Three-dimensional multi-shaft interlocked numerical controlled engraving and milling device

A multi-axis linkage, engraving and milling machine technology, applied in the direction of milling machines, milling machine equipment, metal processing machinery parts, etc., can solve the problem of not being able to finish the products with large shapes and complex shapes, and achieve the effect of high processing level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

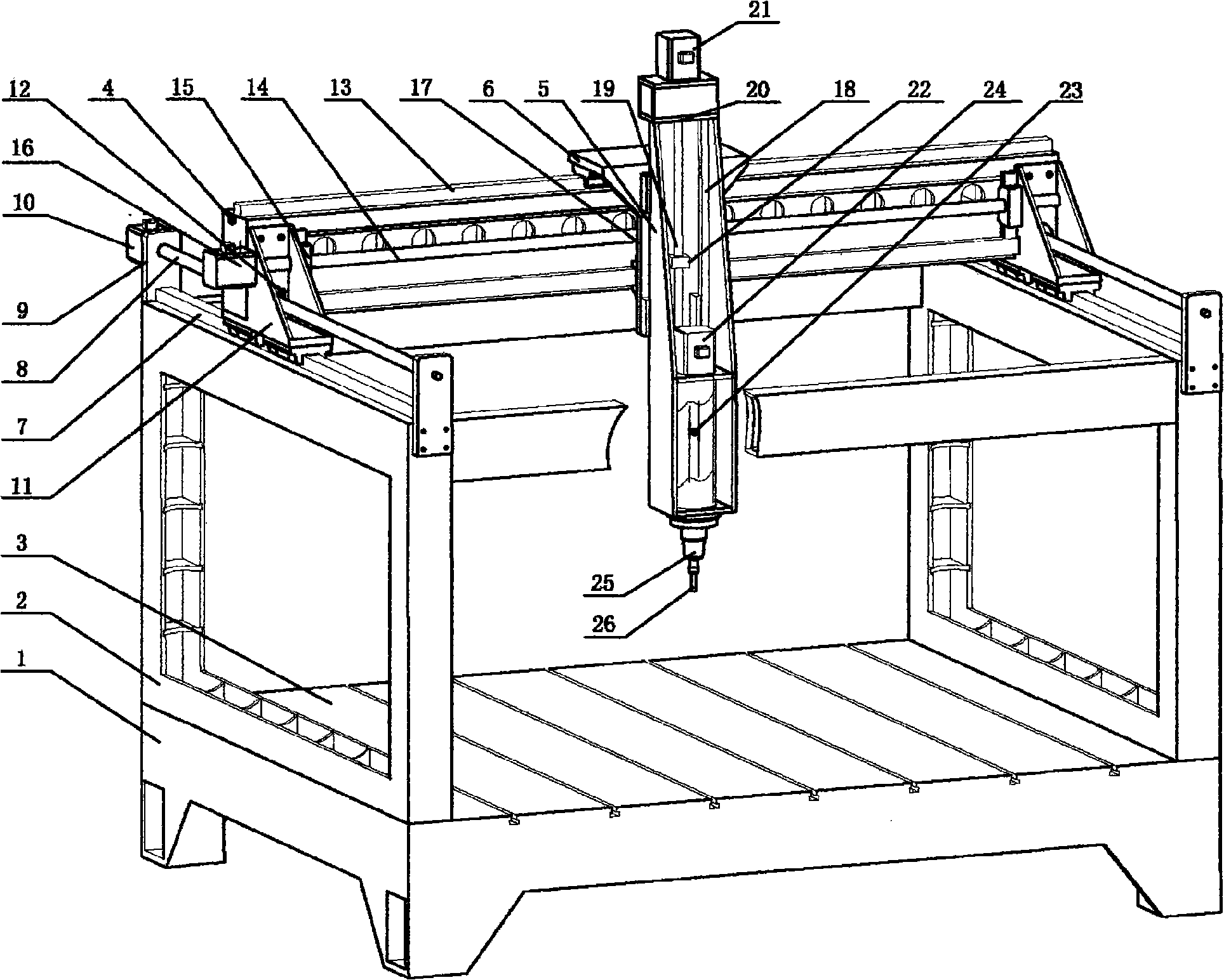

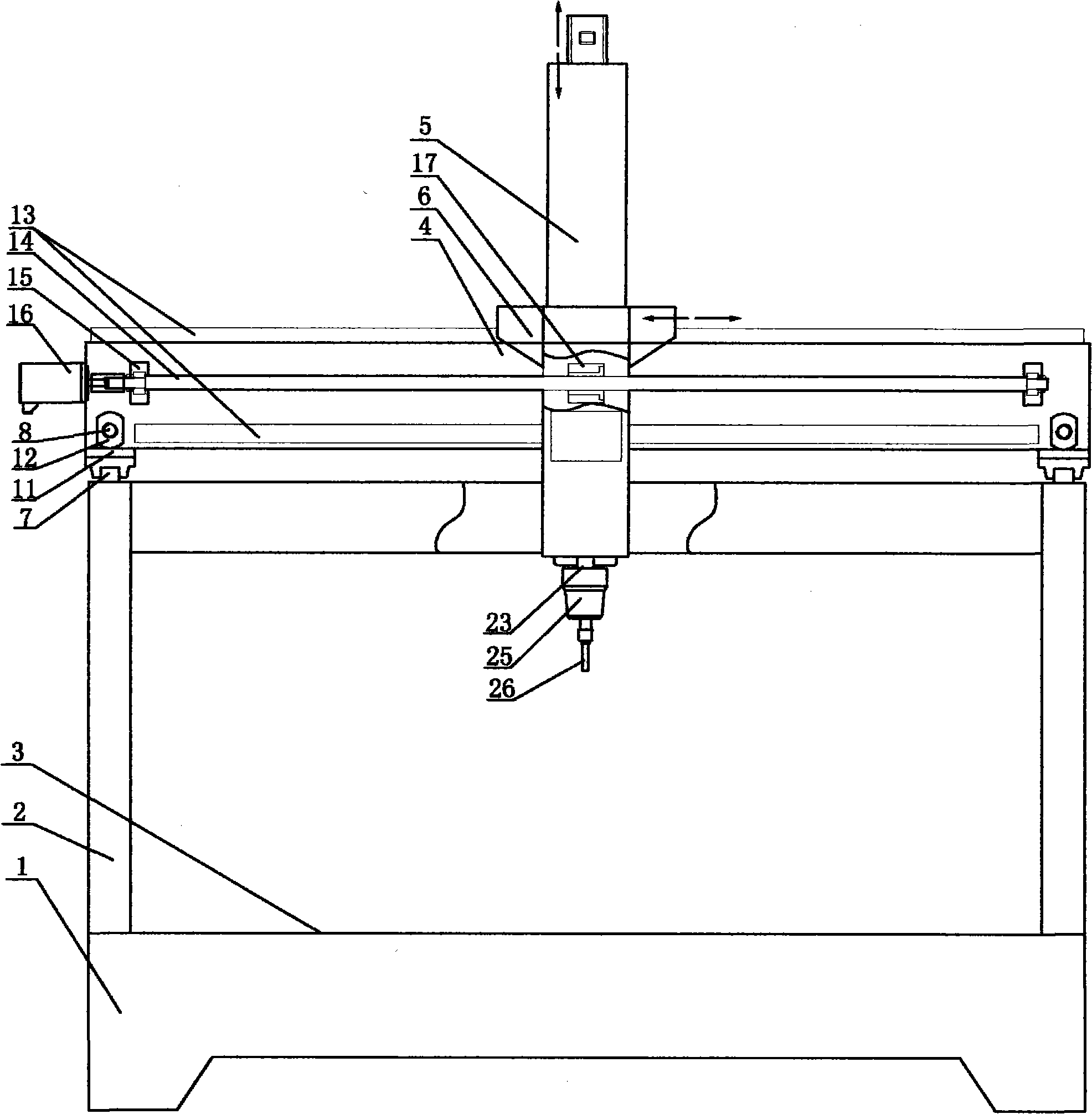

[0016] Such as figure 1 --The three-dimensional multi-axis linkage CNC engraving and milling machine of the present invention shown in 4 is a three-dimensional three-axis linkage CNC engraving and milling machine, which includes: machine base 1, body 2, worktable 3, working beam 4, Z The axial body 5, the Z axial body support 6 and the numerical control unit for controlling the work of the machine tool. Its specific structure is as follows:

[0017] (1) The fuselage 2 is a frame structure, which is composed of four columns, two left and right longitudinal beams, and two front and rear transverse beams. A Y-axis linear guide rail 7 is installed on the two longitudinal beams of the fuselage 2. The Y-axis guide rail 7 on one side or both sides of the body is provided with a drive device y, and the drive device y includes: a ball screw y8, and two screw supports 9 arranged at both ends of the Y-axis guide rail 7 for supporting the ball screw 8 , and the servo motor y10 matched w...

Embodiment 2

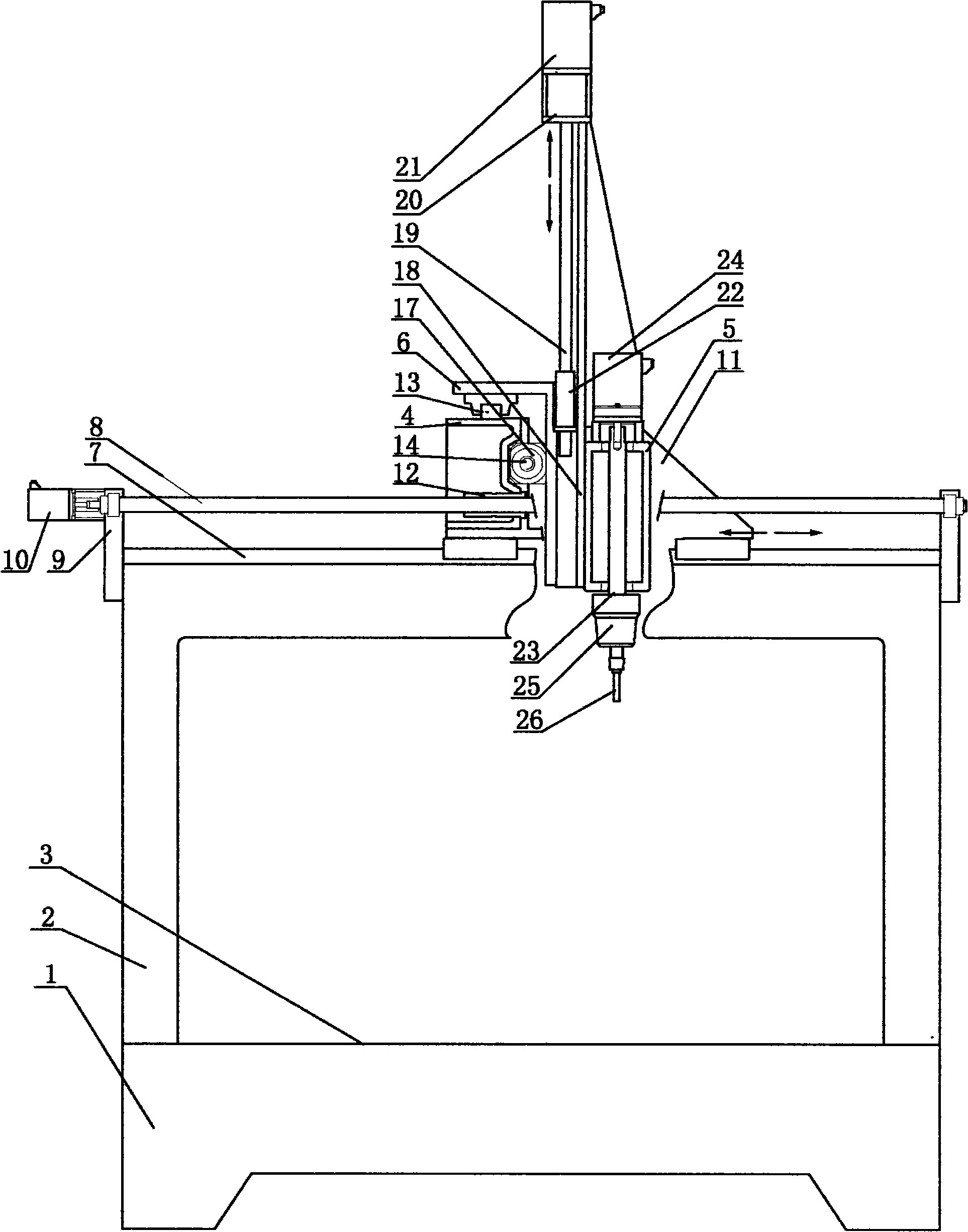

[0023] Such as Figure 5 --The three-dimensional multi-axis linkage CNC engraving and milling machine of the present invention shown in 6 is a three-dimensional five-axis linkage CNC engraving and milling machine, which is based on the three-dimensional three-axis linkage CNC engraving and washing machine. 5, and the Z axis body 5 is provided with an A-axis that can rotate horizontally and circularly, and a C-axis that can rotate vertically and circularly is provided on the A-axis, and the cutter device is arranged on the C-axis. It includes: a machine base 1, a fuselage 2, a worktable 3, a working beam 4, a Z-axis body 5, a Z-axis body support 6 and a numerical control unit for controlling the work of the machine tool. Its specific structure is as follows:

[0024] (1) The fuselage 2 is a frame structure, which is composed of four columns, two left and right longitudinal beams, and two front and rear transverse beams. A Y-axis linear guide rail 7 is installed on the two long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com