Process technique for processing spline tooth profiles through replacing involutes with circular arcs

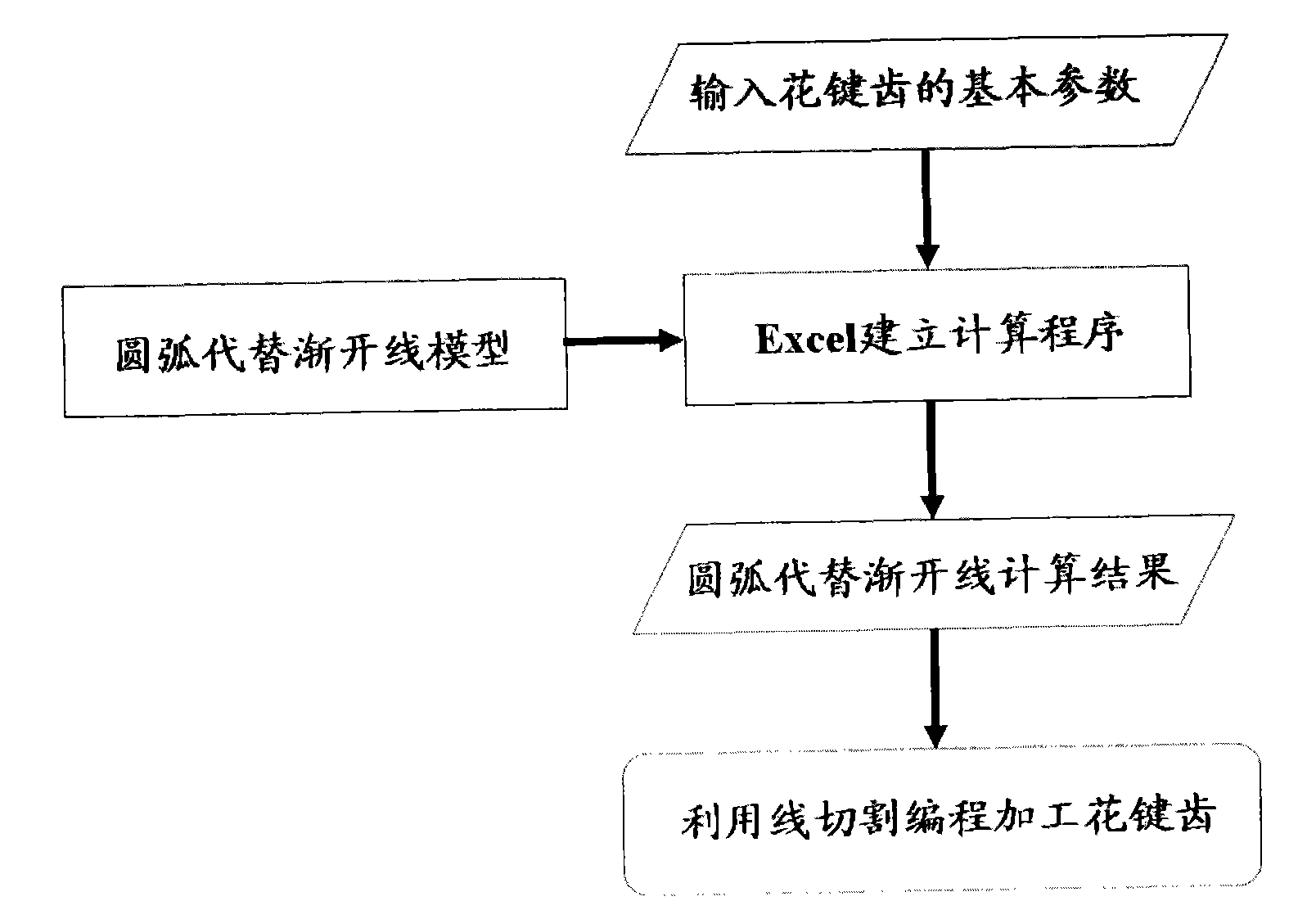

A process technology, involute technology, applied to components with teeth, gear teeth, belts/chains/gears, etc., can solve the problems of cumbersome processing and heavy workload of involute spline teeth, and achieve wire cutting The processing programming is simple, the effect of improving the processing capacity and expanding the processing space

Inactive Publication Date: 2011-06-29

王天甜

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the disadvantages of cumbersome processing and heavy workload of involute spline teeth, the present invention provides a technology for processing spline tooth shapes with circular arcs instead of involutes. Instead of the involute to process the spline tooth shape, the error after the replacement can be controlled within a few thousandths of a millimeter

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

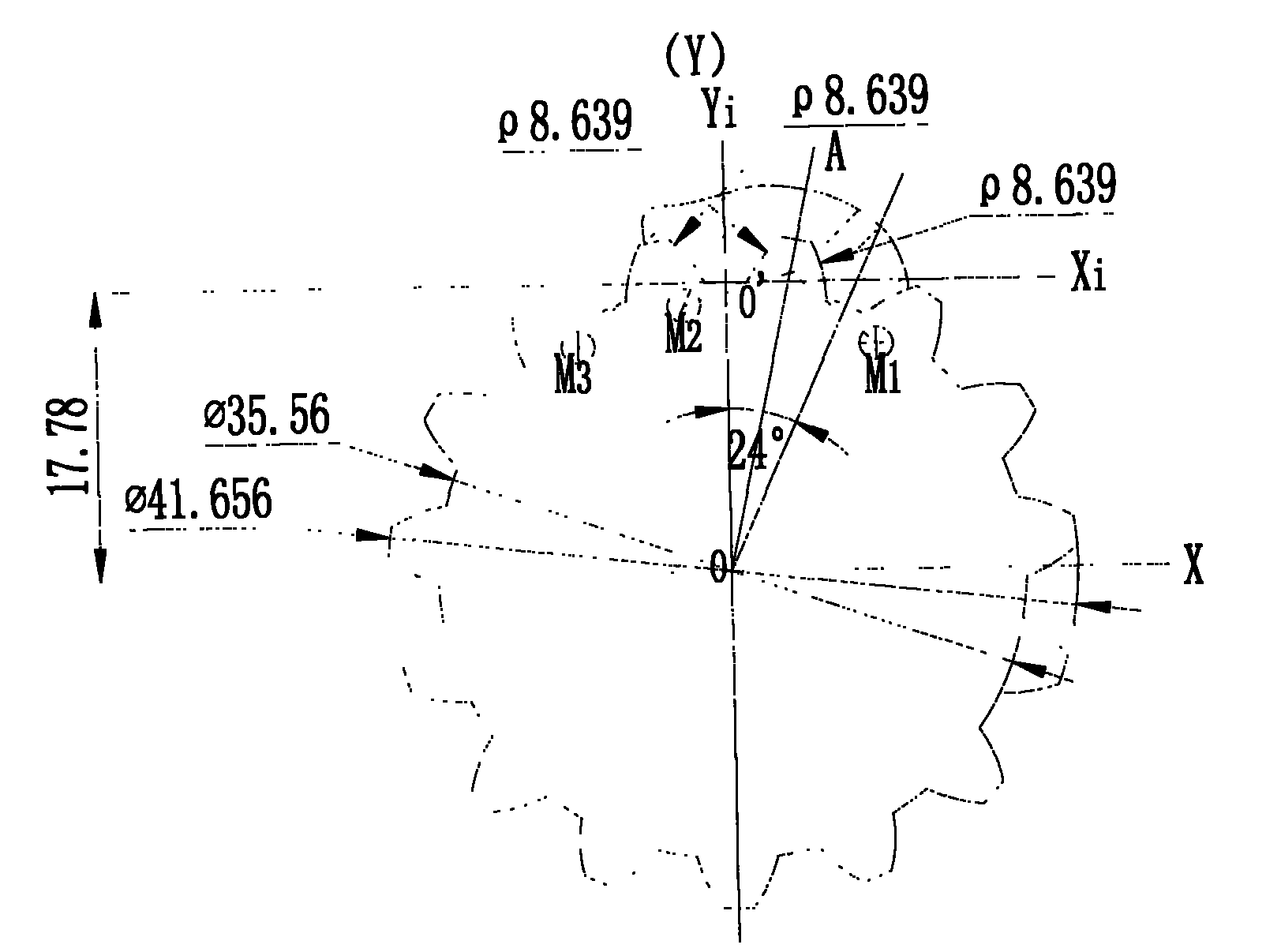

Embodiment 1

[0041] An imported electromagnetic clutch spline shaft and spline hole parameters

[0042]

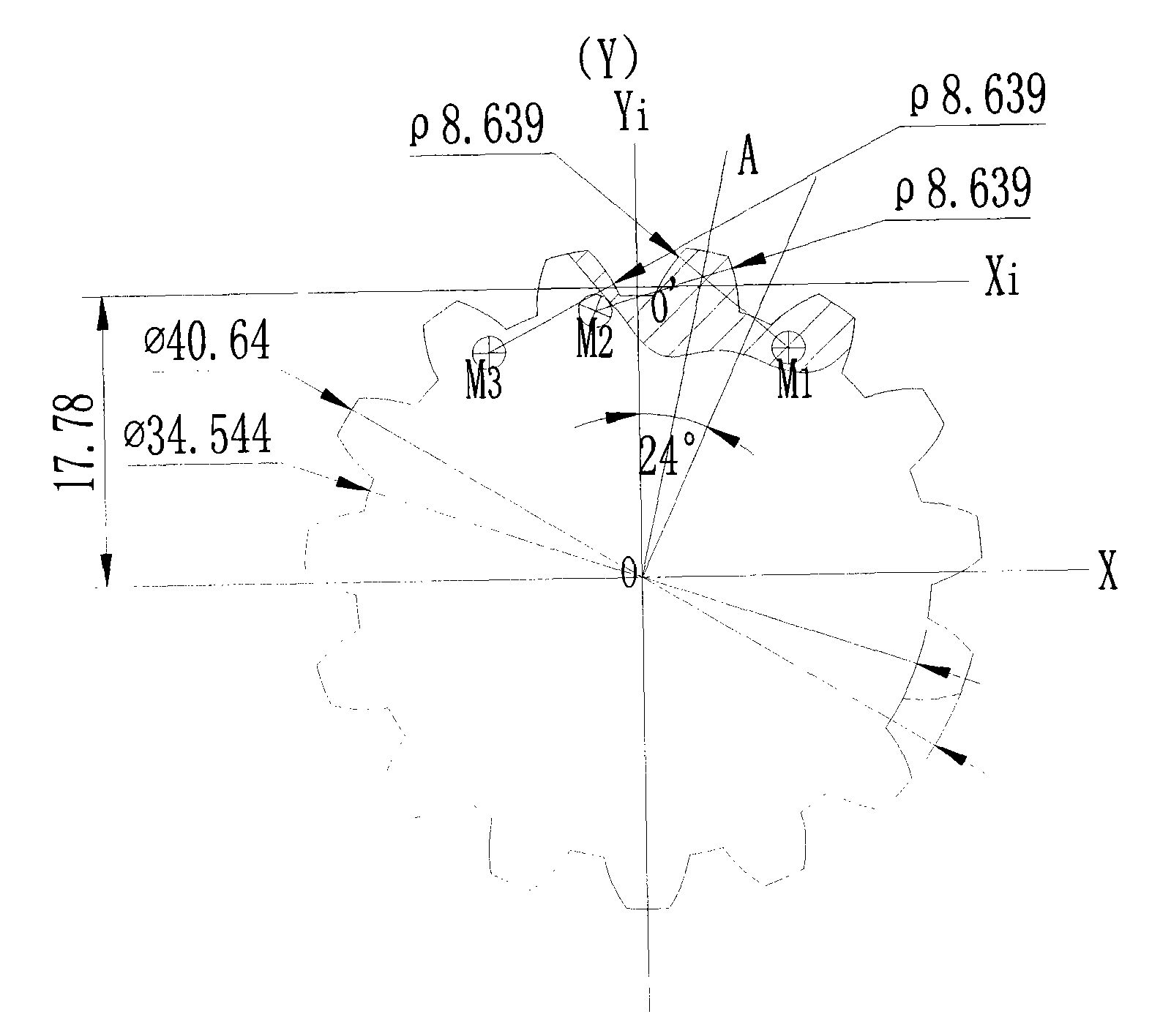

Embodiment 2

[0044] Parameters of a small modulus spline hole of an electromagnetic clutch for an automobile air conditioner

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a process technique for processing spline tooth profiles through replacing involutes with circular arcs, which belongs to the process field of machining. The process technique is implemented by making a calculation program for replacing involutes with circular arcs which are made by an Excel of a computer, so that the results produced by replacing involutes with circular arcs can be displayed immediately just by modifying the basic parameters of spline tooth profiles. According to the invention, spline tooth profiles are processed through replacing involutes with circular arcs, so that the processing of tooth profiles is realized by using a linear cutting machine under the condition that no device such as broaching machines, slotting machines, gear-hobbing machines, and the like is used, the processing capacity is improved, the processing space is expanded, and the processing error of the process technique is just a few thousandths of an millimeter, therefore, the matching and exchanging with traditional processing tooth profiles can be realized, and the processing precision of the process technique can completely meet the application requirements.

Description

technical field [0001] The invention relates to the field of mechanical processing technology, in particular to a technology for processing spline tooth shapes with circular arcs instead of involutes. Background technique [0002] Involute spline is an important transmission connection type in mechanical transmission. It has the advantages of automatic centering, large bearing capacity, long life, easy processing, high precision, and good interchangeability. Generally, when the involute spline tooth profile is processed in batches, different types of tools are required, and correspondingly, machine tools such as broaching machines, slotting machines, and gear hobbing machines are used for processing. For small batches of parts, it is not worth the candle to make tools and find the corresponding machine tool for processing. In this case, it is very convenient and affordable to use a wire cutting machine tool for processing. However, it is more troublesome to program the in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23F15/00B23H7/02

Inventor 王天甜

Owner 王天甜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com