Patents

Literature

53results about How to "Large processing space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

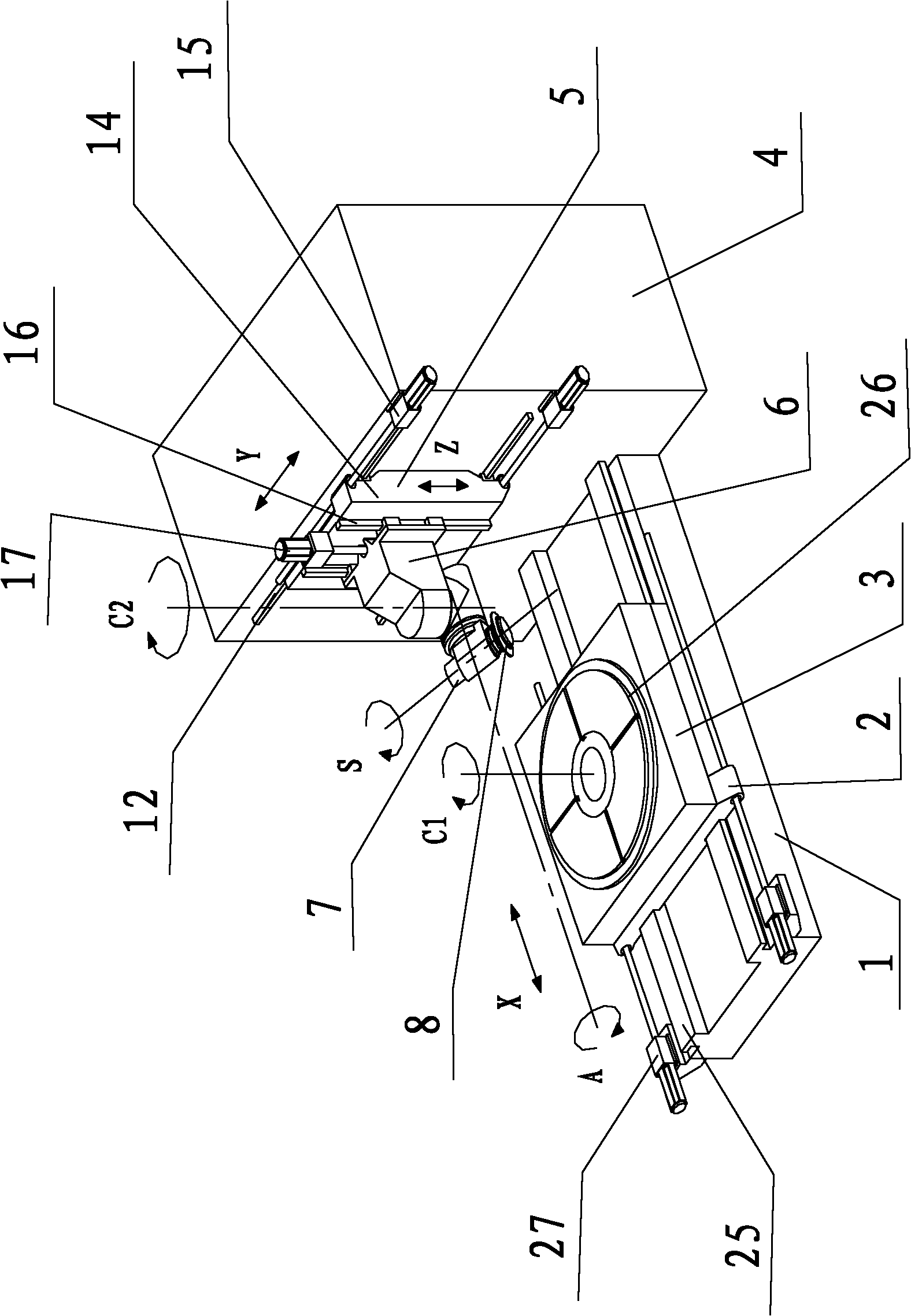

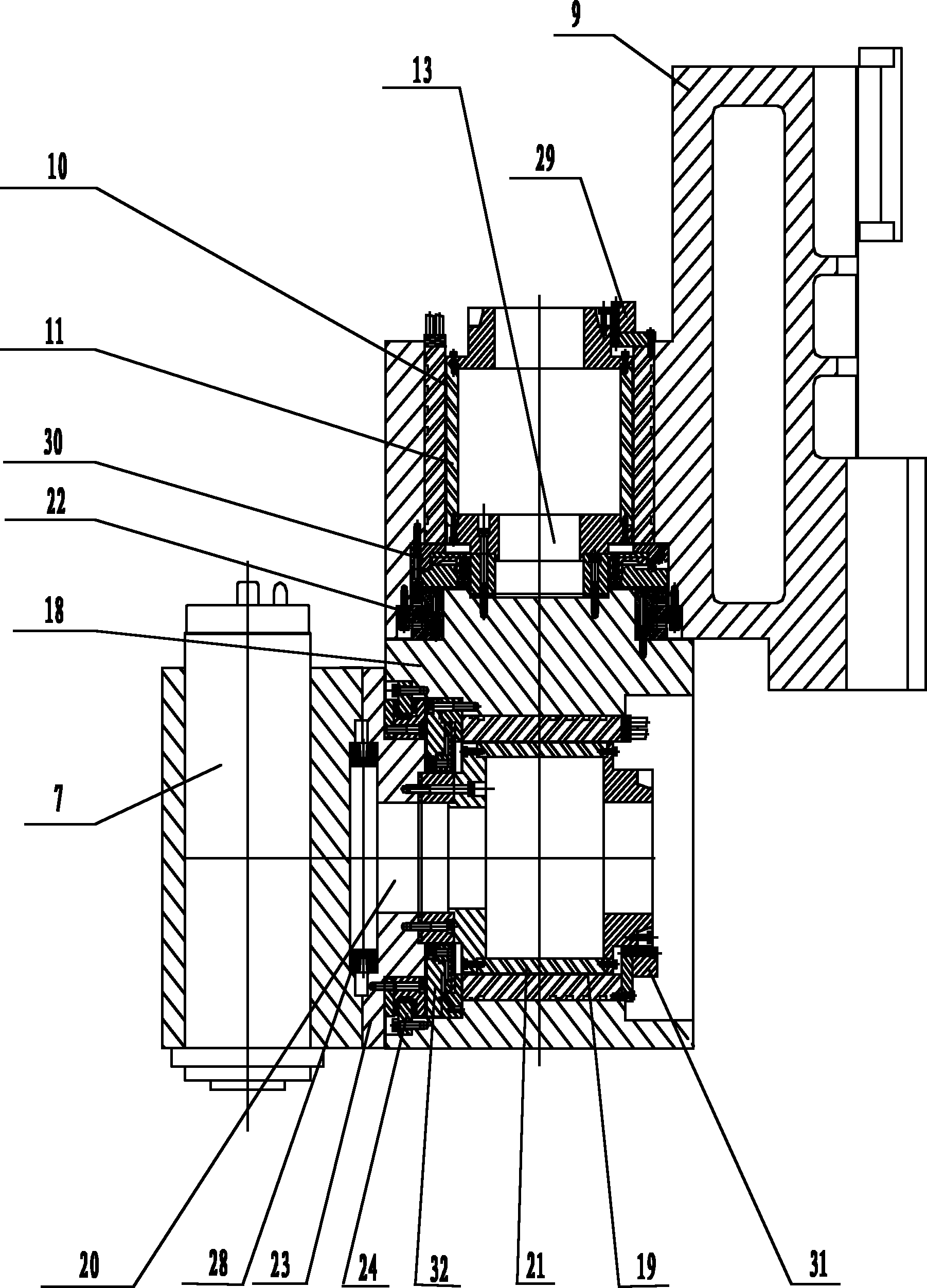

Large-scale numerical control gear machining machine tool

ActiveCN102151909AImprove machining accuracyImprove processing efficiencyLarge fixed membersDriving apparatusLinear motionImpeller

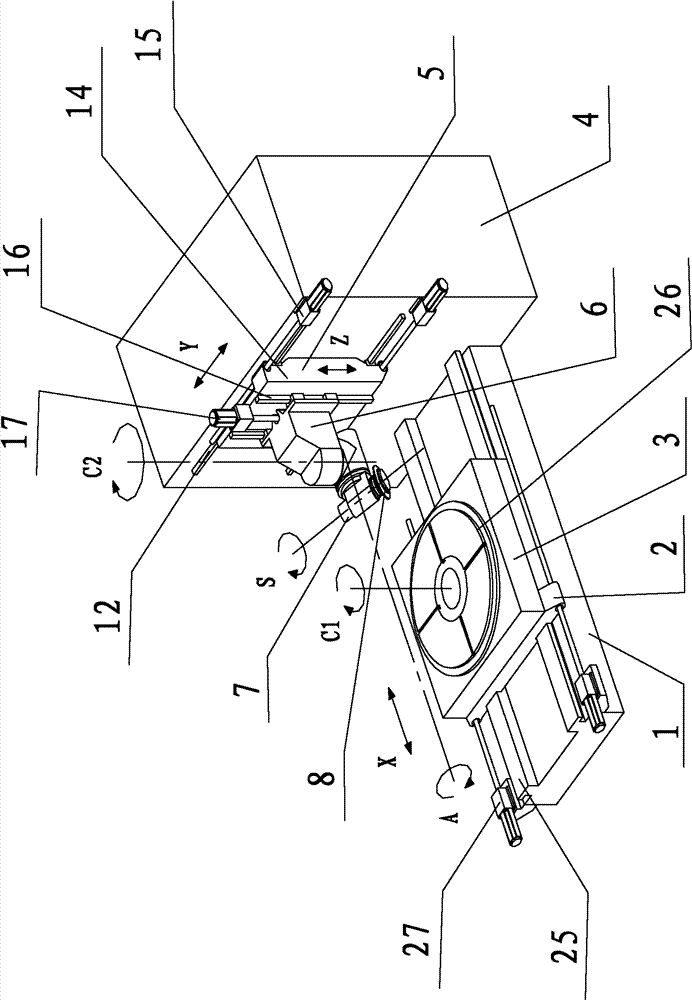

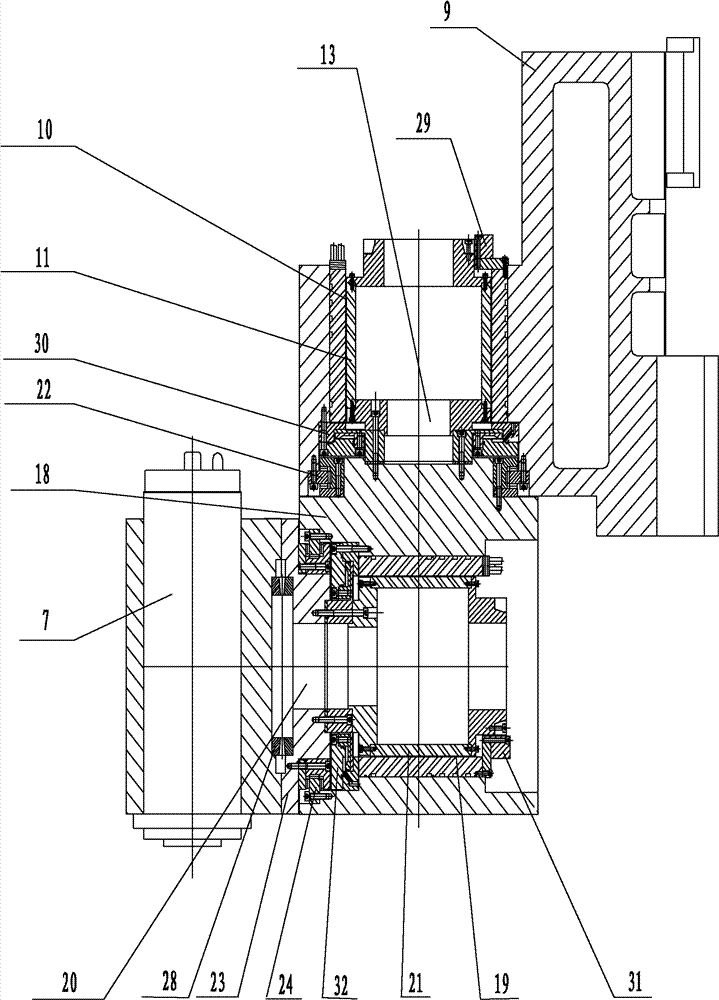

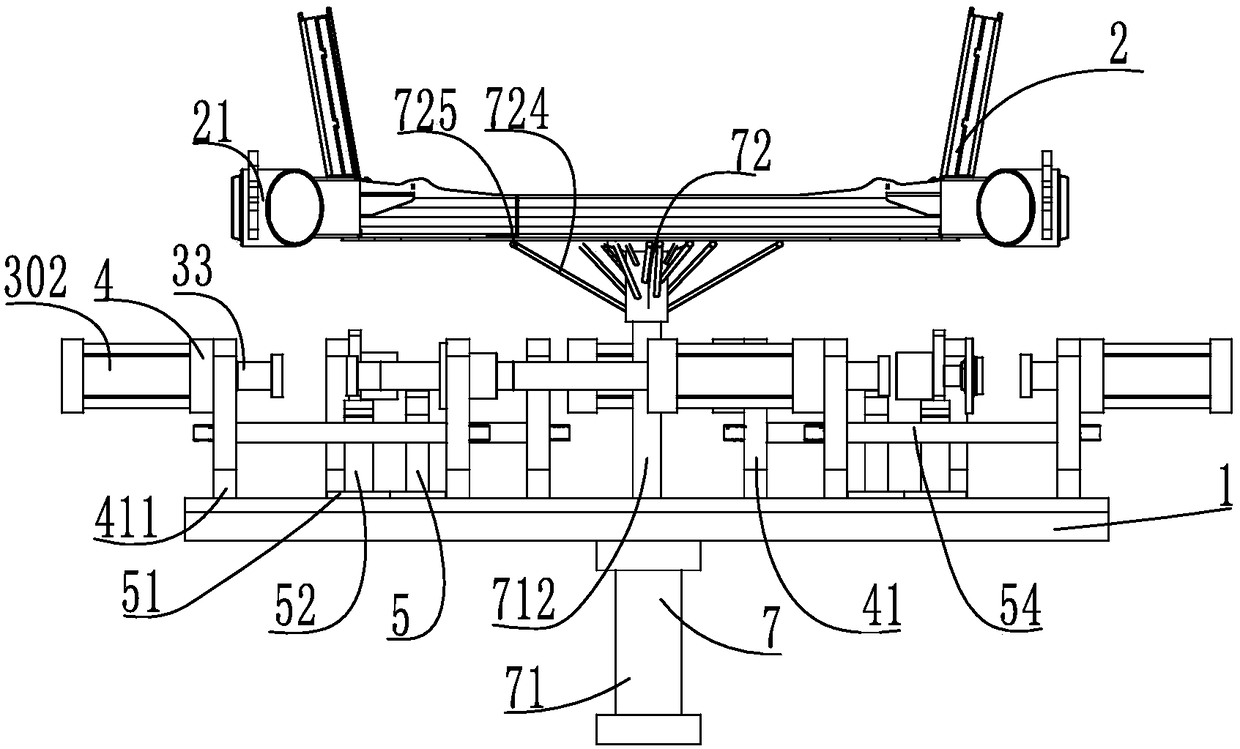

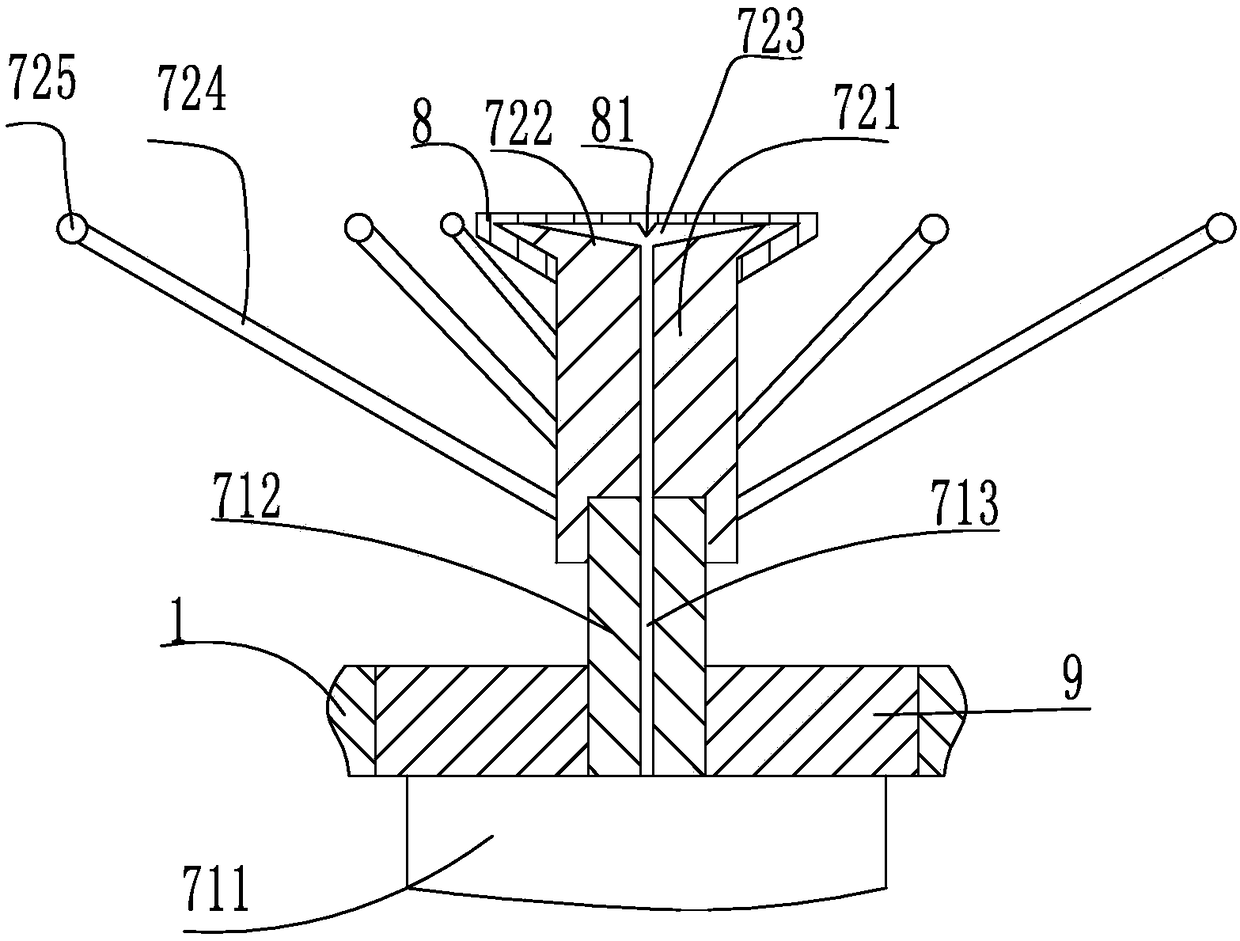

The invention provides a large-scale numerical control gear machining machine tool which has six numerical control coordinate axes, namely X, Y, Z, A, C1 and C2 and adopts a two plus four layout manner. A workpiece has two freedom motion, namely linear motion along the X axis and rotational motion around the C1 axis; and a tool has four freedom motion, namely linear motion along the X axis and the Z axis and rotational motion around the A axis and the C2 axis. The large-scale numerical control gear machining machine tool adopts a six-axis (X, Y, Z, A, CI and C2 axis) five-linkage (X, Y, Z, A and C2 axis linkage) structure; the five numerical control coordinate axes, namely the X, Y, Z, A and C2 axes carry out interpolation motion; and the indexing movement of the workpiece is controlled by the C1 axis to process all tooth surfaces. The rotational axis of the workpiece, namely the C1 axis only finishes the indexing movement and does not participate in the interpolation motion formed bythe tooth surfaces so as to improve the processing precision and the processing efficiency of a large-scale gear. The large-scale numerical control gear machining machine tool can be constructed intoa gear miller or a gear grinder, thereby realizing the curved surface machining of a cylindrical gear, a bevel gear, an impeller and others with the indexing features.

Owner:秦川机床工具集团股份公司

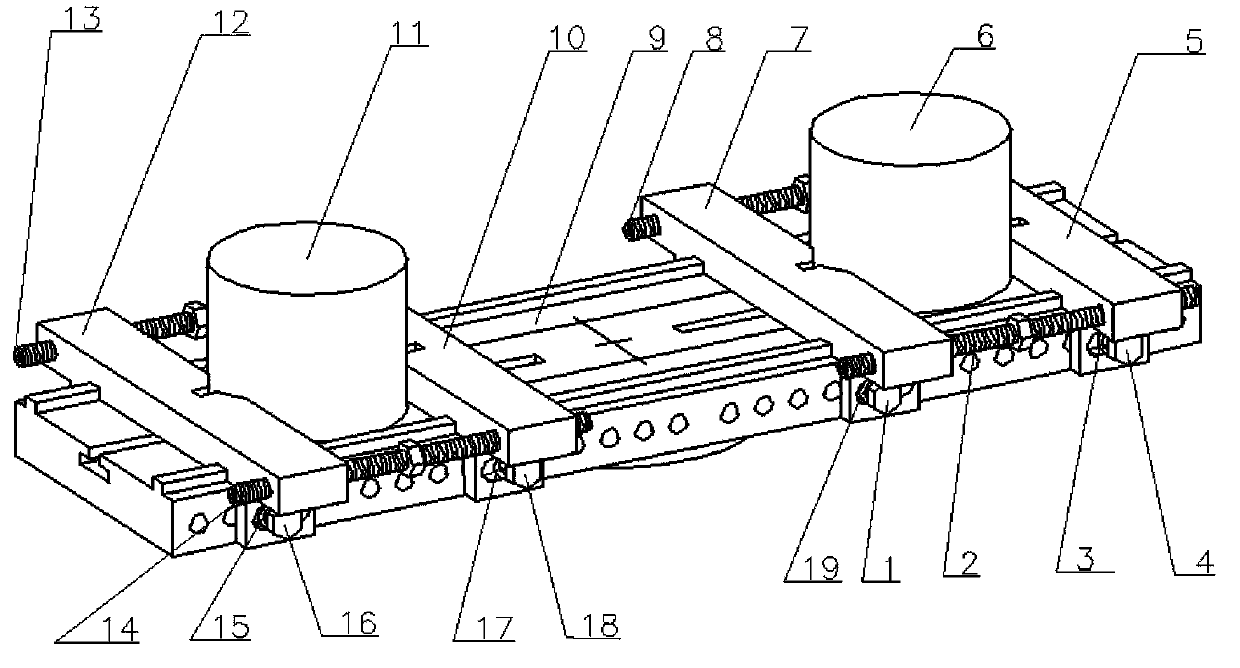

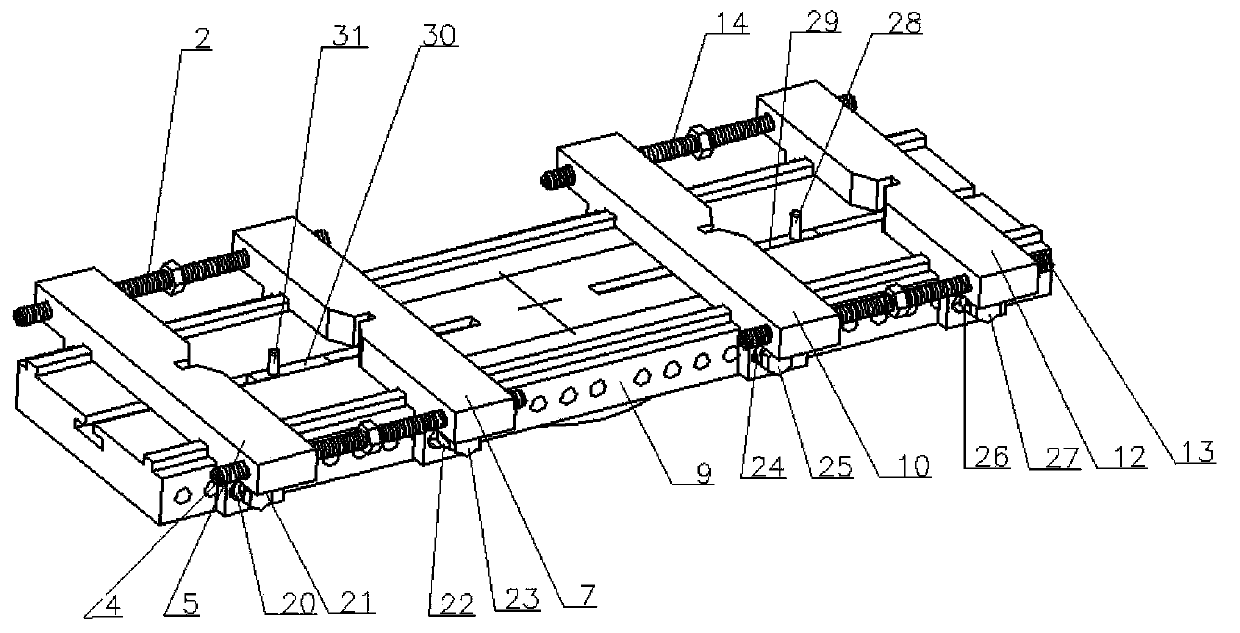

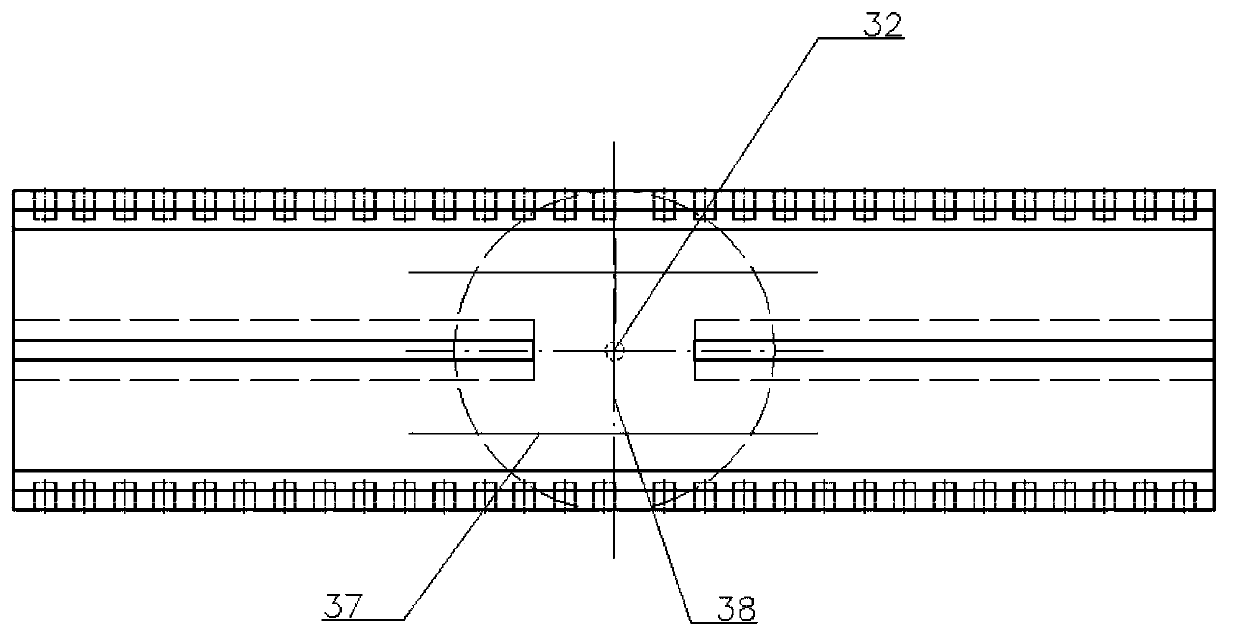

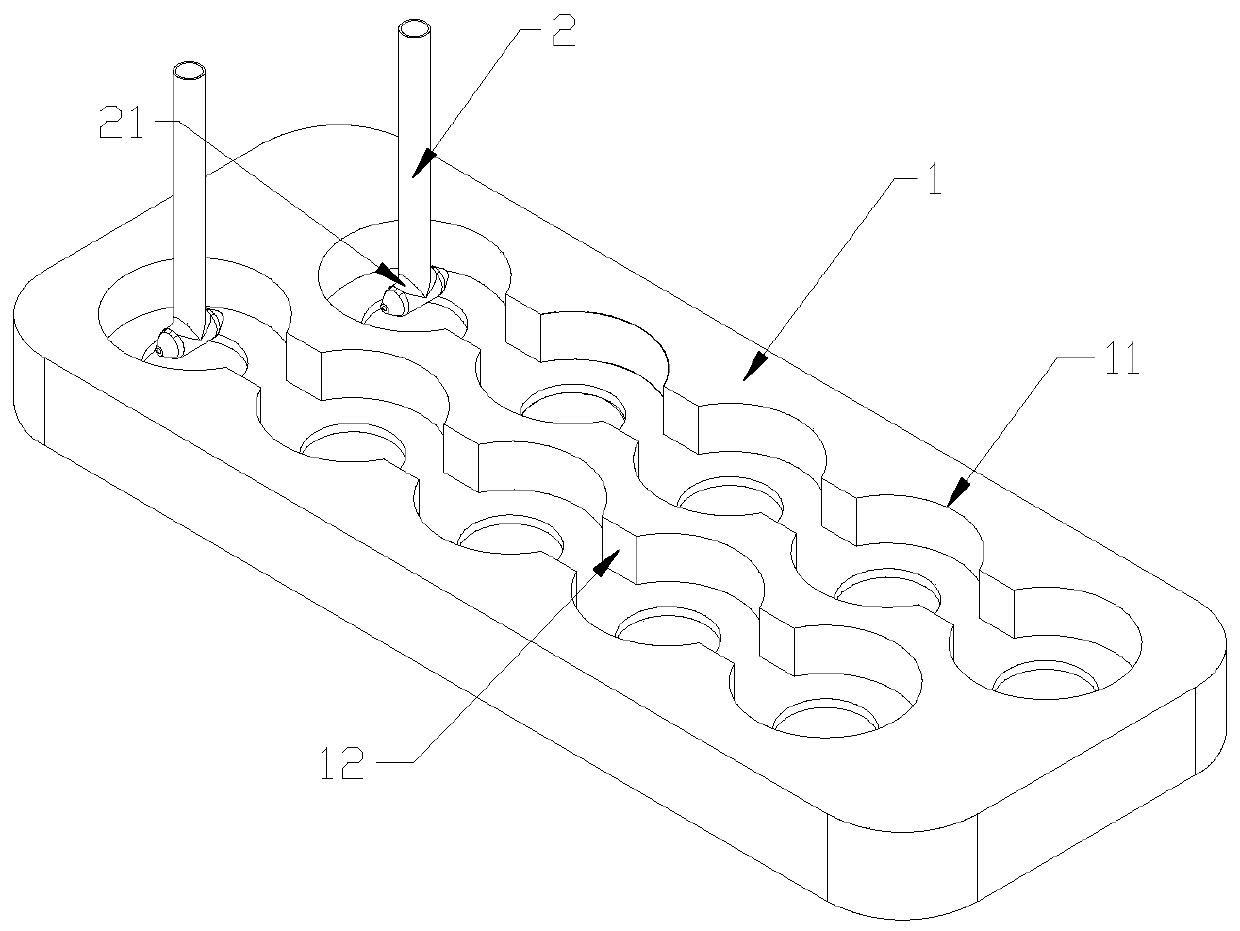

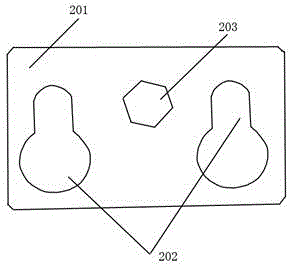

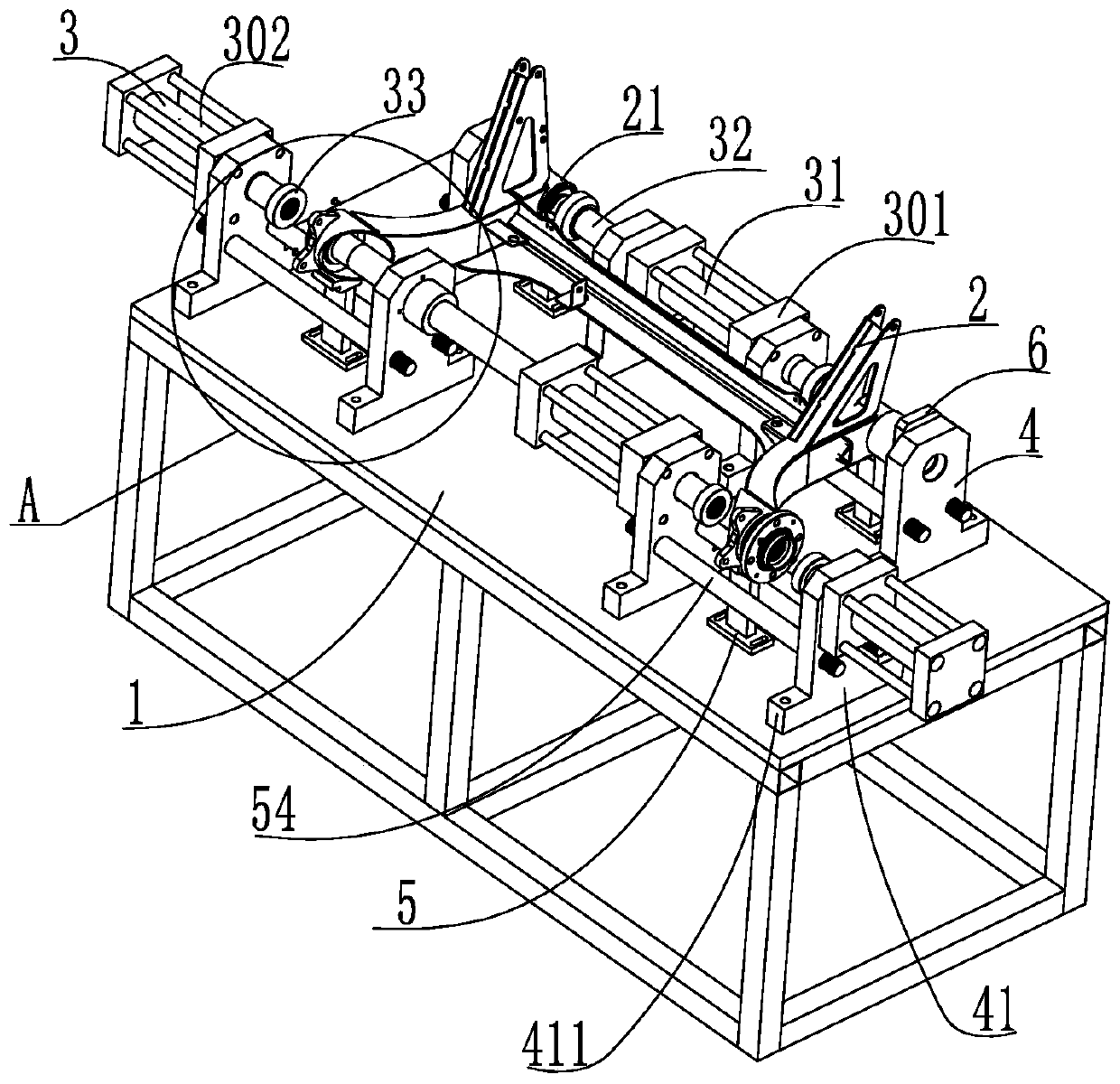

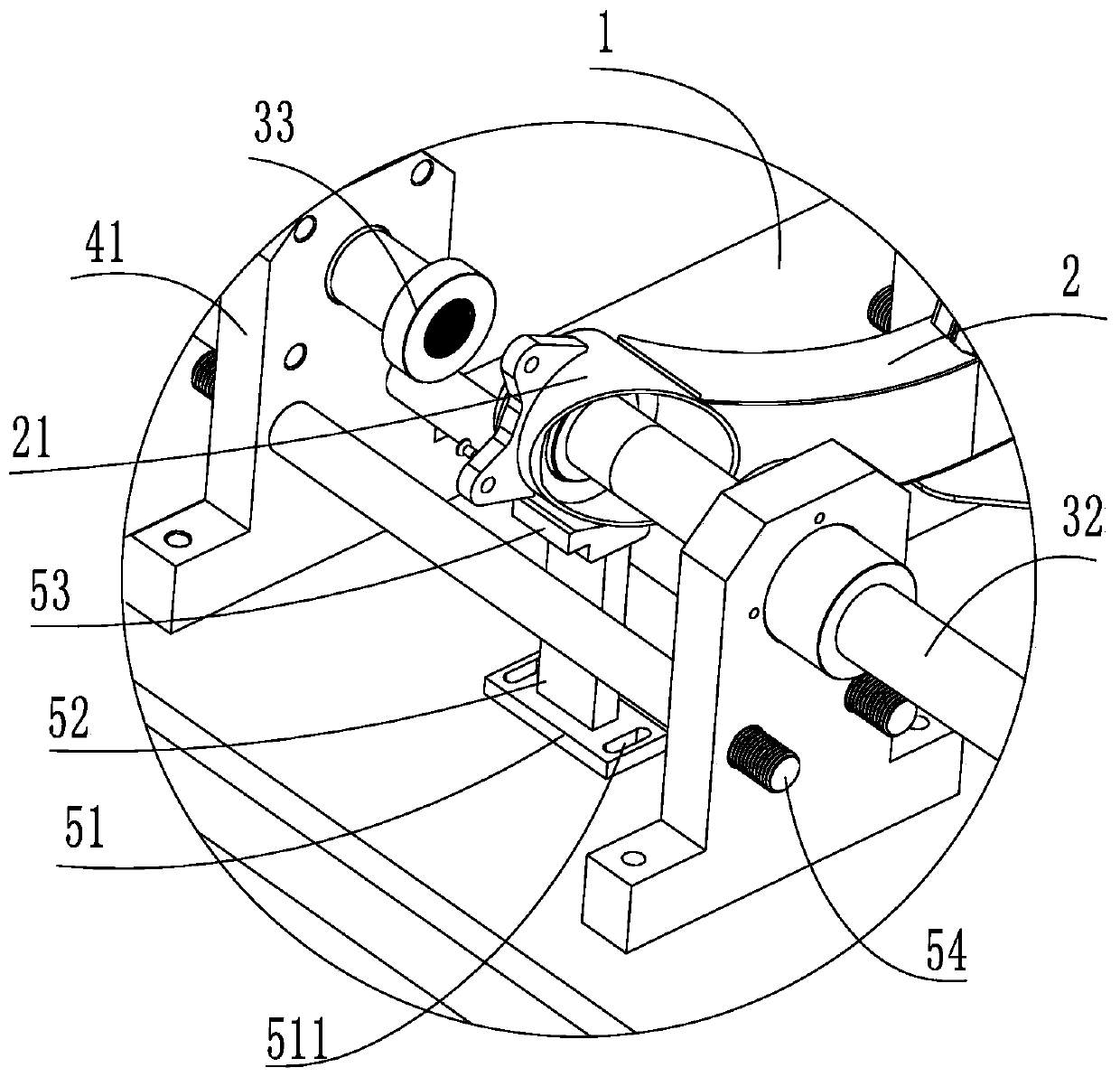

Rotation surface precision machining clamp with adjustable off-axis quantity

ActiveCN103386619ASolve processing problemsLarge processing spacePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a rotation surface precision machining clamp with adjustable off-axis quantity. A guide groove on a V-shaped block can slide along a guide rail on a clamp bottom plate, a T-shaped sliding block is movably connected with a T-shaped groove on the clamp bottom plate, a locating pin is detachably connected in the T-shaped sliding block, a cylindrical workpiece is detachably connected with the T-shaped sliding block through the locating pin so that the location of the cylindrical workpiece on the clamp bottom plate is realized, and the fixing of the V-shaped sliding block and the clamp bottom plate can be realized in a way that the V-shaped sliding block is in threaded connection with corresponding threaded holes in equidistant threaded hole arrays at two sides of the clamp bottom plate. The rotation surface precision machining clamp provided by the invention is suitable for cylindrical workpieces in different sizes, different shapes and different off-axis quantities, the processing problem of a workpiece in larger off-axis quantity can be solved, the universality is better, the processing space is expanded, multiple workpieces can be clamped at the same time, and the processing efficiency is increased.

Owner:JILIN UNIV

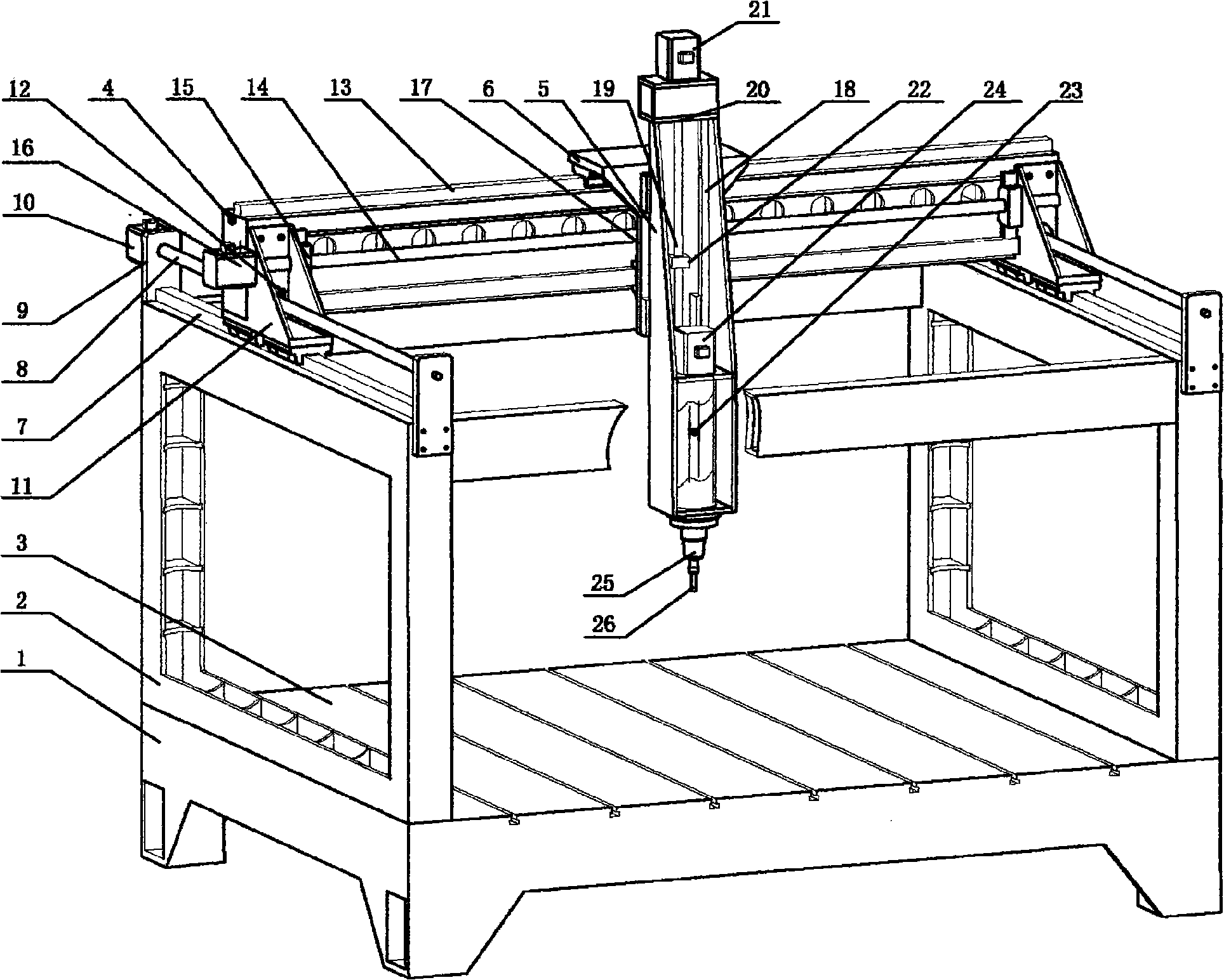

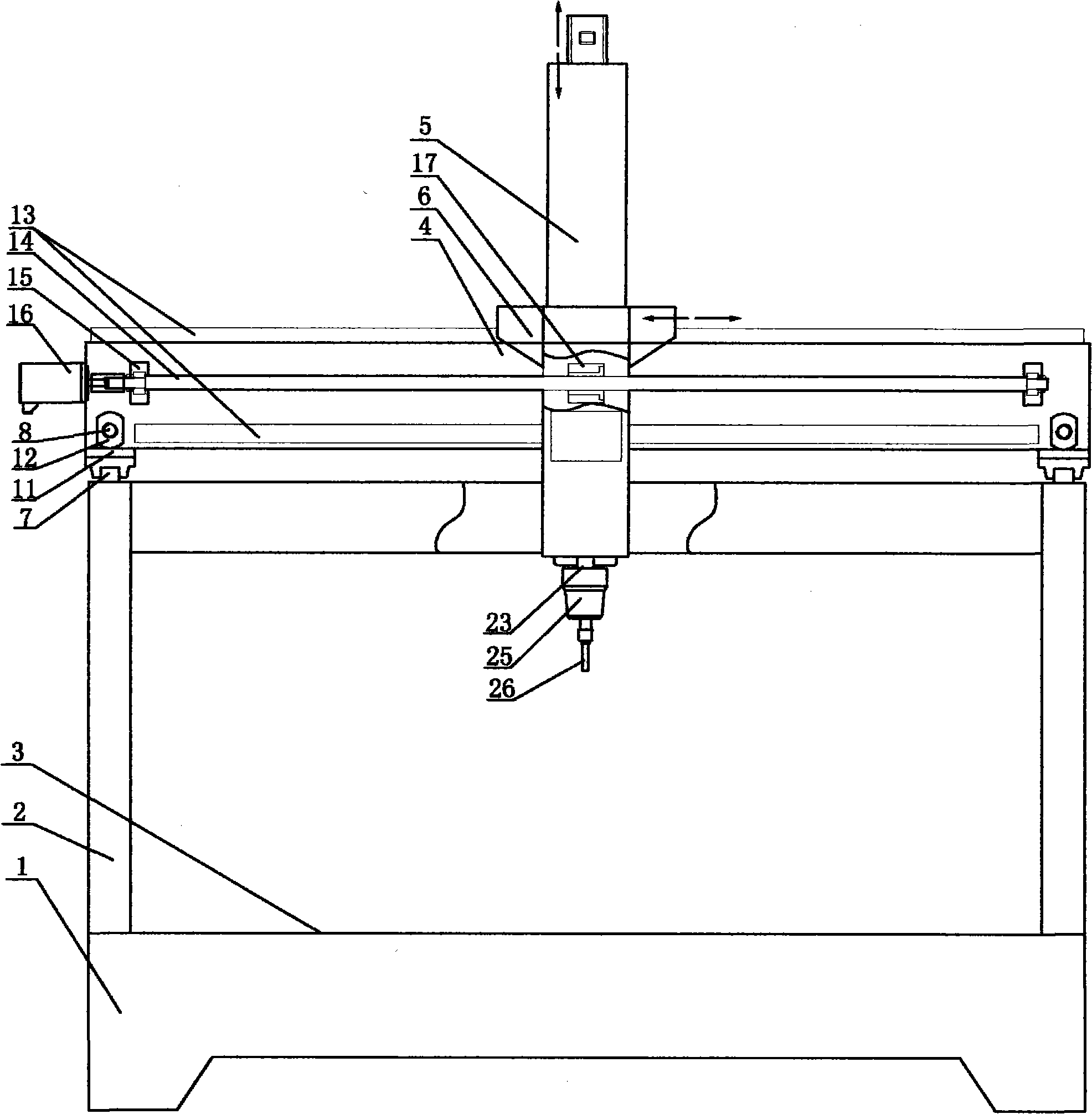

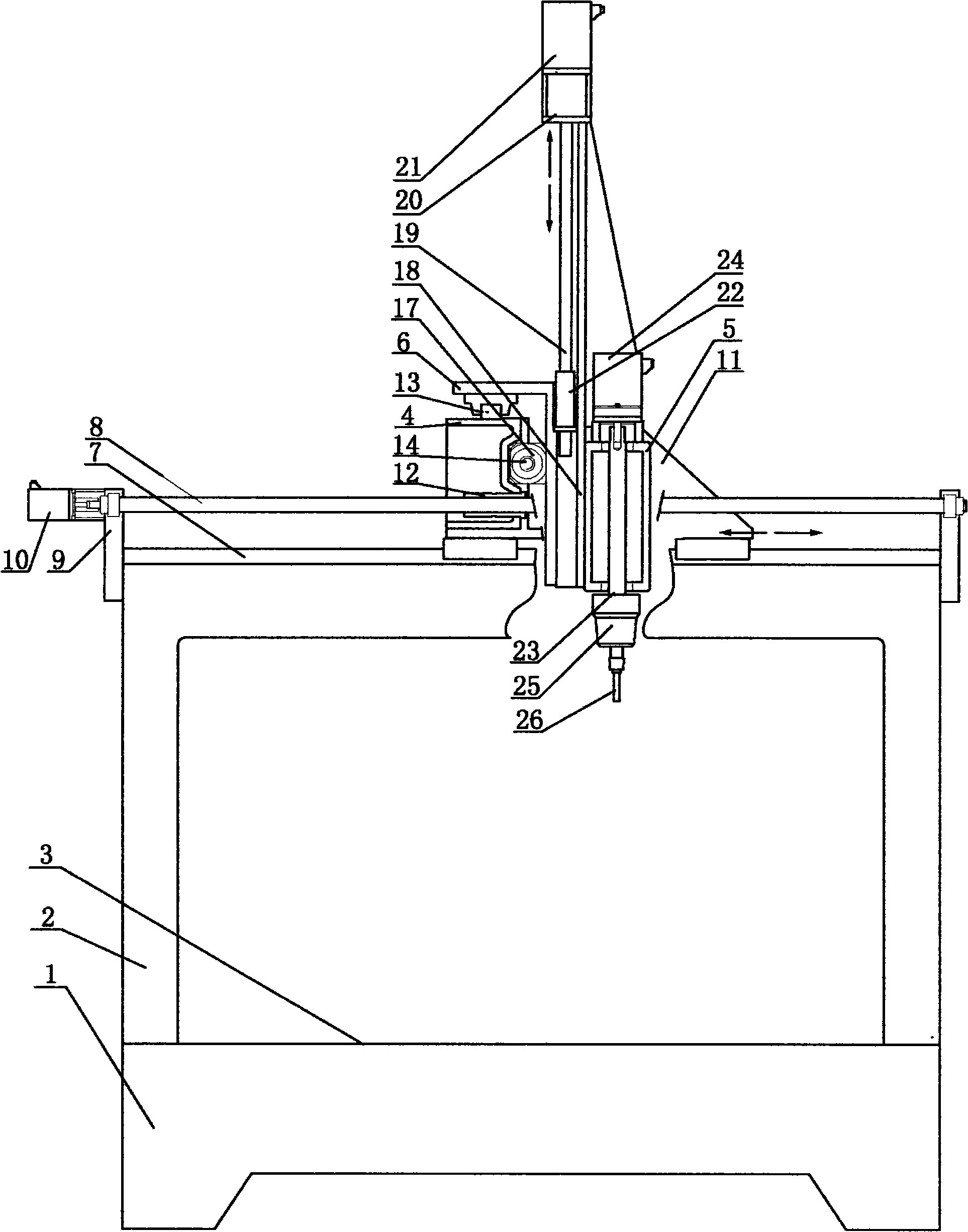

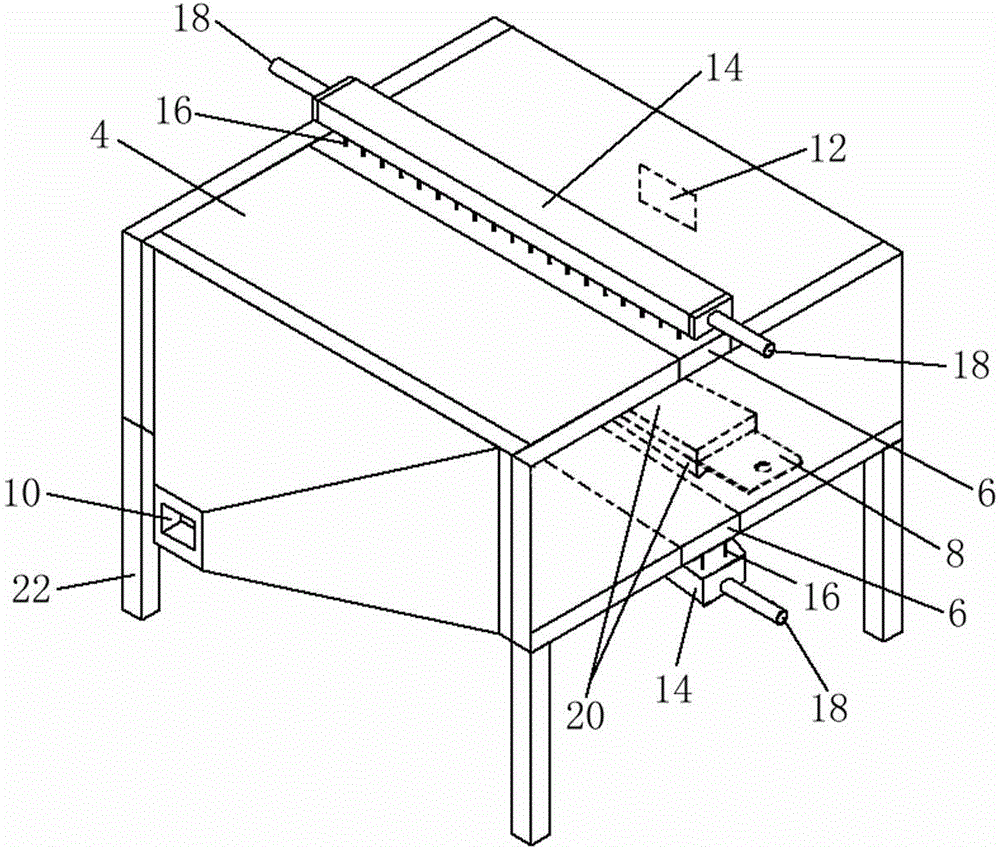

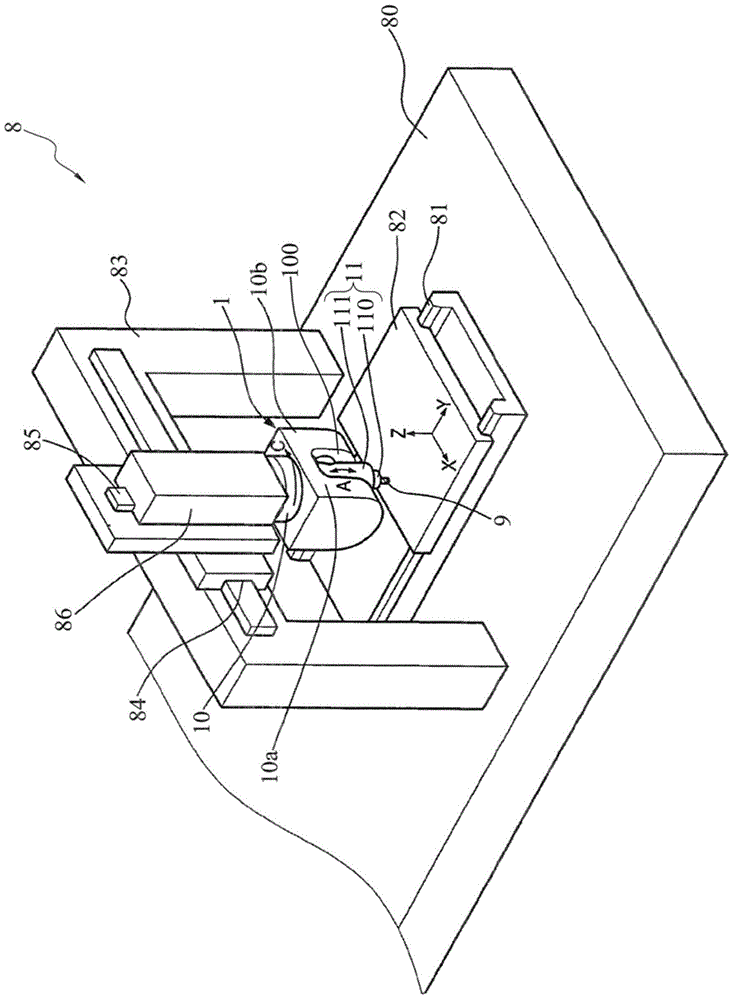

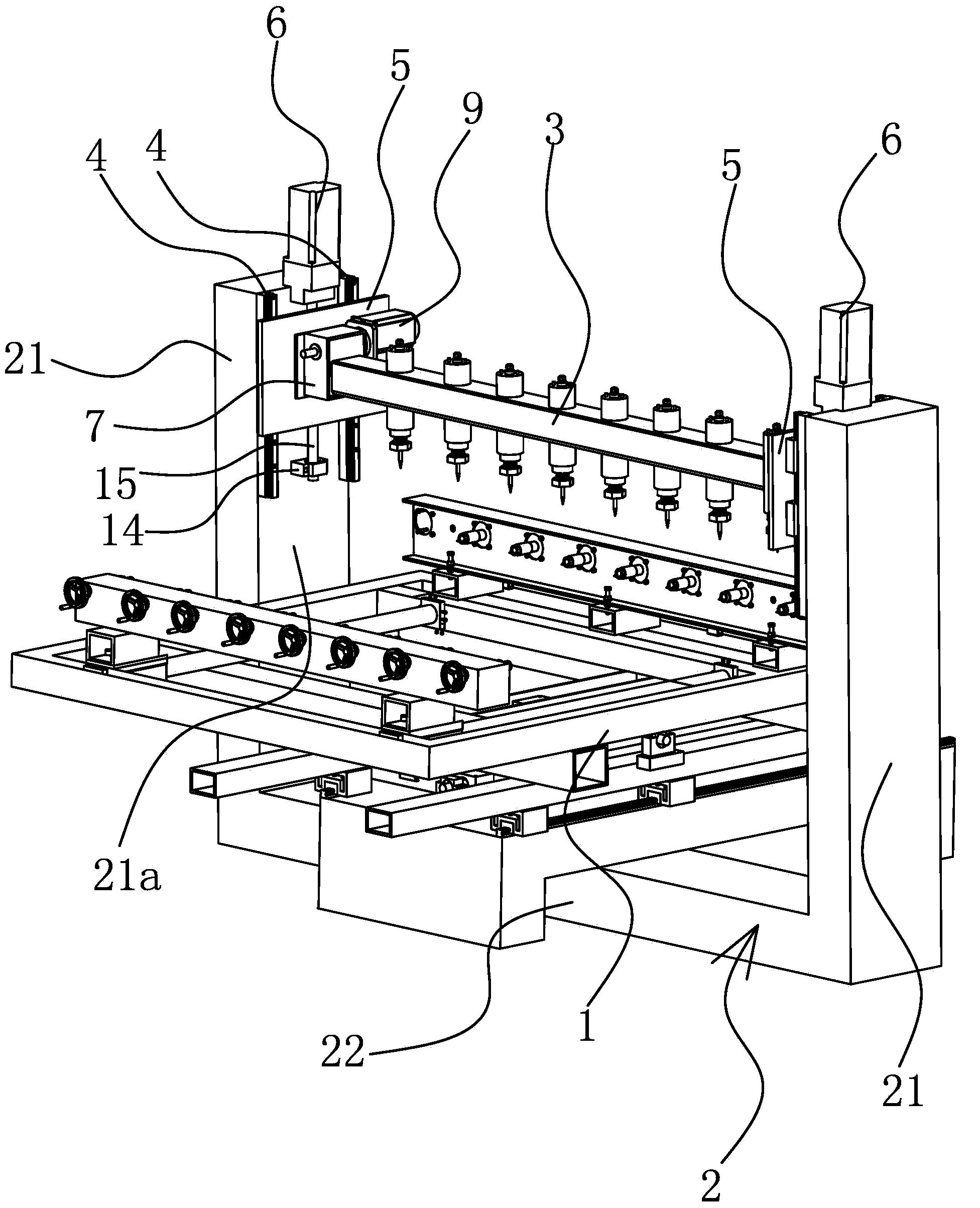

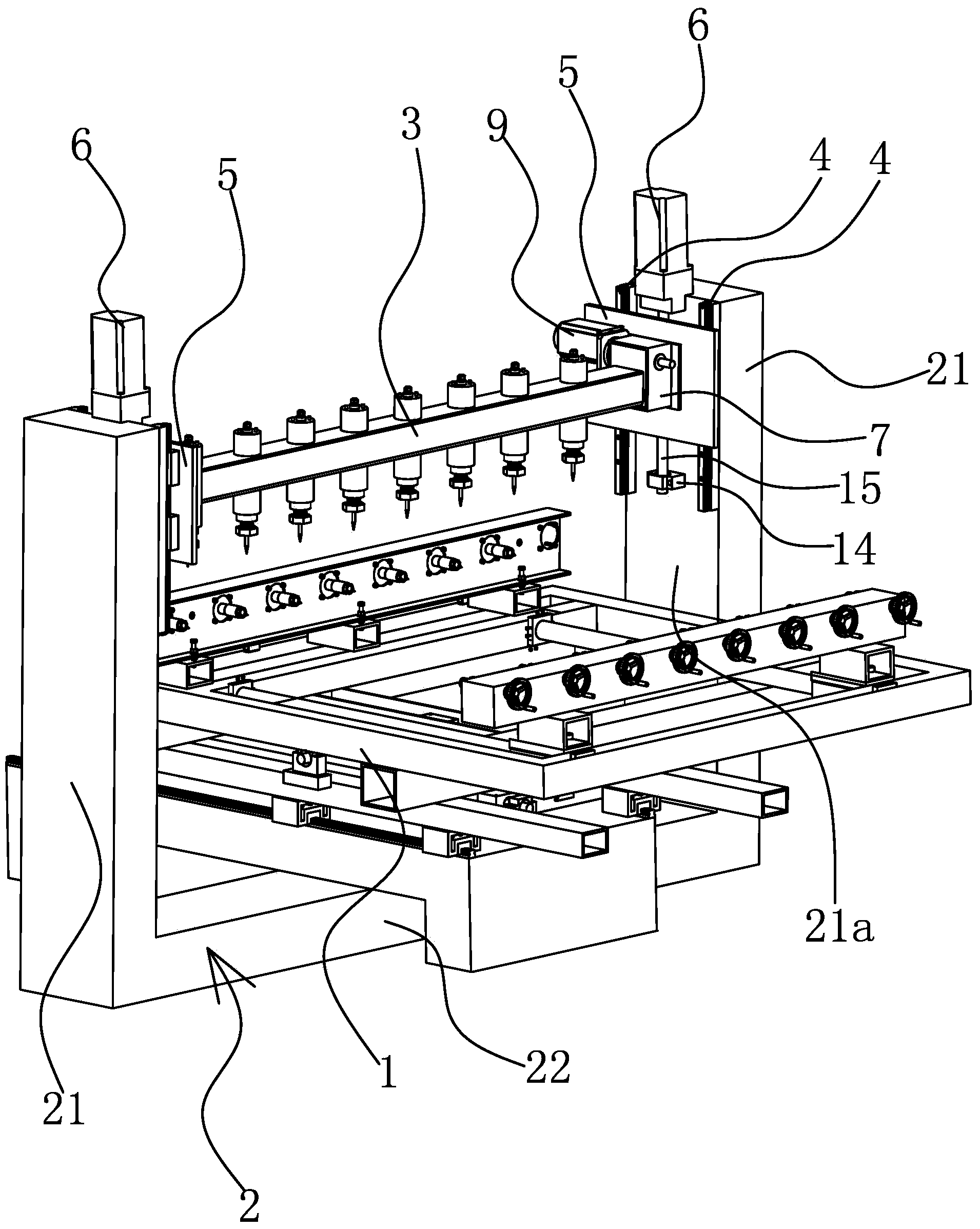

Three-dimensional multi-shaft interlocked numerical controlled engraving and milling device

InactiveCN101491843AImprove processing levelLarge processing spaceMilling machinesLarge fixed membersNumerical controlEngraving

The invention relates to a three-dimensional multishaft ganged digital control engraving and milling machine, which is particularly suitable for performing cutting and engraving and milling processing on large nonmetallic products. The three-dimensional multishaft ganged digital control engraving and milling machine comprises a stand, a body, a work table, a working beam, a Z axial body, a Z axial body support and a digital control unit which is used for controlling the operation of a machine tool, wherein the working beam is connected with the body through a Y axial guide rail and driven by a drive unit to move along a Y axis; the Z axial body support is connected with the working beam through a Z axial guide rail and driven by a drive unit to drive the Z axial body to move along an X axis; the Z axial body is connected with the Z axial support through the Z axial guide rail and driven by a drive unit to move along a Z axis; the body is set to have a frame structure; a Y axial guide rail is arranged on two longitudinal beams of the body respectively; the working beam and a longitudinal beam of the stand form guide rail connection through a beam support; an A axis is arranged on the Z axial body and can perform horizontal and circumferential rotation when being driven by a drive unit; and a C axis is arranged on the A axis and can perform perpendicular and circumferential rotation when being driven by a drive unit. The three-dimensional multishaft ganged digital control engraving and milling machine can implement engraving and milling processing on three-dimensional five axes of the large products when the digital control unit controls various drive units, and the processing level of the machine tool is higher.

Owner:袁焕春 +1

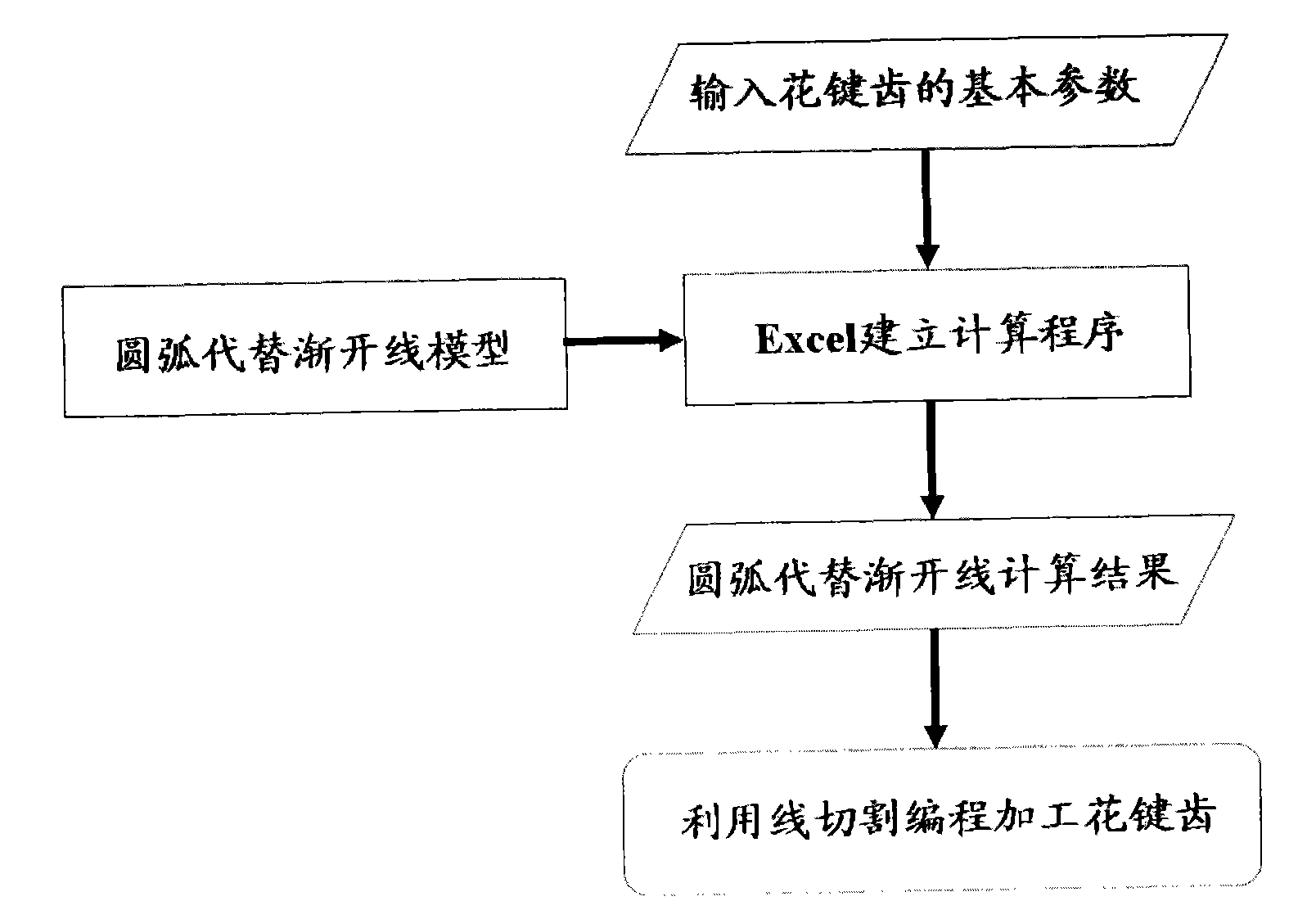

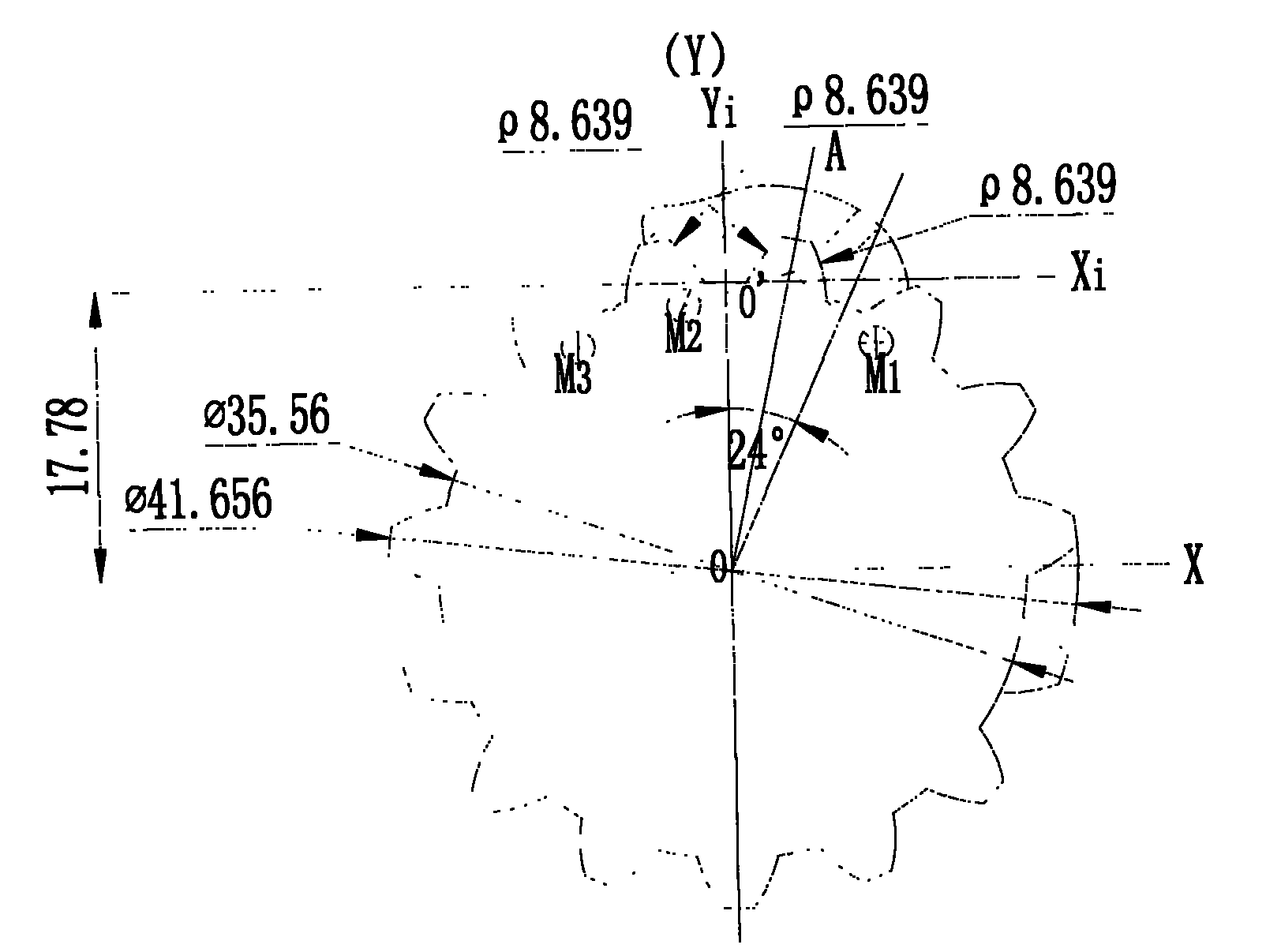

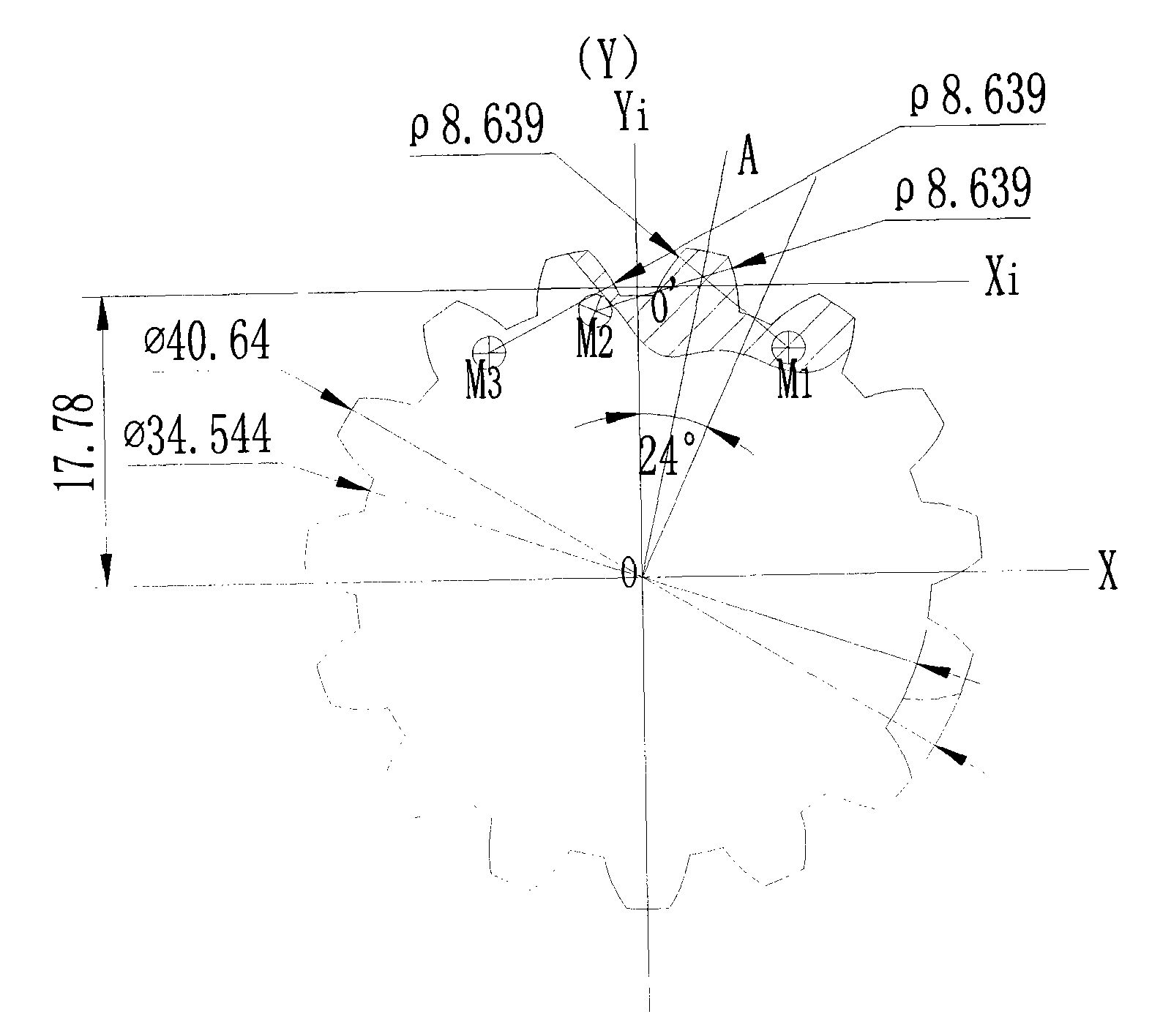

Process technique for processing spline tooth profiles through replacing involutes with circular arcs

The invention discloses a process technique for processing spline tooth profiles through replacing involutes with circular arcs, which belongs to the process field of machining. The process technique is implemented by making a calculation program for replacing involutes with circular arcs which are made by an Excel of a computer, so that the results produced by replacing involutes with circular arcs can be displayed immediately just by modifying the basic parameters of spline tooth profiles. According to the invention, spline tooth profiles are processed through replacing involutes with circular arcs, so that the processing of tooth profiles is realized by using a linear cutting machine under the condition that no device such as broaching machines, slotting machines, gear-hobbing machines, and the like is used, the processing capacity is improved, the processing space is expanded, and the processing error of the process technique is just a few thousandths of an millimeter, therefore, the matching and exchanging with traditional processing tooth profiles can be realized, and the processing precision of the process technique can completely meet the application requirements.

Owner:王天甜

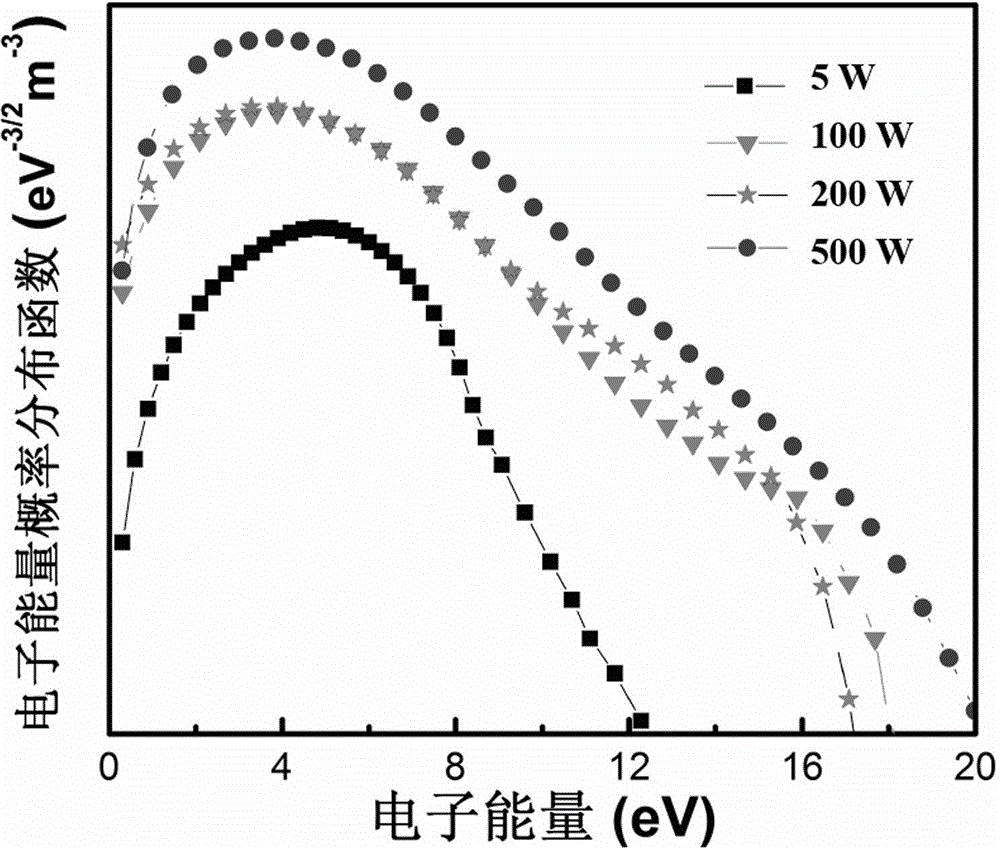

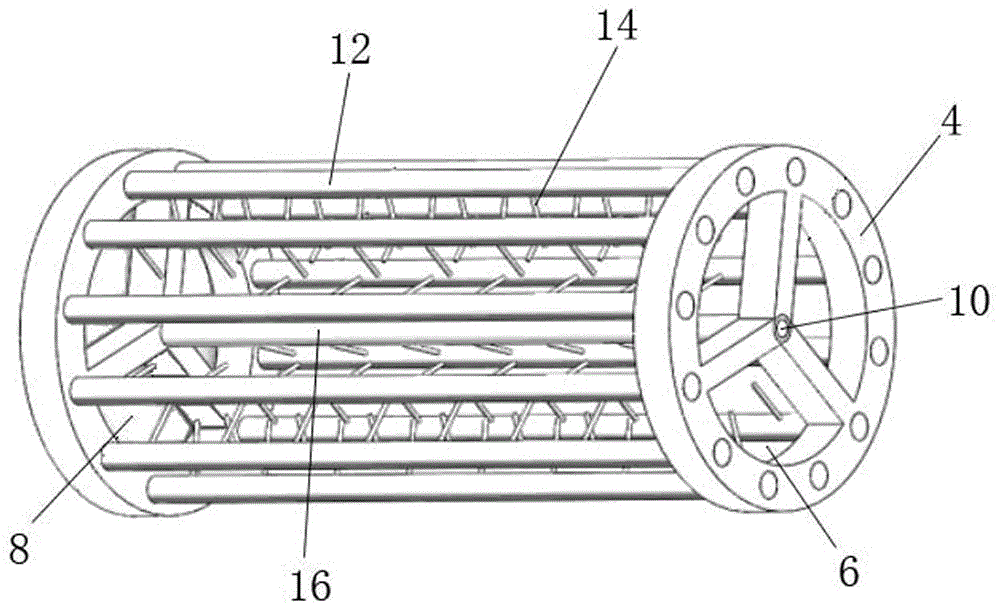

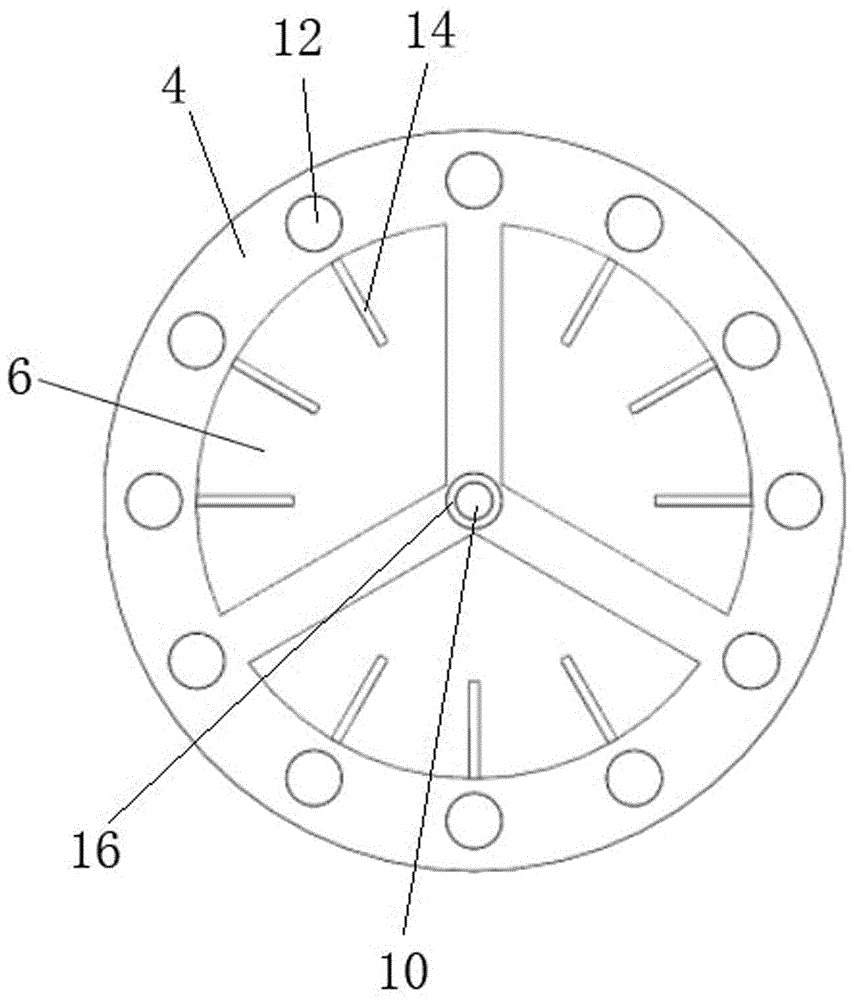

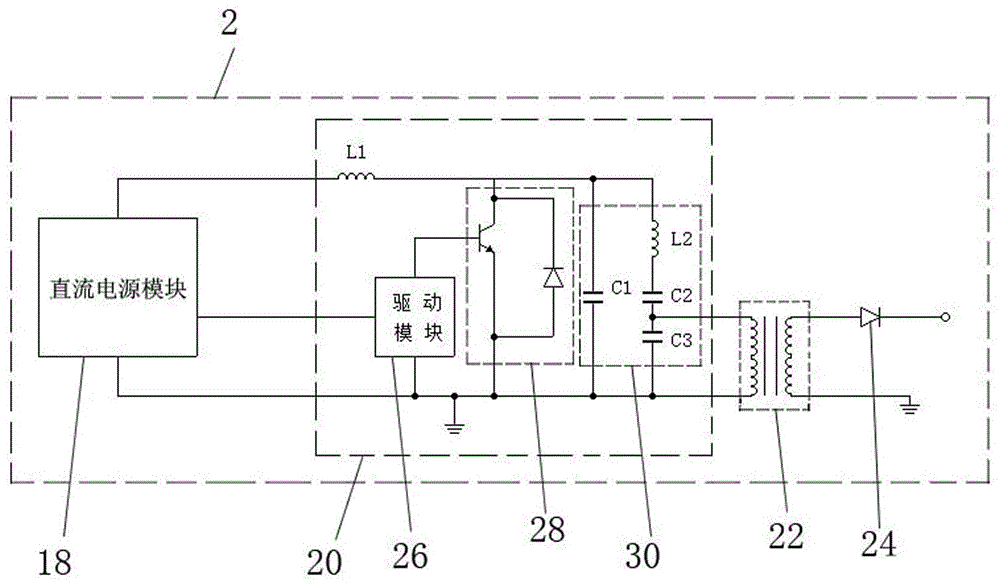

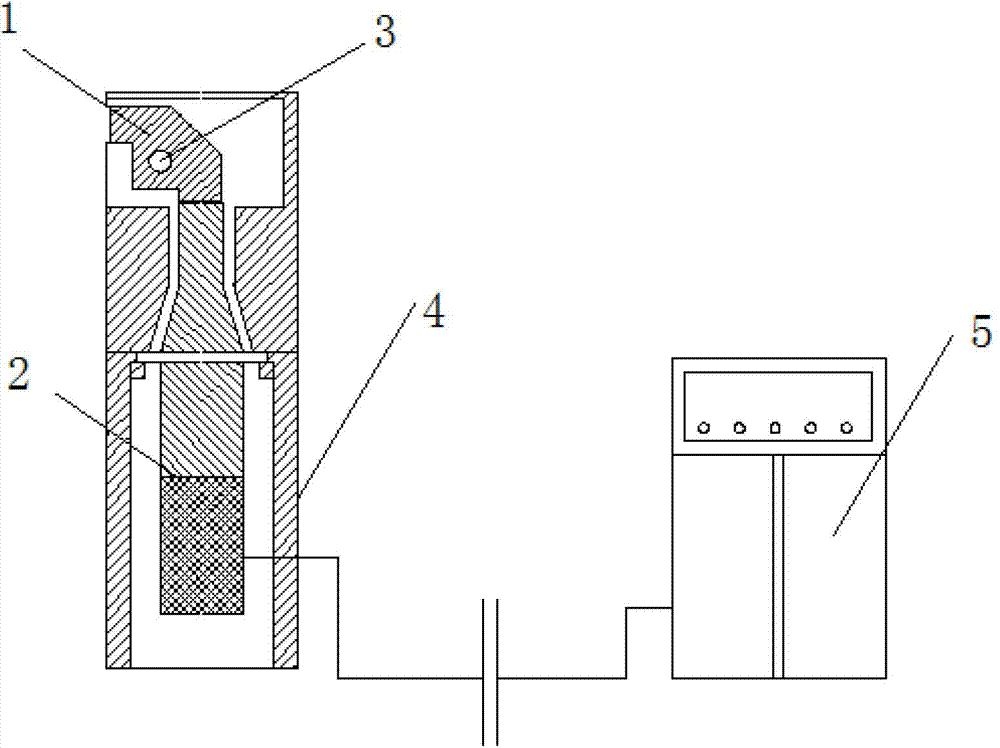

Air plasma waste gas treatment device and method

InactiveCN104689692AEasy to disassemble and cleanLarge spaceDispersed particle separationDielectric slabDecomposition

The invention relates to an air plasma waste gas treatment device. The air plasma waste gas treatment device comprises a high-voltage alternating-current power supply, a housing, two first dielectric slabs installed on the housing and a grounding electrode arranged in the housing, wherein a waste gas inlet and a waste gas outlet are respectively formed in two ends of the housing, a high-voltage electrode is installed on each first dielectric slab and comprises a conductive tube and a capillary tube with one end extending into the conductive tube, an air inlet is formed in at least one end of the conductive tube, the conductive tube is connected with the high-voltage end of the high-voltage alternating-current power supply, the grounding electrode is connected with the grounding end of the high-voltage alternating-current power supply, and the other end of the capillary tube is communicated with the housing. The invention further relates to an air plasma waste gas treatment method. The air plasma waste gas treatment device and method have the advantages of efficient decomposition and low treatment power consumption, and a new thought is provided for industrial waste gas treatment.

Owner:SUZHOU UNIV

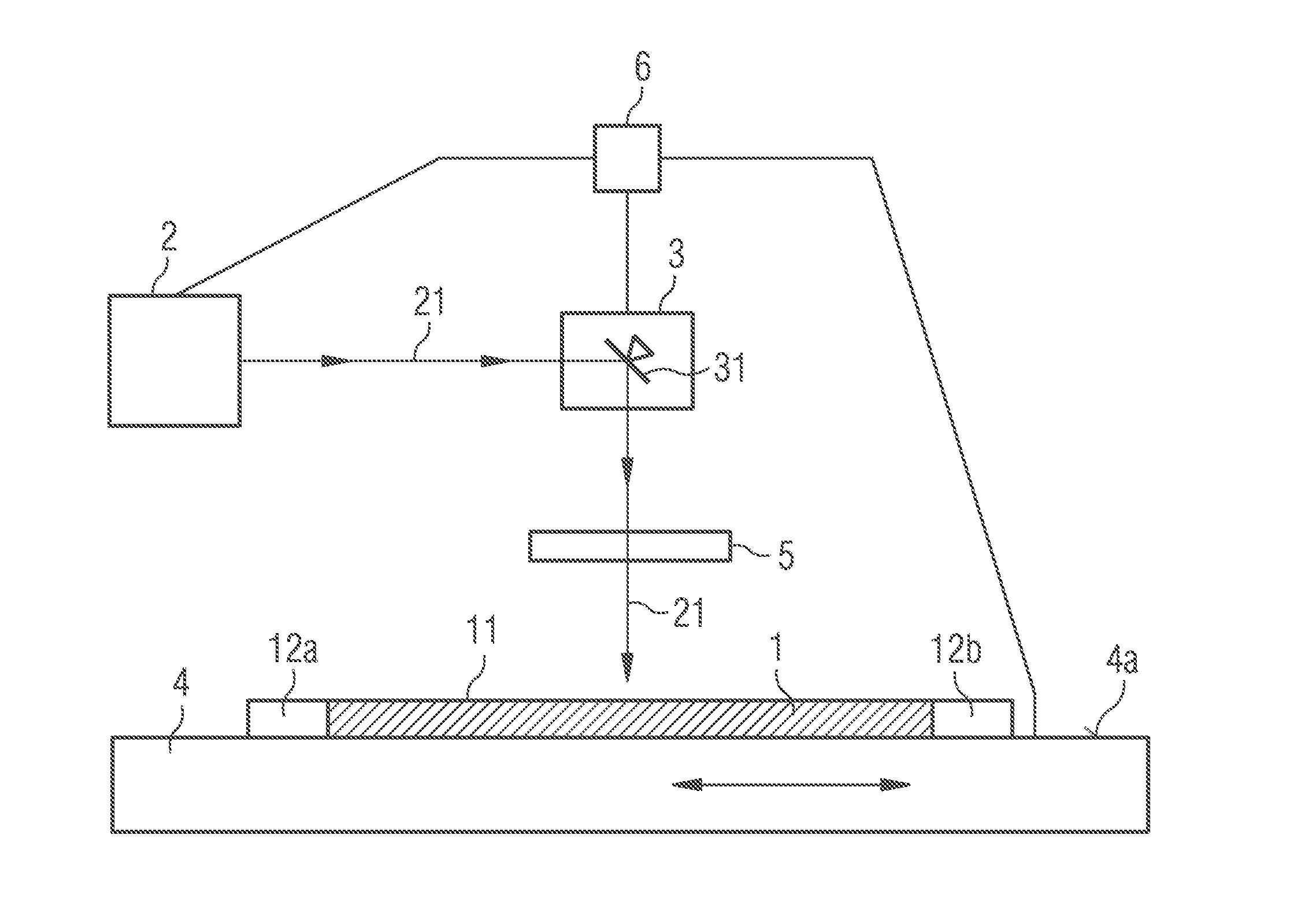

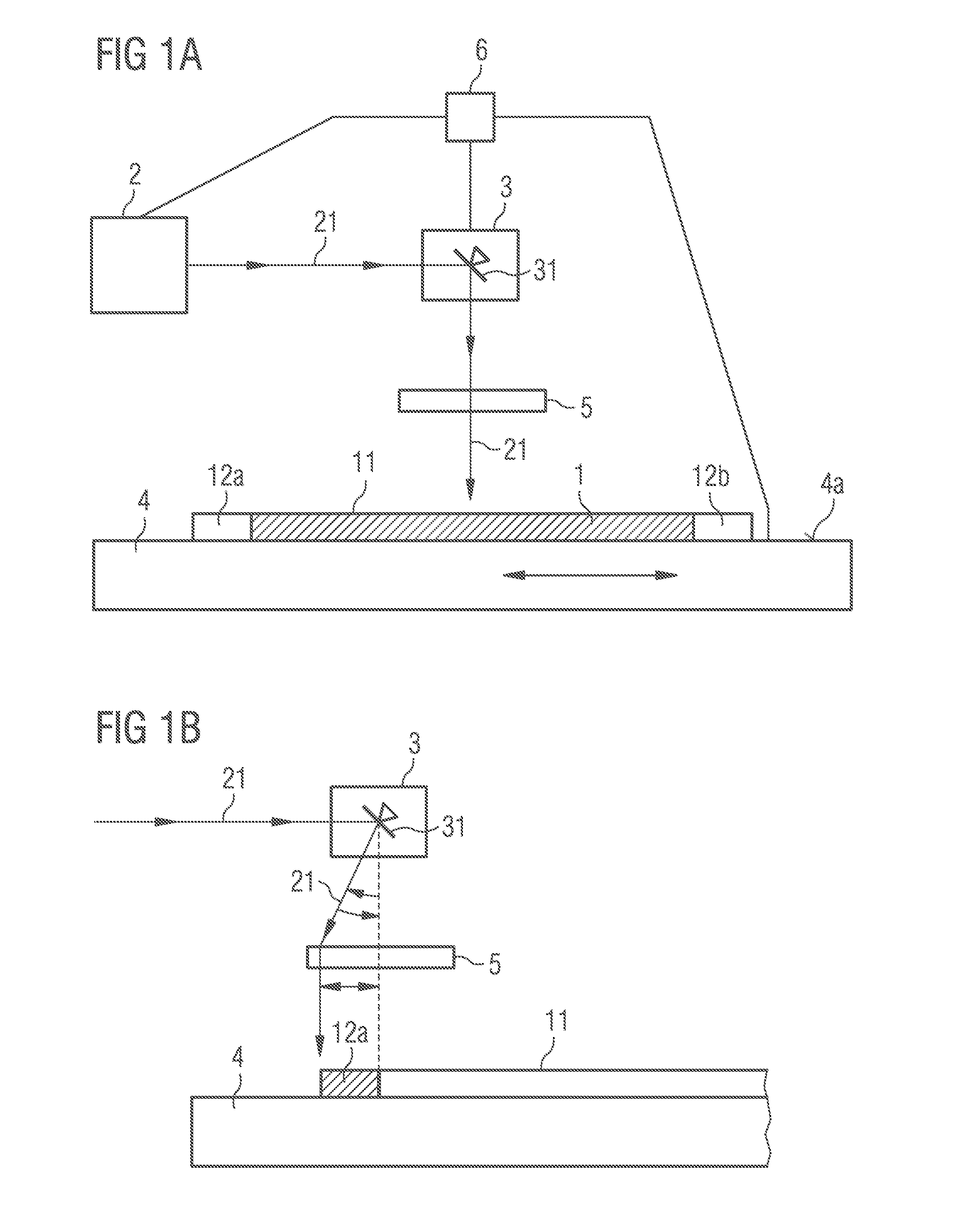

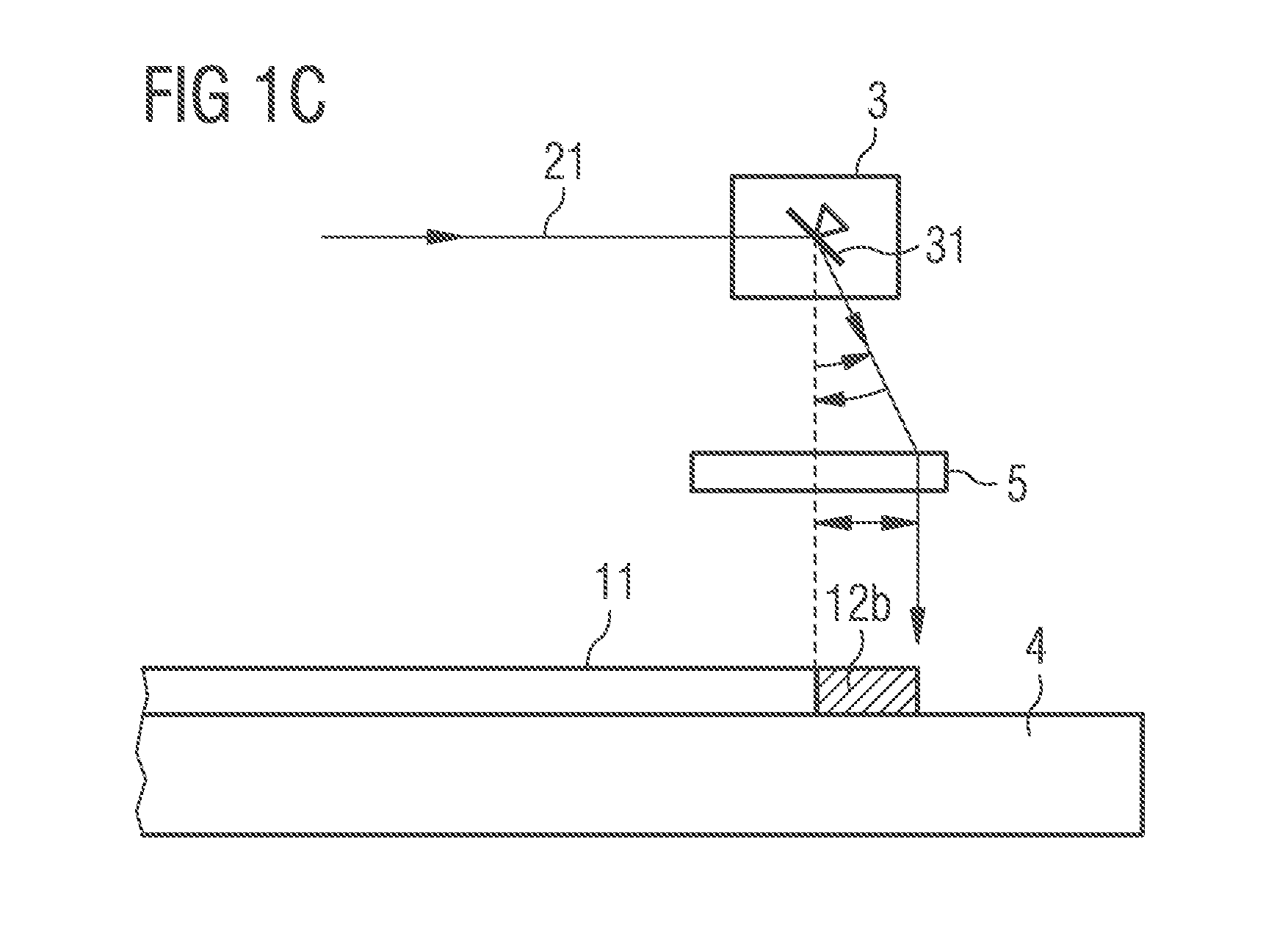

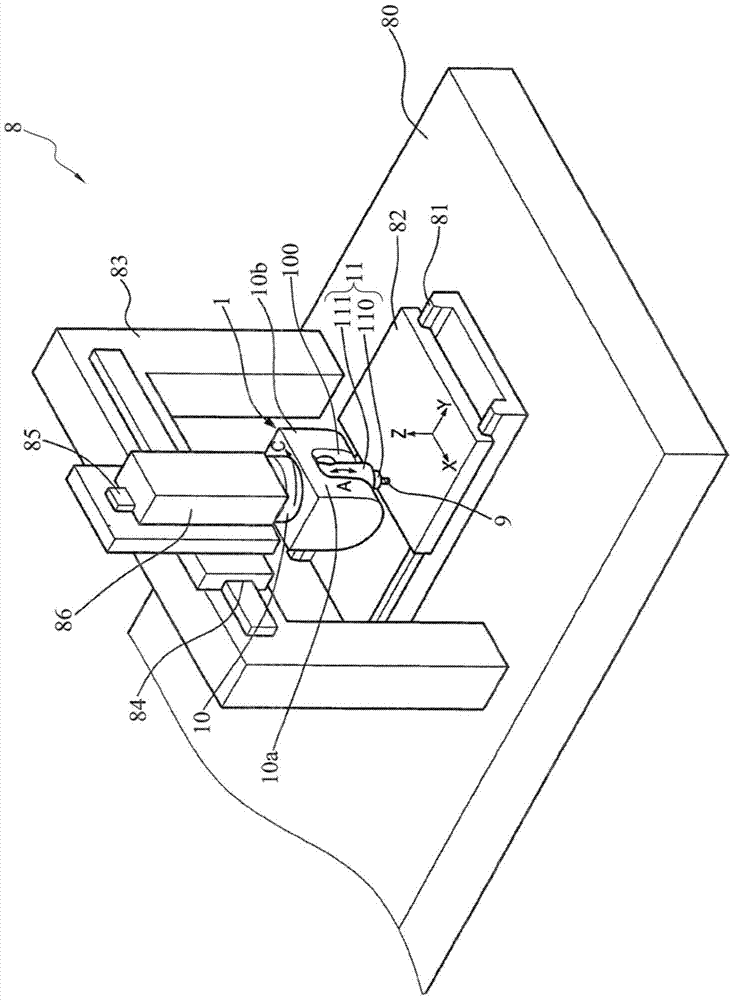

Method and Device for Machining a Workpiece by Means of a Laser

InactiveUS20130126491A1Large processing spaceAccurate settingSemiconductor/solid-state device manufacturingLaser beam welding apparatusLaser beamsEdge region

The invention relates to a method for machining a workpiece by means of a laser, wherein a laser beam of the laser irradiates the workpiece, the laser beam remains stationary and the workpiece is moved when a central region of the workpiece is irradiated, and the laser beam and the workpiece are moved at least intermittently when an edge region of the workpiece is irradiated.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

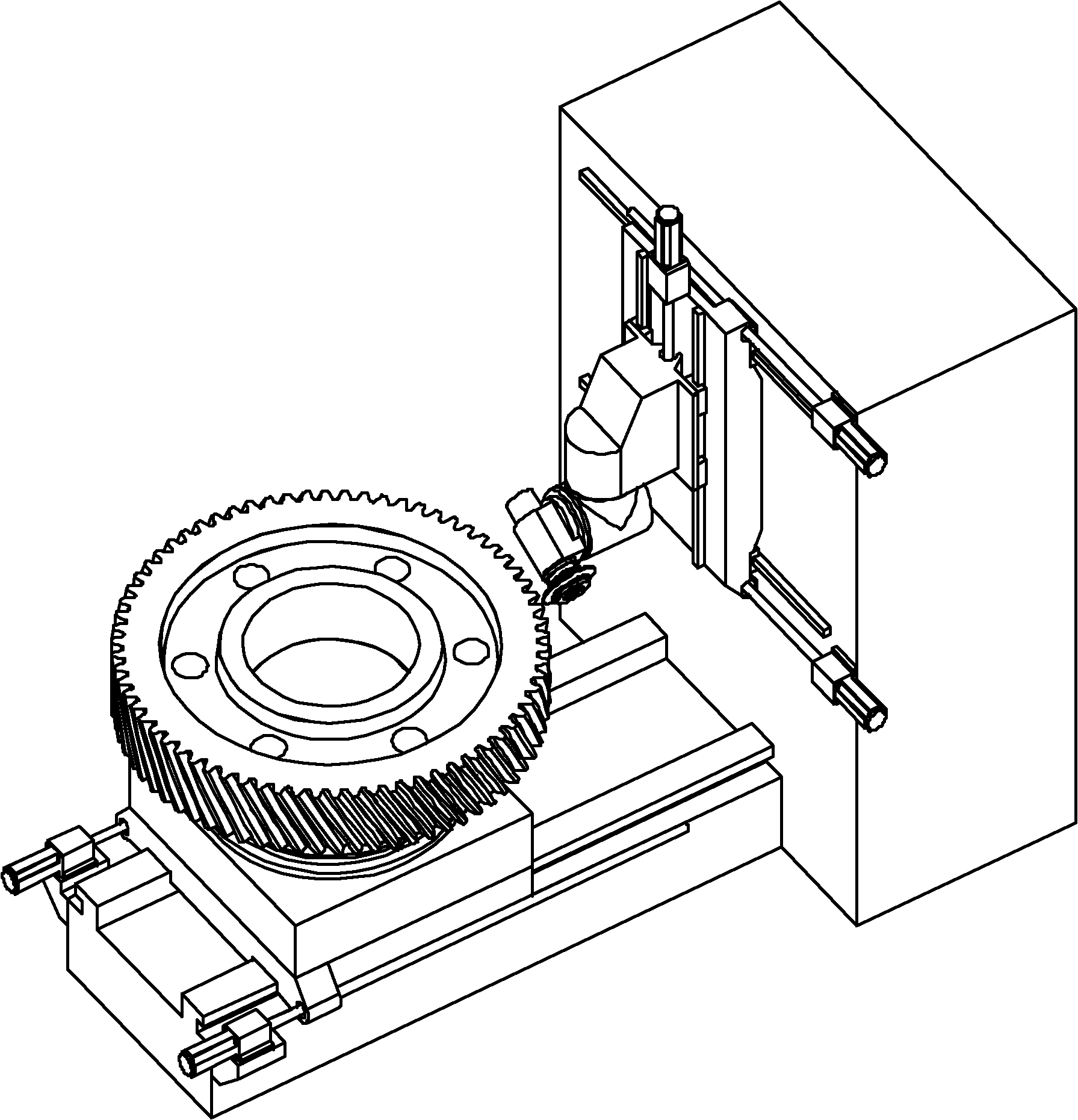

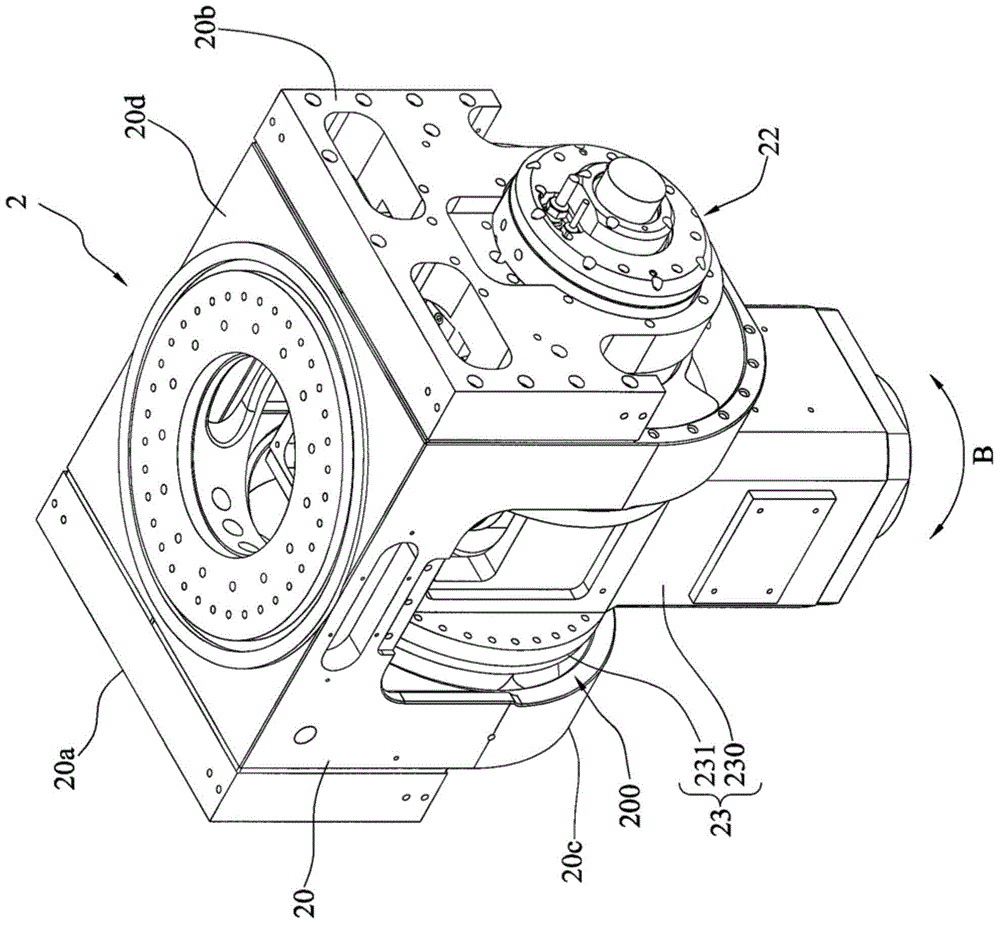

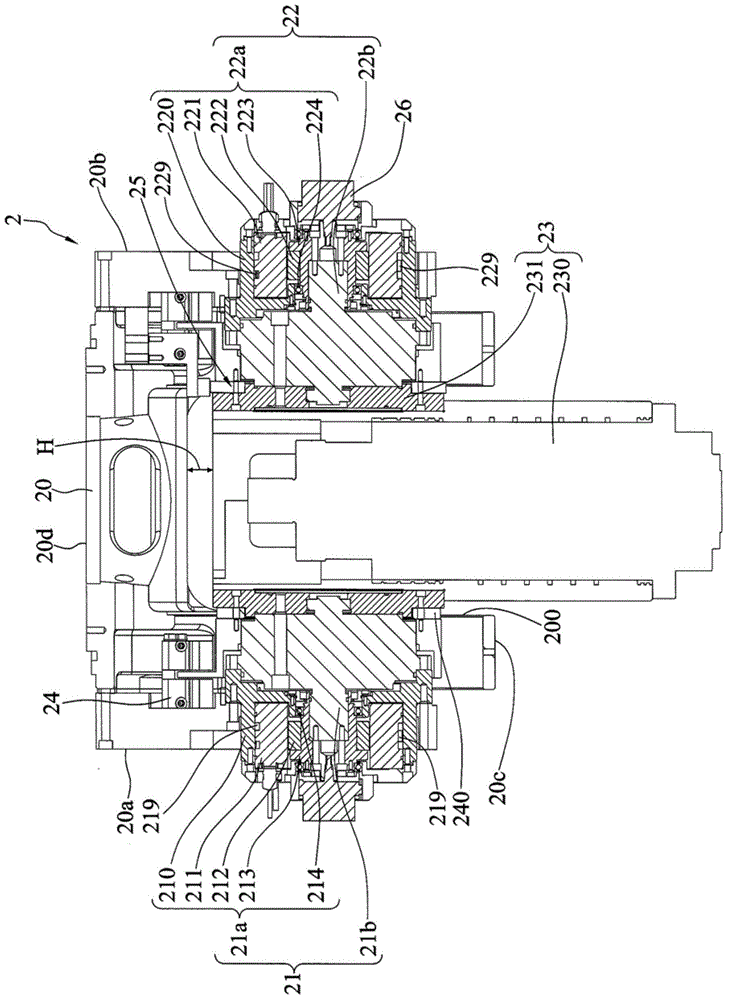

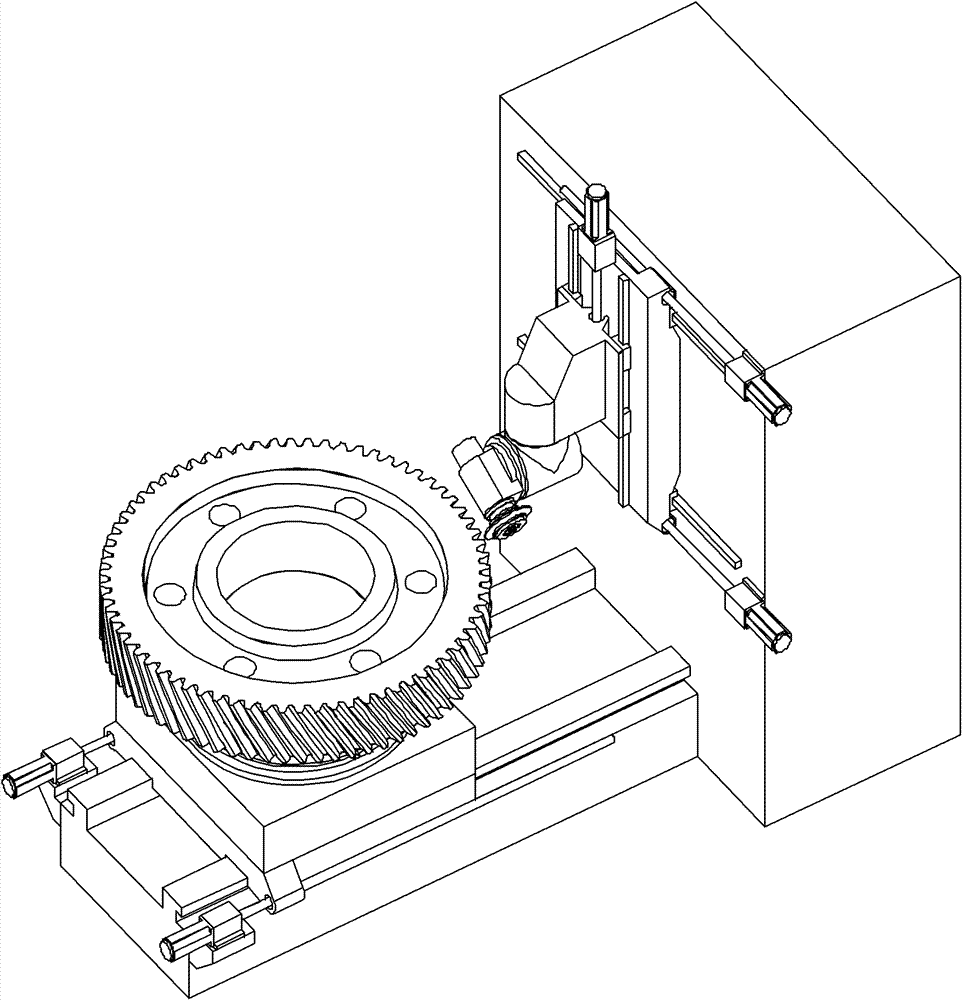

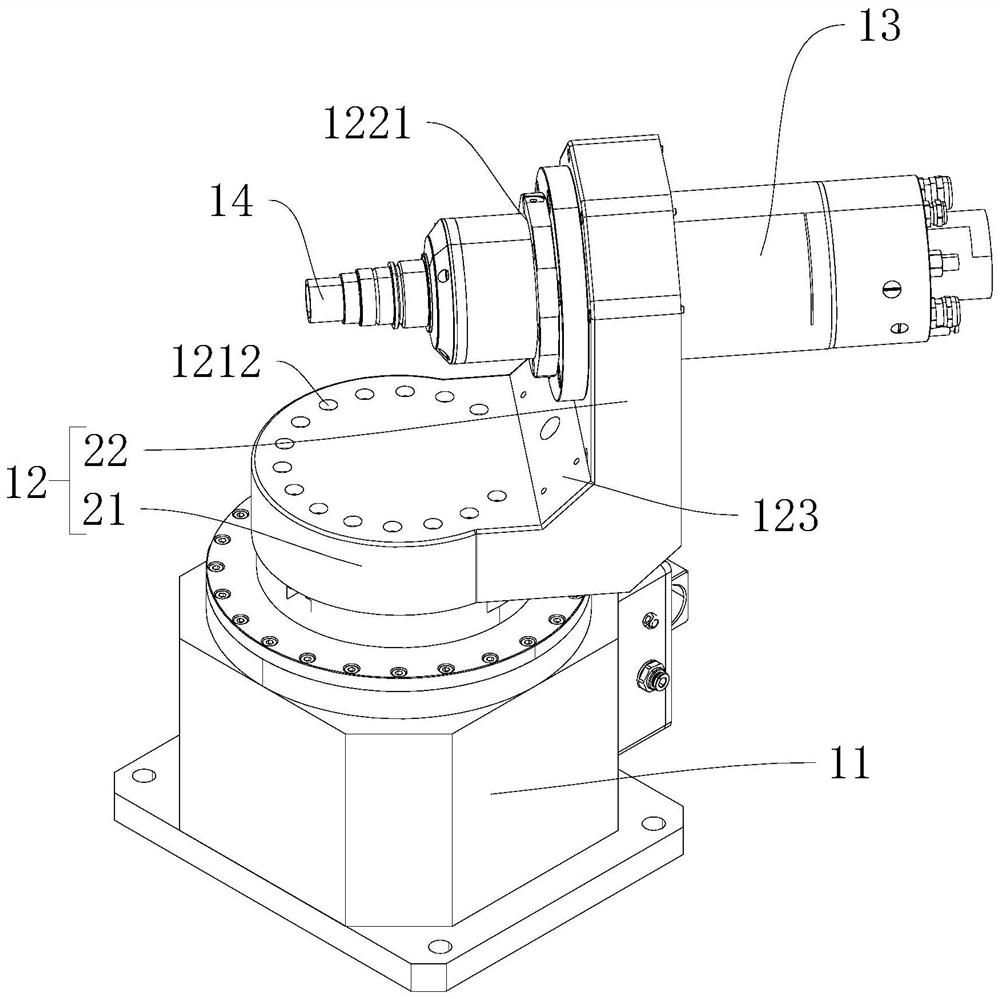

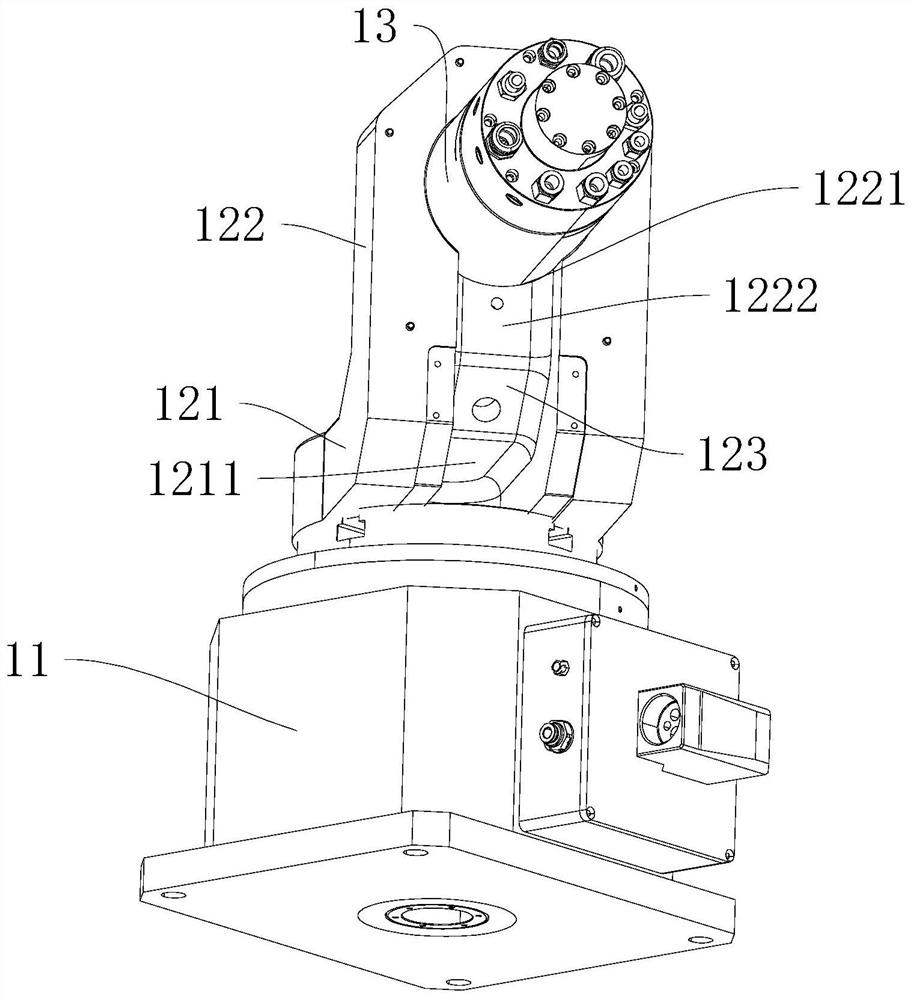

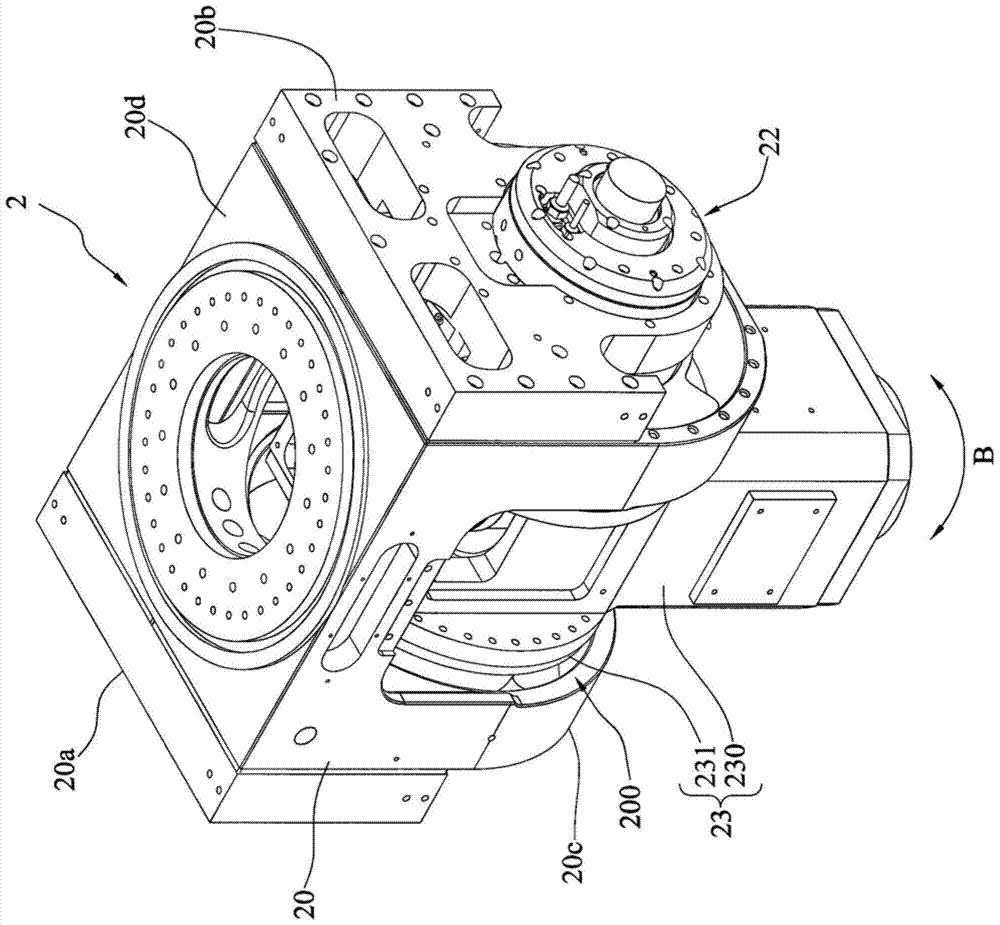

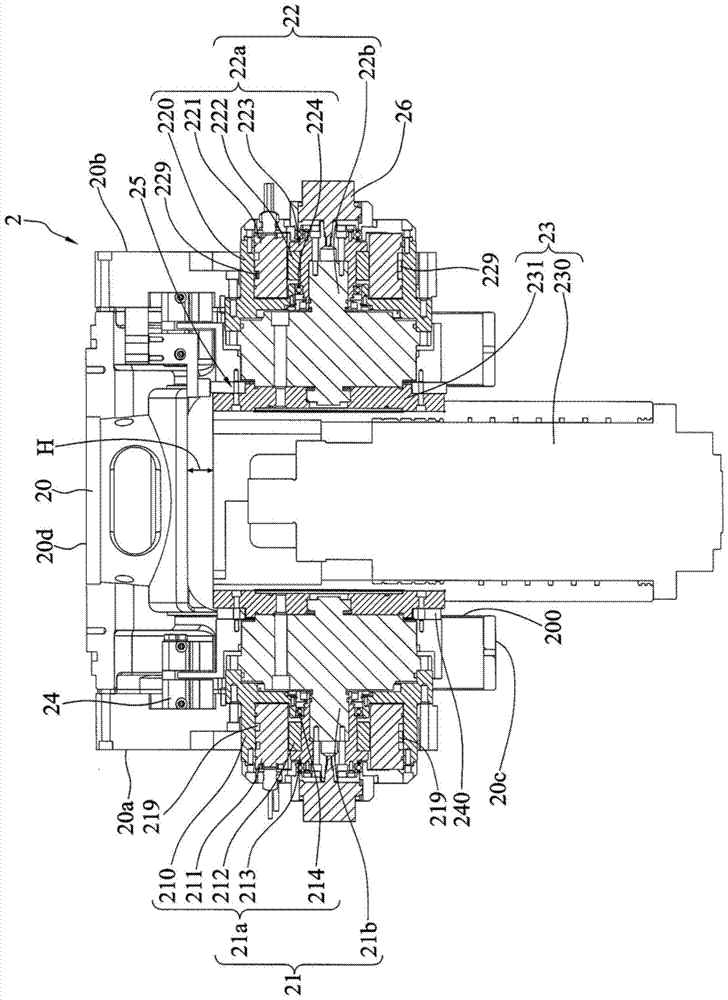

Twin rotation driving apparatus

ActiveCN104607982ASmall turning diameterReduced external volumeProgramme-controlled manipulatorMechanical apparatusGear wheelAutomotive engineering

Owner:IND TECH RES INST

Device and method for treating automobile exhaust with air plasma

ActiveCN106246296AUniform discharge density distributionLarge processing spaceExhaust apparatusSilencing apparatusExhaust gasEngineering

The invention relates to a device for treating automobile exhaust with an air plasma. The device comprises a high-voltage direct-current power supply and two insulating plates, wherein the two insulating plates are disposed oppositely; one insulating plate is provided with at least one exhaust inlet; the other insulating plate is provided with at least one exhaust outlet; a grounding electrode and a plurality of conductive tubes are disposed between the two insulating plates; the grounding electrode is connected with a grounding end of the high-voltage direct-current power supply; the plurality of conductive tubes are connected with a high-voltage end of the high-voltage direct-current power supply; the plurality of conductive tubes are annularly distributed; and each conductive tube is provided with a plurality of steel needles along the length direction. The invention also relates to a method for treating the automobile exhaust with the air plasma. According to the device and the method, a large treatment space can be obtained, the device can be rapidly mounted on an exhaust pipe of an automobile, the automobile exhaust is treated conveniently at any time in any place, the vehicle-mounted effect can be realized, the automobile exhaust is efficiently decomposed and the treatment energy consumption is low.

Owner:SUZHOU UNIV

Three-dimensional engraving machine

The invention provides a three-dimensional engraving machine, and belongs to the technical field of an engraving machine. The three-dimensional engraving machine solves the problem of poor stability of a three-dimensional engraving machine in the engraving process in the prior art. The three-dimensional engraving machine comprises a machine frame and a movable engraving platform arranged on the machine frame, wherein a straight strip-shaped cutter frame used for fixing a cutter is arranged above the engraving platform, the machine frame comprises two upright posts, the two upright posts are respectively and vertically arranged at the two sides of the engraving platform, guide rails in vertical arrangement are respectively arranged on each upright post, a support plate capable of vertically moving along the guide rail is arranged on each corresponding guide rail, the two ends of the cutter frame are respectively connected onto the corresponding support plates, and ascending and descending motors driving the support plates to synchronously and vertically move are also arranged on the machine frame. The three-dimensional engraving machine has the advantages that the operation is stable, and the processing precision is high.

Owner:吴善旺

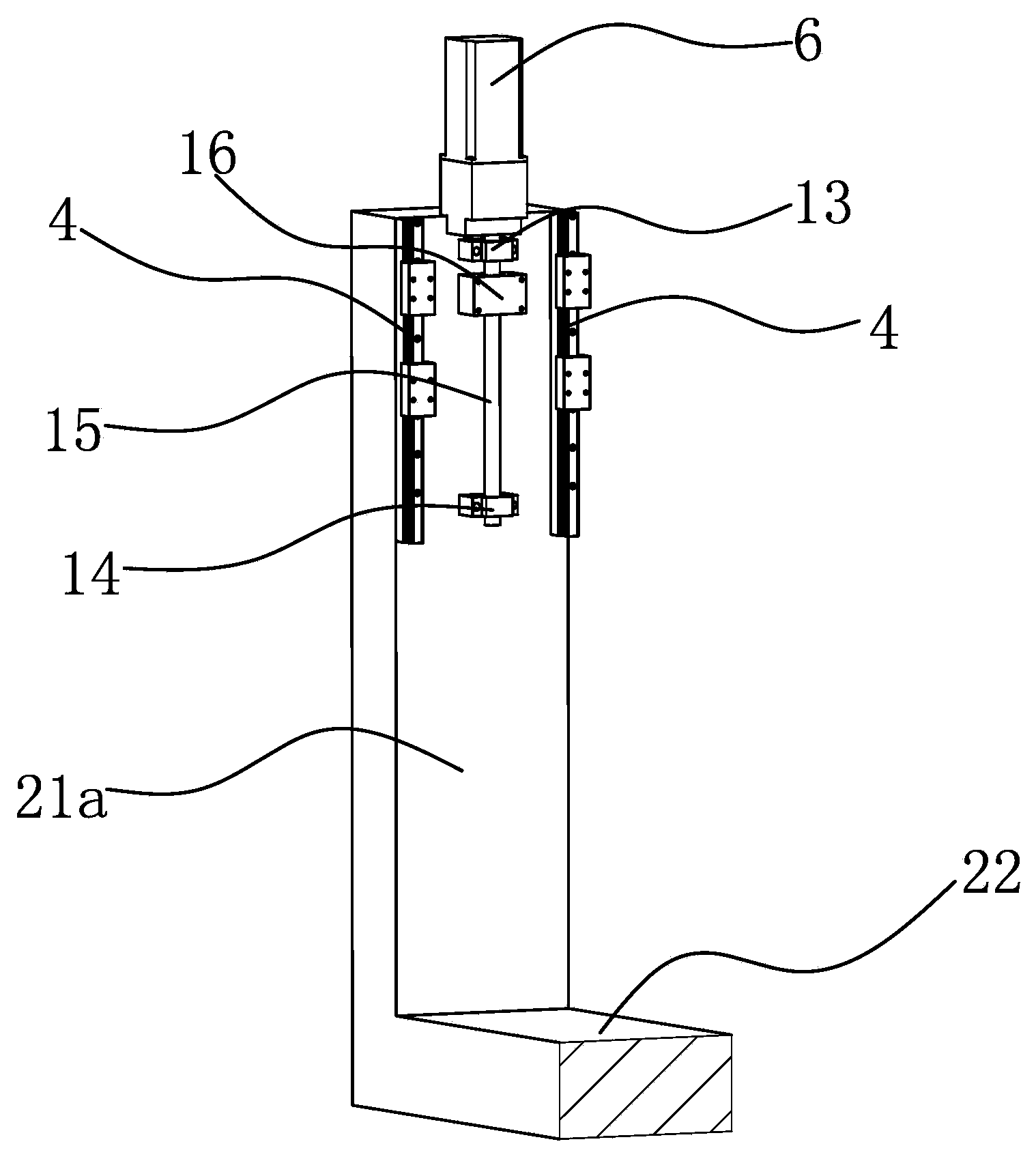

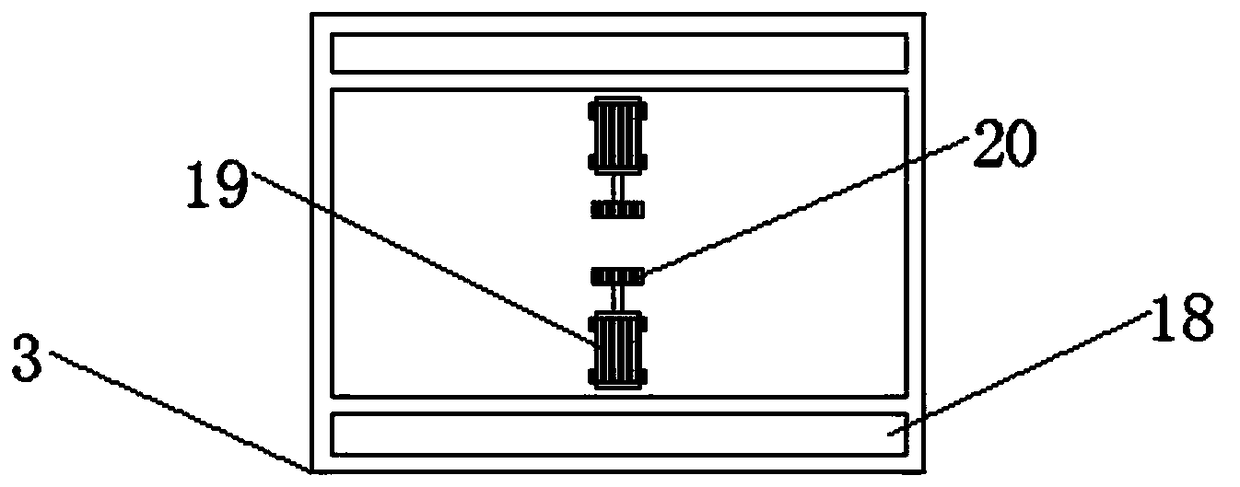

Adjustable supporting table of precision gear machining tool

InactiveCN108723511AImprove work efficiencyLarge processing spaceGear-cutting machinesGear teethAgricultural engineeringMachine tool

The invention discloses an adjustable supporting table of a precision gear machining tool. A table body is arranged on the bottom of a supporting table body, chutes are formed in two sides of the inside of the table body, a strut is mounted in each chute, a rack is mounted on the inner side of each strut, one side of each rack is connected with a first gear in an engaged manner, reels are mountedon the two sides of each first gear, a pull rope is arranged on the outer side of each reel in a winding manner, the bottom end of each pull rope is fixedly connected with a cross plate, an electric push rod is mounted in the middle of the bottom of each cross plate, an adjusting box is mounted on the top of each strut, slide ways are arranged on two sides of the adjusting box, a pulley is mountedin each slide way, a working table plate is mounted on the top of each pulley, barrel grooves are formed in two ends of the two sides of each working table plate; and a telescopic rod is mounted in each barrel groove. Each barrel groove is fixedly connected with the corresponding telescopic rod through a fixing knob, the adjustable supporting table of the precision gear machining tool is simple to operate and convenient to use, a lengthened plate can be fixed, the length of the lengthened plate is adjusted favorably as needed, the machining space of the supporting table body is expanded, andthe load of workers is relieved.

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

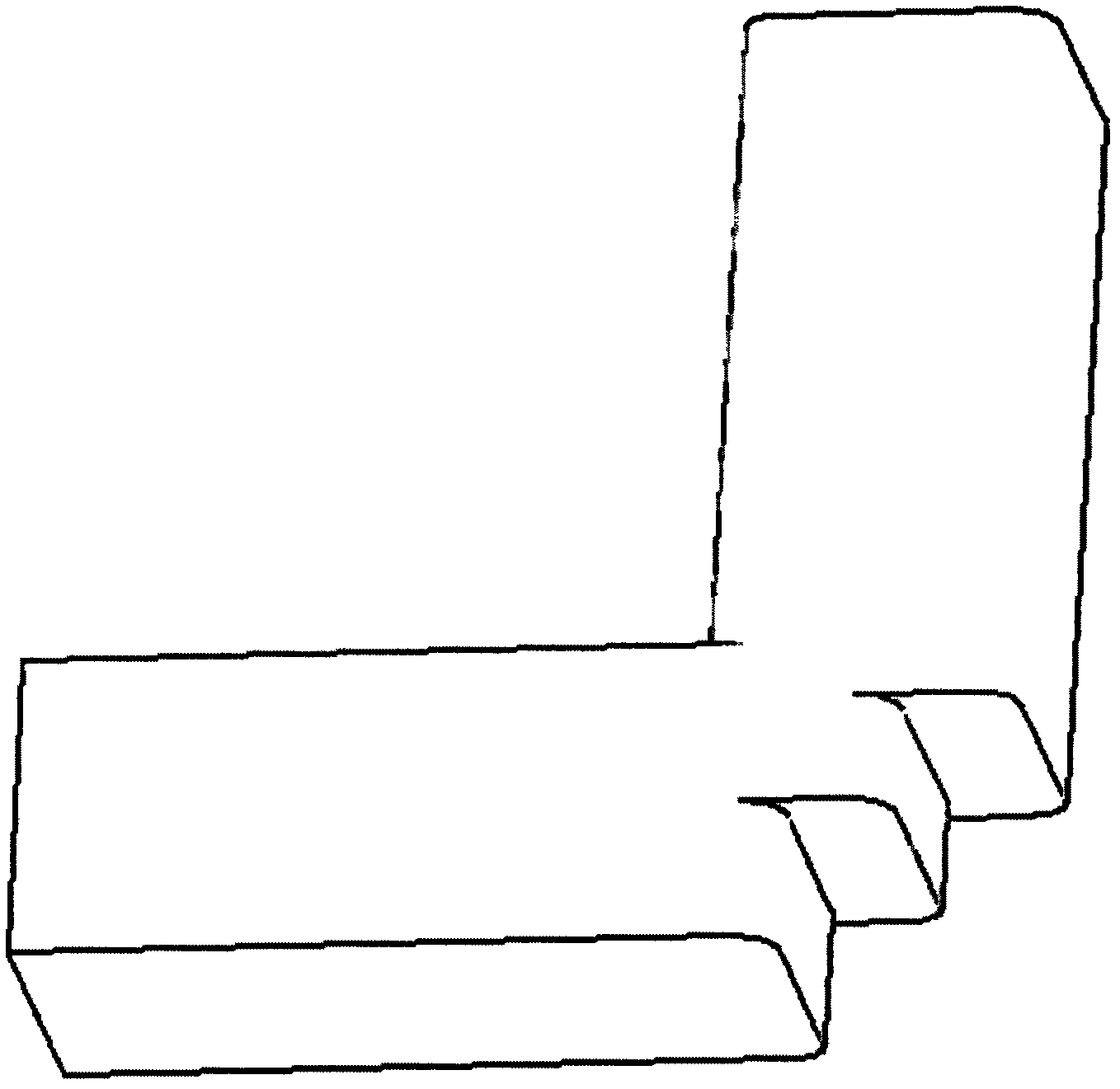

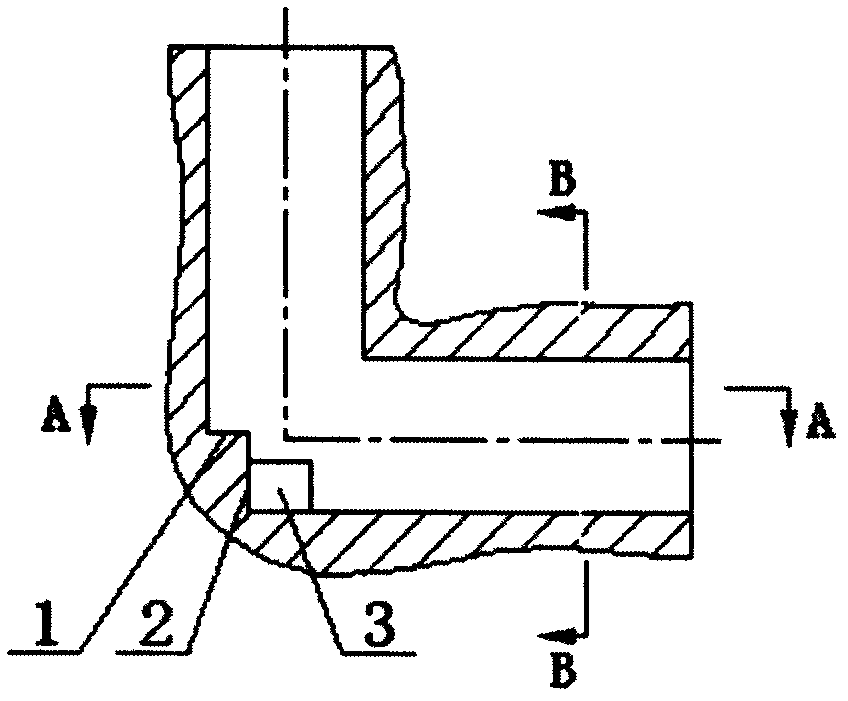

90-degree turning mechanism for microwave waveguide pipeline

The invention relates to a 90-degree turning mechanism for a microwave waveguide pipeline, which is suitable for connection between two waveguide pipes with vertical transmission directions in the field of microwave communication. The 90-degree turning mechanism for the microwave waveguide pipeline comprises a microwave pipeline, wherein the microwave pipeline is formed by connecting two mutually vertical straight pipelines. A step is arranged on an outer corner pipeline wall at a right-angled connection place of the microwave pipeline, and the upper surface and the vertical surface of the step are vertical to the pipeline wall of the microwave pipeline, which on the step is located. The 90-degree turning mechanism for the microwave waveguide pipeline is characterized in that a boss vertical to the vertical surface of the step is arranged at the middle position of the vertical surface of the step, the height of the boss is less than that of the step, and gaps are arranged among both sides of the boss and the pipeline wall of the microwave pipeline. The 90-degree turning mechanism for the microwave waveguide pipeline is small in dimension, wide in use range, and easy for machining.

Owner:PIVOTONE COMM TECH

Efficient spraying type dispensing method

InactiveCN111420852ASimplify the dispensing processShorten production timePrimary cell to battery groupingLiquid surface applicatorsElectrical batteryMechanical engineering

The invention discloses an efficient spraying type dispensing method. The efficient spraying type dispensing method comprises the following steps that a battery module cover plate is prepared, and isfixed to the position below a glue spraying machine, a glue spraying machine glue spraying pipe is aligned with a first battery mounting hole, at least one glue spraying pipe nozzle is mounted, rightfaces two sides in the battery mounting hole and is parallel to the slotting end face, the glue spraying pipe nozzle completely extends into the battery mounting hole, the glue spraying machine is started, two glue spraying pipe nozzles carry out glue spraying at the same time, after glue spraying is finished, the battery module cover plate is fixed, the glue spraying machine glue spraying pipe ismoved, through slotting, the glue spraying pipe nozzles move into the next battery mounting hole, and the two glue spraying pipe nozzles carry out glue spraying at the same time. According to the method, the action track of a dispensing machine is changed, original action is directly simplified into a linear motion of a glue nozzle, the dispensing procedure is simplified, the production time is saved, production efficiency is improved, glue position tail pulling generated by a traditional method can be removed, the dispensing environment is improved, the dispensing quality is improved, and the method is easy and convenient, and efficient and precise.

Owner:安徽江淮华霆电池系统有限公司

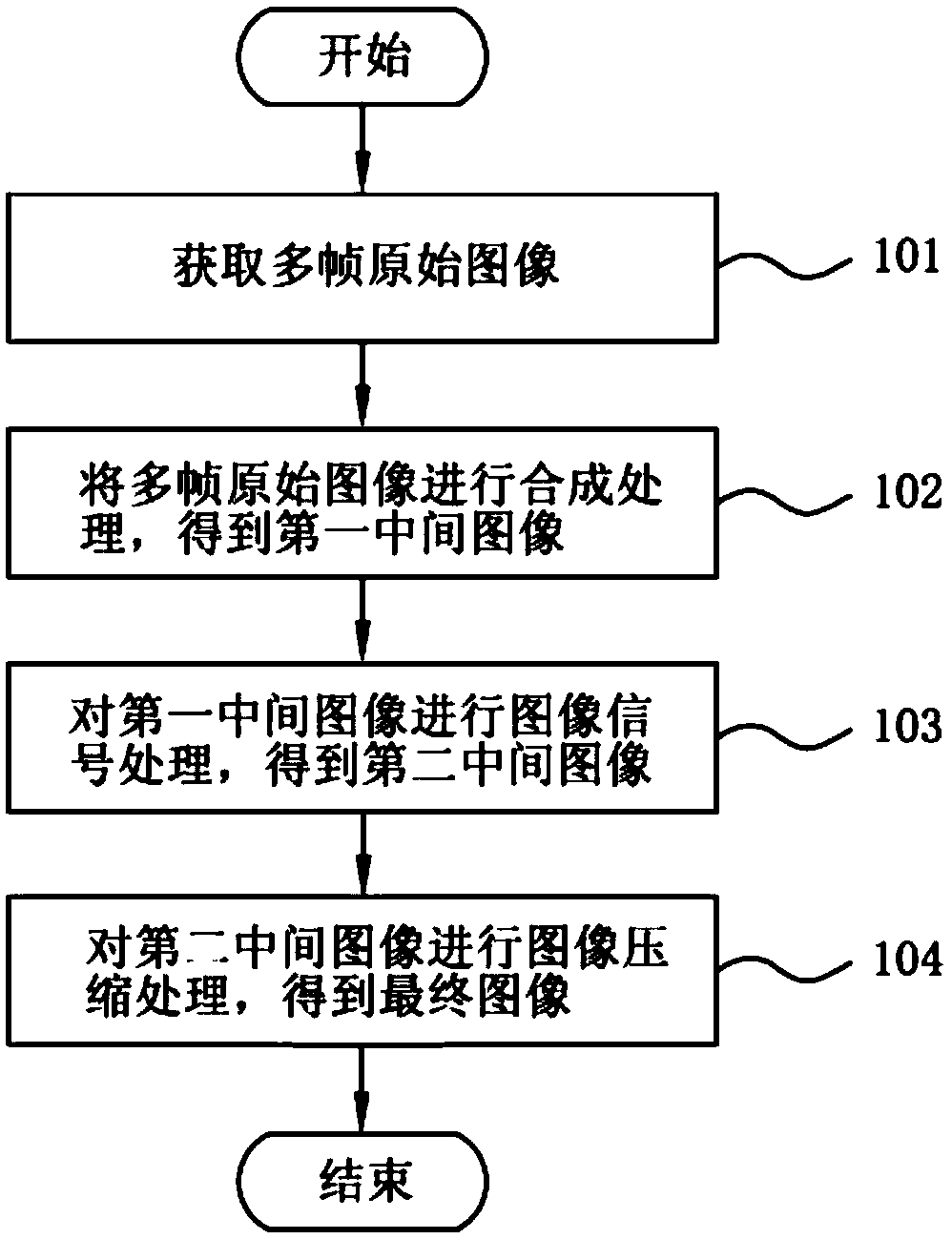

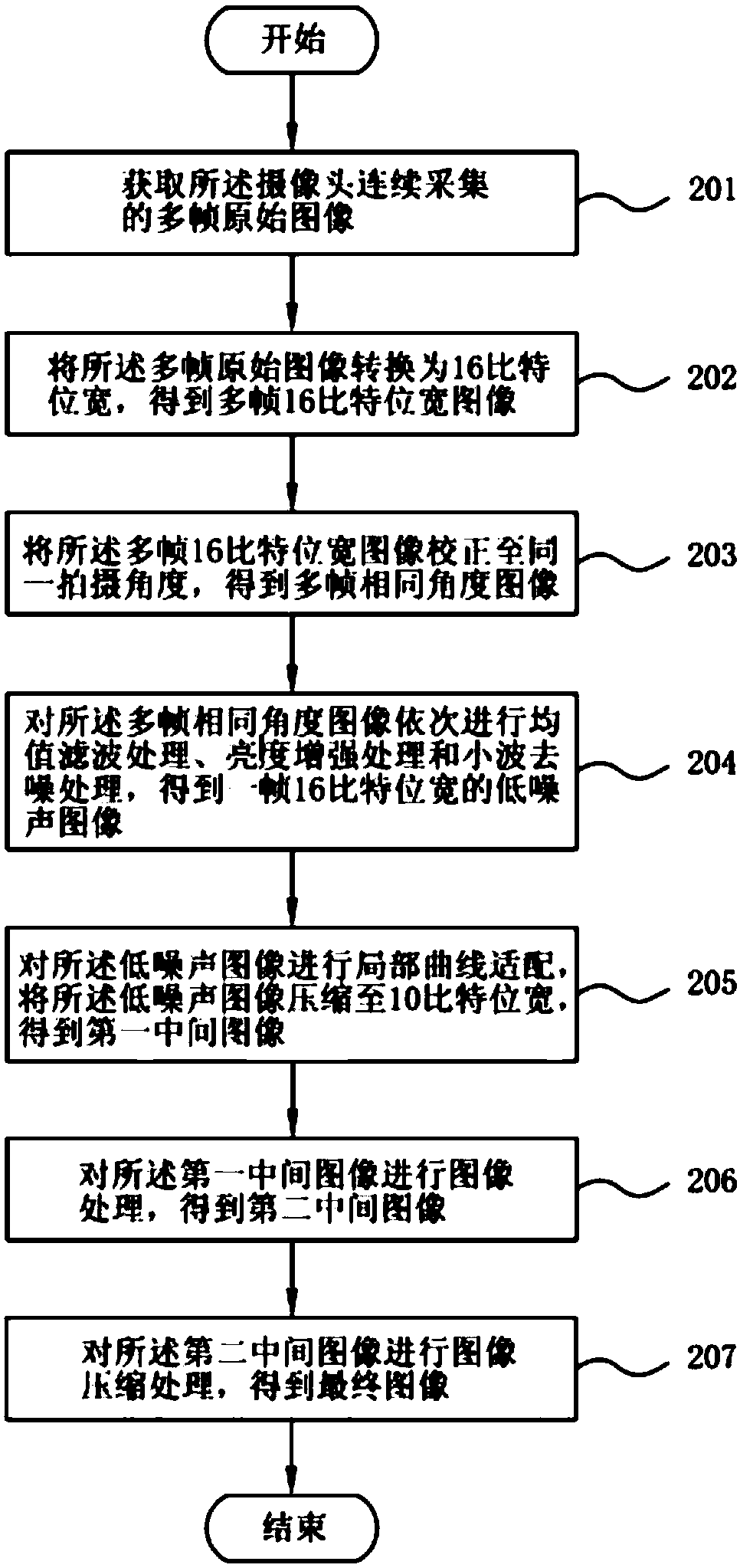

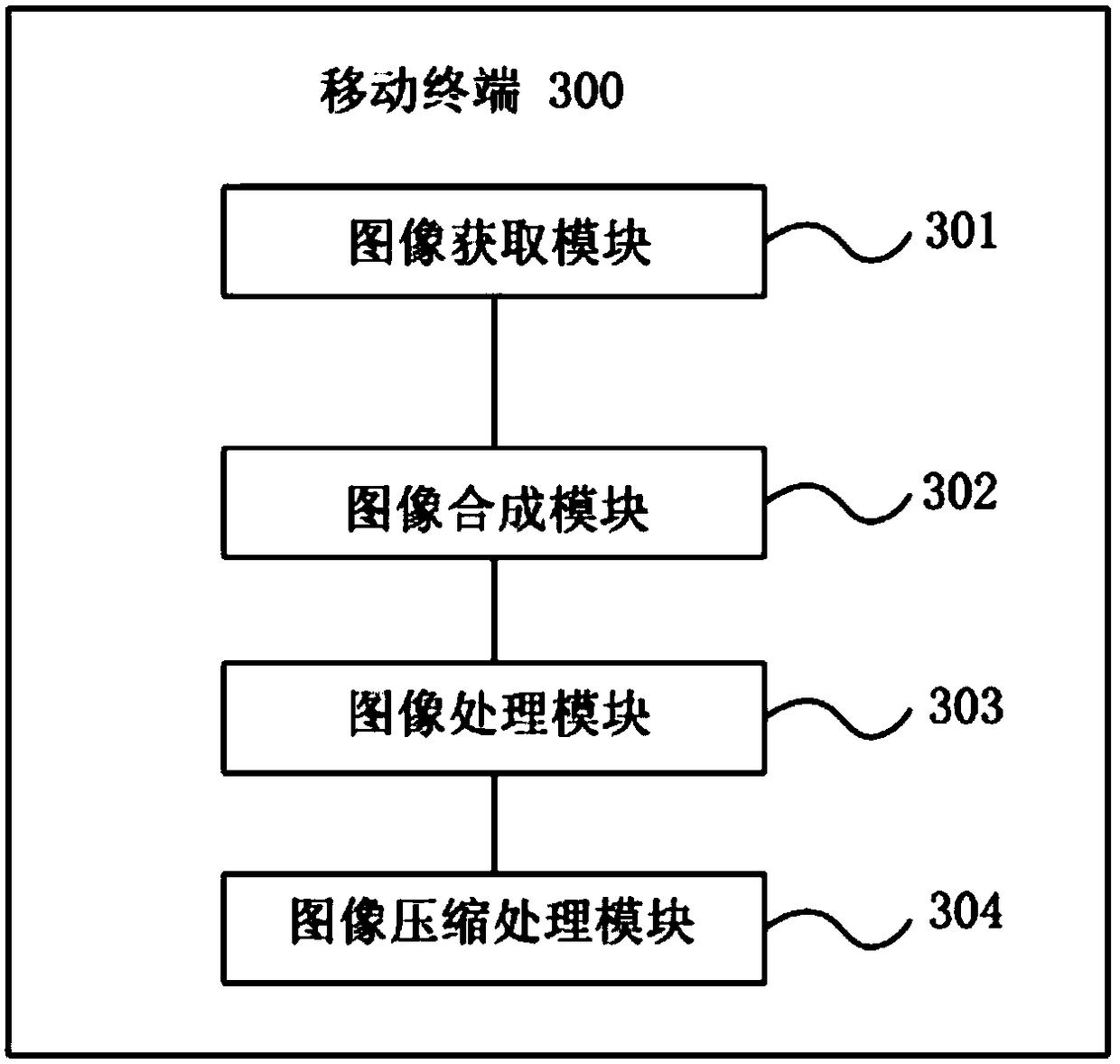

Image processing method and mobile terminal

ActiveCN105827971BGood detailsImprove acceleration performanceImage enhancementTelevision system detailsIntermediate imageImaging processing

Examples of the present invention provide an image processing method and mobile terminal.This image processing method includes: to obtain the multi -frame original image collected continuously in the camera; synthesize the first intermediate image by the preset algorithm;Get the second intermediate image; perform the image compression processing of the second intermediate image to obtain the final image. Among them, the multi -frame primitive image and the first intermediate image are all RAW format images with 10 than the special.The middle image is an 8 -than -wide YUV format image, and the final image is a JPEG format image with a wide range of eights.The image processing method provided by the embodiment of the present invention can obtain a wider dynamic range, less image noise, and more image details when using a mobile terminal to synthesize and enhance the processing.

Owner:VIVO MOBILE COMM CO LTD

Polysebacic acid 1, 3-propylene glycol ester-block-polysuccinic acid butanediol block polyester and preparation method and use thereof

Owner:天津市食品加工工程中心

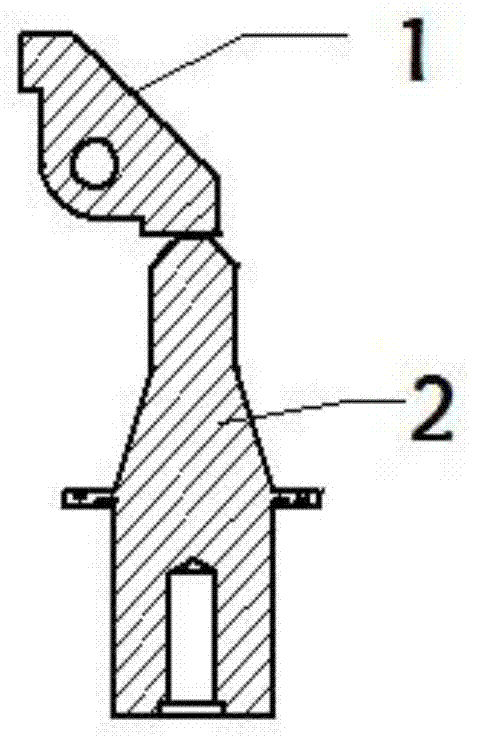

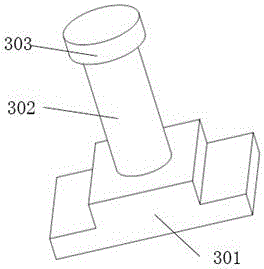

Mechanism for changing conduction direction of ultrasonic wave

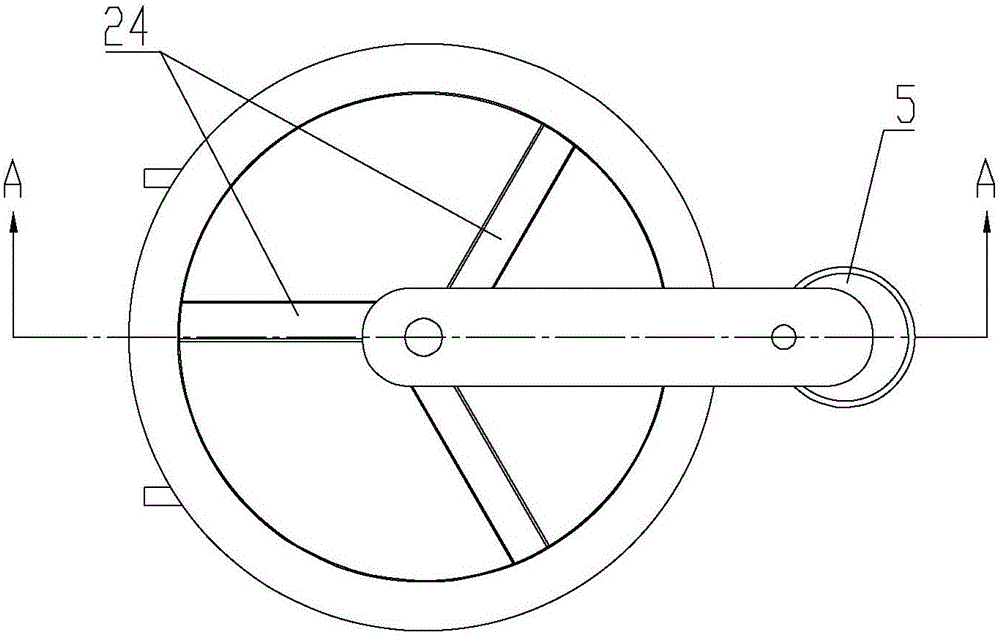

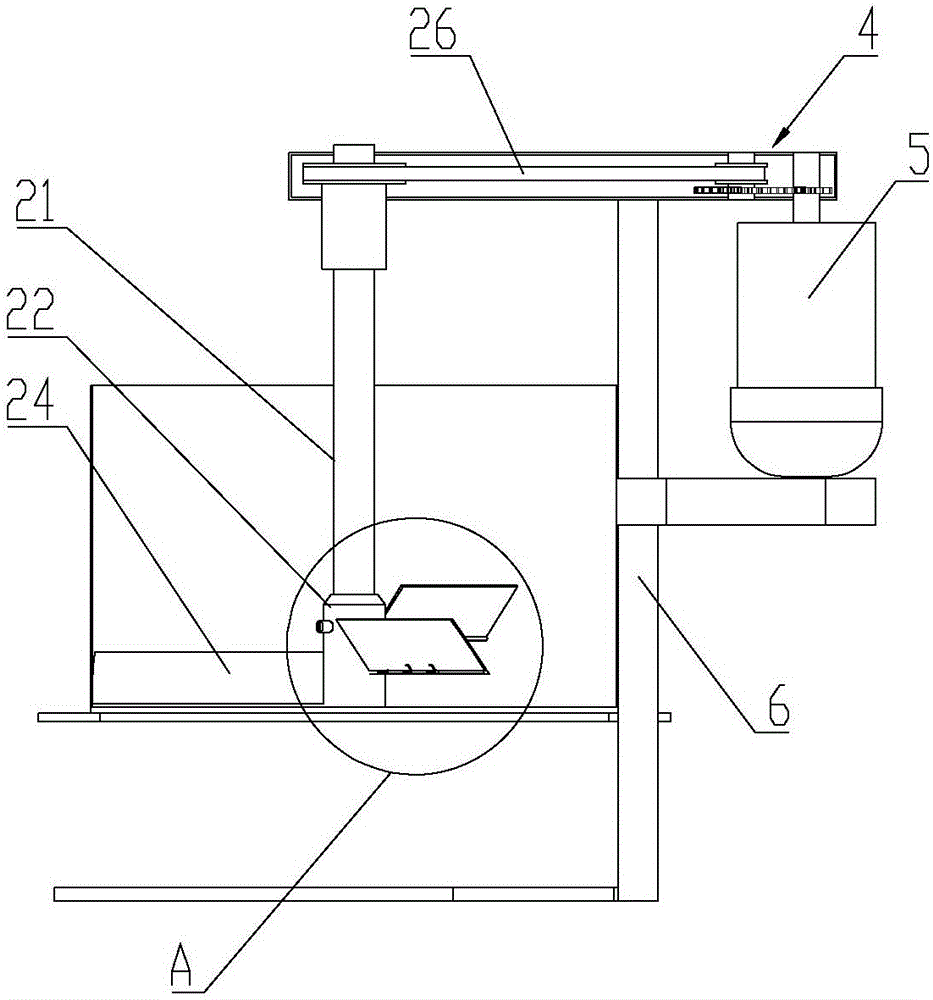

The invention particularly discloses a mechanism for changing the conduction direction of ultrasonic wave, which comprises an amplitude-change pole and a rocker arm, wherein one end of the rocker arm is contacted with the head of the amplitude-change pole, the other end which is opposite to the end of the rocker arm is perpendicular to a workpiece to be machined, and the inclined angle between the centre line of the other end of the rocker arm and the centre line of the amplitude-change pole is more than 0 degree. The mechanism has the beneficial effects that the ultrasonic wave direction of the original ultrasonic wave device which is perpendicular to the workpiece to be machined is converted by the device through the rocker arm, so that the ultrasonic wave device can be in parallel with the workpiece to be machined, and the distance among the machining device, equipment and the workpiece can be reduced. The machining space can be enlarged, the machining range can be increased, the surface roughness can be reduced, and the surface hardness of the workpiece can be enhanced.

Owner:韩连江

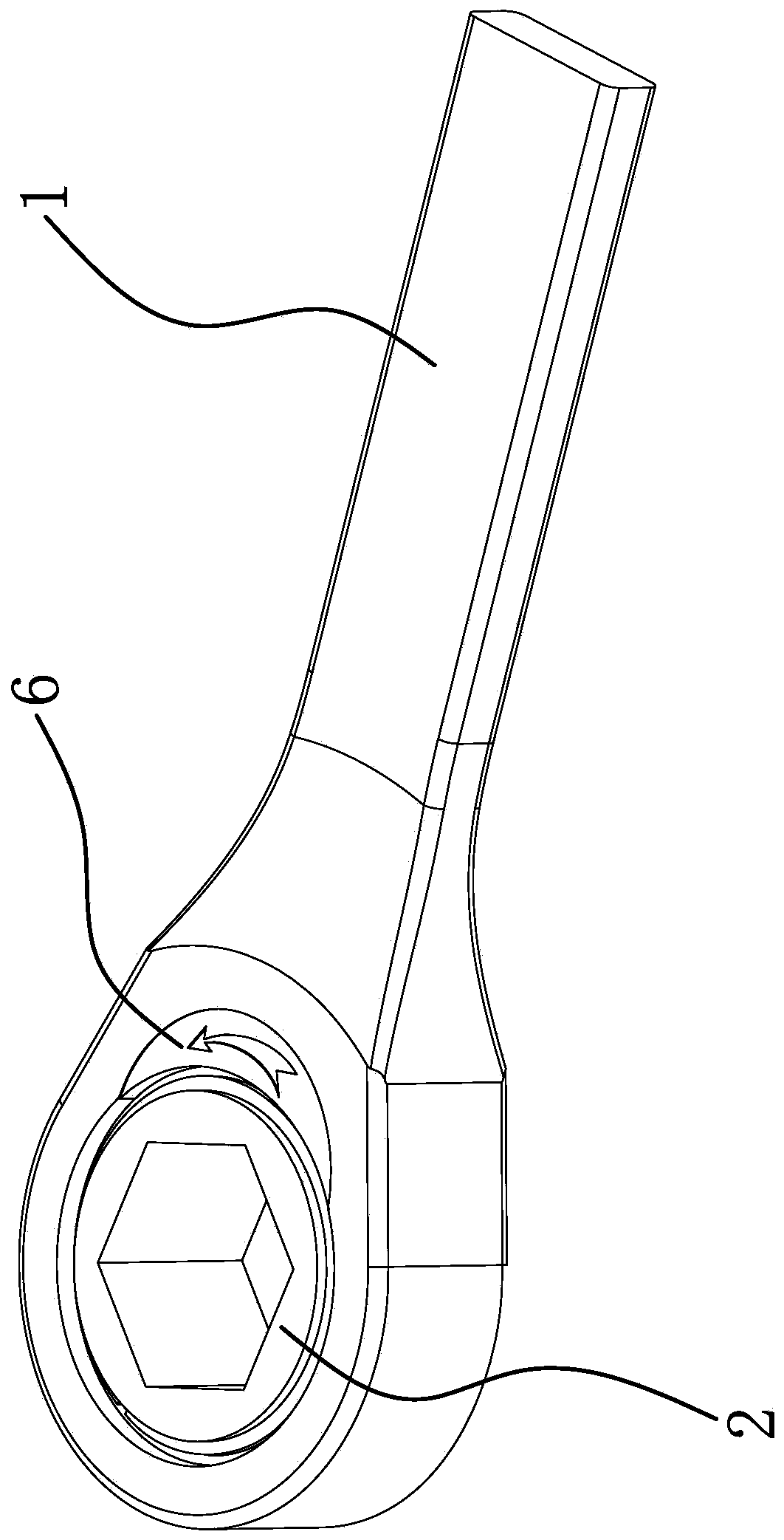

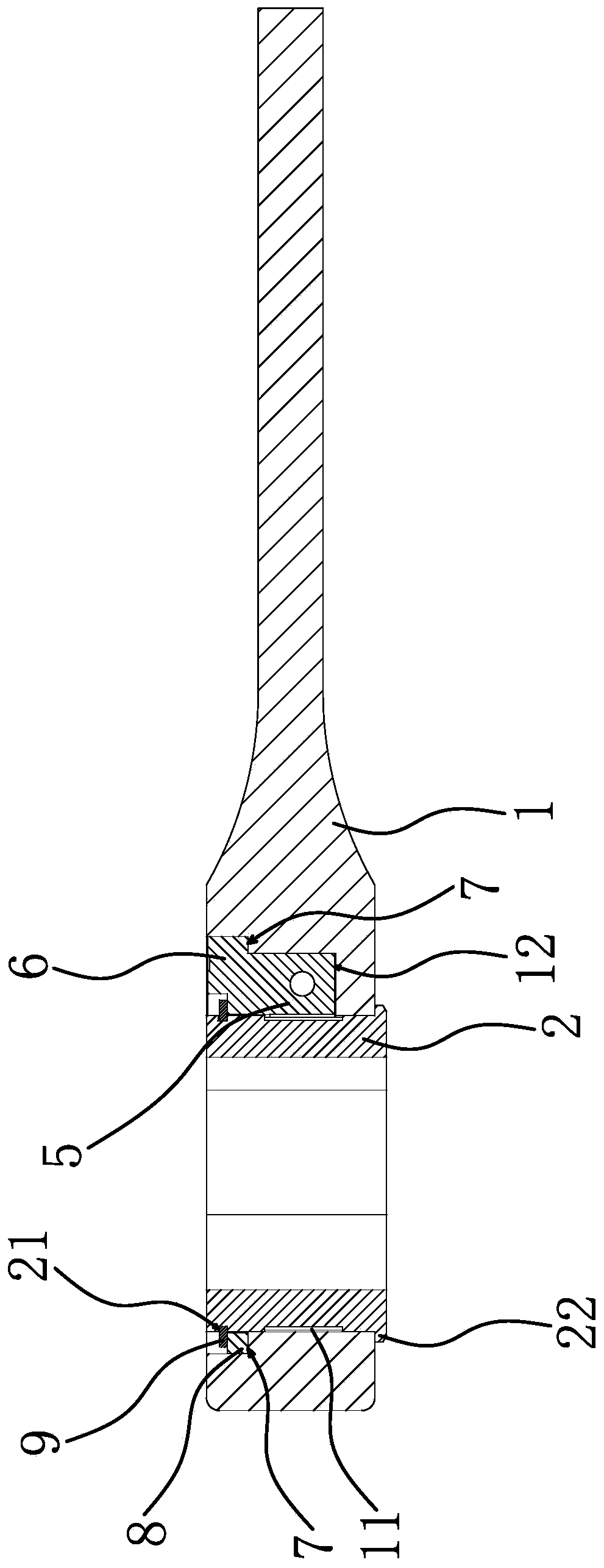

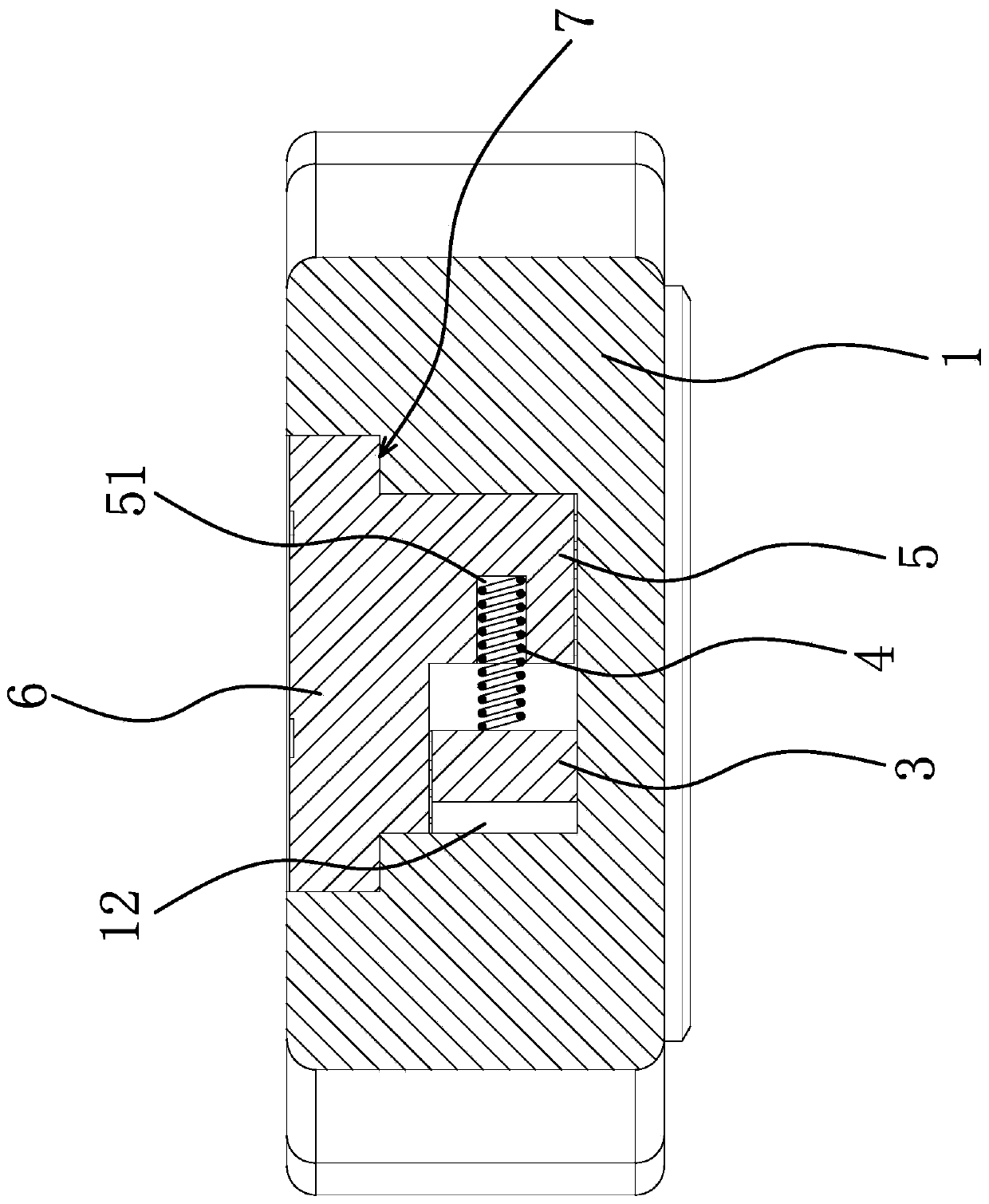

One-way ratchet wrench

PendingCN111267025ALarge processing spaceImprove assembly efficiencySpannersWrenchesRatchetClassical mechanics

The invention provides a one-way ratchet wrench, and belongs to the technical field of wrenches. The wrench solves the problem that an existing wrench is low in assembling efficiency. The one-way ratchet wrench comprises a wrench body, a ratchet wheel, a tooth block, a spring, an ejection block and a pressing plate, a containing hole is formed in the head of the wrench body, the ratchet wheel is arranged in the containing hole, a containing groove communicating with the containing hole is formed in the upper surface or the lower surface of the head of the wrench body, and the tooth block and the ejection block are arranged at the two ends of the containing groove correspondingly; and the pressing plate is arranged in the containing groove and located above the ejection block and the pressing plate, the pressing plate is located on the wrench body, the pressing plate and the ejection block are integrally formed, the spring is arranged between the ejection block and the tooth block, andthe tooth block is meshed with the ratchet wheel and can be separated from the ratchet wheel. The structure obviously improves the assembly efficiency of the one-way ratchet wrench.

Owner:ZHEJIANG YIYANG TOOL MFG

Large-scale numerical control gear machining machine tool

ActiveCN102151909BImprove machining accuracyImprove processing efficiencyLarge fixed membersDriving apparatusLinear motionImpeller

The invention provides a large-scale numerical control gear machining machine tool which has six numerical control coordinate axes, namely X, Y, Z, A, C1 and C2 and adopts a two plus four layout manner. A workpiece has two freedom motion, namely linear motion along the X axis and rotational motion around the C1 axis; and a tool has four freedom motion, namely linear motion along the X axis and the Z axis and rotational motion around the A axis and the C2 axis. The large-scale numerical control gear machining machine tool adopts a six-axis (X, Y, Z, A, CI and C2 axis) five-linkage (X, Y, Z, A and C2 axis linkage) structure; the five numerical control coordinate axes, namely the X, Y, Z, A and C2 axes carry out interpolation motion; and the indexing movement of the workpiece is controlled by the C1 axis to process all tooth surfaces. The rotational axis of the workpiece, namely the C1 axis only finishes the indexing movement and does not participate in the interpolation motion formed bythe tooth surfaces so as to improve the processing precision and the processing efficiency of a large-scale gear. The large-scale numerical control gear machining machine tool can be constructed intoa gear miller or a gear grinder, thereby realizing the curved surface machining of a cylindrical gear, a bevel gear, an impeller and others with the indexing features.

Owner:秦川机床工具集团股份公司

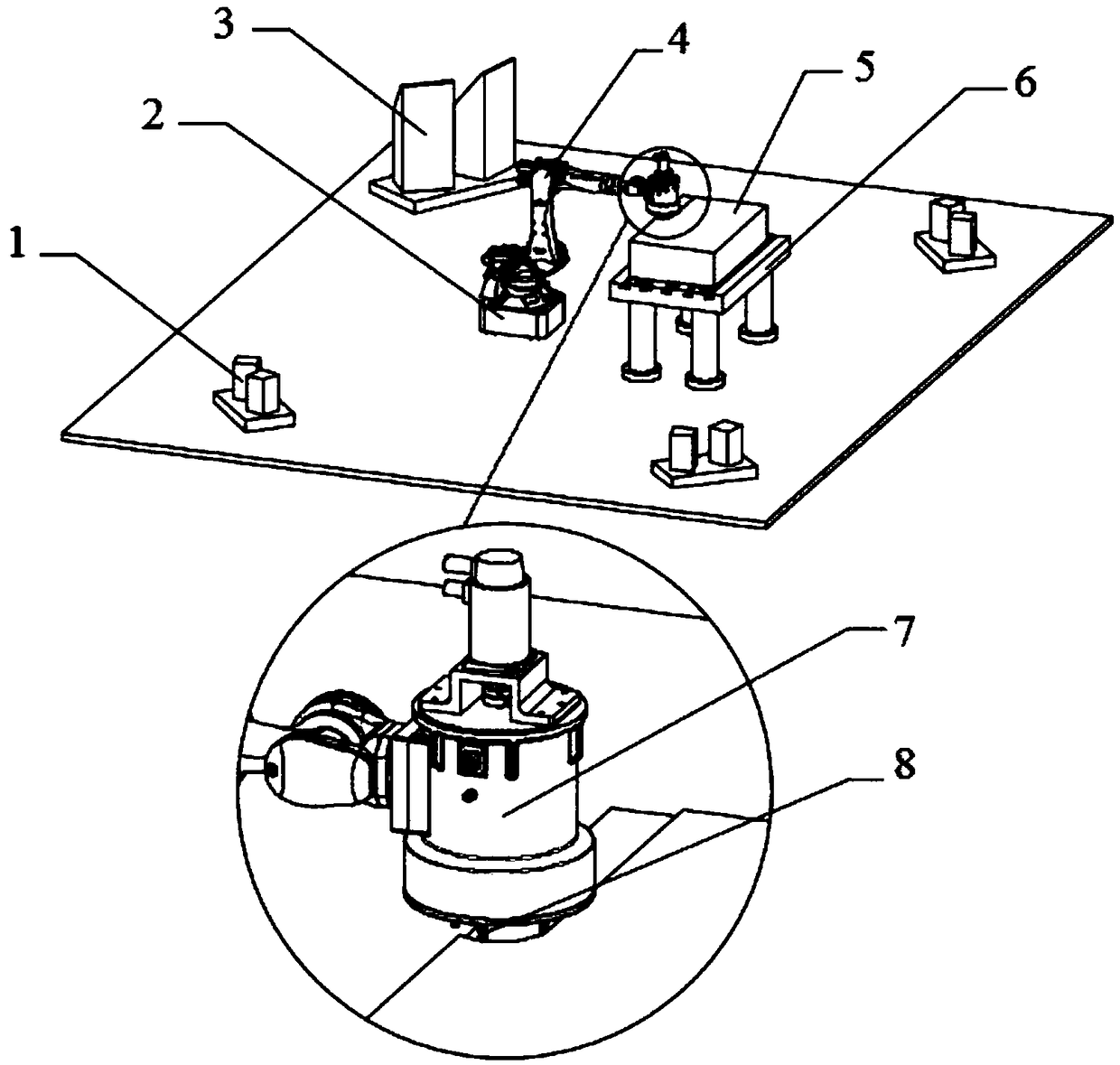

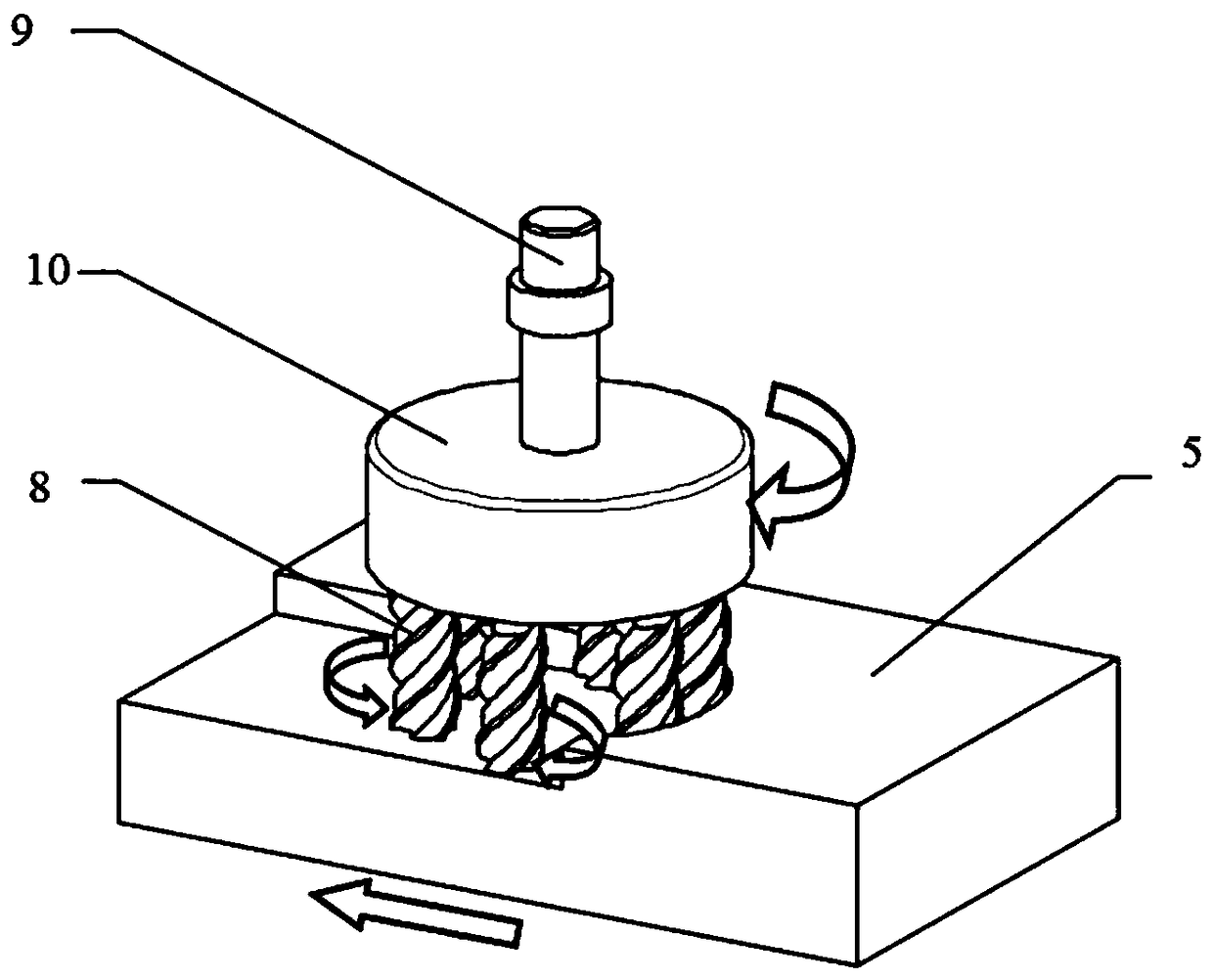

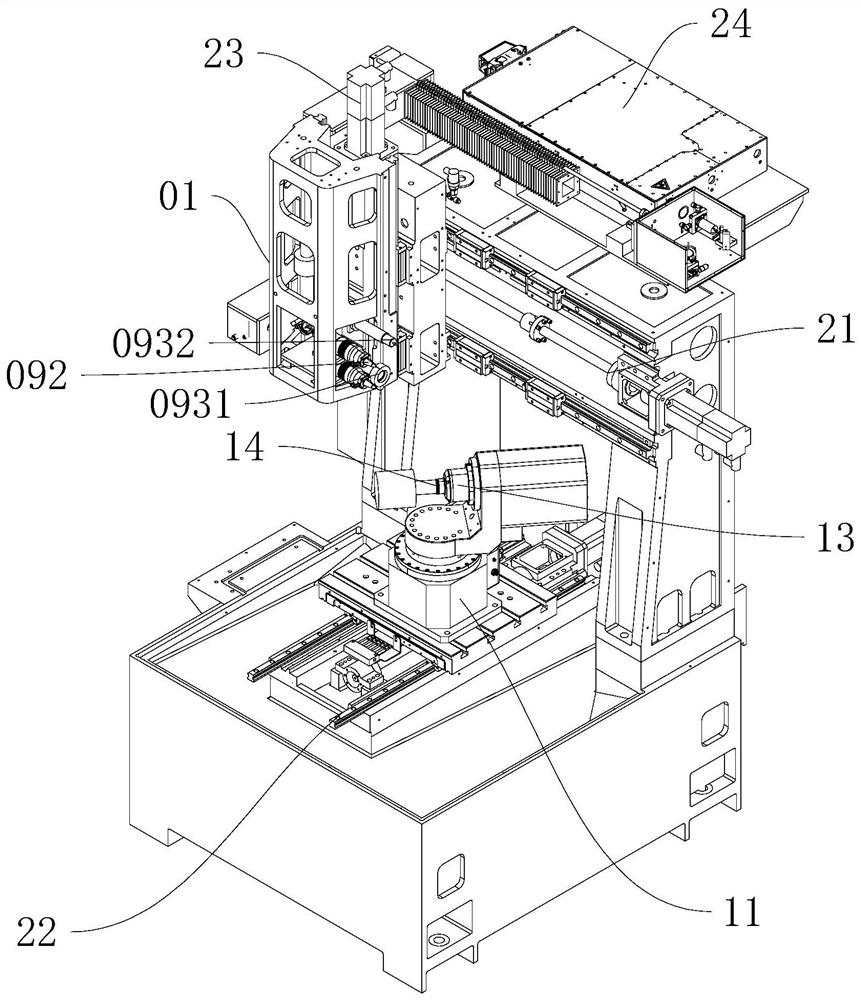

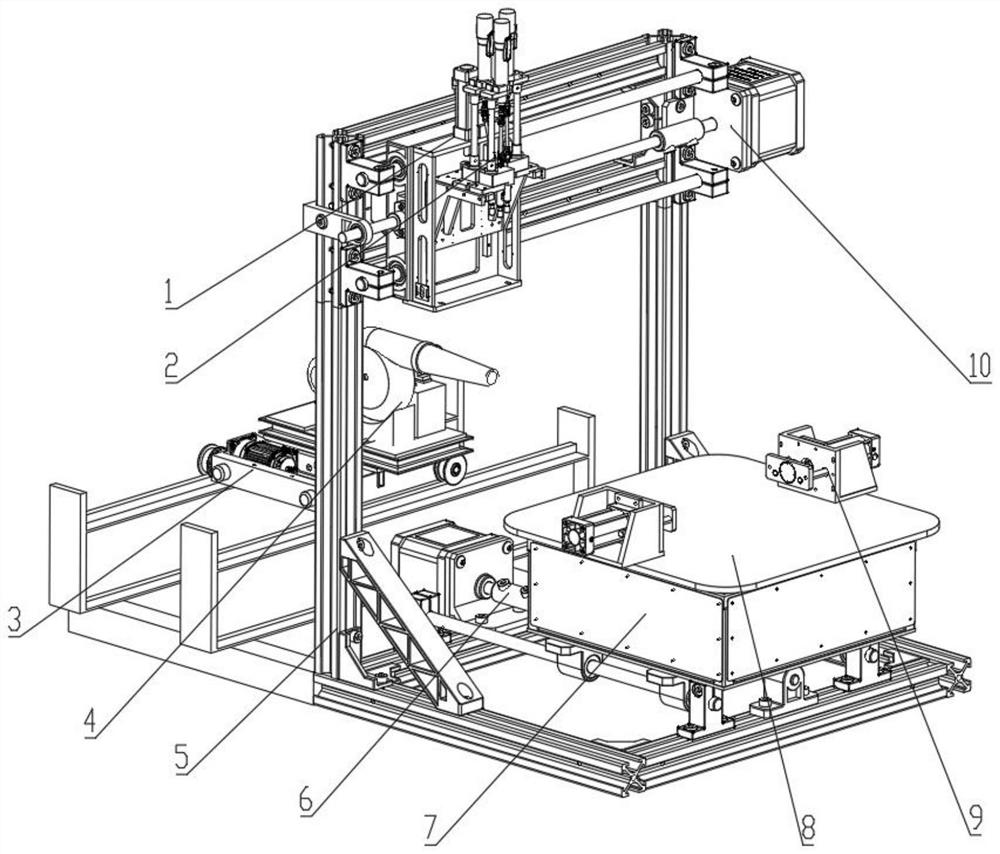

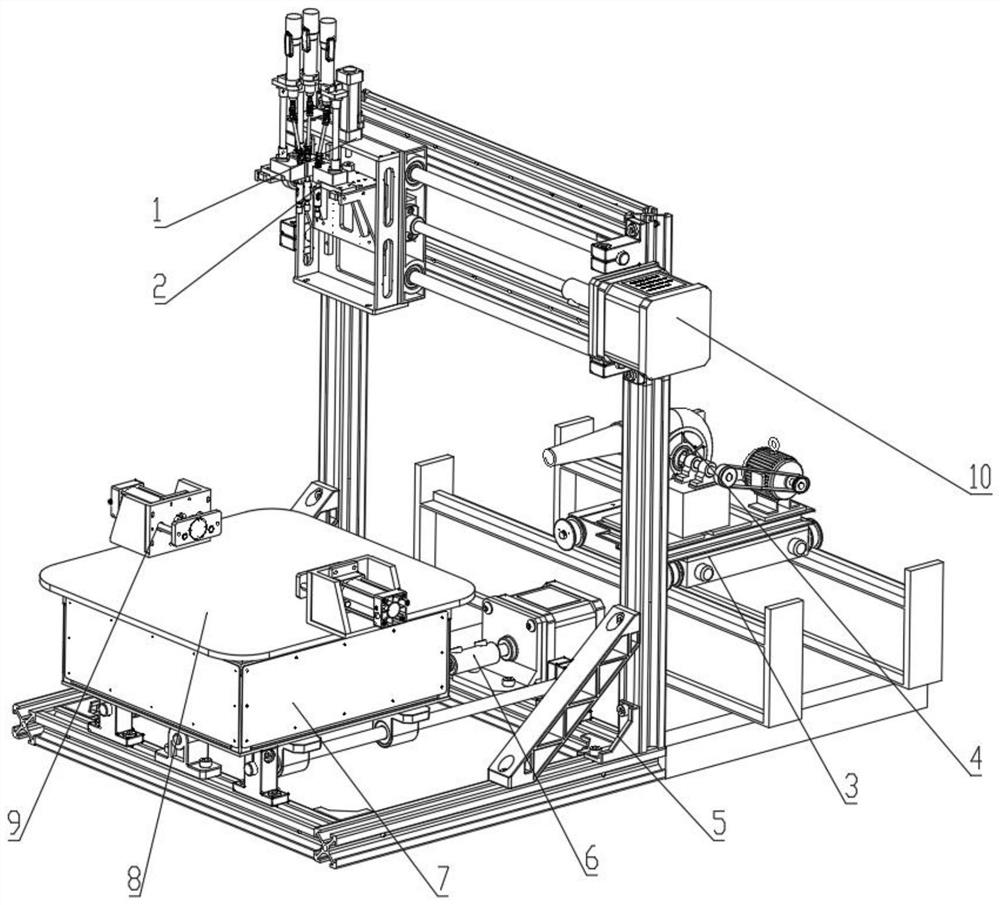

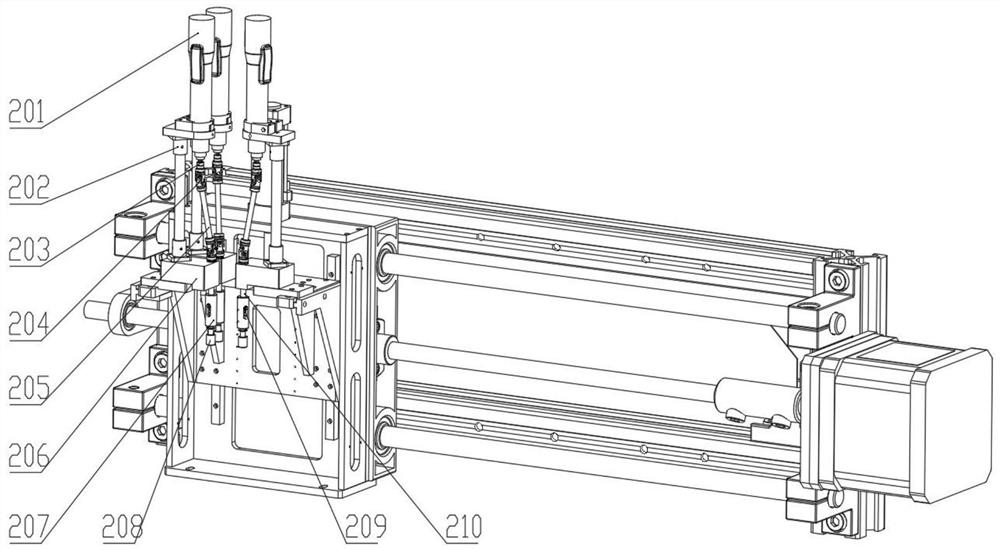

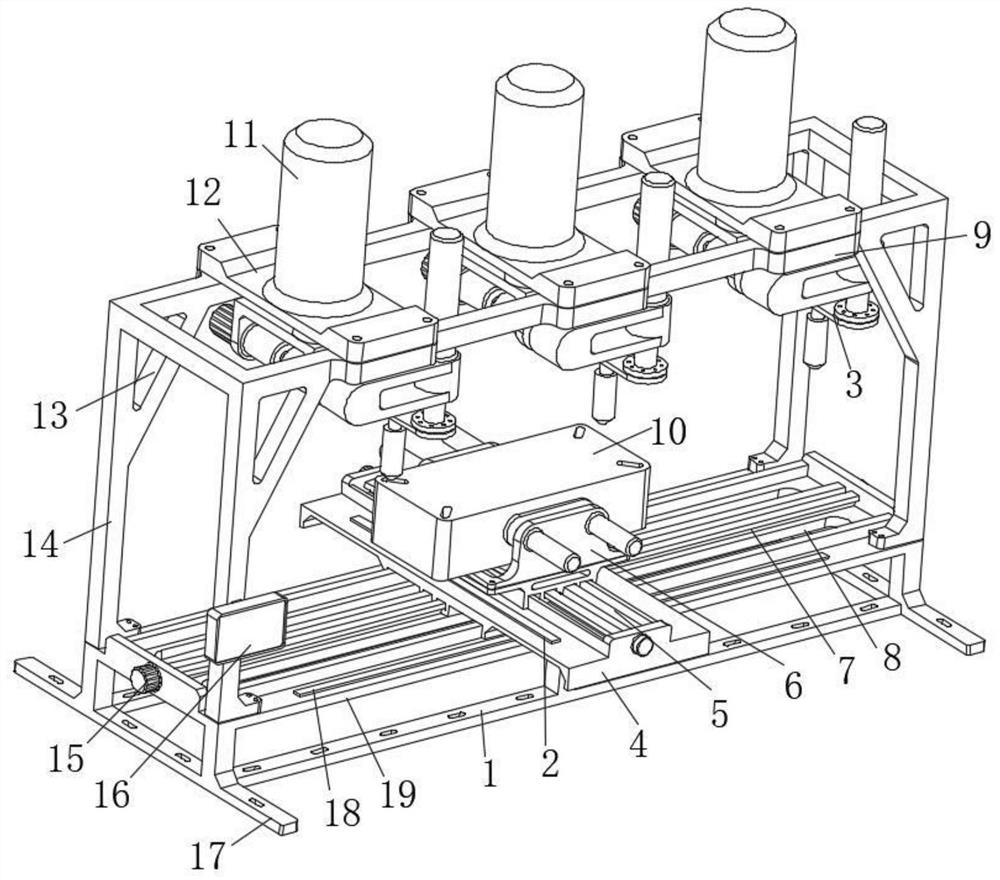

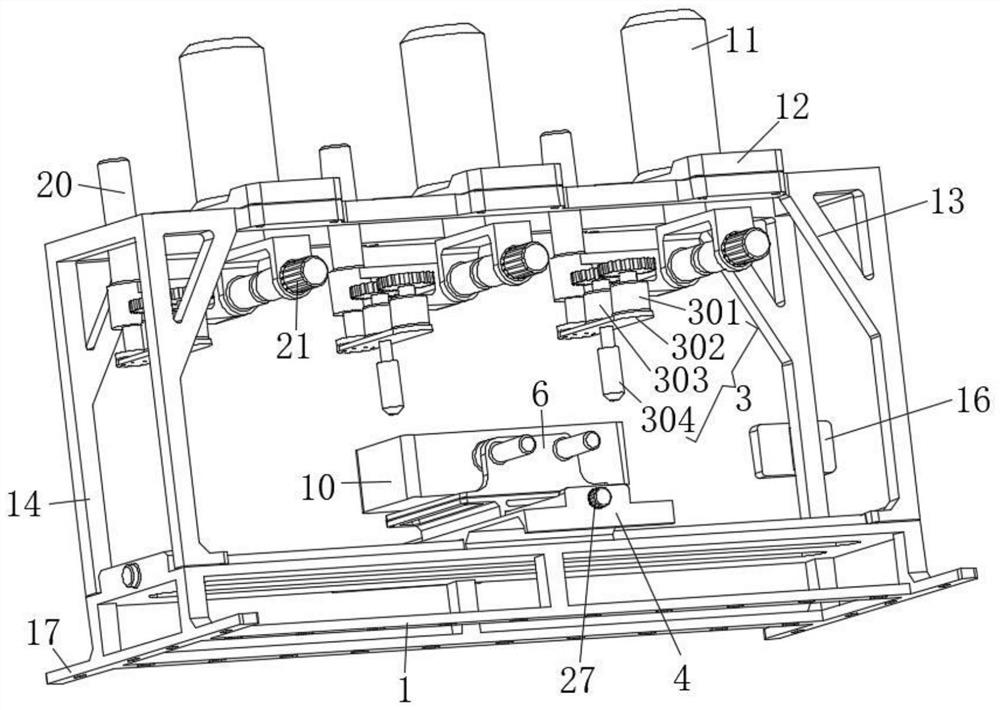

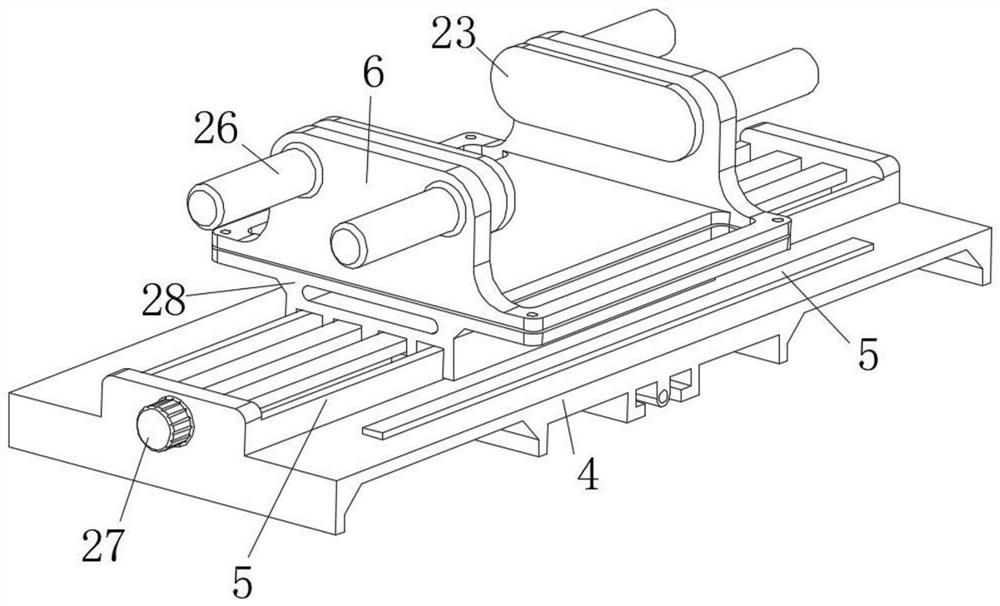

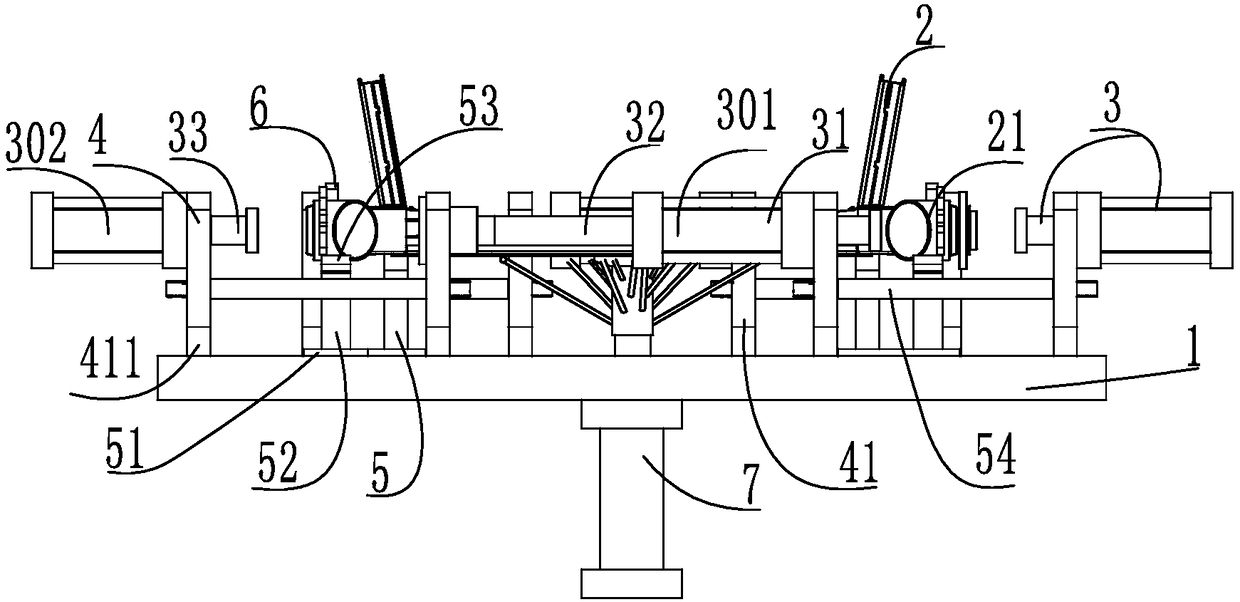

High-flexibility machining system and method based on milling-milling combined machining principle

InactiveCN108746783AGuarantee qualityExtended processing spaceMeasurement/indication equipmentsMilling equipment detailsEngineeringCutting force

The invention discloses a high-flexibility machining system and method based on the milling-milling combined machining principle. The high-flexibility machining system based on the milling-milling combined machining principle comprises a supporting feeding mechanism, a control mechanism, an auxiliary machining mechanism and a power head mechanism. The supporting feeding mechanism adopts an industrial robot. A power head is installed at the tail end of a mechanical arm through an adapter plate. The auxiliary machining mechanism comprises an indexable workbench. A workpiece to be machined is placed on the indexable workbench. The industrial robot, the indexable workbench and the power head mechanism are in signal connection with a numerical control module in the control mechanism. Multiple end mills are fixed to a cutter head of the power head and evenly distributed in the circumferential direction. Each end mill rotates around the axis of the cutter head and also rotates around own axisat the same time. The rotation directions of every two adjacent planetary end mills are opposite. The high-flexibility machining system and method based on the milling-milling combined machining principle have the advantages that the cutting force is small, the cutting temperature is low, cutting vibration is small, the wear of cutters is little, the service lives of the cutters are long, and themachining efficiency is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

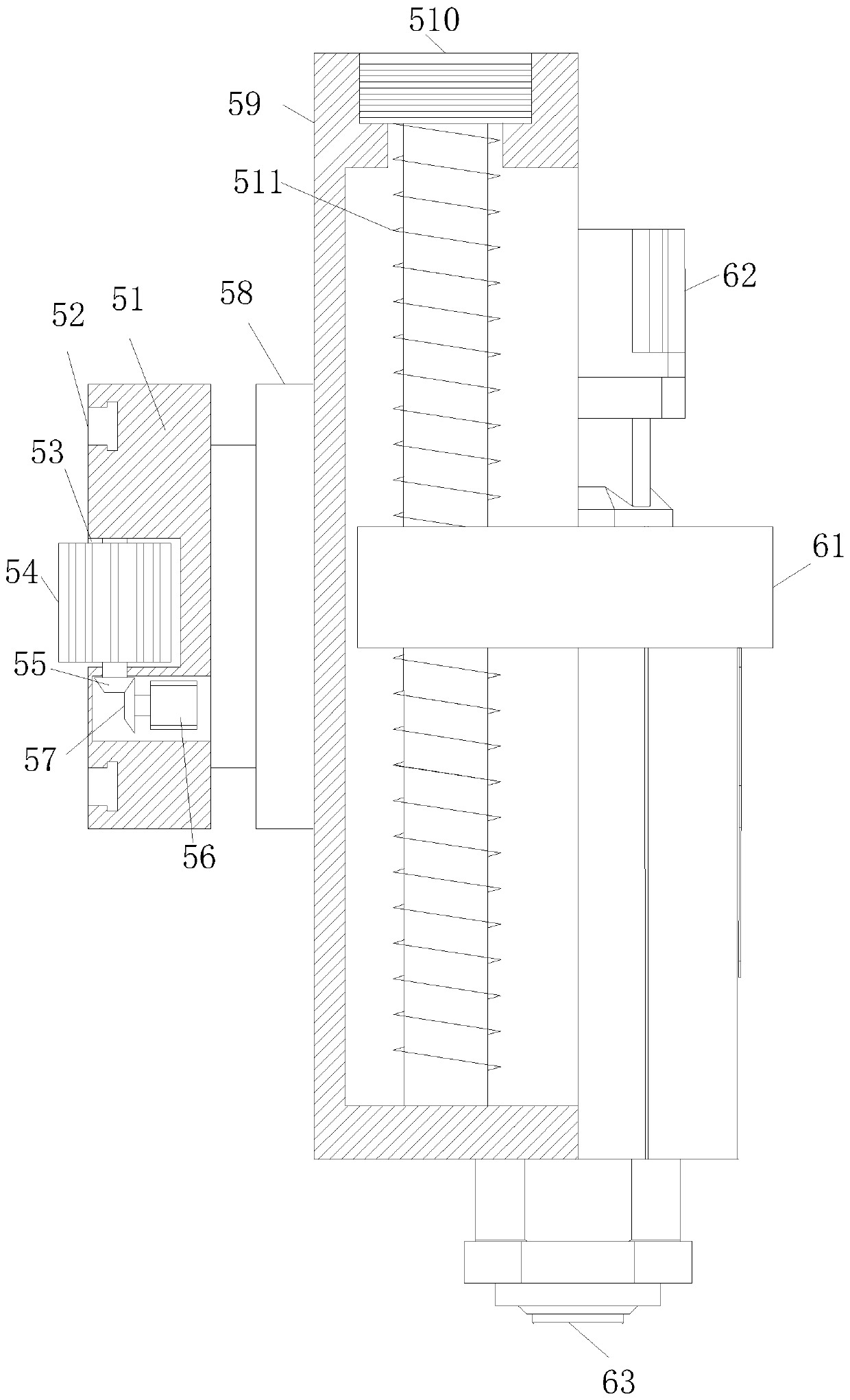

Laser processing equipment

PendingCN113369710AAdjustable relative positionMilling to achieveLaser beam welding apparatusLaser processingEngineering

The invention discloses laser processing equipment. The equipment comprises a rack, a Y-axis movement mechanism, a clamping table, an X-axis movement mechanism, a Z-axis movement mechanism, a laser assembly and a laser box; the Y-axis movement mechanism is arranged on the rack; the clamping table is arranged on the Y-axis movement mechanism, the Y-axis movement mechanism drives the clamping table to move front and back, the clamping table is used for clamping a bar, the clamping table drives the bar to swing around a C axis and drives the bar to rotate around an A axis, and the length direction of the bar is parallel to the A axis; the X-axis movement mechanism is arranged on the rack; the Z-axis movement mechanism is arranged on the X-axis movement mechanism; the laser assembly is fixed to the rack and is used for generating laser; the laser box is used for machining a workpiece, the laser assembly is connected with the laser box through a light path, the laser box is arranged on the Z-axis movement mechanism, and the Z-axis movement mechanism drives the laser head to move in the Z-axis direction. The laser processing equipment is convenient in processing, and the possibility of interference during processing can be reduced.

Owner:GUANGDONG ORIGINAL POINT INTELLIGENT TECH CO LTD

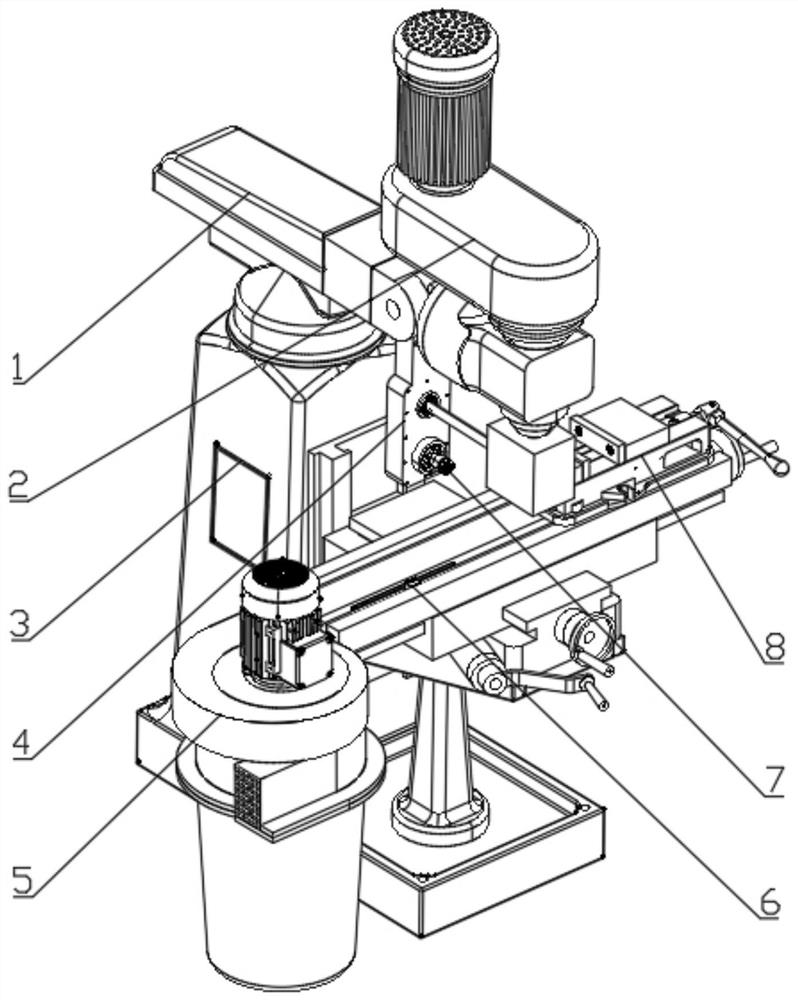

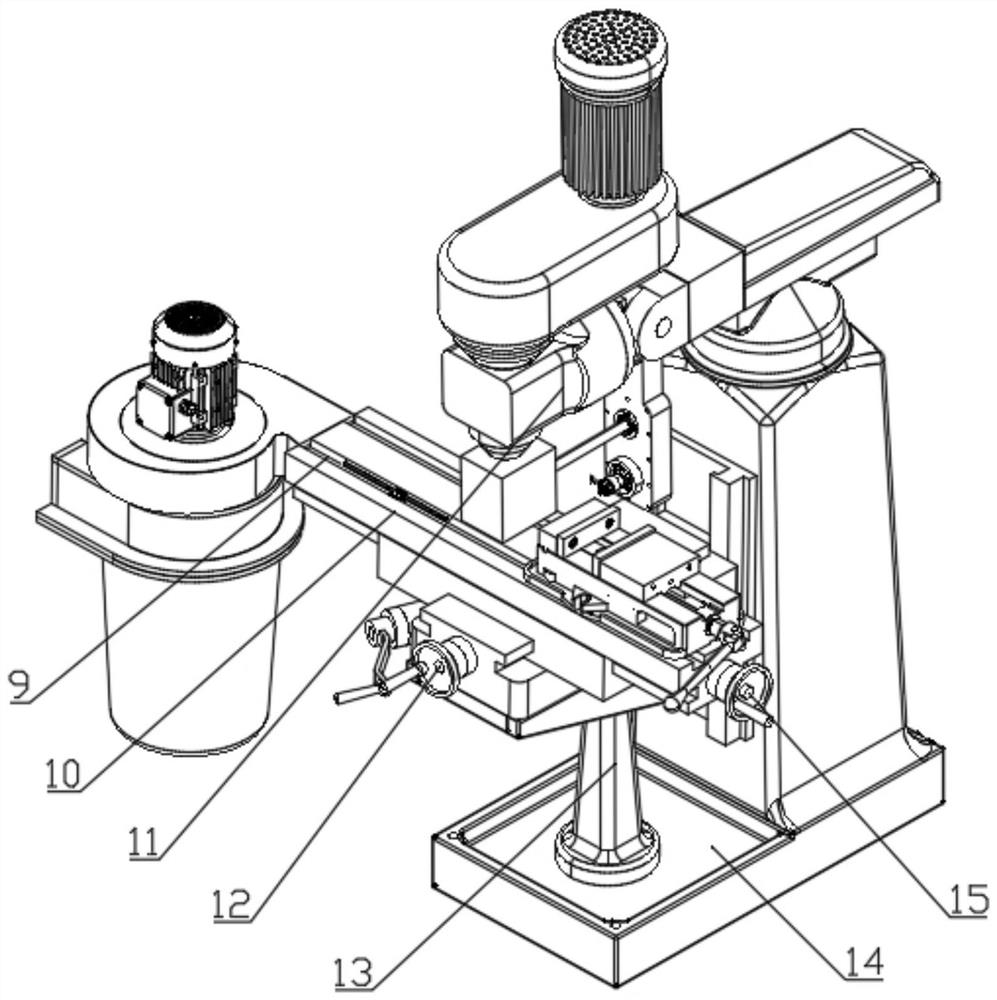

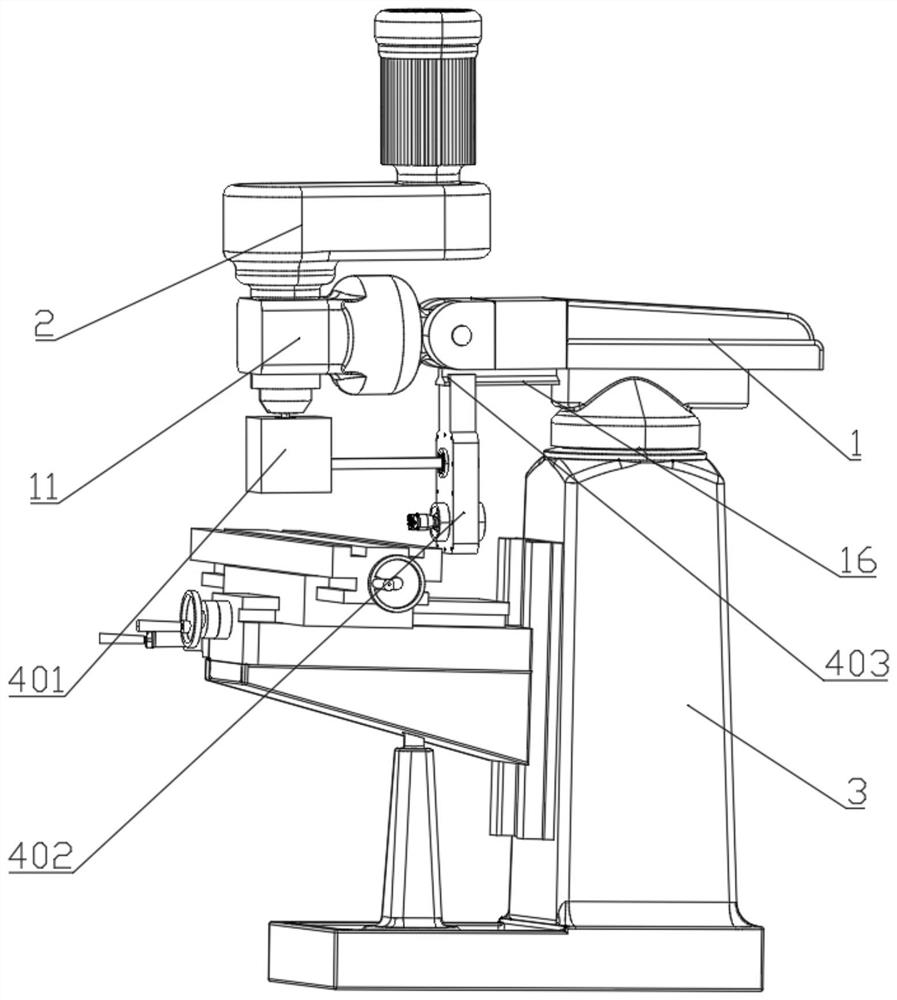

Machining milling machine provided with rotating mechanism and machining method of machining milling machine

PendingCN113084540ALarge processing spaceThe processing power remains unchangedFeeding apparatusLarge fixed membersMachine partsEngineering

The invention relates to the technical field of milling machines, in particular to a machining milling machine provided with a rotating mechanism. The machining milling machine comprises a supporting frame, a machining mechanism, a rotating mechanism, a chip removal mechanism, a placing table, a longitudinal moving mechanism, a lifting mechanism and a transverse moving mechanism, wherein the transverse moving mechanism is arranged in the middle of the front side of the lower end of the supporting frame, the rotating mechanism is arranged at the upper end of the transverse moving mechanism, the placing table is arranged at the upper end of the rotating mechanism, the longitudinal moving mechanism is arranged on the front side of the upper end of the supporting frame, the lifting mechanism is arranged at the front end of the longitudinal moving mechanism, the machining mechanism is arranged at the front end of the lifting mechanism, and the chip removal mechanism is arranged on the rear side of the lower end of the supporting frame. According to the machining milling machine provided with the rotating mechanism, the machining mechanism is arranged to change the milling machine into a plurality of machining devices, multiple different types of milling can be conducted on machined parts at the same time, and the rotating mechanism is arranged to drive the machined parts to rotate to conduct multi-position machining. The invention further provides a machining method of the machining milling machine provided with the rotating mechanism.

Owner:重庆贻晨兴工业设计有限责任公司

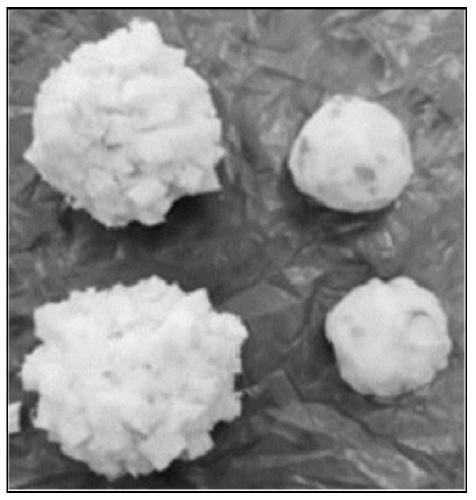

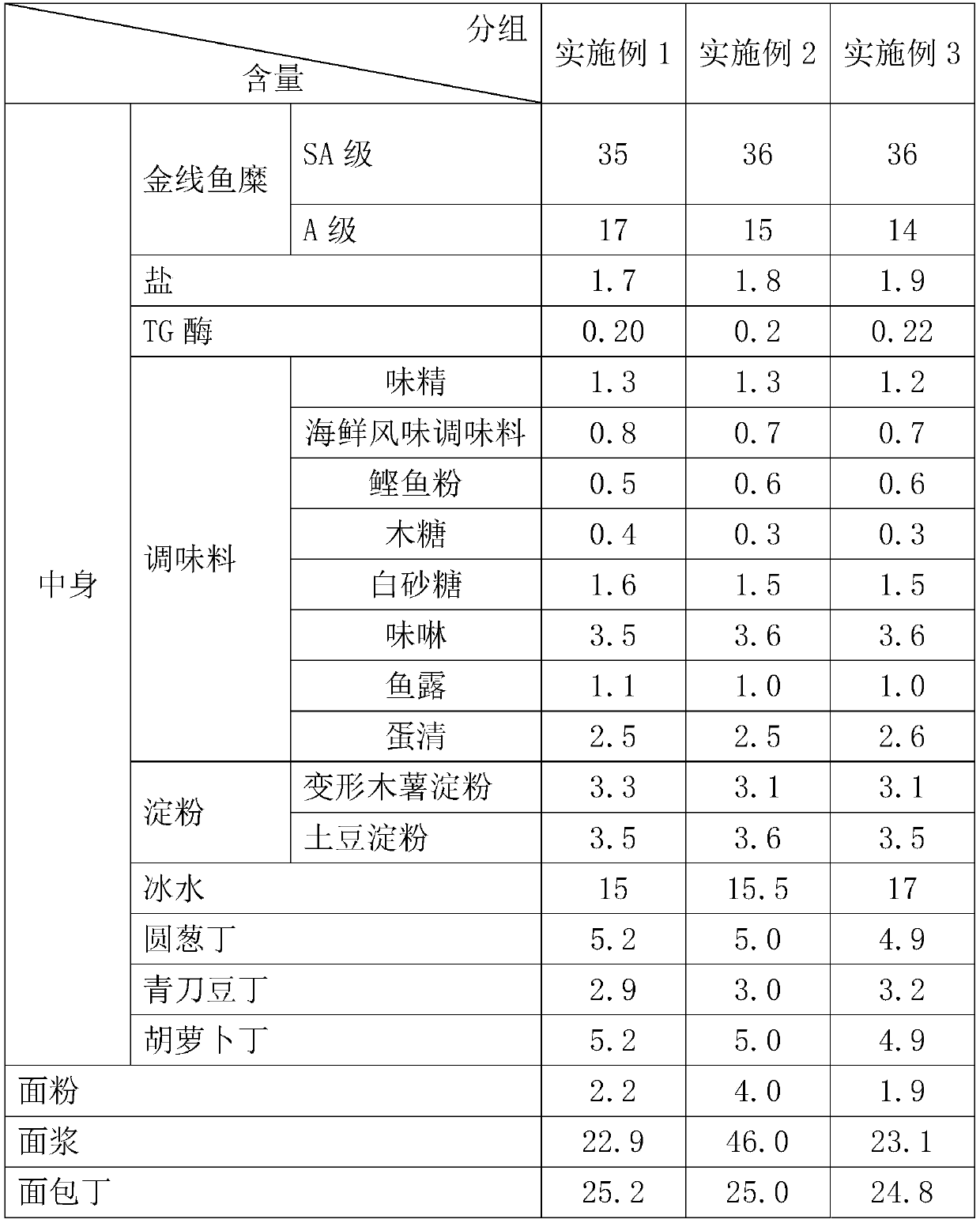

Seafood large meatball product and preparation method thereof

The invention discloses a seafood large meatball product and a preparation method thereof. The seafood large meatball product comprises a ball-shaped middle body, and the outer side of the middle bodyis sequentially wrapped with flour, batter and croutons. The product comprises the following components in parts by weight: 49-51 parts of the middle body, 3.9-4.1 parts of the flour, 45-47 parts ofthe batter and 49-51 parts of the croutons. The middle body is prepared from 50-52 parts of fish surimi, 1.7-1.9 parts of salt, 0.20-0.22 part of TG enzyme, 11.5-11.7 parts of seasonings, 6.6-6.8 parts of starch, 15-17 parts of ice water and 12-14 parts of diced vegetables. The invention provides the seafood large meatball product. The fish surimi is used as a main raw material, the delicious seasonings and the diced vegetables are used as auxiliary materials to prepare the middle body, the outer side of the middle body is wrapped with the croutons, after cooking, the product is good in color,fragrance, taste and nutrition, the inner layer is smooth and elastic, and the product is fragrant in fish flavor, fresh, tender, good in mouth feel, convenient to process and high in operability, and expands the processing space of marine products.

Owner:RONGCHENG TAIXIANG FOOD

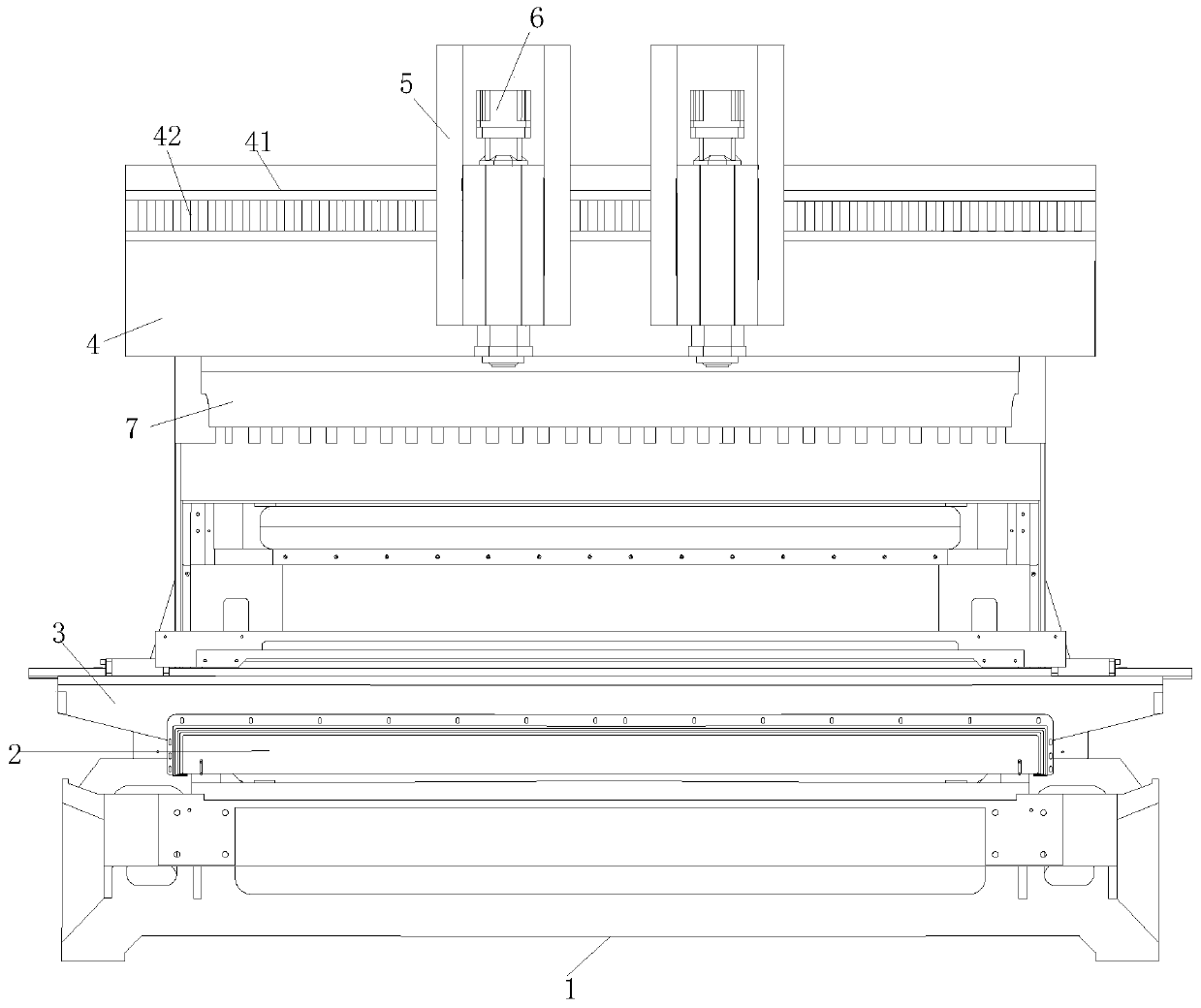

Double-shaft composite numerical control machine tool

InactiveCN110834204ASmall footprintLarge processing spaceFeeding apparatusLarge fixed membersNumerical controlControl engineering

The invention discloses a double-shaft composite numerical control machine tool. The machine tool comprises a base, a lathe bed is fixedly mounted on the base, a workbench is mounted on the lathe bed,the upper end of the lathe bed is provided with a gantry, two driving mechanisms are slidably mounted on the gantry, spindle mechanisms are mounted on the driving mechanisms, the driving mechanisms can drive the spindle mechanisms to move along an X axis and a Z axis, the spindle mechanisms can also be driven to rotate, a straight-line tool magazine is mounted below the spindle mechanisms, and the straight-line tool magazine is slidably mounted on the gantry. According to the double-shaft composite numerical control machine tool, the two driving mechanisms are arranged, the driving mechanismseach drive one spindle mechanism to move along the gantry and drives the corresponding spindle mechanism to move and rotate along the Z axis, so that the flexibility of movement of the spindle mechanisms is improved, and multi-angle machining can be carried out on a workpiece; and automatic tool changing is achieved through forward stretching of the straight-line tool magazine, the tool magazineretracts into the gantry during standby of the machine tool, so that the occupied space of the tool magazine on the machine tool is reduced, and the machining space of the machine tool is increased.

Owner:安徽省临泉县智创精机有限公司

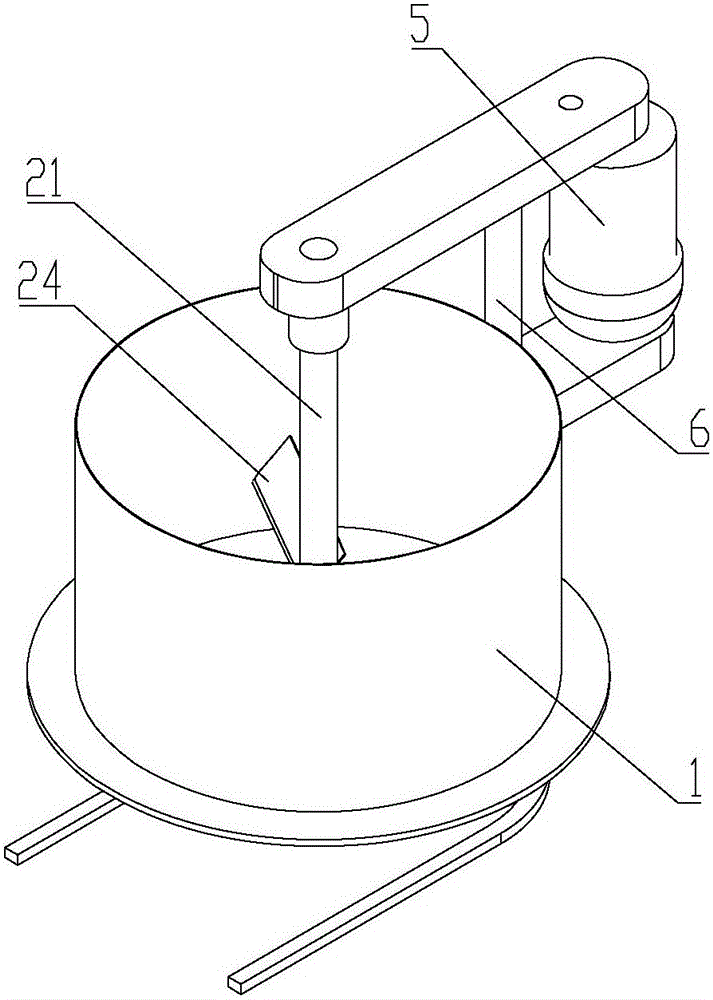

automatic wok

ActiveCN103609919BEvenly heatedAvoid the problem of being thrown outCooking vesselsFood preparationImpellerEngineering

The invention discloses an automatic wok which comprises a wok body, a three-oblique-blade paddle type stirrer as well as a transmission device and a power device for driving the three-oblique-blade paddle type stirrer to operate, wherein the wok body is a cylindrical pan, an enveloping surface formed by the movement of the blades in the three-oblique-blade paddle type stirrer covers the whole wok bottom, the three-oblique-blade paddle type stirrer comprises a stirring shaft, an impeller coaxially arranged on the stirring shaft and three handles circumferentially and uniformly arranged on the impeller, a blade is arranged on each handle, and the distances from the lower end surfaces of the three blades to the wok bottom are increased in turn. According to the automatic wok disclosed by the invention, the setting mode of blades on the traditional stirrer is improved so that the food heating in the wok is more uniform and the stirring efficiency of food frying is improved.

Owner:河北玉龙食品机械制造有限公司

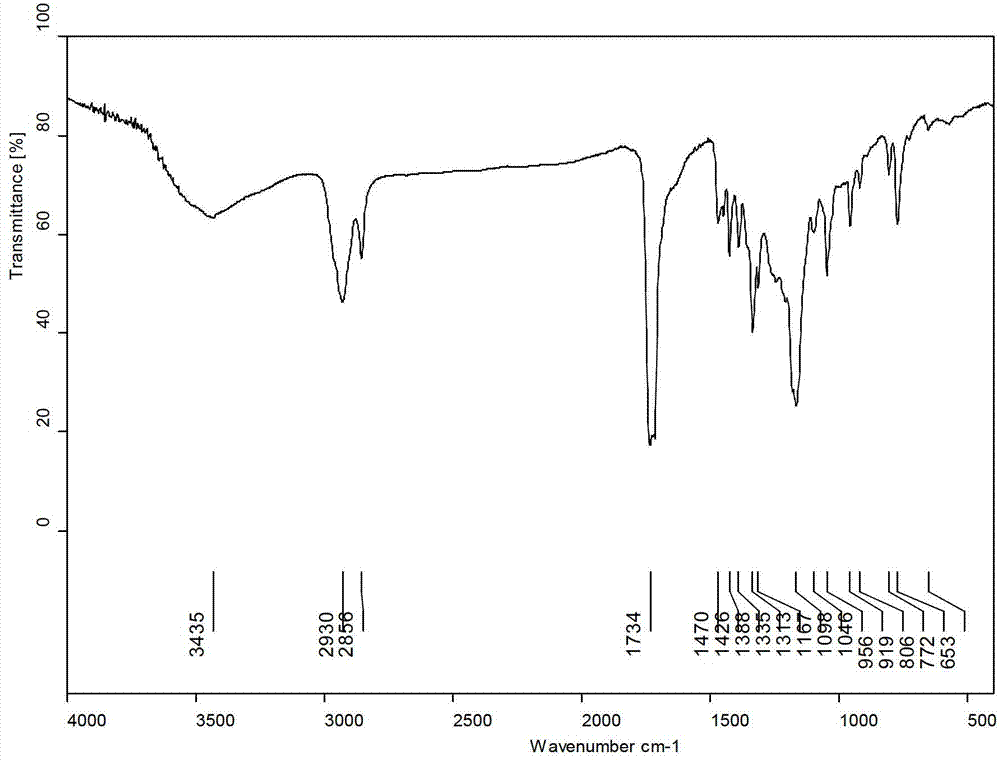

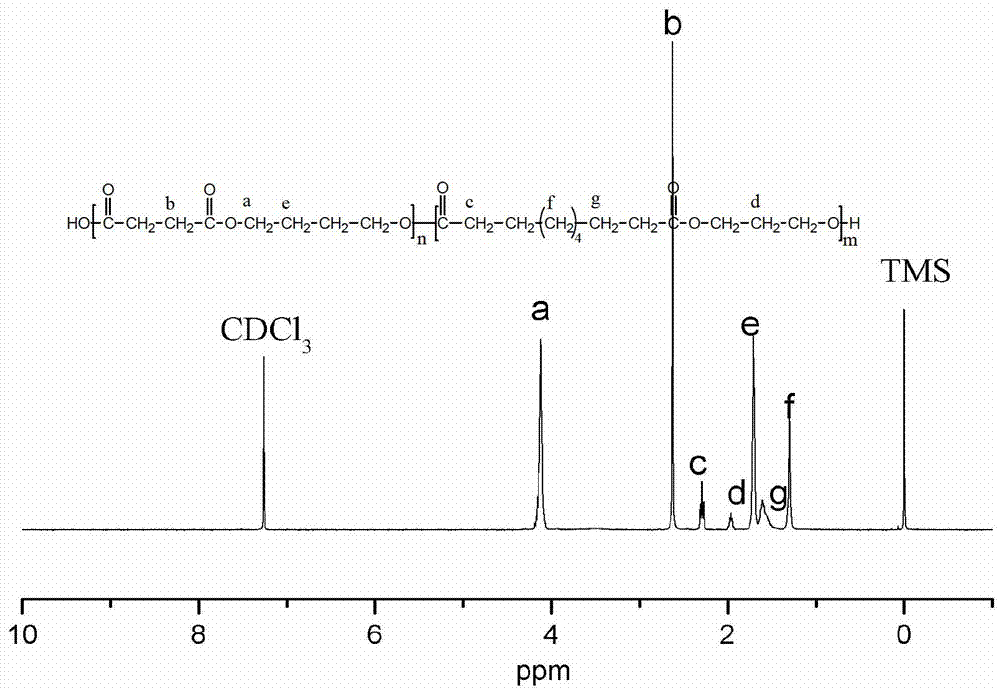

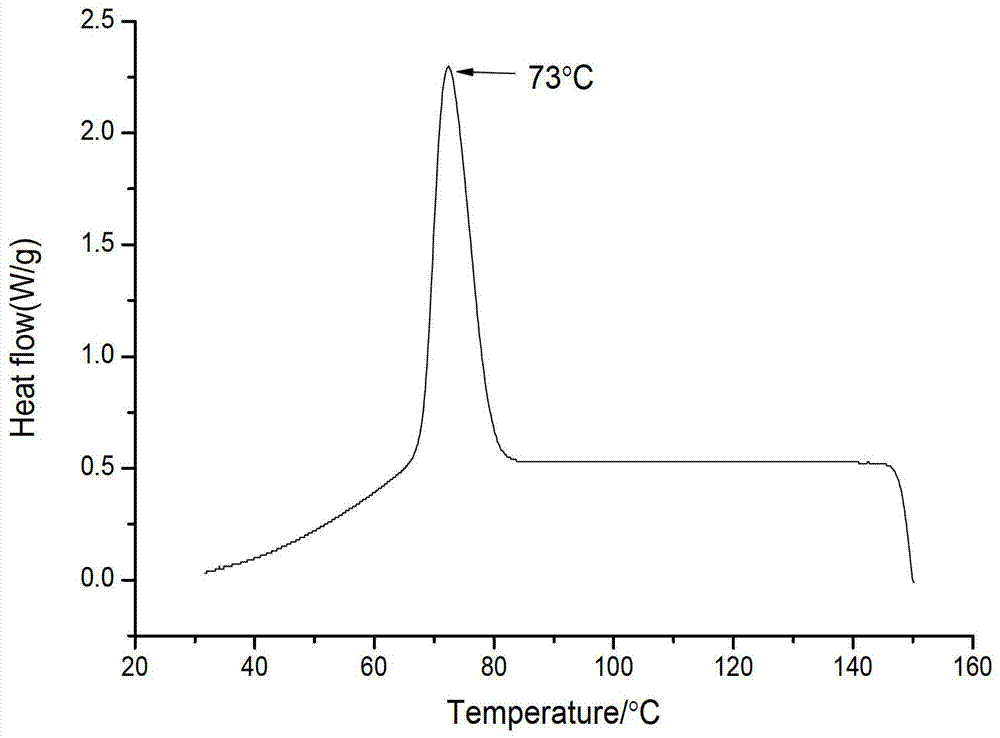

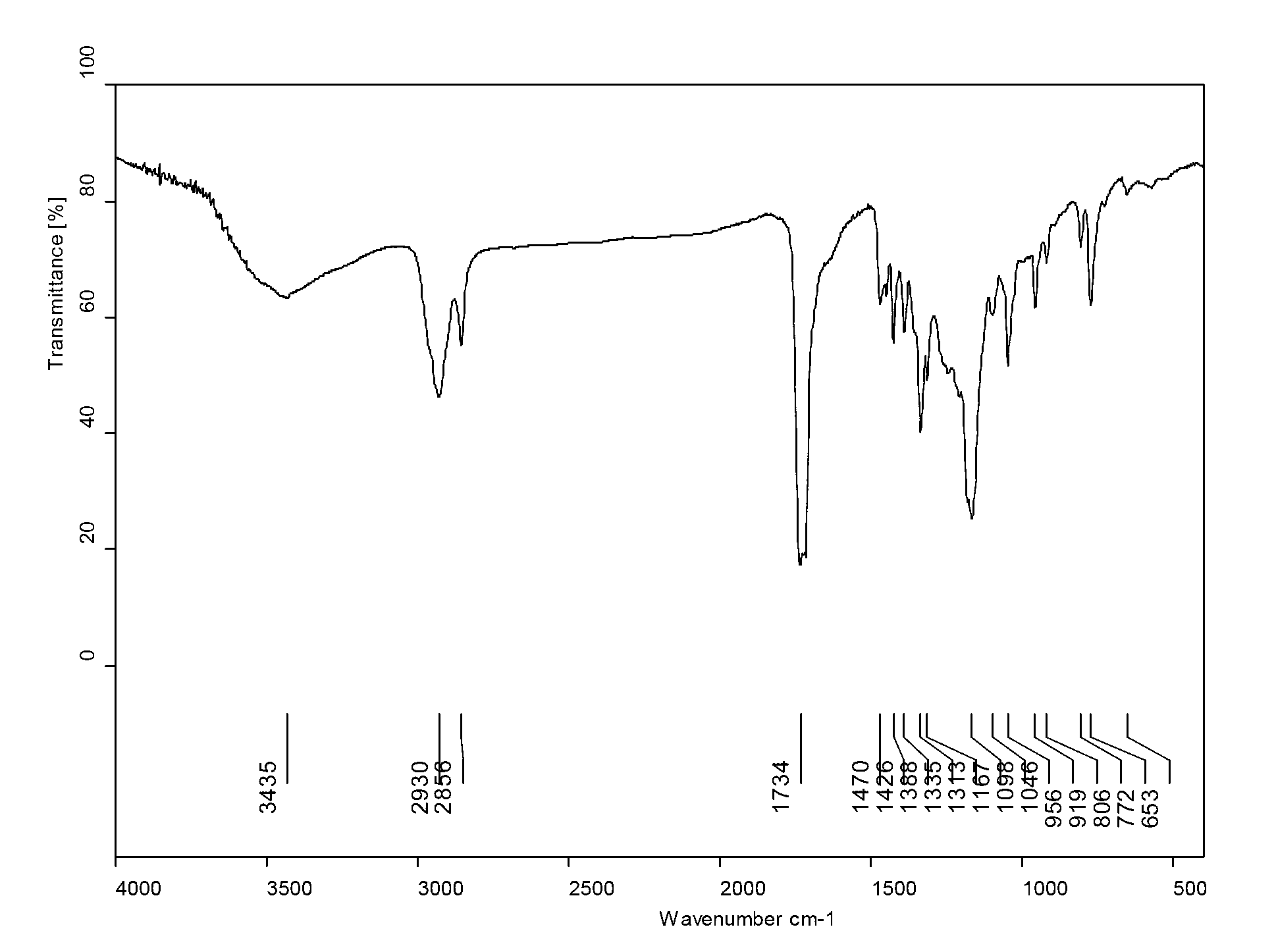

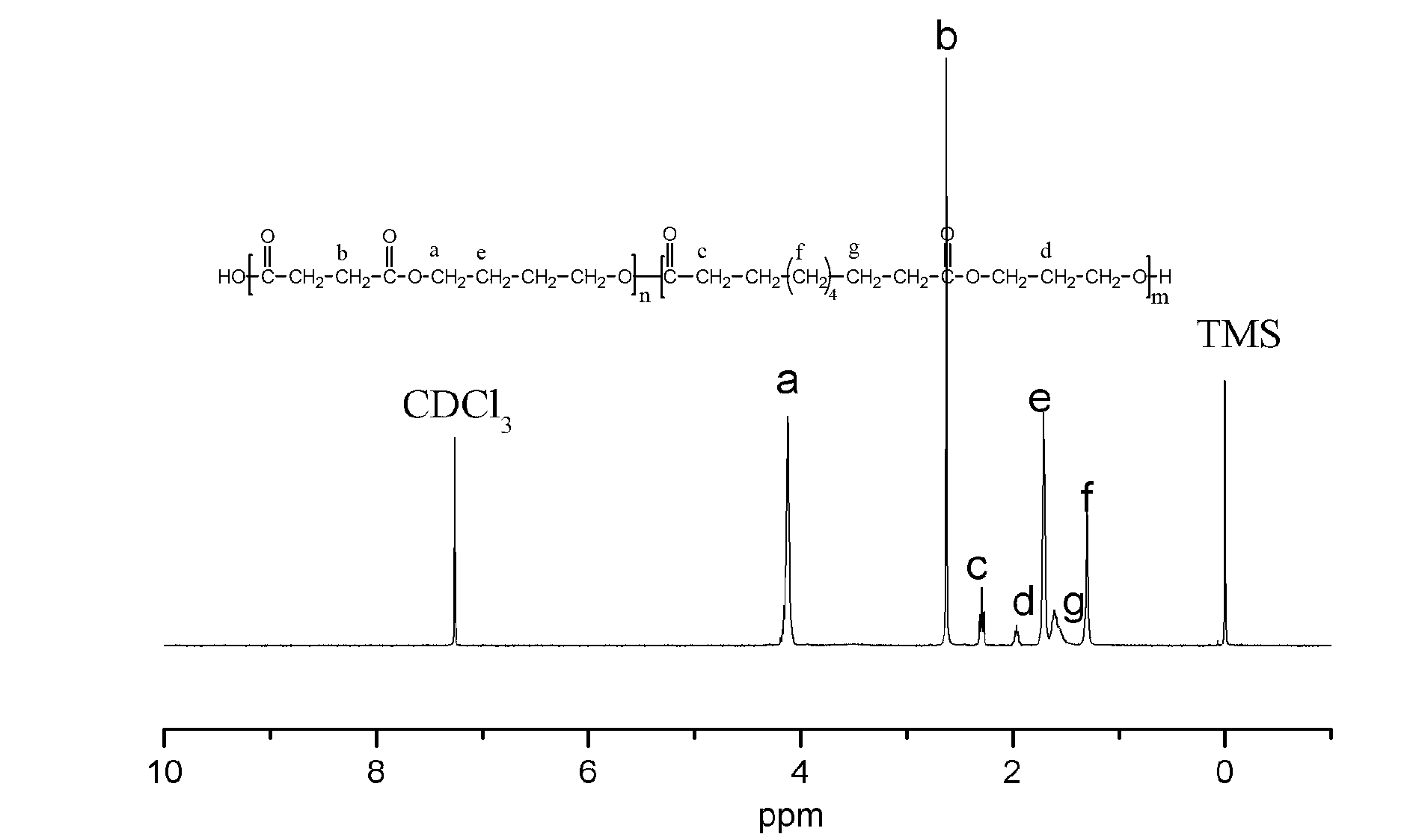

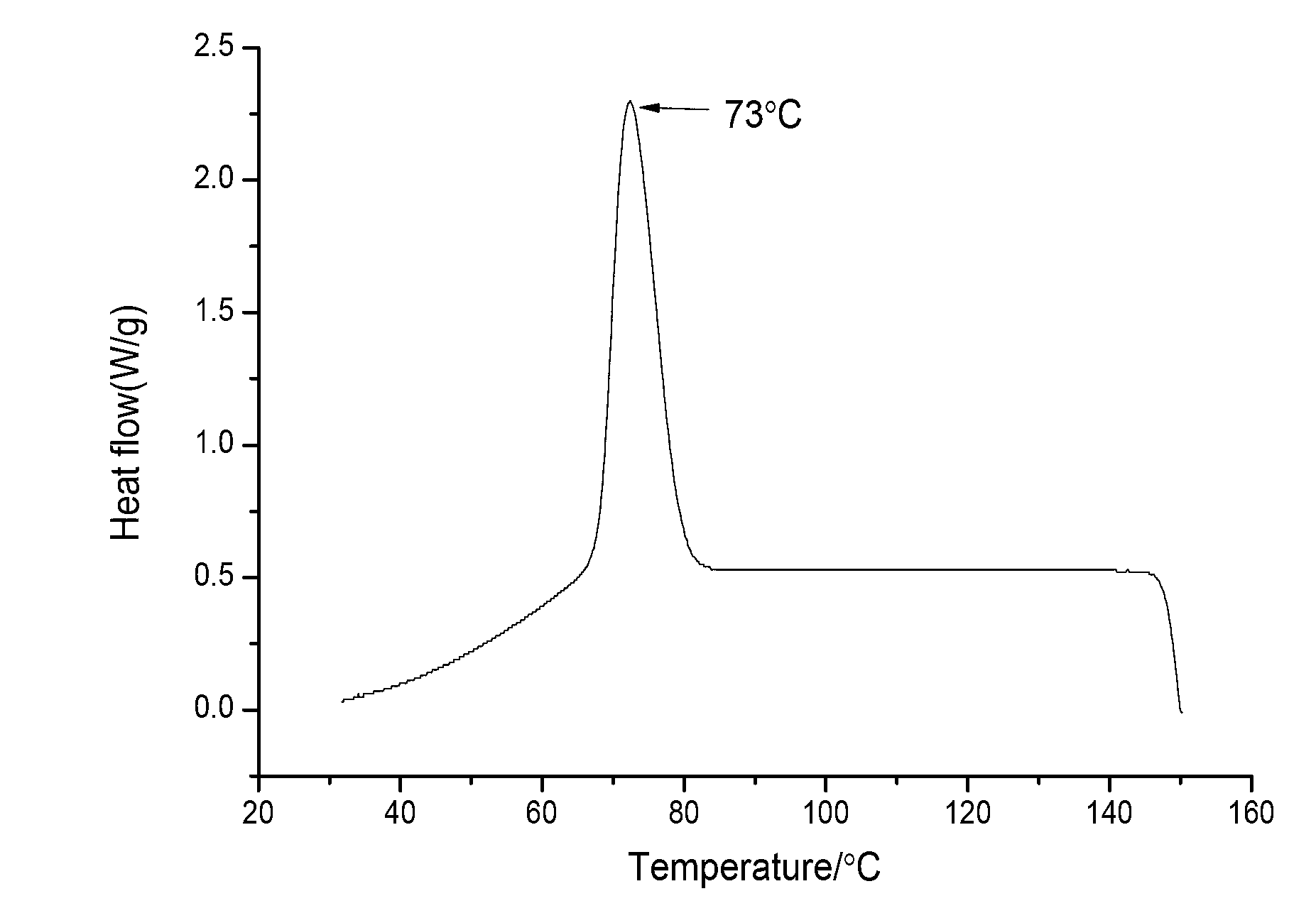

Polysebacic acid 1, 3-propylene glycol ester-block-polysuccinic acid butanediol block polyester and preparation method and use thereof

The invention relates to polysebacic acid 1, 3-propylene glycol ester-block-polysuccinic acid butanediol block polyester, wherein the general formula is shown in the specification, the molecular weight is in a range from 10000 to 50000. The molecular weight of the polyester provided by the invention is in the range from 10000 to 50000, the thermodynamic property of the polyester is equivalent to that of PBS (Polybutylene Succinate), the degradation performance is remarkably improved, the melting point is greater than 100 DEG C, the thermal stability is better, and the processing space is wider, so that the polyester can be used in the field of high molecular materials such as food package, agricultural plastic mulching films and medical sutures, and has a wide application prospect.

Owner:天津市食品加工工程中心

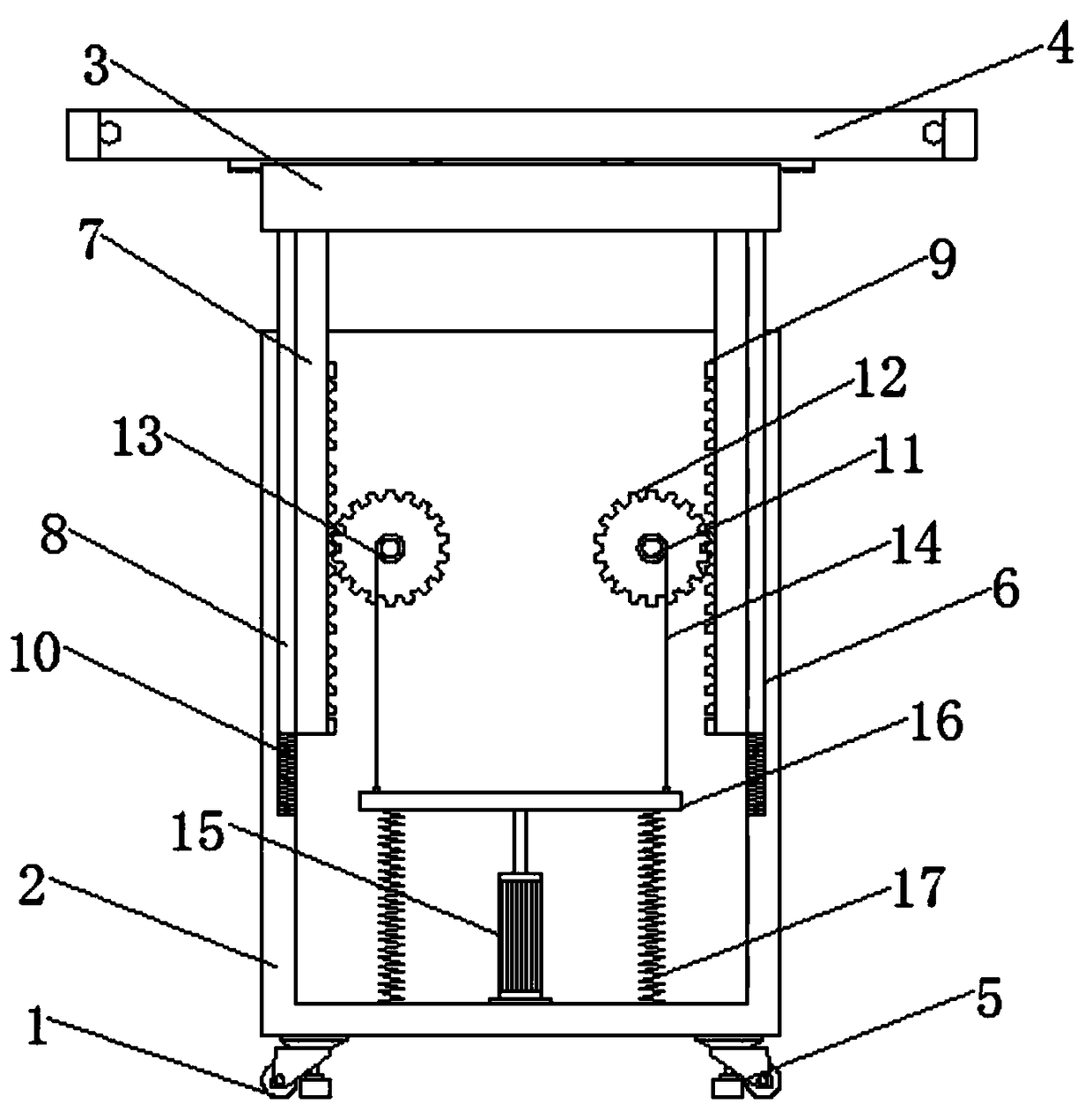

A special-shaped hole processing device for large machinery

ActiveCN110788370BReduce occupancyLarge processing spaceBoring/drilling machinesMachine partsMachine

The invention relates to the technical field of machining, in particular to an irregularly-shaped hole machining device for a large machine. The irregularly-shaped hole machining device comprises a bottom frame, an installation table is welded to the bottom frame, the installation table is fixedly provided with a first guide rail through bolts, and the first guide rail is slidably provided with afirst moving base. The irregularly-shaped hole machining device has the advantages that through the cooperation of the installation table and a main installation rack, the device can provide a largermachining space, the limitations of a traditional machine tool to the size of a workpiece are broken through, therefore, irregularly-shaped holes in large machine parts can be automatically and efficiently machined instead of manual operation, and much less manpower is occupied. The device can achieve drilling, boring and milling formation of the irregularly-shaped holes through the cooperative work of a plurality of drilling devices in the main installation rack and a plurality of different cutters in the drilling devices, therefore, the irregularly-shaped holes can be directly machined and formed in a single one device, the time for repeated loading and transfer is saved, and the production efficiency is further improved.

Owner:台州巴斯图视觉机器人有限公司

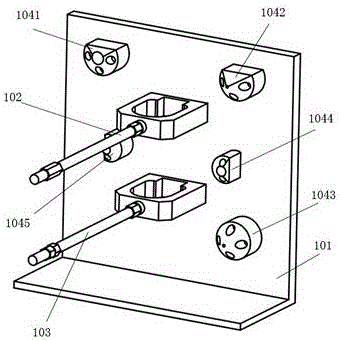

Fixture for machining engine cylinder end surface and crankshaft hole

InactiveCN106112605ALarge processing spaceFlexible processingPositioning apparatusMetal-working holdersEngineeringCrankshaft

The invention provides a fixture for machining an engine cylinder end surface and a crankshaft hole. The fixture comprises a pull rod module, a pressing plate module and a support frame module; the pull rod module includes a base, an upper support rod, a lower support rod and a positioning mechanism; the pressing plate module is a rectangular block body; a special-shaped hole and a pressing point are arranged on the pressing plate module; and the support frame module includes a support base, a support column and a support body. The fixture has the following technical effects: after the fixture is used, the problems of low clamping efficiency and large occupied space can be solved, so that the machining of a whole engine cylinder can be finished by using two machining centers.

Owner:芜湖智高汽车部件有限公司

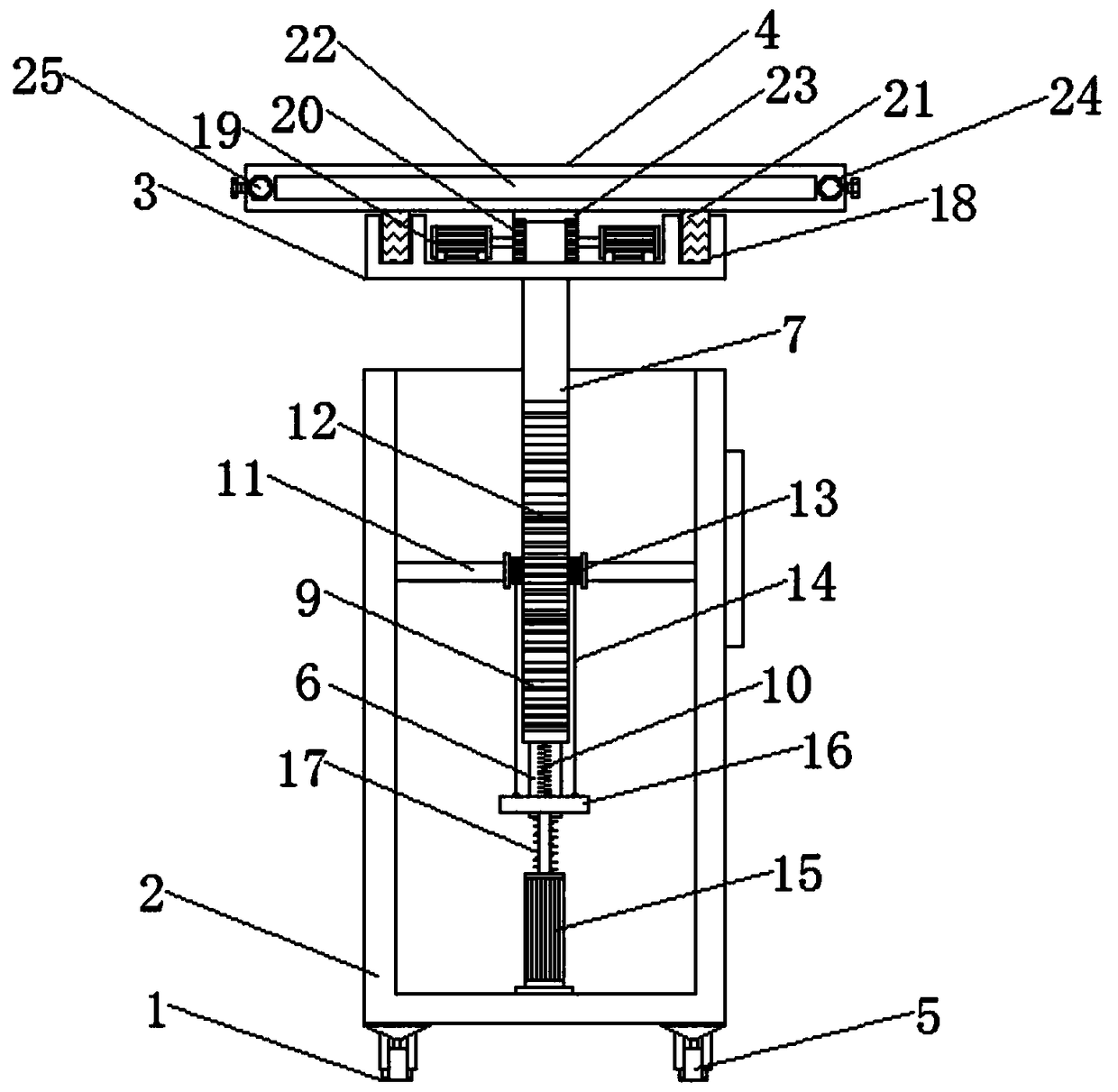

Synchronous positioning and press-fitting device for multi-station rear axle bearing

ActiveCN108544208AEasy to pre-locateImprove installation efficiencyVehicle componentsMetal working apparatusTransverse planeMechanical engineering

The invention discloses a synchronous positioning and press-fitting device for a multi-station rear axle bearing. The synchronous positioning and press-fitting device for the multi-station rear axle bearing comprises a working table and a rear axle mold, wherein the rear axle mold comprises a plurality of bearing seats; bearings to be pressed are arranged in the bearing seats; pressurizing oil cylinders are arranged at least one side of two side surfaces in the axial direction of each bearing seat; each pressurizing oil cylinder comprises an oil cylinder shell and a pressurizing piston rod; apressurizing block is arranged at one outward end of each pressurizing piston rod; a positioning assembly is arranged under each bearing seat; a feeding and blanking mechanism is arranged on the upperside surface of the working table, and comprises a power mechanism; and a positioning mold capable of supporting the rear axle mold is arranged above the power mechanism. The synchronous positioningand press-fitting device for the multi-station rear axle bearing provided by the invention has the advantages that the rear axle mold is convenient and safe to feed and blank; the bearing is pressed in a horizontal plane, so that the processing space is large, no repetitive positioning is needed, the positioning times is less, and the pressing-fit efficiency is high; and the feeding and blanking mechanism can be used for pre-positioning the rear axle mold, so that the bearing can be processed and positioned conveniently and can be quickly pressed.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

Dual Rotary Drive

ActiveCN104607982BSmall turning diameterReduced external volumeProgramme-controlled manipulatorMechanical apparatusGear wheelDouble rotation

Owner:IND TECH RES INST

A multi-station synchronous rear axle bearing pressing equipment

ActiveCN108637645BImprove processing efficiencyImprove work efficiencyVehicle componentsMetal working apparatusPillow block bearingStructural engineering

The invention discloses a multi-station synchronous rear axle bearing press-fitting device. The device comprises a workbench and a rear axle die, the rear axle die comprises a plurality of bearing seats, the bearing seats are internally provided with to-be-pressed bearings, at least one side of the two axial side faces of each bearing seat is provided with a pressure applying oil cylinder, each pressure applying oil cylinder comprises an oil cylinder shell and a piston rod, pressure applying blocks attached to the side faces of the to-be-pressed bearings are arranged at the ends, facing outwards, of the piston rods, the piston rods are coaxial with the to-be-pressed bearings, the axis of each to-be-pressed bearing is parallel to the working upper plane of the workbench, a limiting assemblyand a positioning assembly for positioning the rear axle die are arranged on the workbench, and the pressure applying oil cylinders are fixed on the limiting assembly. The device has the advantages that when re-machining is carried out after pre-positioning, fixing of the rear axle die is completed by the pressure applying oil cylinders and the pressure applying blocks, the machining space is enlarged, positioning and machining are convenient, the machining precision of the to-be-pressed bearings and the bearing seats is improved, the to-be-pressed bearings are prevented from being eccentricto the bearing seats, the plurality of to-be-pressed bearings can be synchronously machined through the pressure applying oil cylinders, so that the working efficiency of bearing press-fitting is improved.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

Axial stable machining milling machine and machining method thereof

PendingCN113020669AImprove machining accuracyLarge processing spaceMilling machinesMaintainance and safety accessoriesMachiningWind power

The invention relates to the technical field of milling machines, in particular to an axial stable machining milling machine which comprises a fixing base, a transmission conversion mechanism, a transmission device, a workbench and a scrap removing mechanism. The transmission device is arranged at the upper end of the fixing base and rotationally connected with the fixing base, the upper end of the transmission conversion mechanism is arranged inside the lower end of the transmission device and connected with the transmission device in a transmission mode, the workbench is arranged at the front end of the fixing base, and the scrap removing mechanism is arranged on one side of the workbench. Due to the fact that the conversion mechanism is arranged, vertical machining of the milling machine is changed into axial machining, and the machining space and the machining range of machining of the milling machine are enlarged; and due to the fact that the scrap removing mechanism is arranged, a wind power scrap removing mode is adopted, residual scraps on the workbench are sucked away, most of the scraps can be effectively removed, and the corrosion damage of the scraps to the workbench is reduced. The invention further provides a machining method of the axial stable machining milling machine.

Owner:勤利自动化设备(韶关)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com