Fixture for machining engine cylinder end surface and crankshaft hole

A technology for engine cylinder block and crankshaft hole, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. Compact clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural features of the present invention will now be described in detail in conjunction with the accompanying drawings.

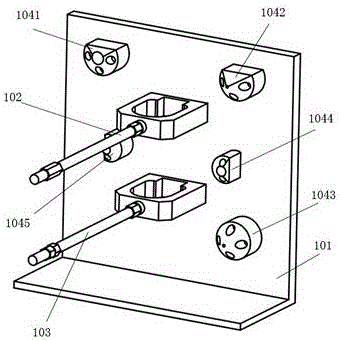

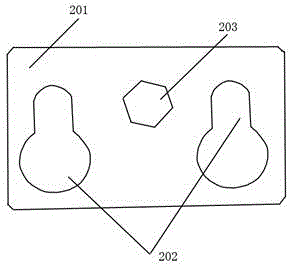

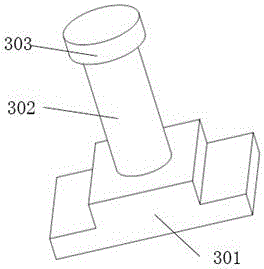

[0026] see figure 1 , 2 And 3, a fixture for engine block end face and crankshaft hole machining, including a tie rod assembly, a pressing plate assembly, and a support frame assembly.

[0027] see Figure 4 , 5 and 6, the rod assembly includes a base 101, an upper support rod 102, a lower support rod 103, and a positioning mechanism. Wherein, the base 101 is composed of vertical plates and horizontal plates, and is L-shaped. The vertical plate and the horizontal plate of the base 101 are at 90° to each other.

[0028] On the vertical plate of the base 101, an upper support rod 102, a lower support rod 103 and a positioning mechanism are arranged. The positioning mechanism is a block. The length of the upper support rod 102 is between 200mm and 700mm. The length of the lower support rod 103 is between 200mm and 700mm. Nuts are all eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com