Method for measuring parameters of conical bearing ring based on three coordinates

A technology of tapered bearings and measuring methods, applied in measuring devices, instruments, etc., can solve the problems of unguaranteed repeatability, harsh measurement requirements, and difficulty in mastering, so as to avoid batch rework or scrapping and improve the grinding process level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing.

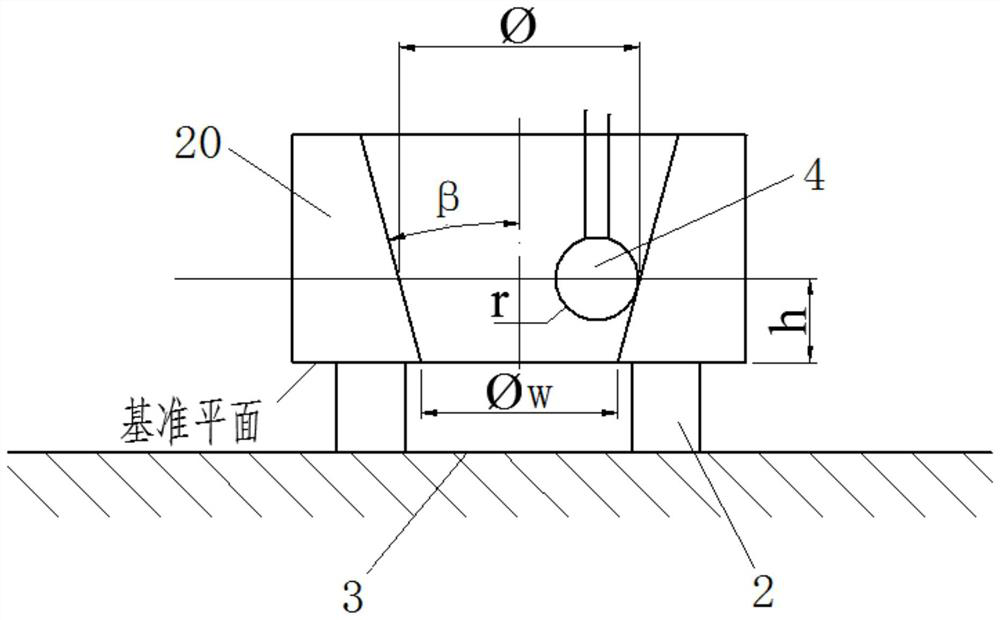

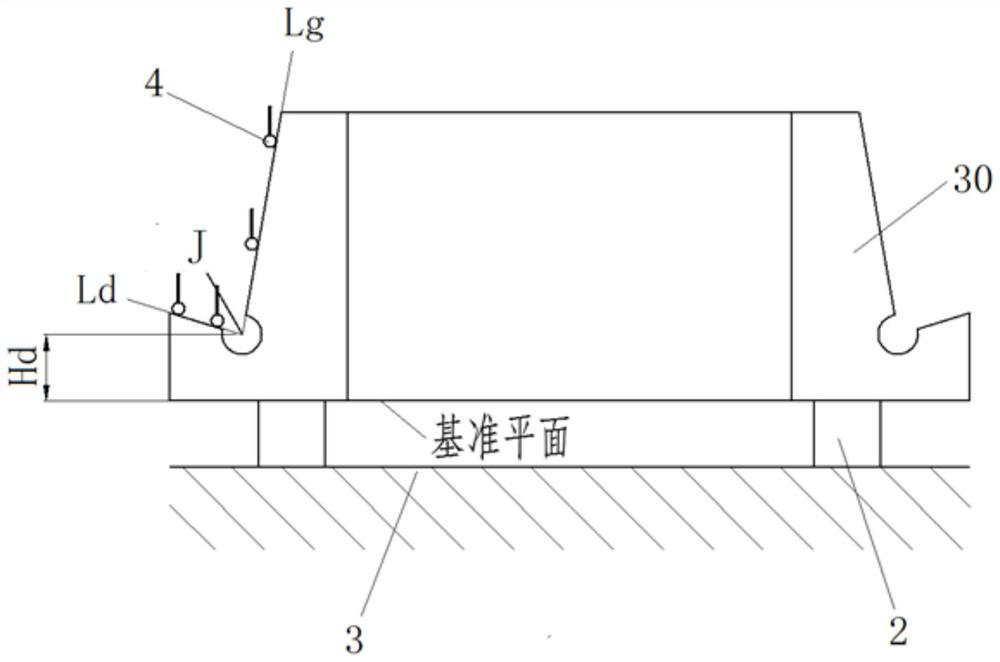

[0053] The method for measuring the parameters of the tapered bearing ring based on three coordinates of the present invention includes measuring the raceway diameter of the inner ring, measuring the raceway diameter of the outer ring, measuring the height of the large rib of the inner ring and measuring the height of the outer ring of the double row tapered bearing The middle diameter of the raceway.

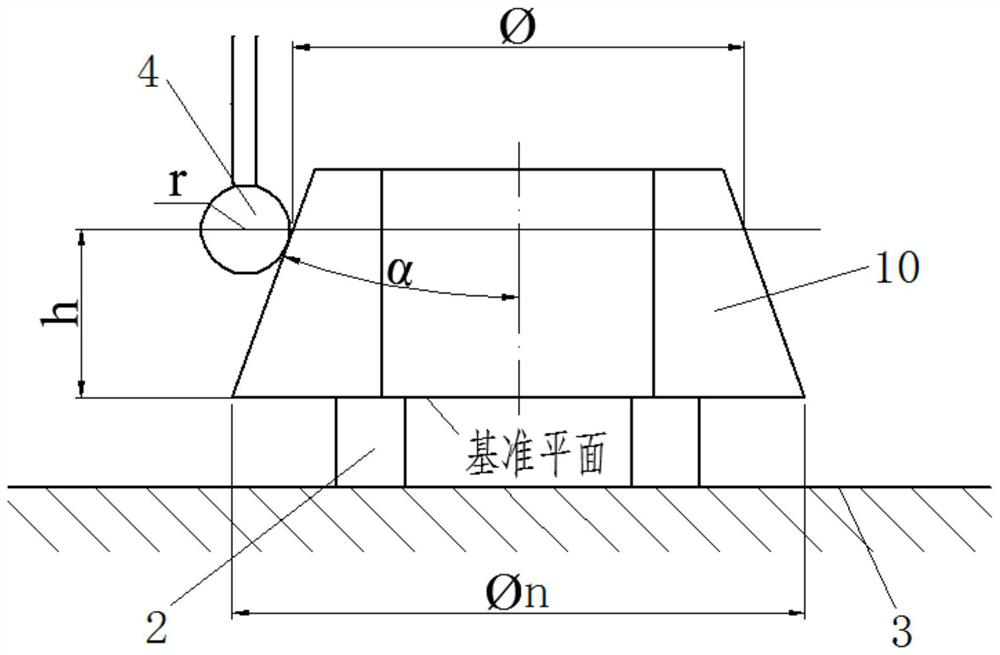

[0054] see figure 1 , the following steps are included when measuring the raceway diameter of the inner ring:

[0055] Step 1: Use standard steel balls to calibrate the accuracy of the measuring head 4 in each orientation according to the size of the inner ring 10 to be tested and the measuring position; according to the size of the inner ring 10 to be tested, select the diameter of the measuring head 4 to be 2 mm or 3 mm;

[0056] Step 2, place two custom-made equal-height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com