Synchronous positioning and press-fitting device for multi-station rear axle bearing

A synchronous positioning and multi-station technology, applied in the field of bearing press-fitting, can solve the problems of low efficiency and low precision of rear axle bearing press-fitting, and achieve the effects of improving installation and positioning efficiency, improving work efficiency, and convenient positioning and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

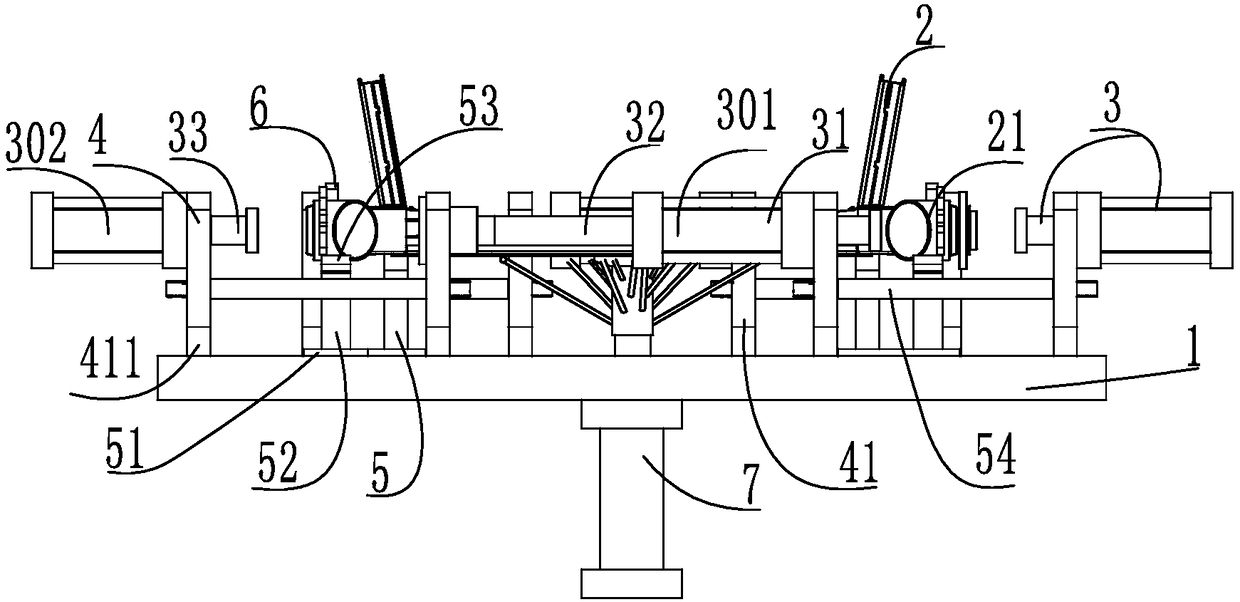

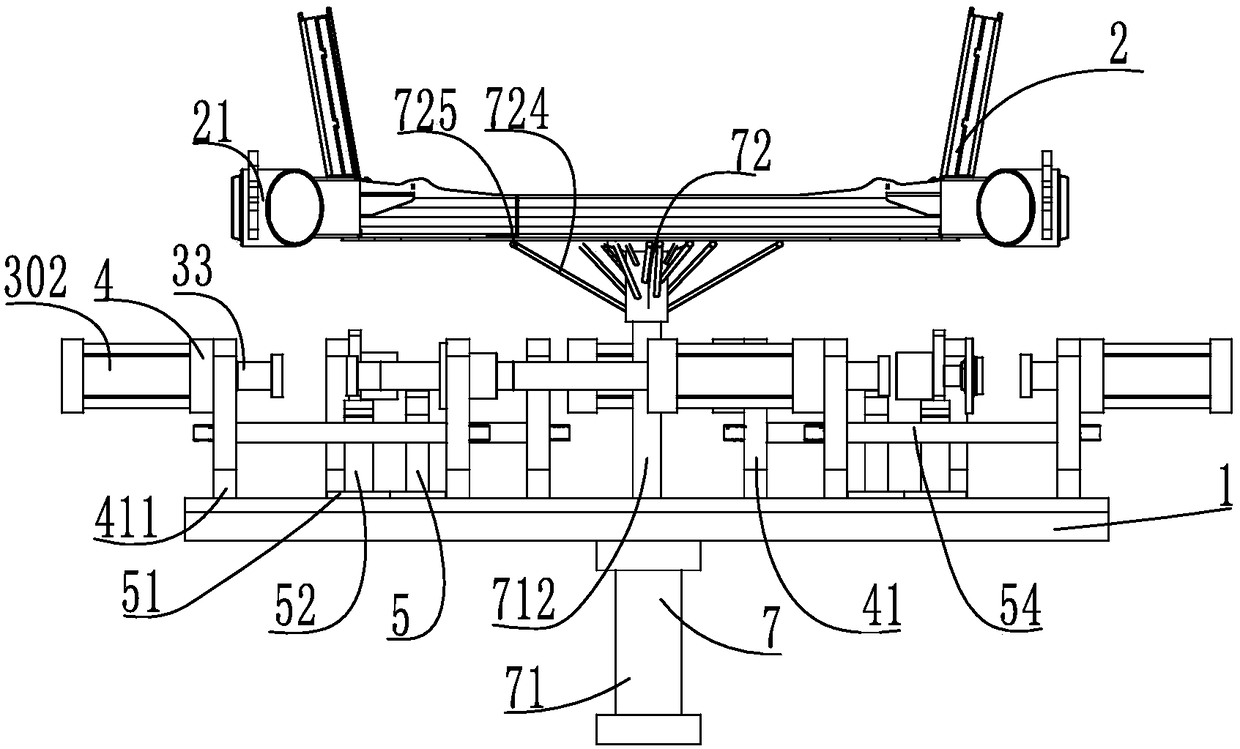

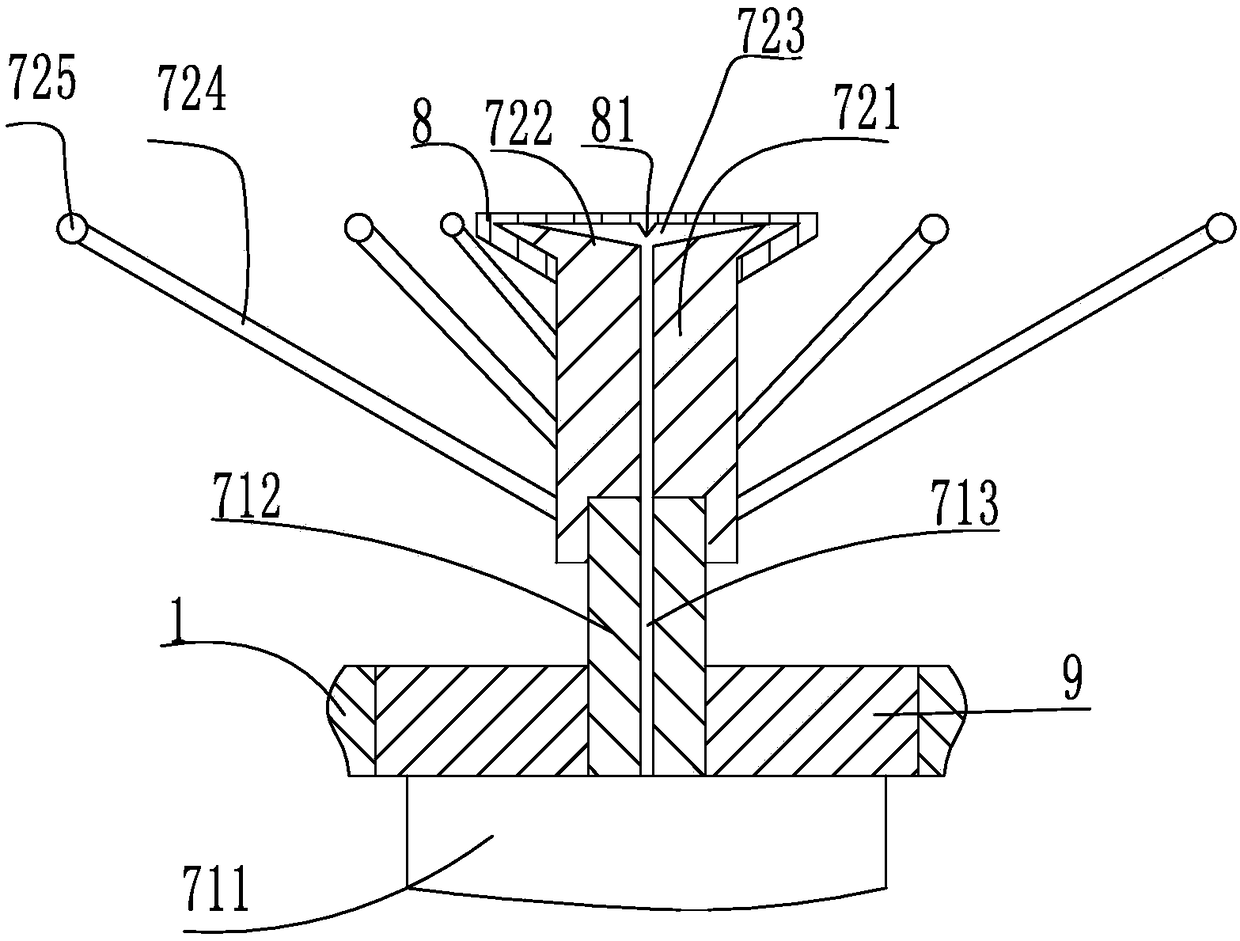

[0030] figure 1 Among them, a multi-station rear axle bearing synchronous positioning and pressing equipment includes a workbench 1 and a rear axle mold 2. The rear axle mold 2 includes several bearing seats 21, and bearing seats 21 are provided with bearings to be pressed. Each bearing seat At least one side of the two axial sides of 21 is provided with a pressure applying cylinder 3; 4. The fixed block 4 is a cuboid structure. The upper side of the fixed block 4 is provided with stress-resistant transition chamfers. The lower side of the fixed block 4 extends to both sides to form two connecting ears 41. The fixed block 4 is perpendicular to the upper working plane. The planes where the different fixing blocks 4 are located are parallel to each other, and the fixing blocks 4 are fixed on the working upper plane of the work bar by connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com