Efficient spraying type dispensing method

A jetting, dispensing technology, applied in the direction of primary battery to battery grouping, sustainable manufacturing/processing, climate sustainability, etc. To achieve the effect of eliminating glue point pulling, simplifying the dispensing process and improving the quality of dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-efficiency jet dispensing method, comprising the following steps:

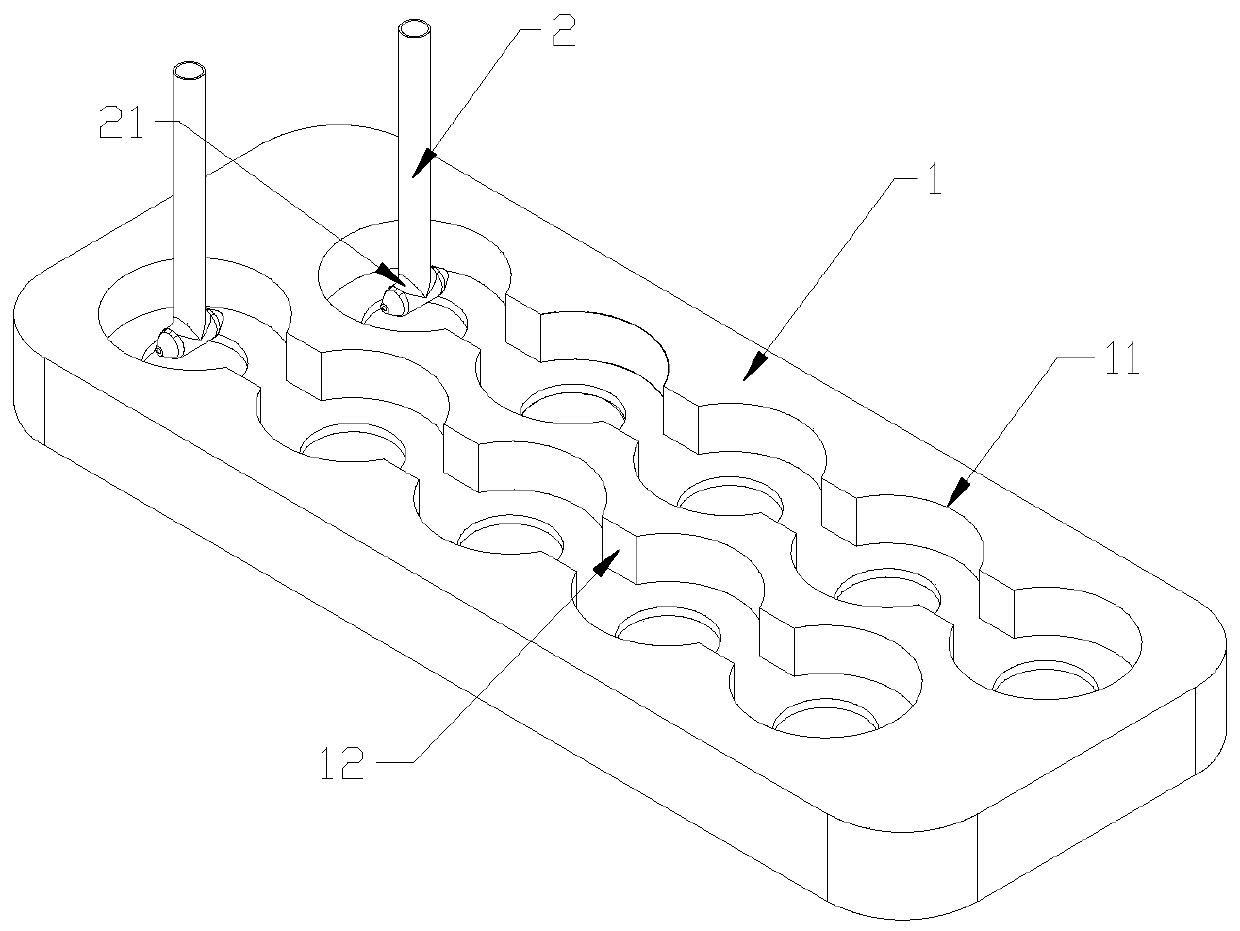

[0031] S1: prepare the battery module cover plate 1, there are two rows of battery installation holes 11 on the battery module cover plate 1, open the battery installation holes 11 to form slots 12;

[0032] S2: Fix the battery module cover plate 1 under the glue sprayer, align the spray pipe 2 of the glue sprayer with the first battery installation hole 11, and set one spray pipe 2 of the glue sprayer to align with the first hole 11 of one of the rows. a battery mounting hole 11;

[0033] S3: There are two glue spray nozzles 21, which are mirror images of each other. The glue spray nozzles 21 are facing the inner sides of the battery installation hole 11 and are parallel to the end surface of the slot 12;

[0034] S4: The spray nozzle 21 of the glue spraying pipe is fully extended into the battery installation hole 11, and the glue spraying machine spraying pipe 2 is coaxial with the battery in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com