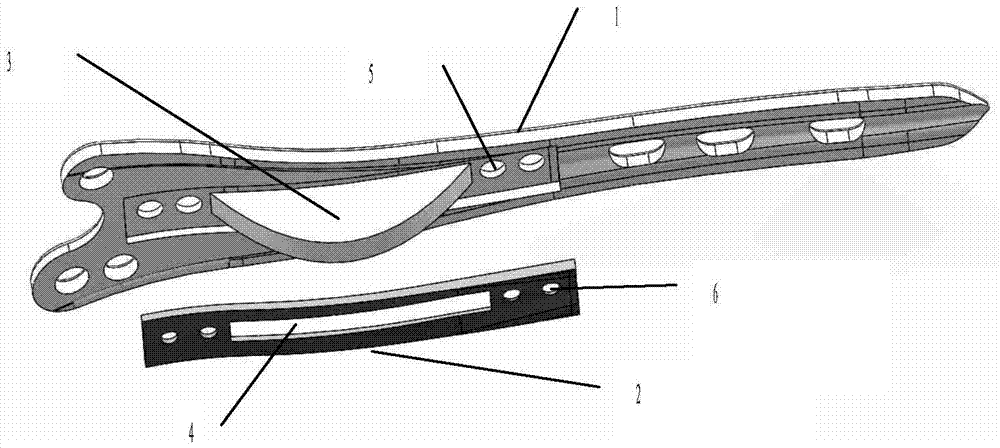

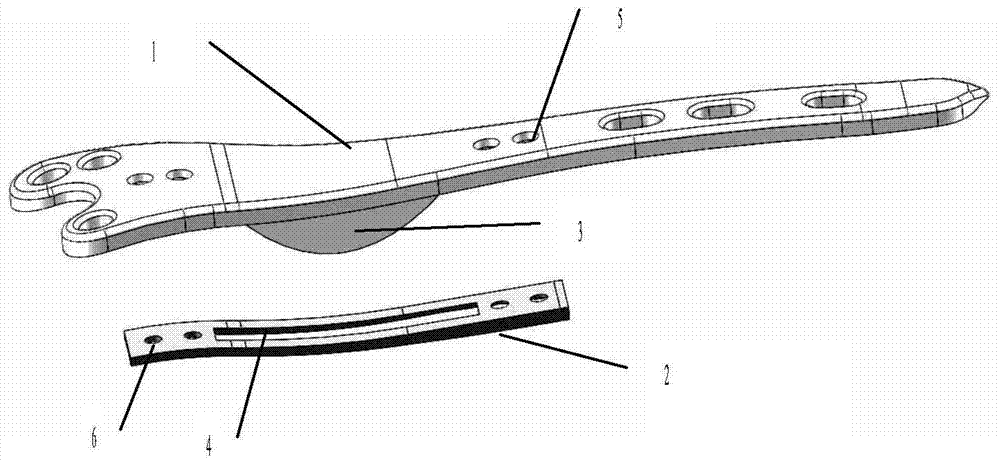

A bone plate device for distal femur fracture

ActiveCN105342682BAvoid stress concentrationAvoid breakingBone platesDistal femur fractureFracture femur

Owner:无锡倍达医疗科技有限公司

Steam turbine generator base assembling and welding concentricity guaranteeing device

ActiveCN111230387AReduce tiltEasy accessWelding/cutting auxillary devicesAuxillary welding devicesElectric generatorStructural engineering

The invention relates to a steam turbine generator base assembling and welding concentricity guaranteeing device. The device comprises a base, a first lead screw and a positioning rod, a stand columnis rotationally connected to the top of the base, a first transmission groove is formed in the bottom, close to the stand column, of the base, a worm gear is connected to the interior, close to the first transmission groove, of the stand column, a worm penetrates through the side, close to the worm gear, of the base, and a first motor is fixed to one side of the base. According to the steam turbine generator base assembling and welding concentricity guaranteeing device, after annular plates are sequentially placed, the first lead screw drives a positioning block to move towards the inner sidesof the annular plates, so that the positioning block drives the positioning rod to enter the inside of a positioning groove conveniently, through the positioning rod and the positioning groove, the annular plates and the positioning block are fixedly connected conveniently, the annular plates are positioned through the positioning block, the circle centers of the annular plates coincide with thecircle center of the stand column, the circle centers of the annular plates on different layers coincide conveniently, and welding of the annular plates is positioned.

Owner:四川双鑫电气股份有限公司

A wire slack adjustment device

ActiveCN105790163BHigh adjustment accuracyReduce fixed difficultyApparatus for overhead lines/cablesTowerConductor sag

The invention relates to a wire sag adjusting device, which solves the defect of large labor intensity of a technician when the wire sag is adjusted in the prior art. According to the wire sag adjusting device provided by the invention, a hoisting device is fixed on a frame body; the hoisting device is used for adjusting sag of the wire, the sag of the wire is reasonably controlled by a processor according to temperature parameters detected by a temperature sensor, and thus, the wire sag adjusting precision is greatly improved. The frame body comprises a base, the base is fixed with a clamping block clamping the base on a beam, and when the wire sag adjusting device is fixed, as the beam is generally located at the top end of a tower, the technician is hard to fix the wire sag adjusting device in place at once in the case of overhead operation. The clamping block plays a role of pre-location, the technician can pre-locate the wire sag adjusting device conveniently, and the wire sag adjusting device fixing difficulty is greatly reduced.

Owner:LISHUI POWER SUPPLY COMPANY OF STATE GRID ZHEJIANG ELECTRIC POWER +2

universal joint

ActiveCN105465204BEasy to pre-locateAchieving tightnessClutchesYielding couplingUniversal jointEngineering

The invention relates to a universal joint with a universal joint cross, which has a number of main journals, each of which is supported in a bushing by means of a journal bearing arrangement and in order to hold the universal joint cross Relative to the seal of the shaft sleeve, a sealing device is provided. In order to achieve an effective yet economical sealing provision, the sealing device has a sealing body which is seated in a static sealing manner on the universal joint spider, the sealing body having at least one first sealing lip directed radially outwards or inwards, The first sealing lip is in dynamic sealing contact on the bushing or on a sleeve connected to the bushing in a rotationally fixed manner, the sealing body has at least one second radially inwardly directed sealing lip, the second The sealing lips are in dynamic sealing contact on the bushing or sleeve, the sealing body with all its sealing lips is designed as a one-piece polymer part and the seal has no further sealing body. Additionally, sleeves of different configurations may be used.

Owner:AB SKF

An automatic winding device and winding method for soldering wire

The present application relates to an automatic winding device for soldering wire and its winding method, and relates to the field of soldering material processing equipment, which includes a workbench, a coil set on the workbench and used to drive the rotation of the I-shaped cylinder Around the assembly, the sliding bar that slides horizontally on the workbench, the connecting bar arranged on the sliding bar, the lower guide wheel that is rotatably connected to the connecting bar and used to guide the tin wire, and the connecting bar arranged on the A linkage assembly on the workbench, the linkage assembly drives the sliding bar to reciprocate along the length direction of the I-shaped cylinder. In this application, the winding assembly, the lower guide wheel and the linkage assembly are arranged on the workbench, the winding assembly drives the I-shaped cylinder to rotate, and the tin wire can be wound on the I-shaped cylinder, and the linkage assembly drives the lower guide wheel along the The length direction of the I-shaped cylinder reciprocates, so that the lower guide wheel can guide the tin wire, and the tin wire is evenly wound on the I-shaped cylinder.

Owner:GUANGDONG ANSON SOLED & TIN PROD MADE

Multi-layer type automatic clamp capable of conveniently and rapidly clamping flat boards

ActiveCN109333093AReduce setup timeReduce positioningWork clamping meansPositioning apparatusPulp and paper industry

Owner:湖南凯斯机械股份有限公司

Positioning clamp for bent pipe machining

InactiveCN113732752AImprove positioning efficiencyEasy to usePositioning apparatusMetal-working holdersClassical mechanicsStructural engineering

The invention relates to a positioning clamp, in particular to a positioning clamp for bent pipe machining. The positioning clamp for bent pipe machining comprises a bottom plate, a vertical plate and a support are fixed to the bottom plate, the support and the vertical plate are arranged in a spaced manner, the support is hinged to the middle of a lever, a pressing head is hinged to one end of the lever, and the pressing head is used for being matched with one end of a bent pipe workpiece; and the vertical plate is provided with a groove opened towards the support, the groove is used for being matched with the other end of the bent pipe workpiece, at least two clamping mechanisms used for clamping the bent pipe workpiece are arranged on the side face of the groove, and a circumferential positioning mechanism used for conducting circumferential positioning on the bent pipe workpiece is arranged between the clamping mechanisms and the support. The clamp has the advantage that the bent pipe can be pre-positioned to avoid repeated disassembly and assembly of the bent pipe so as to adjust the position of the bent pipe.

Owner:DONGYANG LINIX MECHANICAL&ELECTRICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com