Patents

Literature

33results about How to "Small turning diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

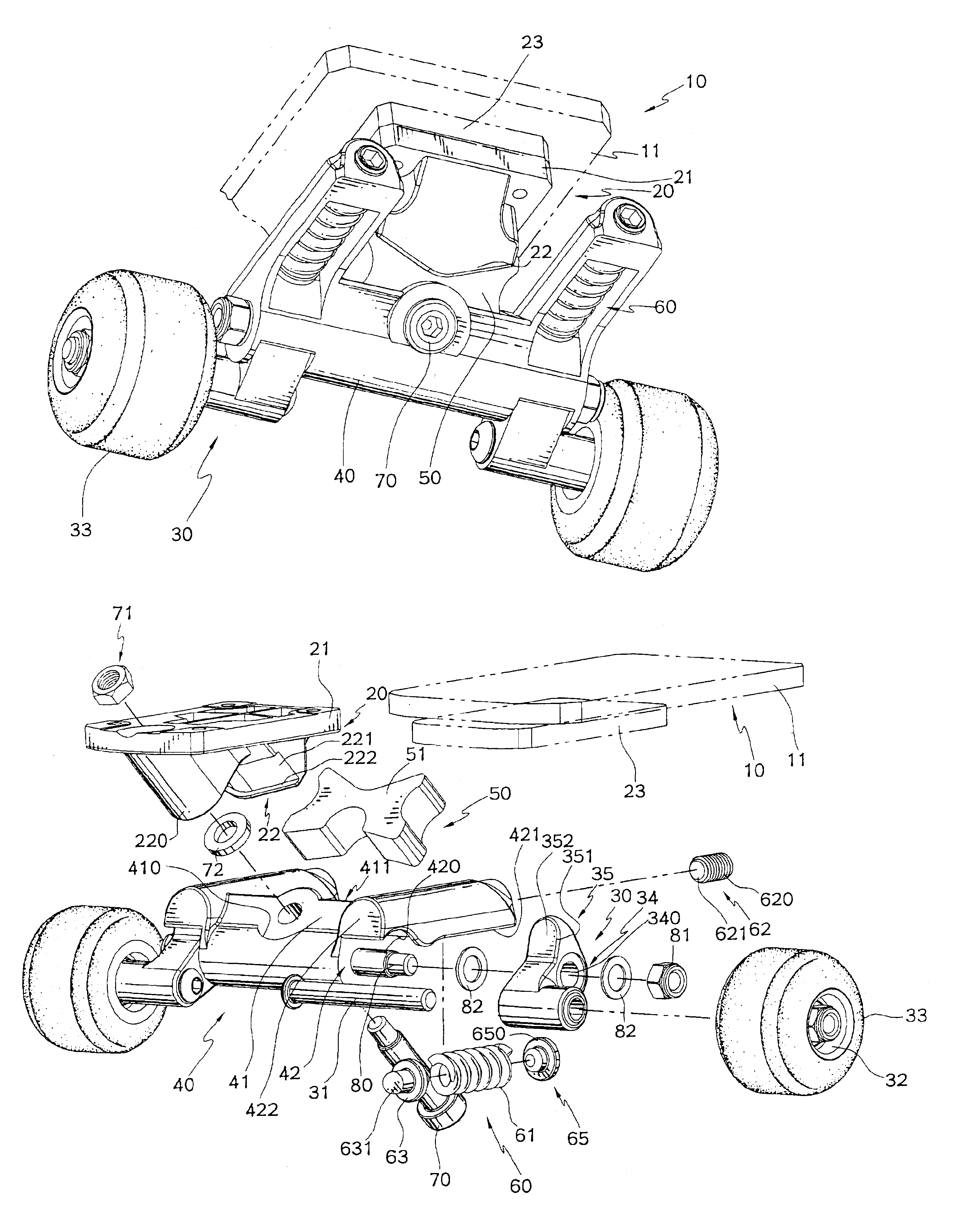

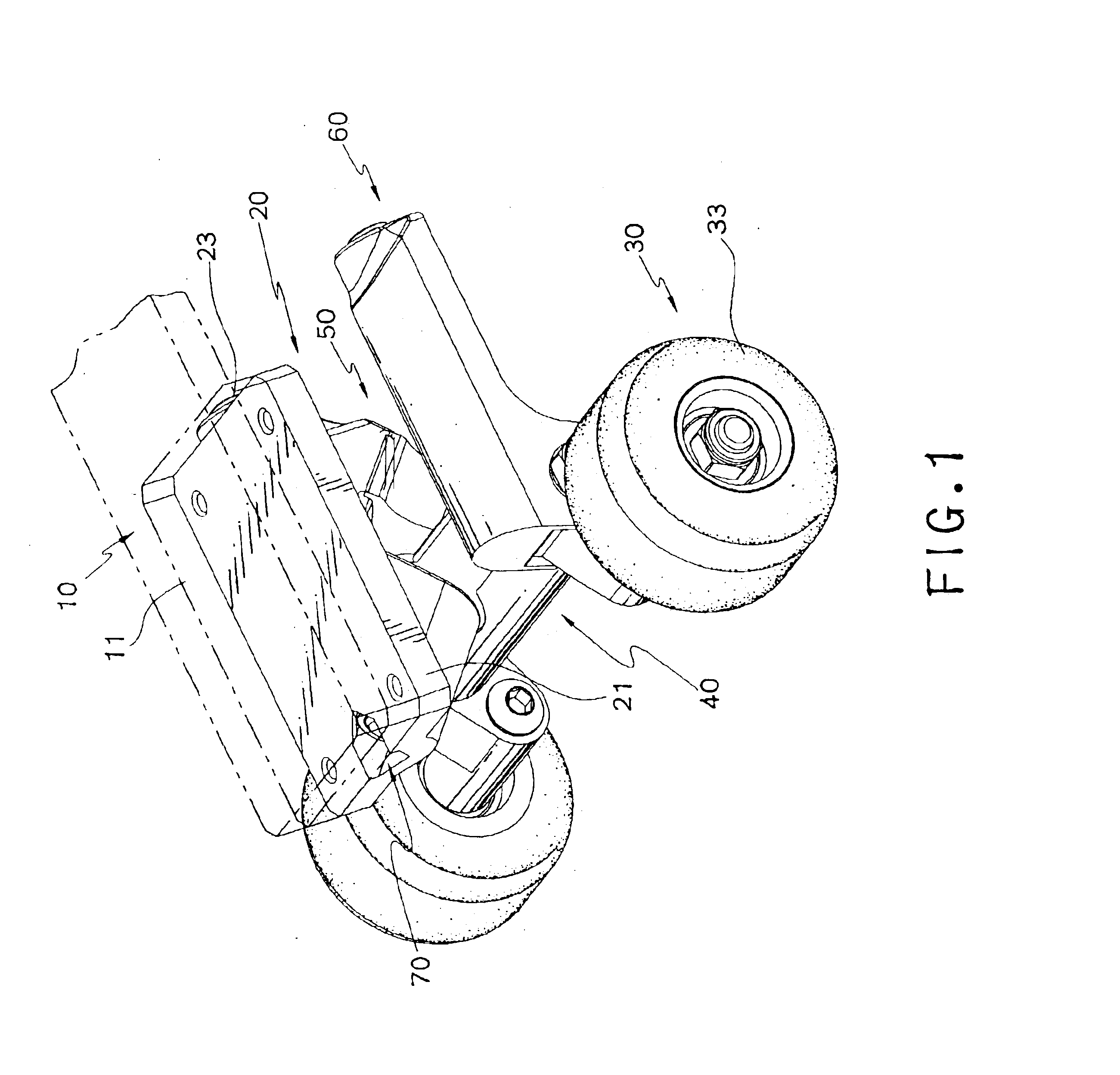

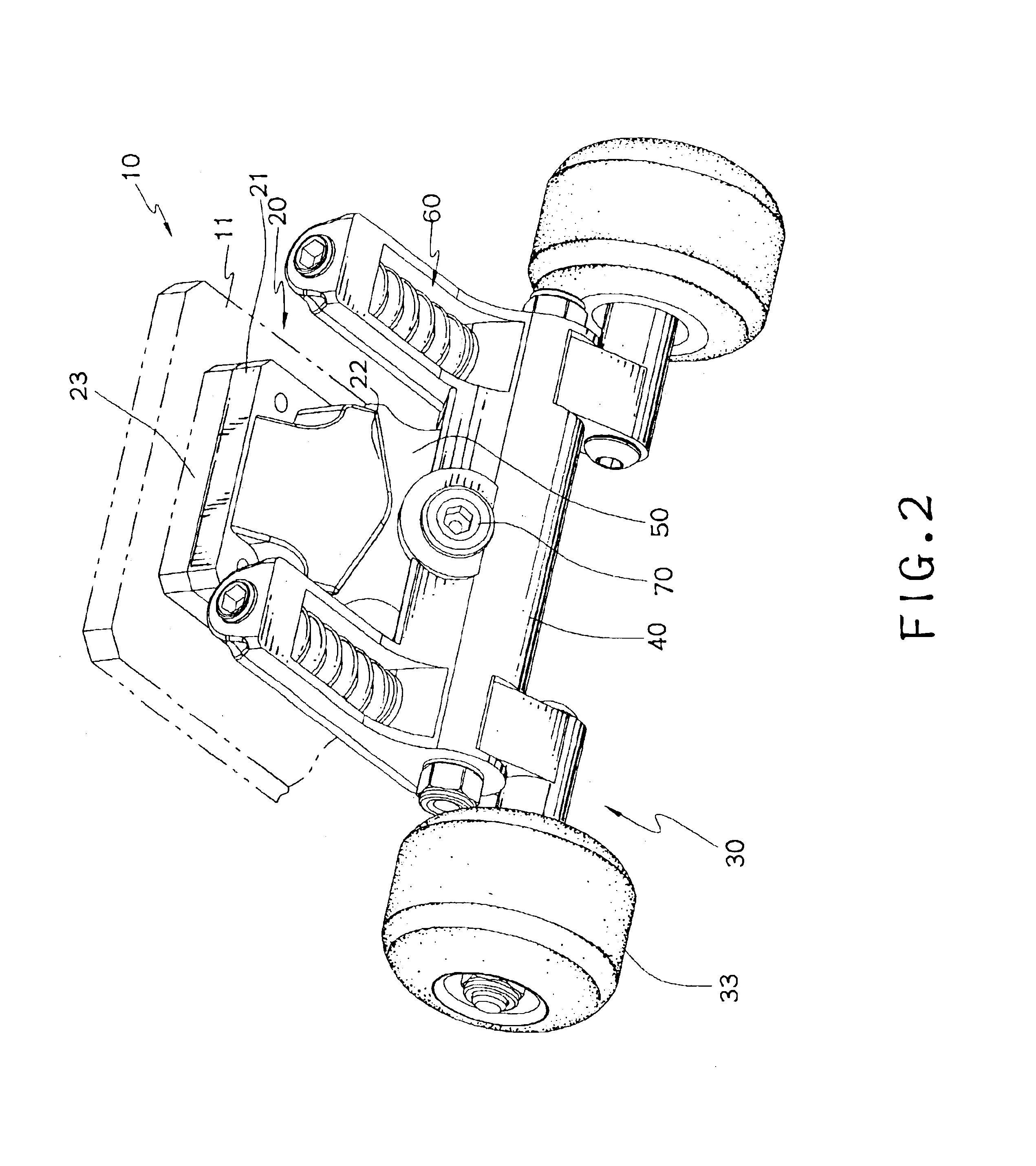

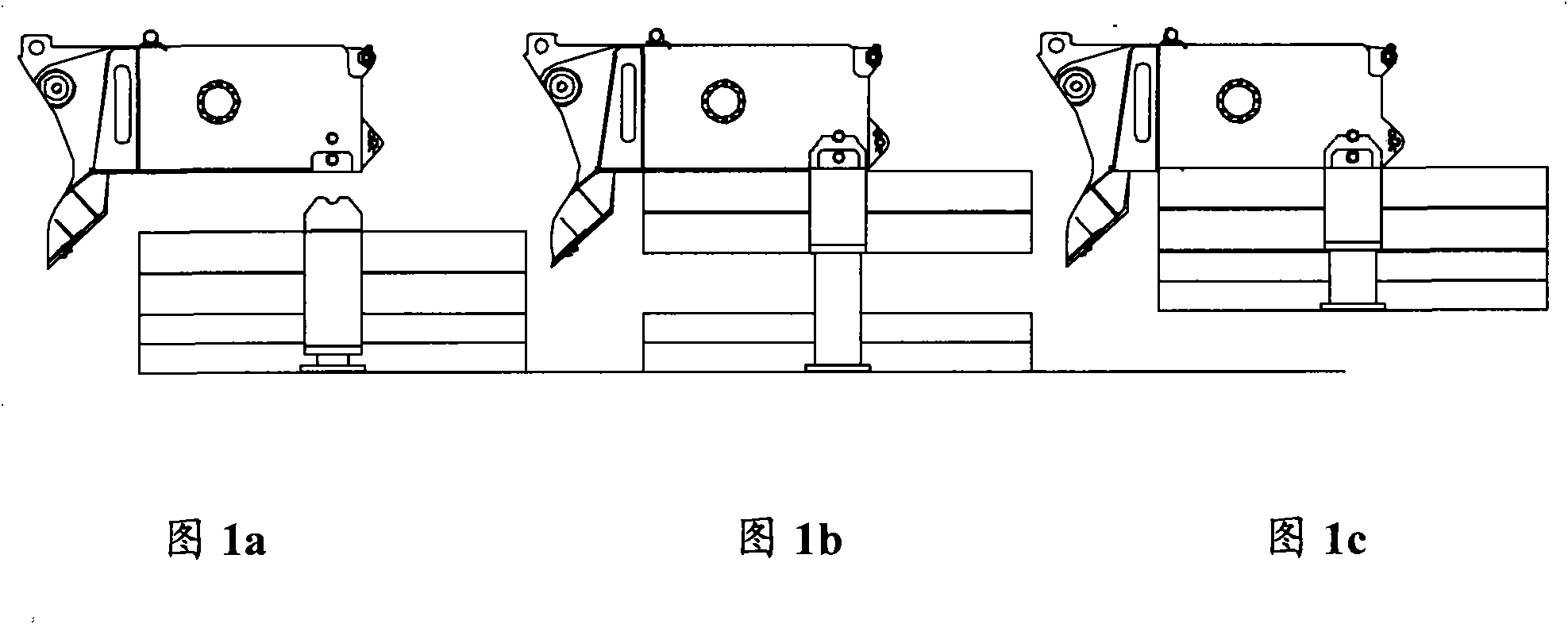

Skateboard having a three-dimensional independent suspension balance system

InactiveUS6913272B2Small turning diameterImprove mobilitySkatesRider propulsionEngineeringMechanical engineering

A skateboard includes a board body having a bottom provided with a base having a bottom provided with two opposite wheel seats. Each of the two wheel seats includes a wheel axle for mounting a roller. The wheel axle of each of the two wheel seats has a center located at a height different from that of a center of the respective wheel seat, thereby forming an eccentric state, so that each roller has independent horizontal and vertical displacement, thereby forming a balance effect, so that the skateboard can be moved in a stable manner.

Owner:CHANG CHUCK

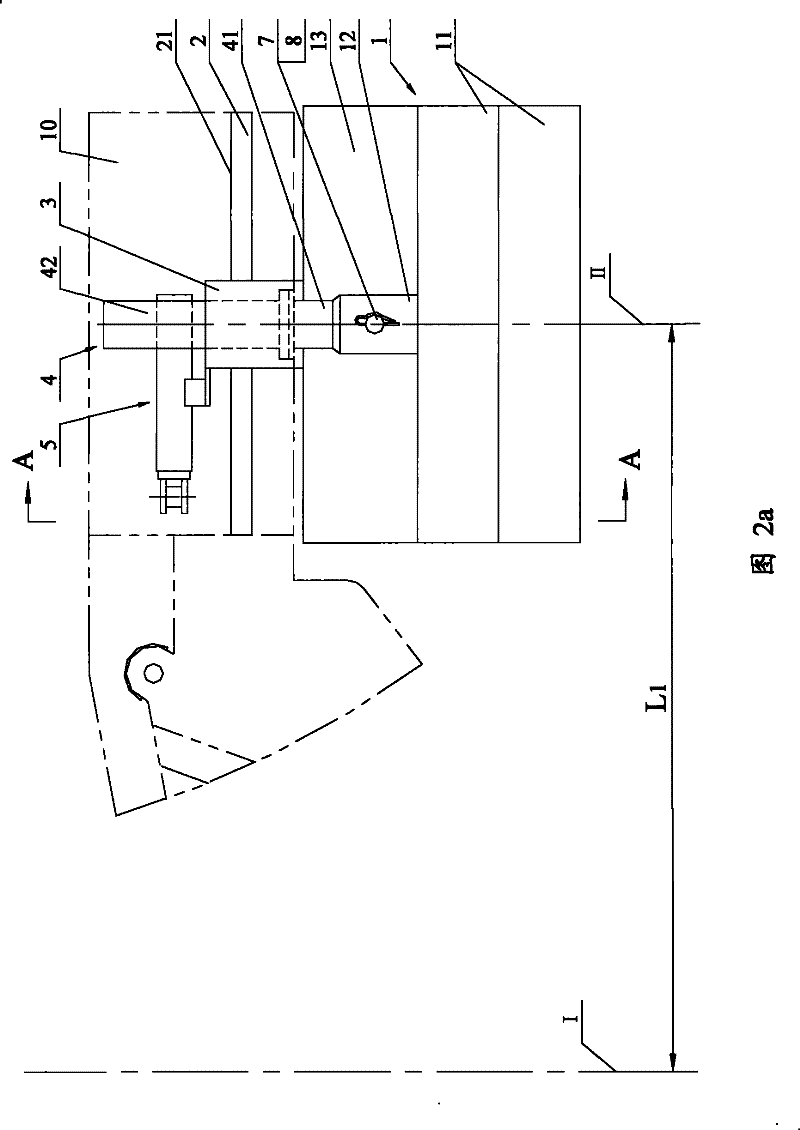

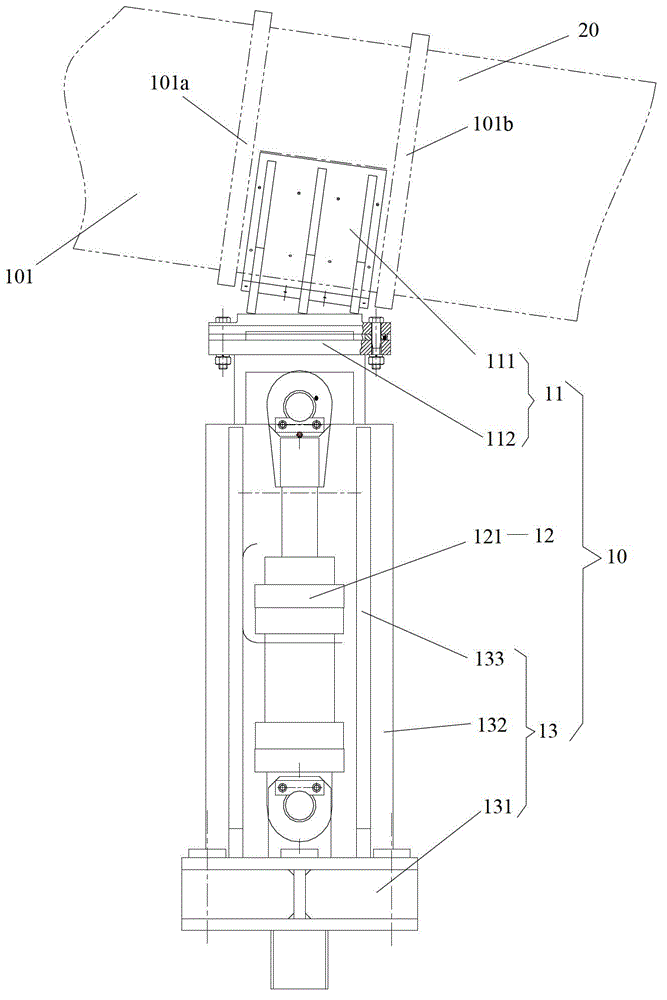

Combined counterweight device and crane using same

The invention discloses a combined counterweight device and a crane using the same and aims to solve a problem that the prior counterweight device cannot move backwards and forwards. The combined counterweight device of the invention comprises a counterweight body, two horizontal slide rails, a counterweight bracket, two vertical oil cylinders and two horizontal oil cylinders, wherein the vertical oil cylinders are fixed on the counterweight bracket through the two vertical oil cylinders, and the counterweight bracket can slide backwards and forwards along the horizontal slide rails fixedly arranged on two sides of the tail part of a turntable under the action of the two horizontal oil cylinders. The key design points of the combined counterweight device and the crane using the same include: the counterweight body can move backwards and forwards to effectively improve the length of the big arm and the vehicle stability under a large amplitude working condition of the crane and to reduce the vehicle length to impact the structure of the crane respectively; and at the same time, the crane has a relatively small radius when driving on a curve, so the rideability of the crane is greatly improved.

Owner:XUZHOU HEAVY MASCH CO LTD

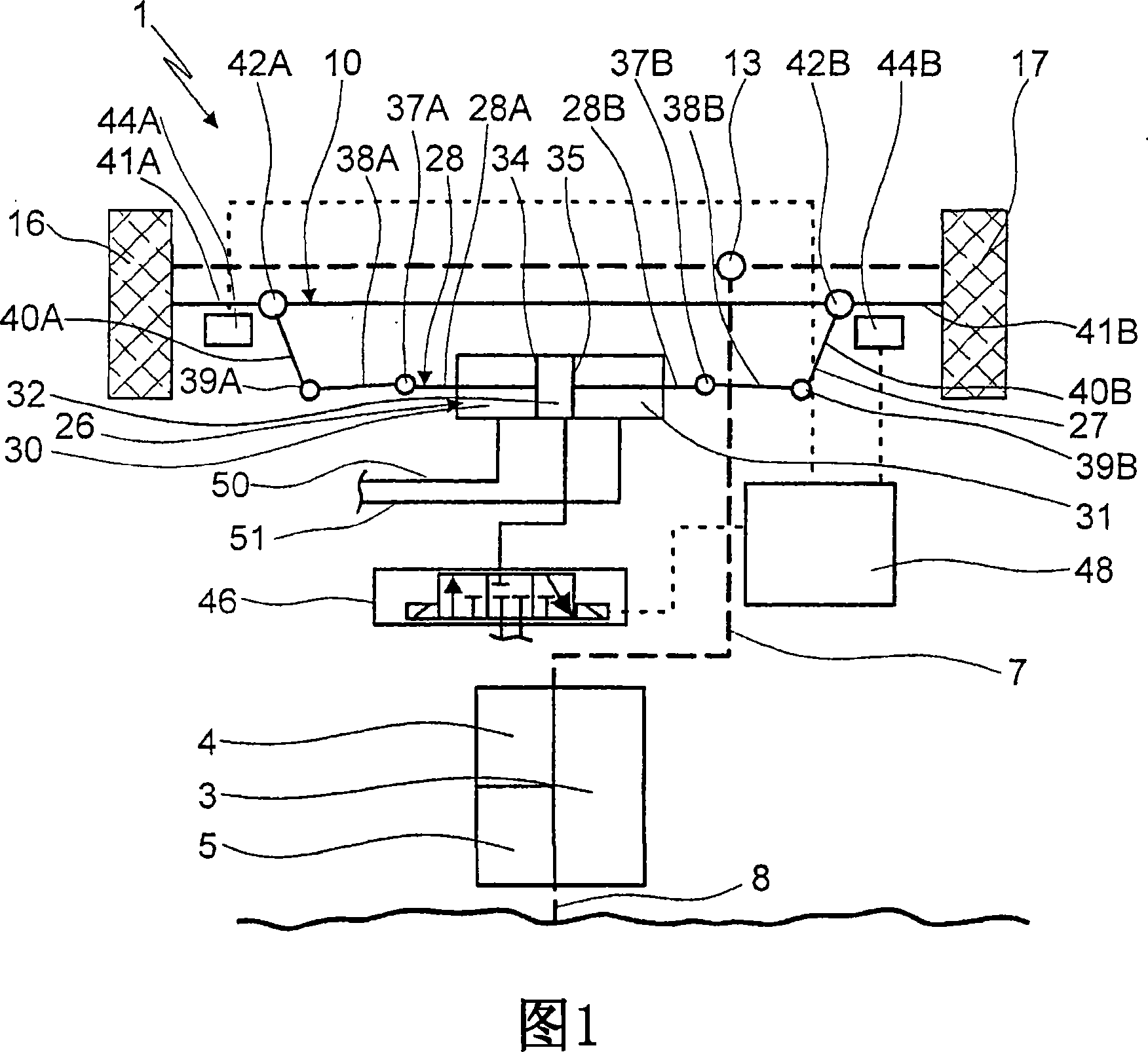

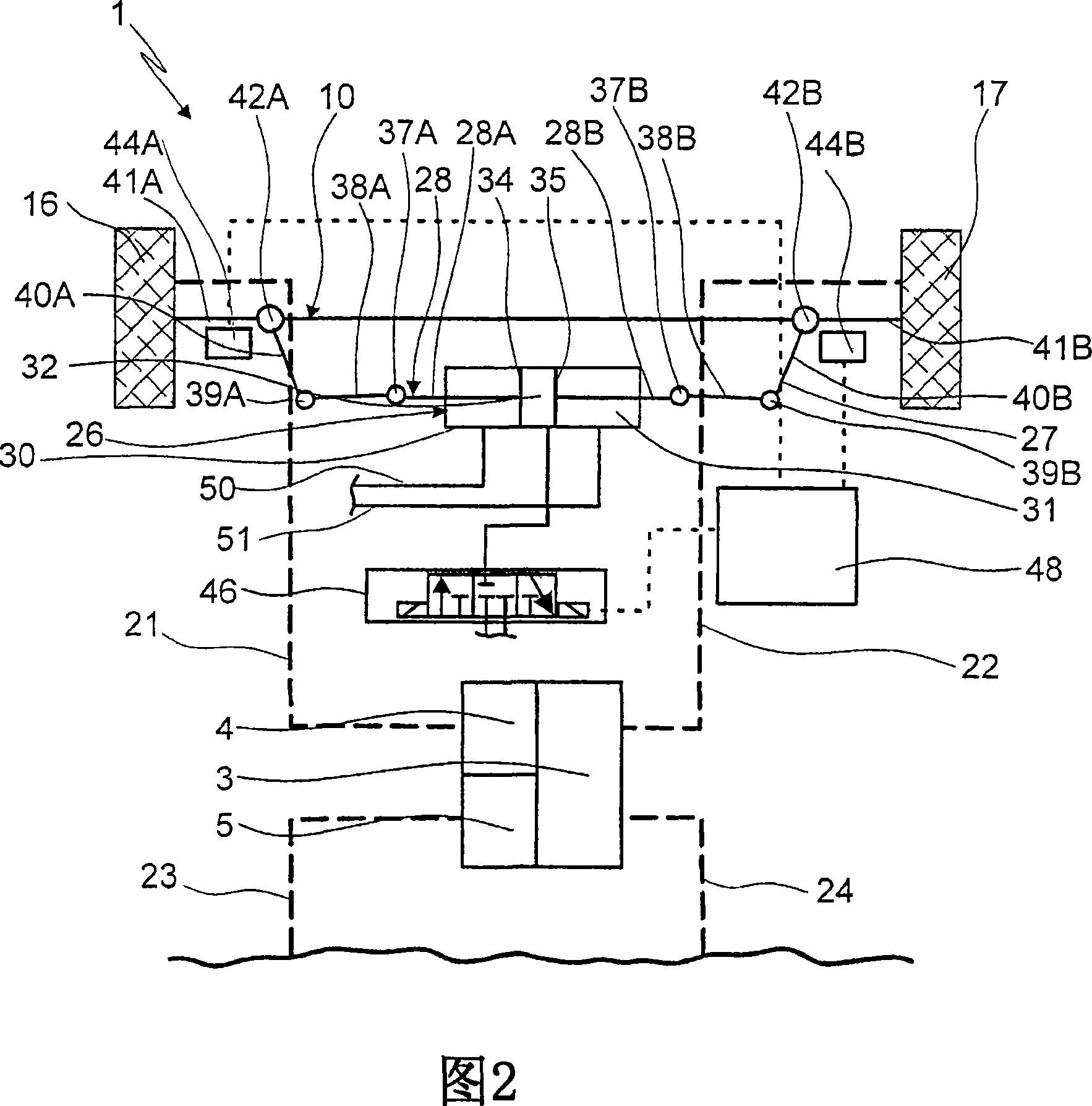

Vehicle, in particular an all-wheel drive vehicle, with a first steered vehicle axle and a second steered vehicle axle

InactiveCN101096215ASmall turning diameterReduce errorsSteering linkagesFluid steeringSteering angleElectric control

An all-wheel drive vehicle with two steered vehicle axles. Each having a main steering cylinder with piston rods actively connected with the wheels. The main steering cylinders each have first and second chambers ( 30, 31 ) delimited by at least one piston element ( 34, 35 ) which moves longitudinally in the cylinder and is connected to the piston rod ( 28 ), such that adjusting pressure in the cylinder with an electric control unit, biases the piston elements and the piston rods to achieve specified wheel steering angles. Furthermore, a third chamber ( 32 ), which can be pressurized, is provided between a first and a second piston element ( 34, 35 ) of a main steering cylinder ( 26 ), which respectively delimit the first and second chamber ( 30, 31 ). The piston rods are sectioned, such that a first section is connected to the first piston element and a second section is connected to the second piston element.

Owner:ZF FRIEDRICHSHAFEN AG

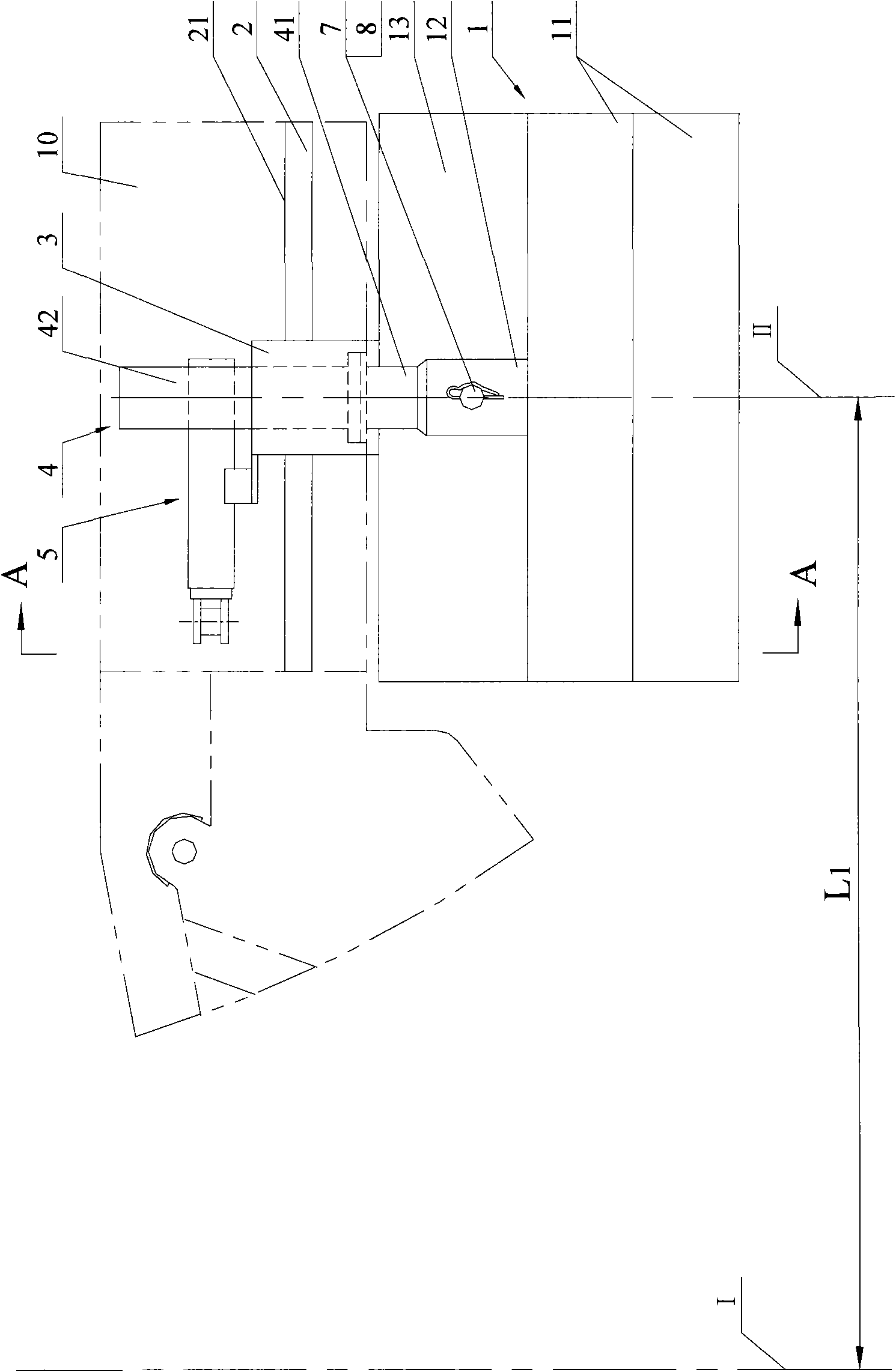

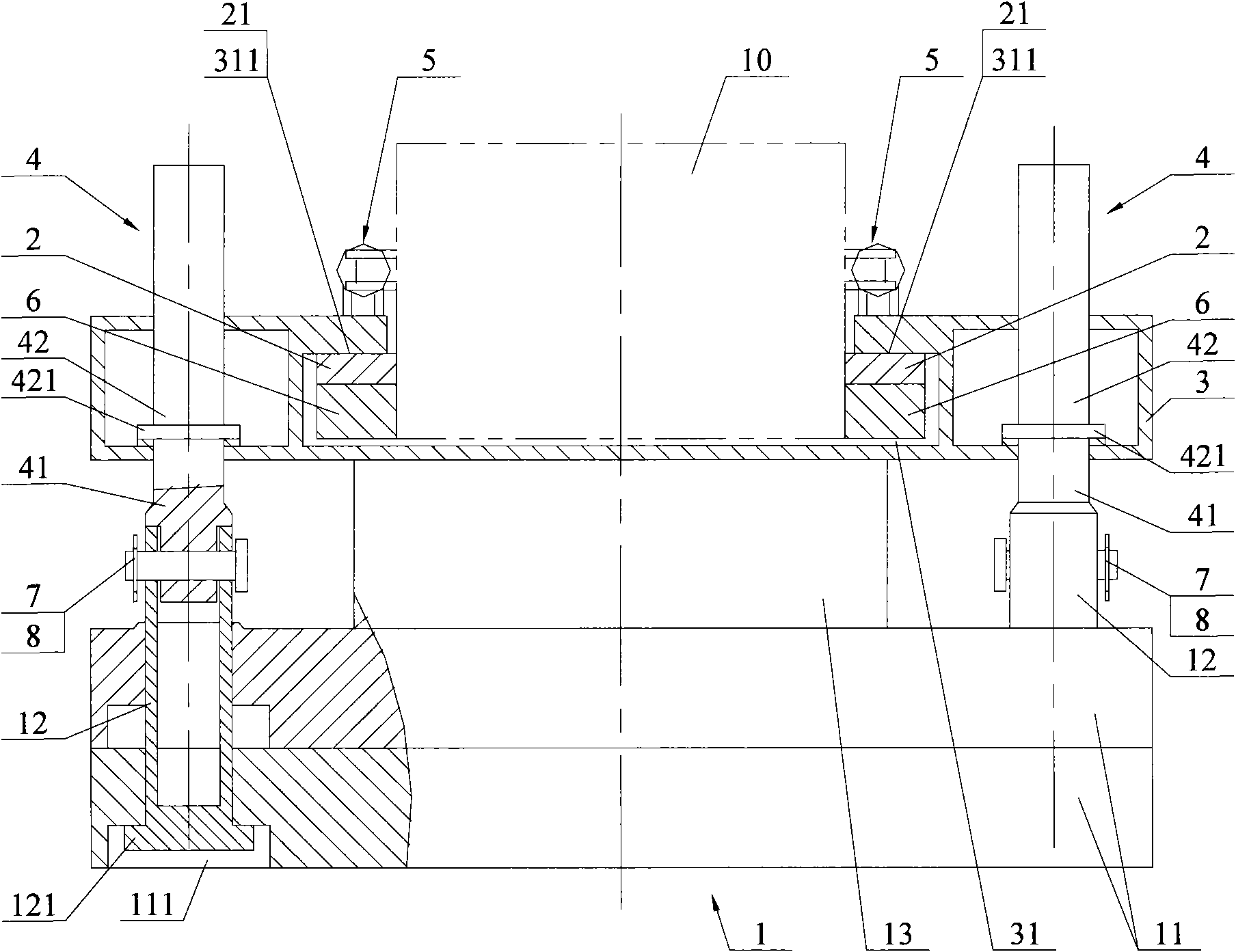

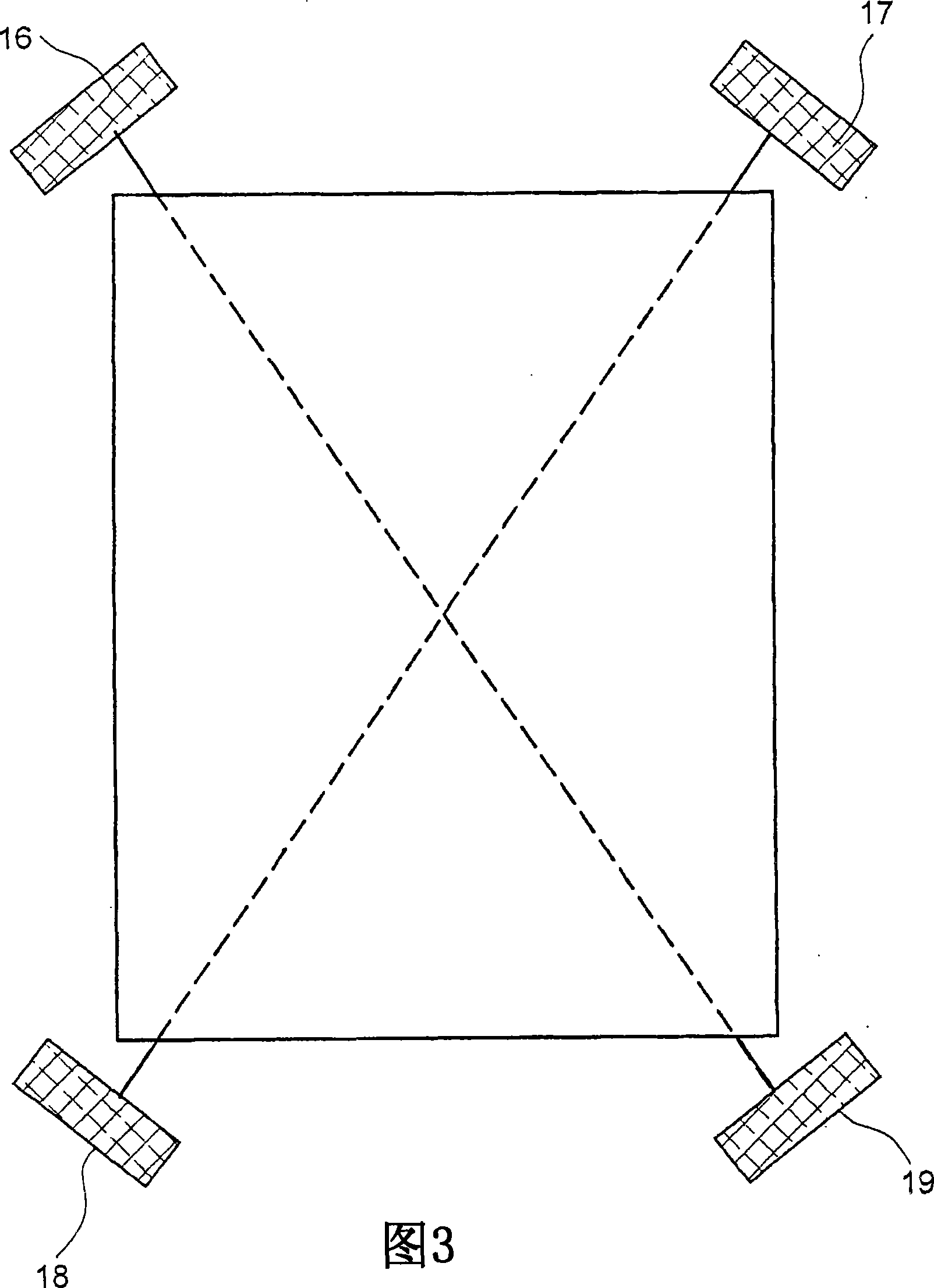

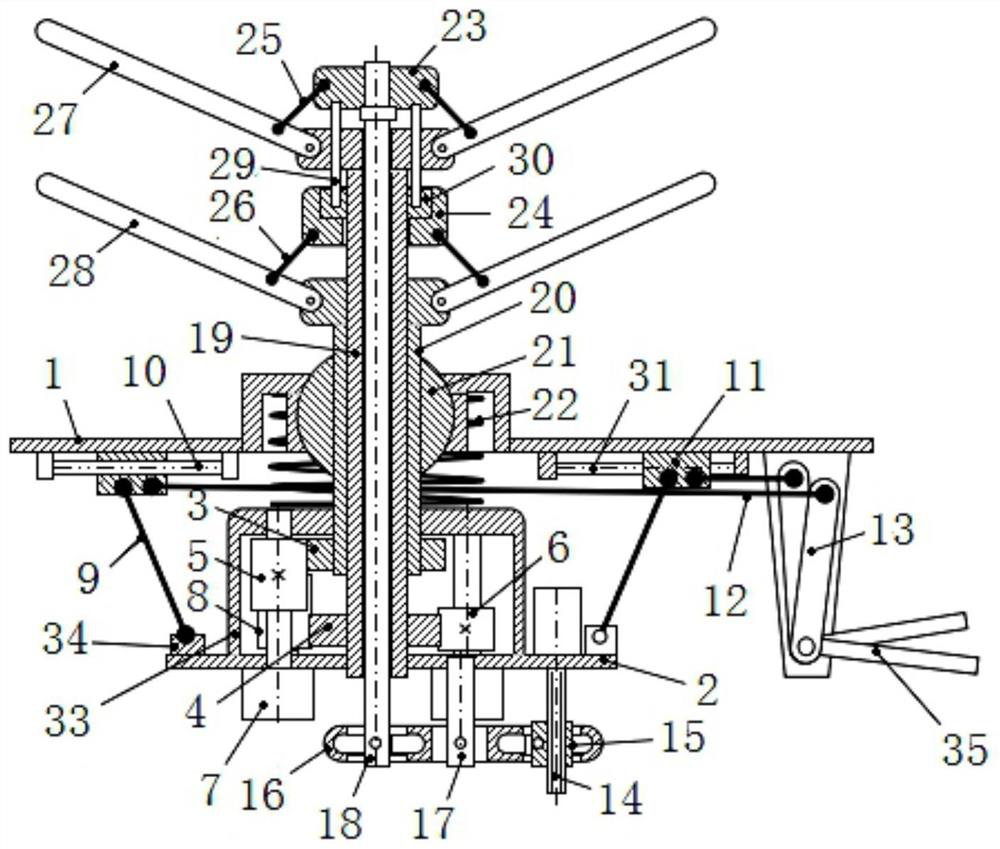

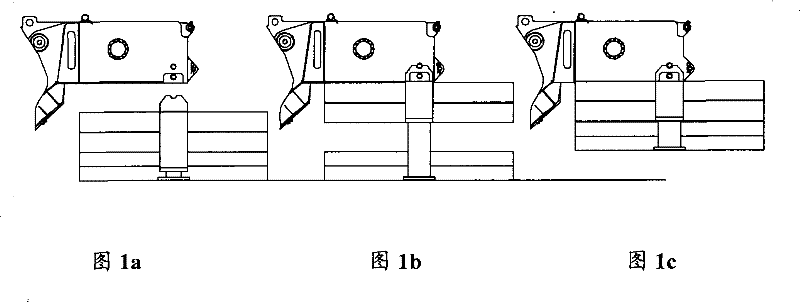

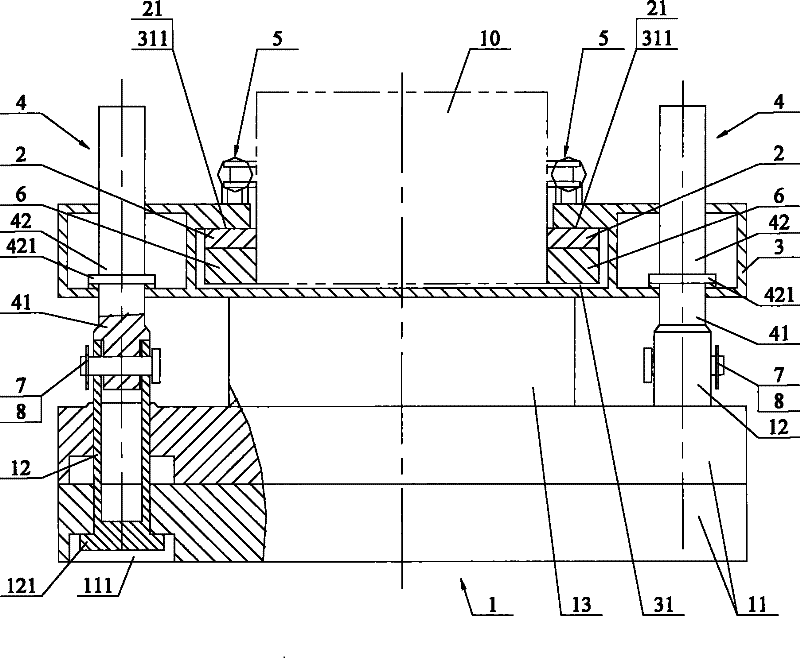

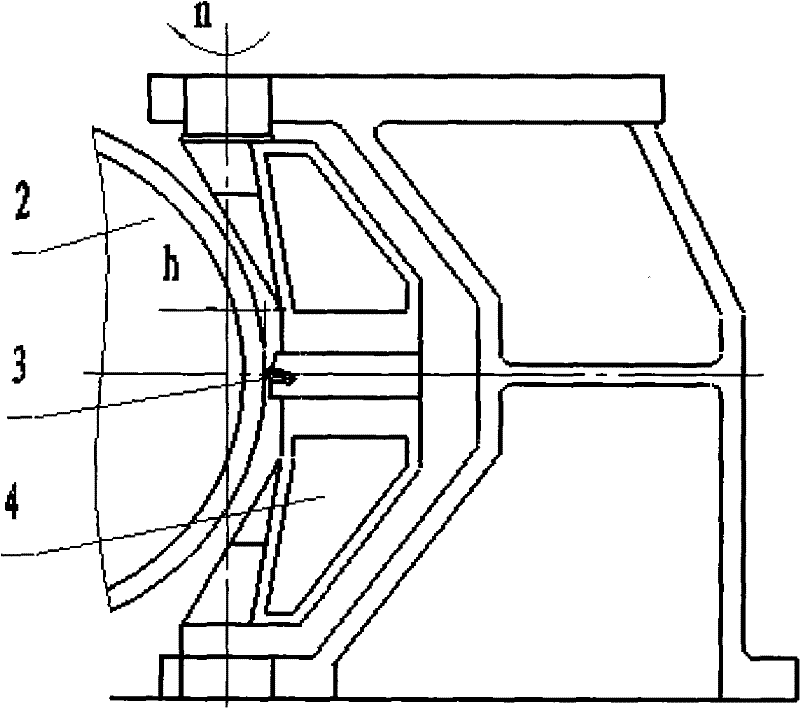

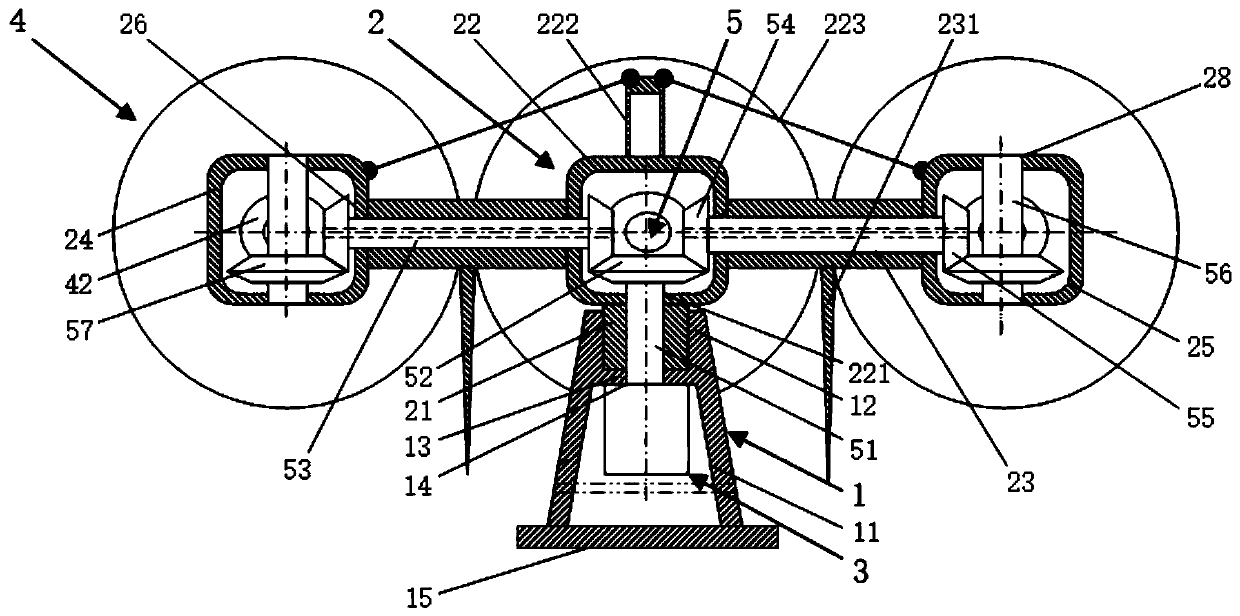

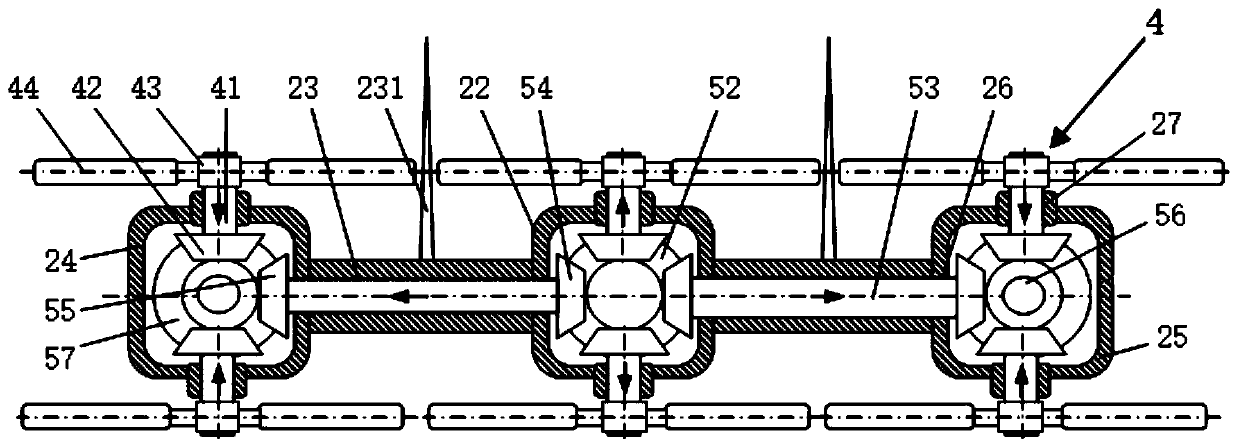

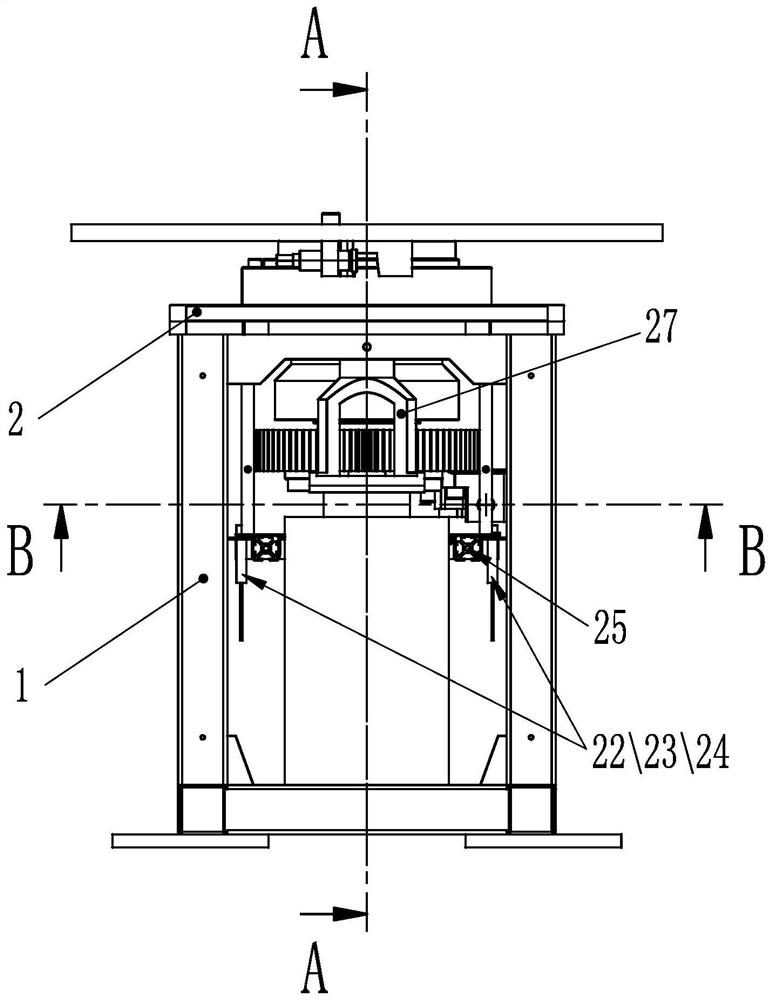

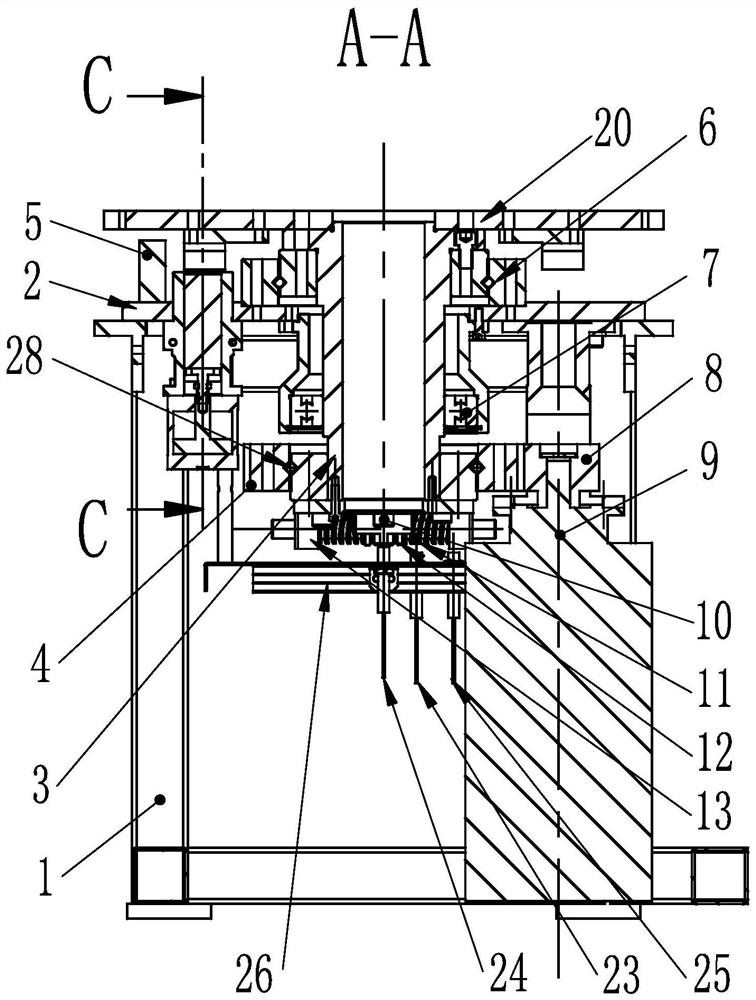

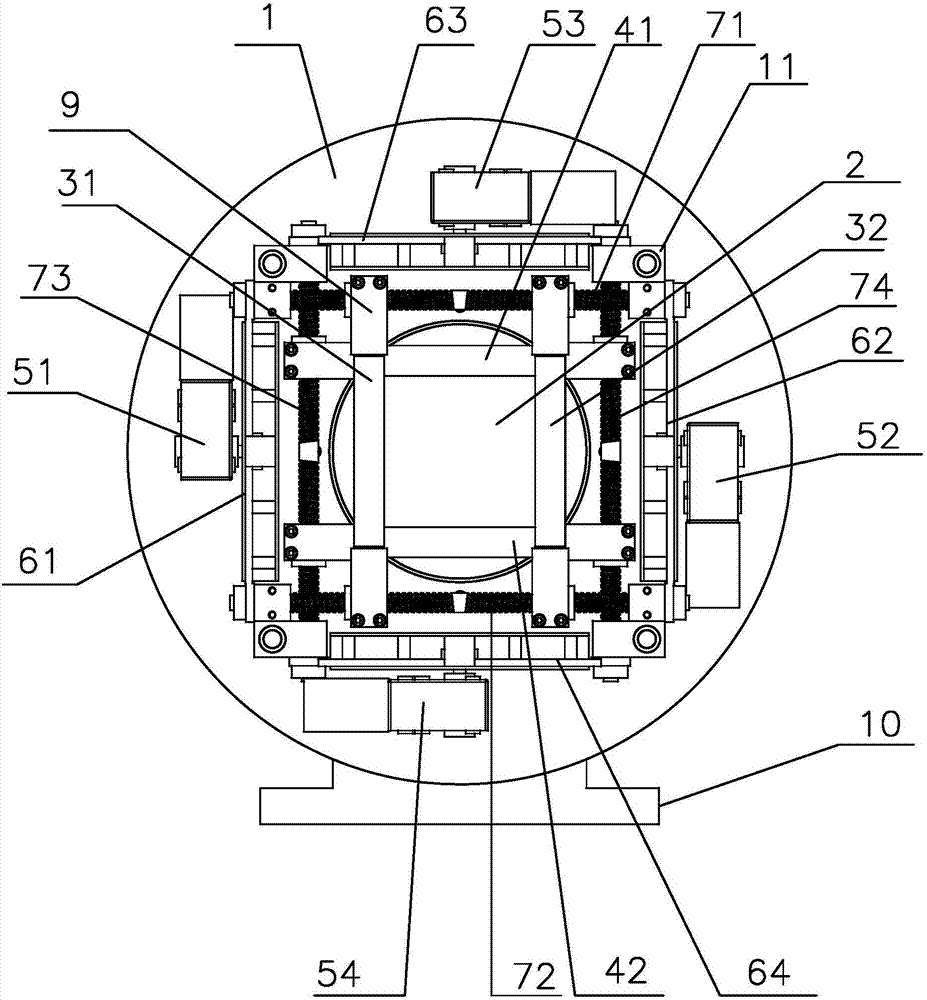

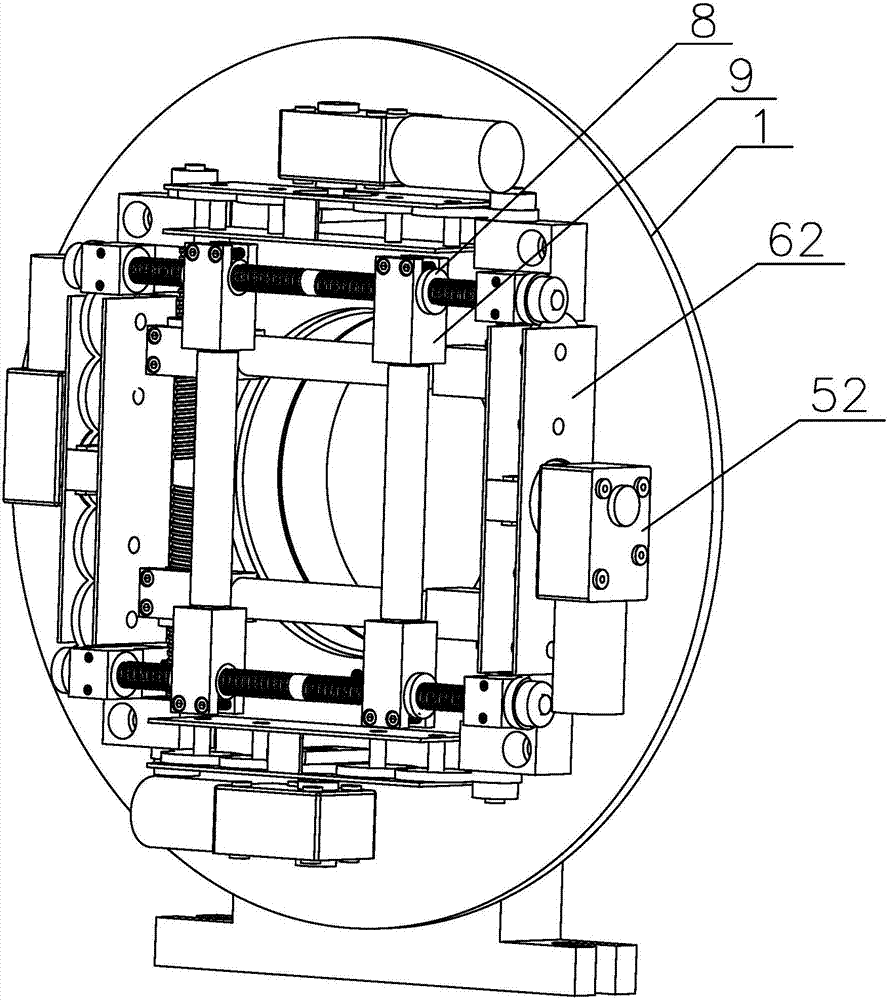

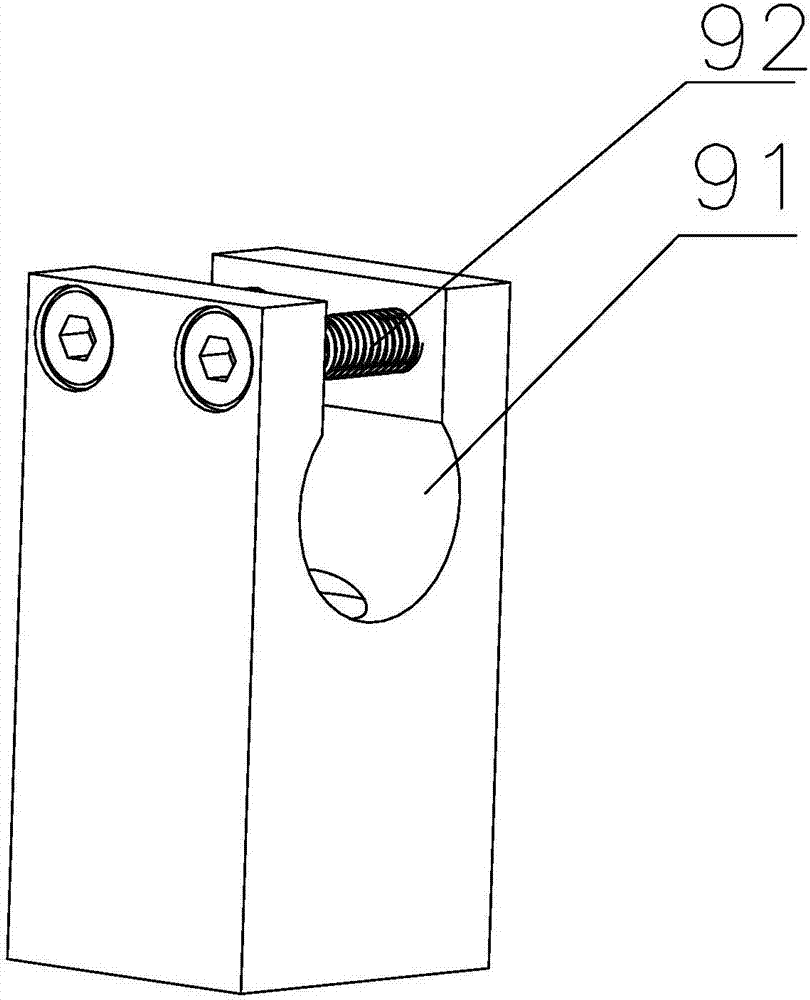

Claw-free chuck for clamping pipes

ActiveCN105710592AOmit the jawsConsistent centering accuracyWelding/cutting auxillary devicesAuxillary welding devicesMaximum diameterEngineering

The invention relates to the technical field of pipe clamps, in particular to a claw-free chuck for clamping pipes. A through hole accepting penetration of the pipes is formed in the middle of a main plate, and the main plate is provided with a claw-free clamp capable of clamping the pipes and enabling the pipes to slide in the through hole in the axial direction of the center of the main plate. According to the claw-free chuck for clamping the pipes, claws and clamping bases pushing the claws are eliminated, and therefore the thickness of the claw-free chuck for clamping the pipes is reduced, the self weight of the chuck is lowered, and feeding waste of the pipes is reduced; because the claws are eliminated, the problem that claw handles extend out of the maximum diameter part of the chuck (namely the main plate) is avoided, the installation space of the chuck is greatly reduced, the manufacturing cost of the chuck is greatly reduced, and the stability is high; pipe loads are retained by screw rods firstly, worm motors just need to bear small retaining force, and gearboxes of the worm motors are protected against damage caused by overload due to the two-stage retaining function. In addition, the claw-free chuck is simple in structure, small in size and light in self weight and has full stroke.

Owner:常州市力源恒机械有限公司

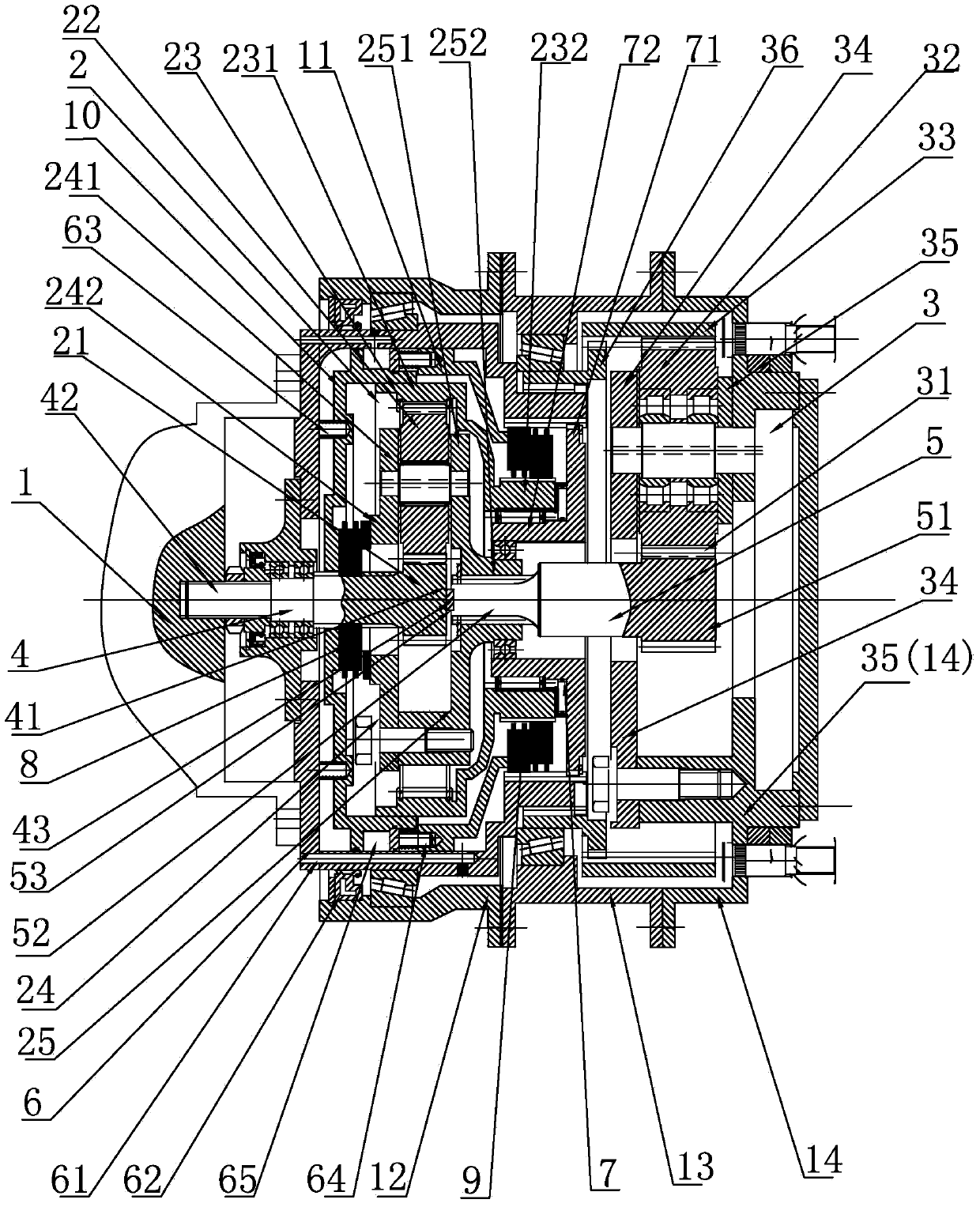

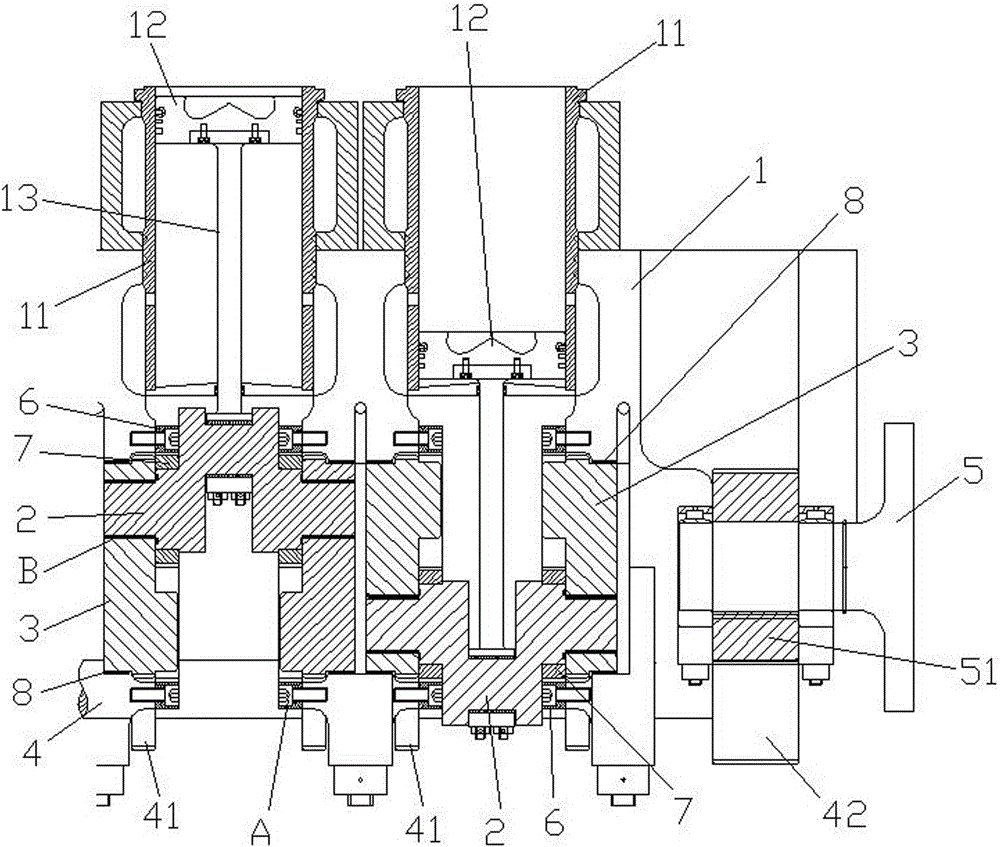

Electric drive two-gear double-stage hub reduction gear

ActiveCN103994187ARealize movementHigh speed movementToothed gearingsTransmission elementsReduction driveElectric drive

The invention relates to a speed reducer in an automobile transmission system, and provides an electric drive two-gear double-stage hub reduction gear which is compact in transmission structure, high in transmission efficiency, flexible to arrange and capable of achieving independent drive of each wheel. The electric drive two-gear double-stage hub reduction gear comprises a primary planetary speed reduction mechanism, a secondary planetary speed reduction mechanism, a reduction gear input shaft, a reduction gear output shaft, an outer shell, an inner shell, a first clutch, a second clutch, a first oil pressure control device and a second oil pressure control device. A motor is arranged on the left side of the outer shell, an output shaft of the motor is connected with the input end of the reduction gear input shaft, the primary planetary speed reduction mechanism is arranged at the output end of the reduction gear input shaft, the secondary planetary speed reduction mechanism is arranged at the output end of the reduction gear output shaft, the transmission mode of the primary planetary speed reduction mechanism is changed through the first clutch and the second clutch, and therefore output of different speed ratios is achieved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

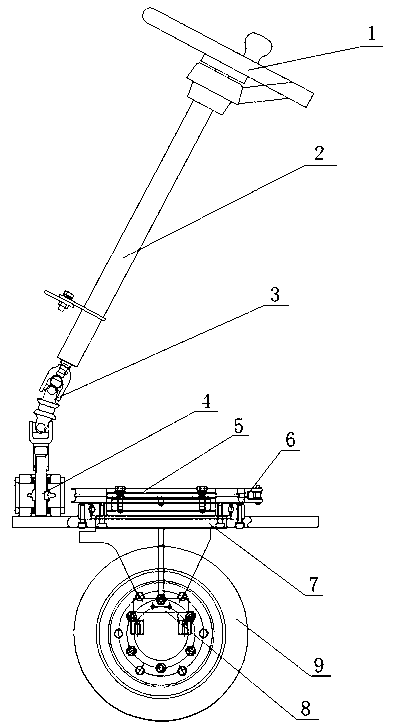

Electric fork-lift truck steering device

InactiveCN102975760AClearance adjustableSmall self-vibrationMechanical steering gearsHand wheelsSteering columnVehicle frame

The invention discloses an electric fork-lift truck steering device which comprises a steering wheel, a steering column, a cardan joint, a steering actuating device, a carframe and a shift wheel, wherein the steering column is arranged below the steering wheel and is connected with the steering wheel. The cardan joint is arranged below the steering column and is connected with the steering column. The steering actuating device is connected with the cardan joint. The carframe is connected with the steering actuating device. The shift wheel is arranged on the carframe. The steering actuating device comprises a chain wheel mechanism and the steering wheel, wherein the horizontally arranged steering is connected with the cardan joint through the chain whell mechanism. The carframe comprises a vertical part and a horizontal part, wherein the horizontal part is connected with the bottom end of the vertical part. The top end of the vertical part of the carframe is fixedly connected with the end face of the steering wheel. The horizontal part of the carframe is provided with the shift wheel. The electric fork-lift truck steering device has the advantages of being simple in structure, convenient to operate and low in cost. In the process of steering, a driver can adjust angles of the shift wheel by constantly steering the steering wheel according to factors such as road surface bending changes and speed changes to maintain steering tracks which a driver wants to reach, and therefore the electric fork-lift truck steering device is reliable in steering, and low in stoppage rate and the like.

Owner:ANHUI HECHA FORKELEVATOR

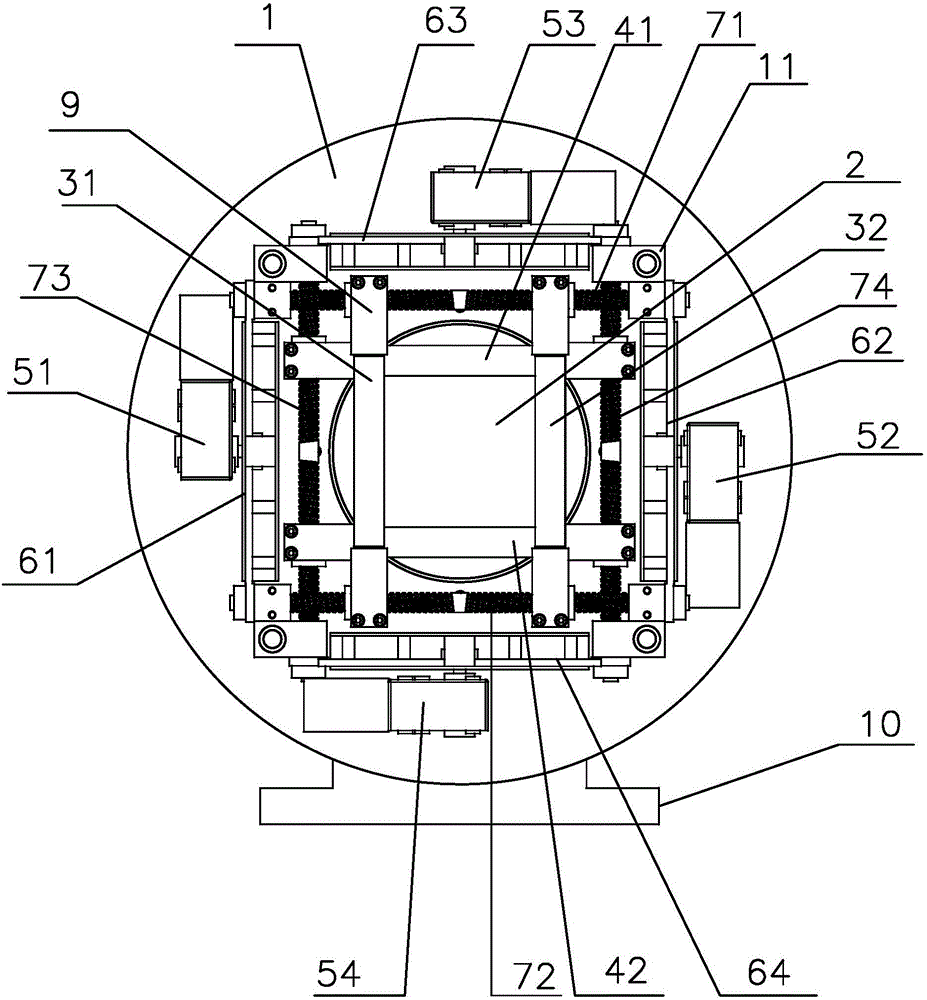

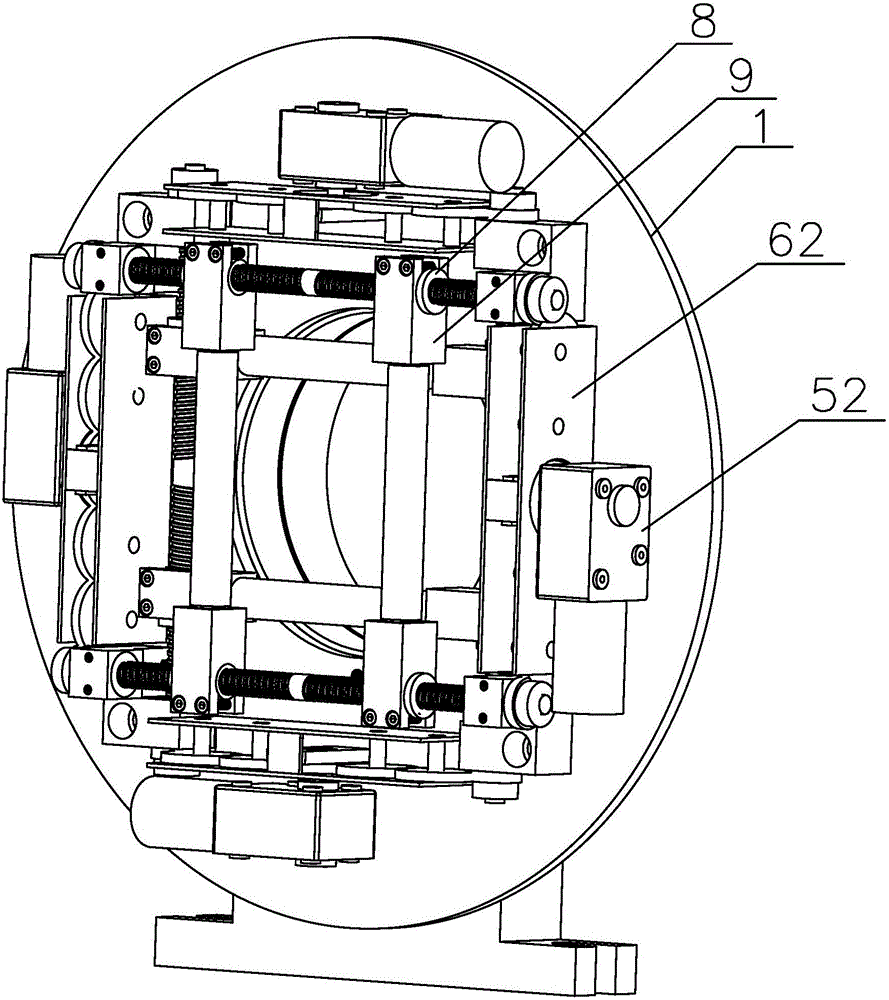

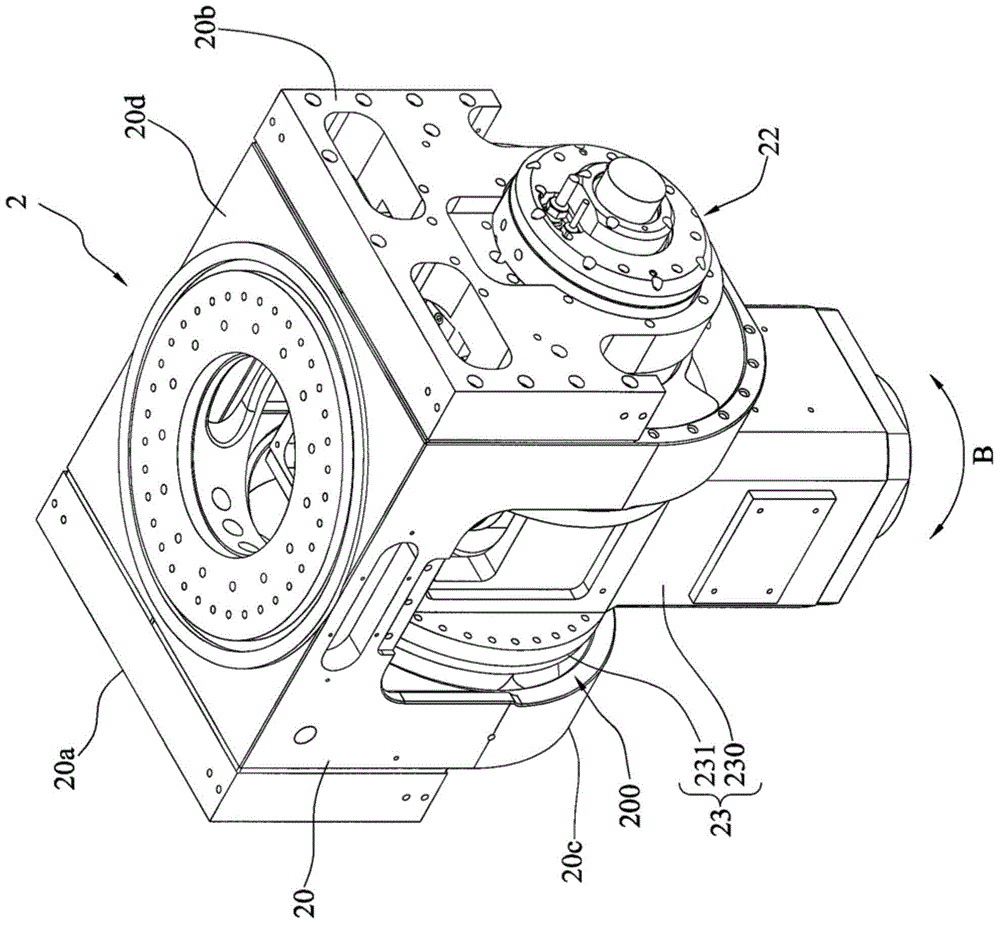

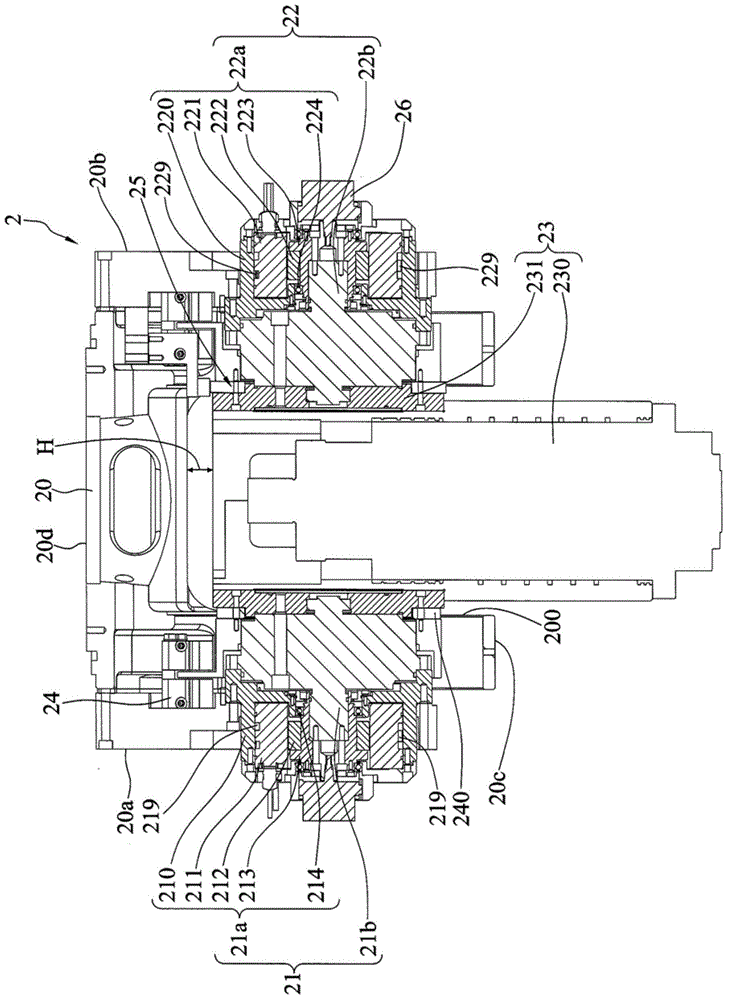

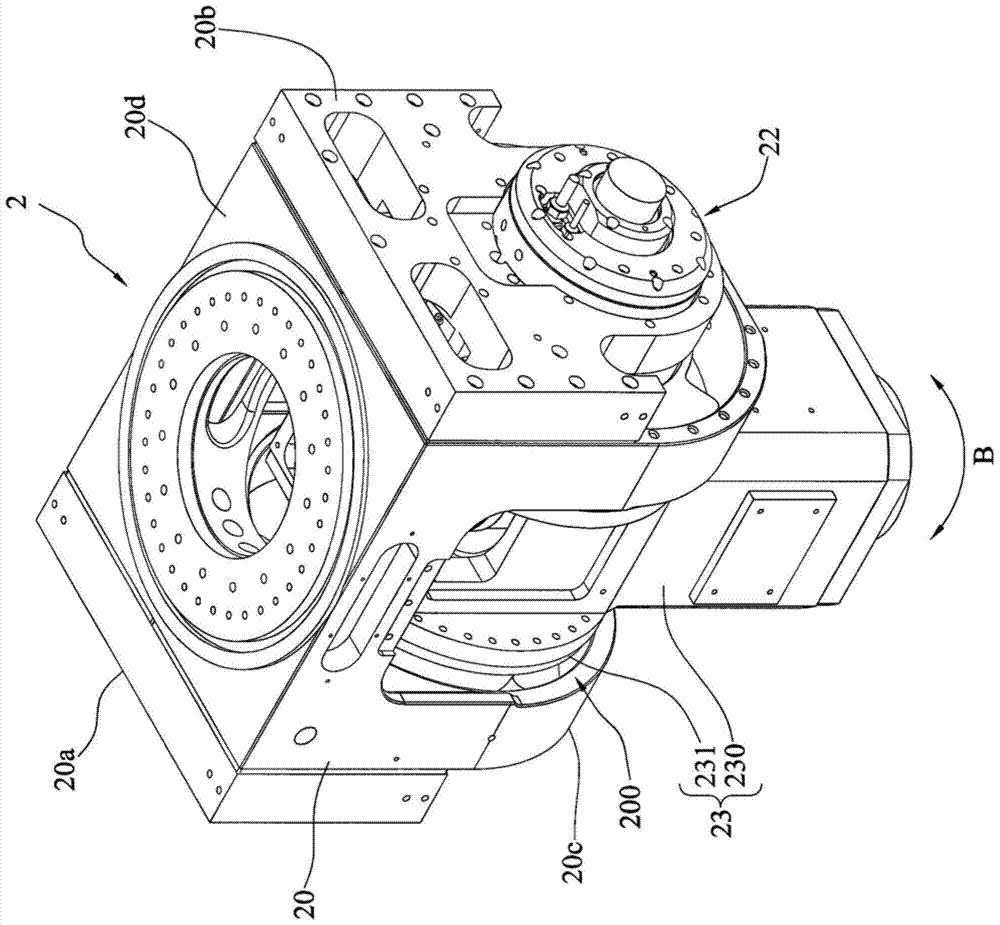

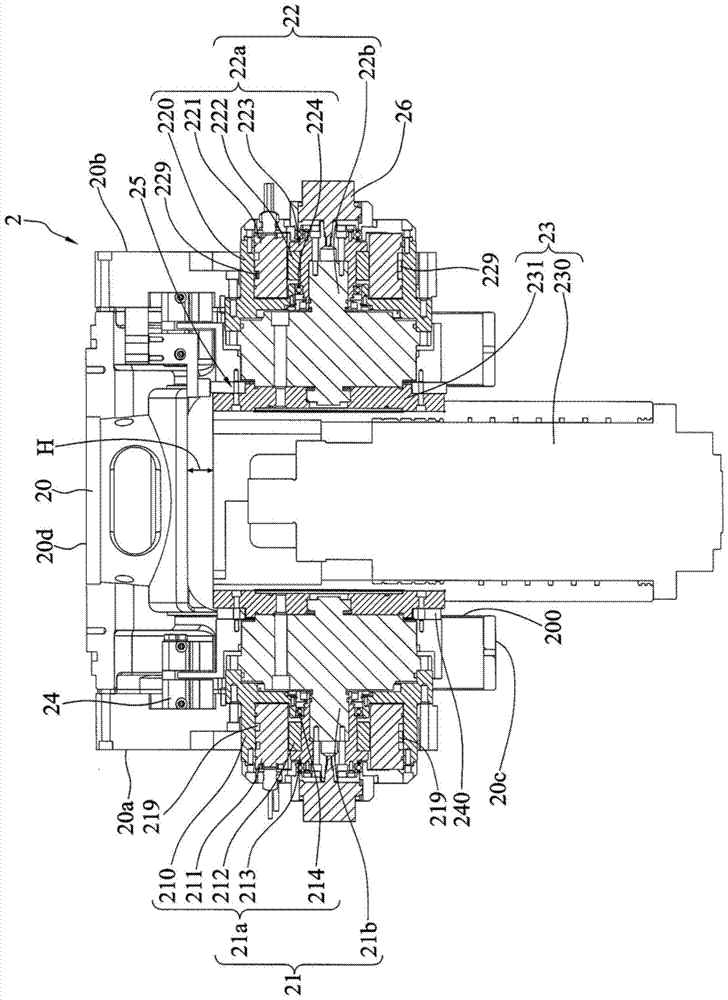

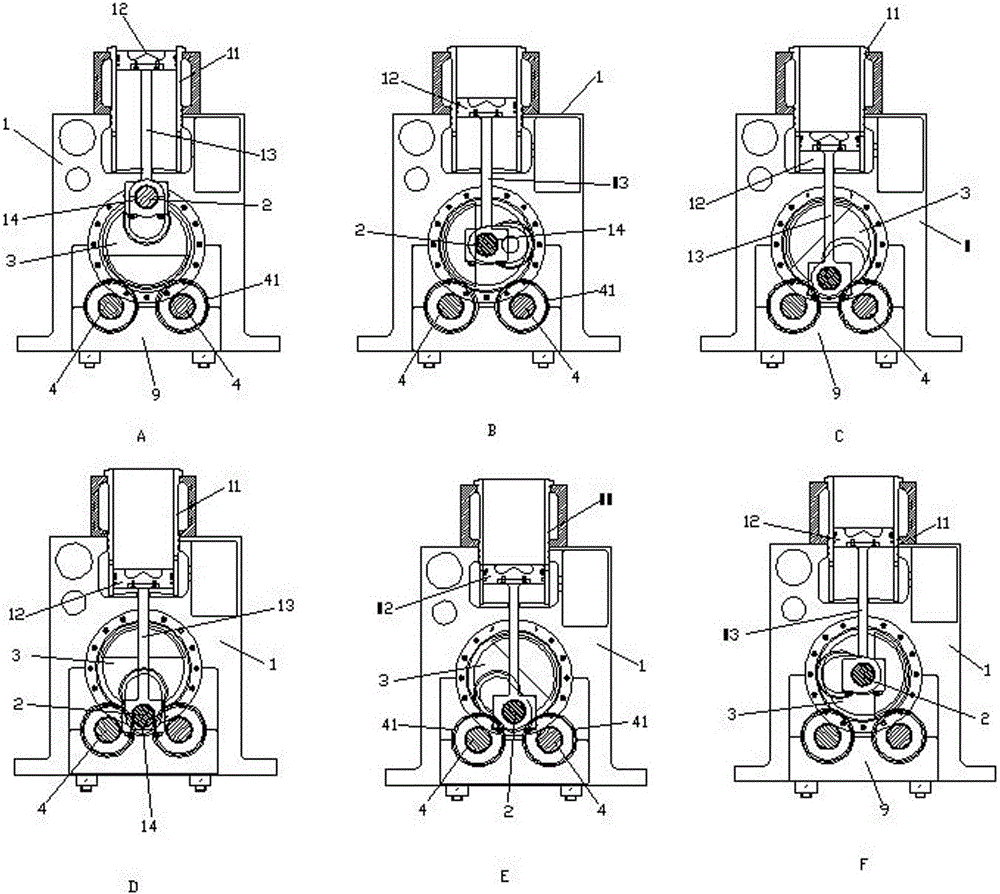

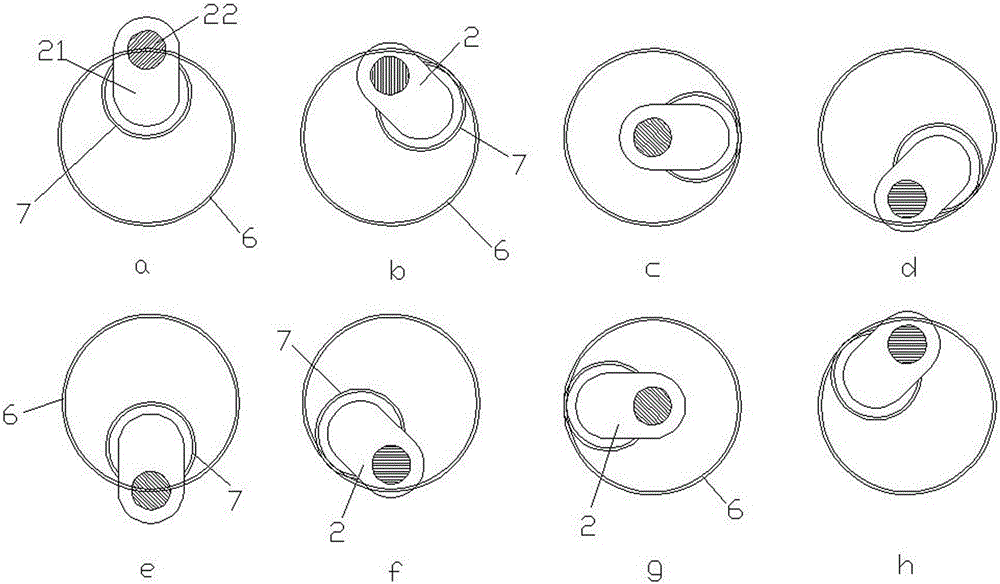

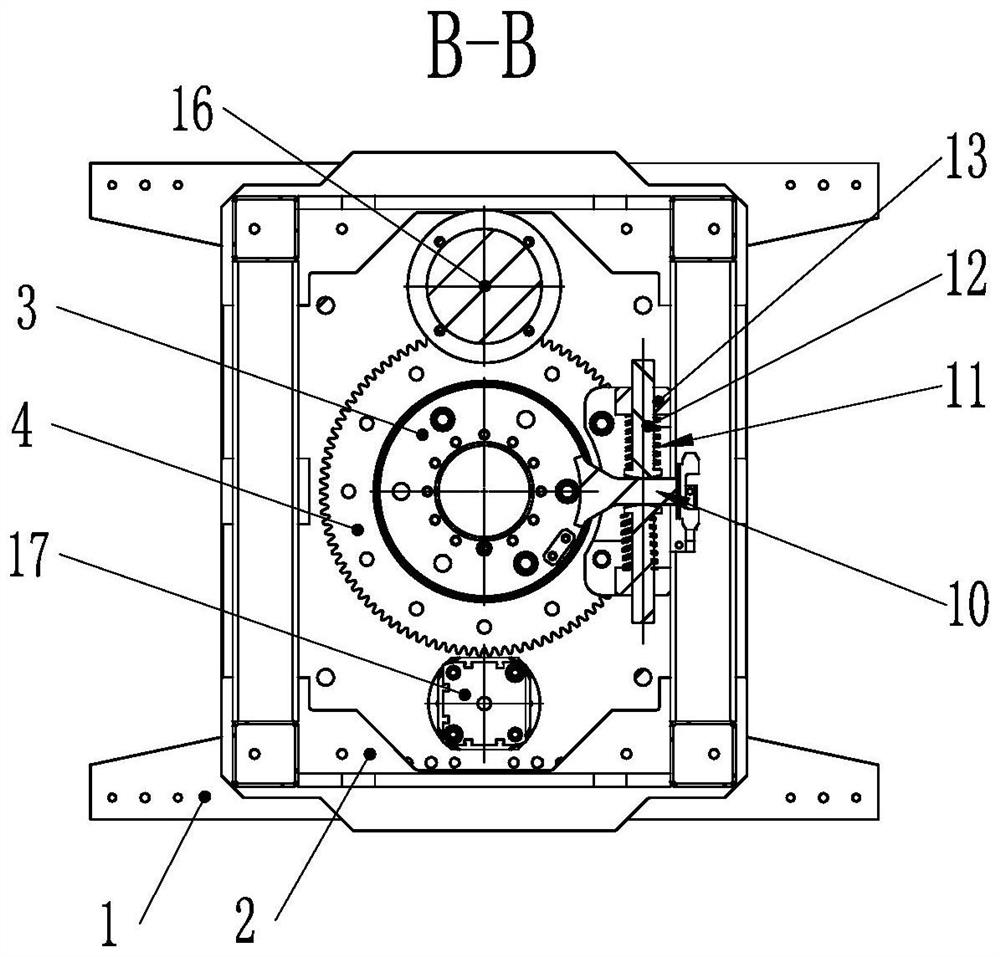

Twin rotation driving apparatus

ActiveCN104607982ASmall turning diameterReduced external volumeProgramme-controlled manipulatorMechanical apparatusGear wheelAutomotive engineering

Owner:IND TECH RES INST

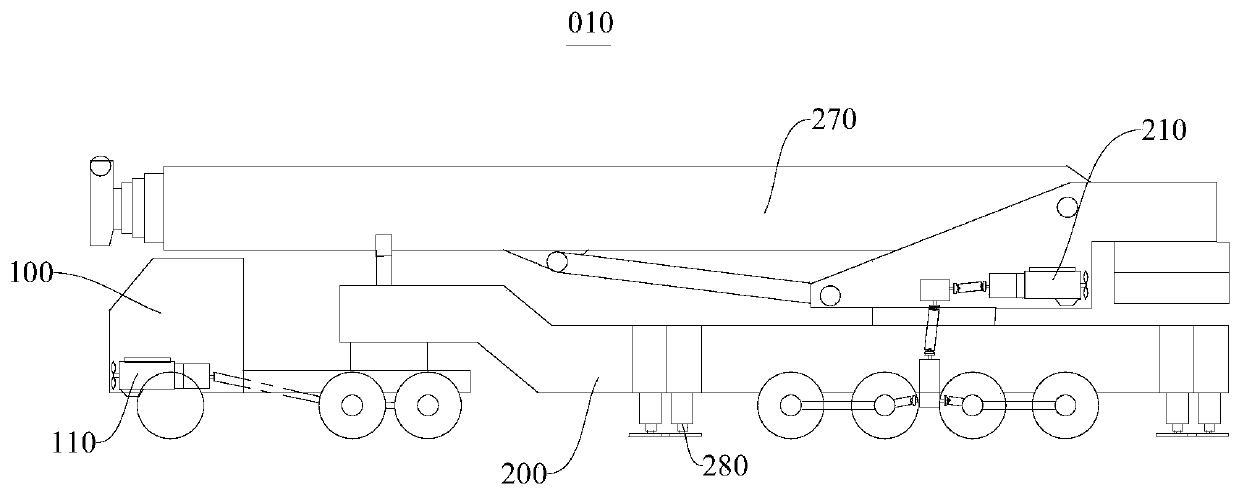

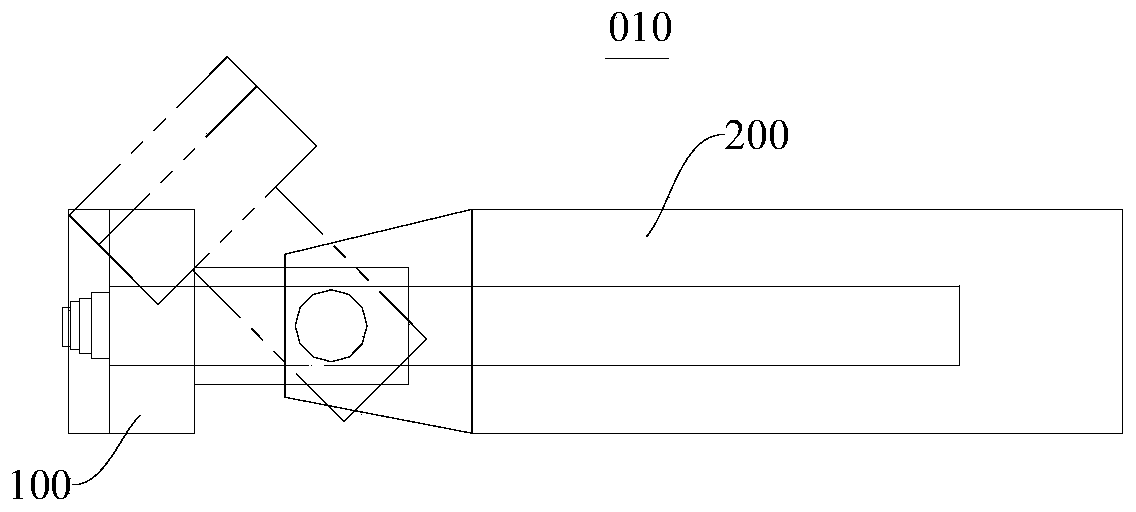

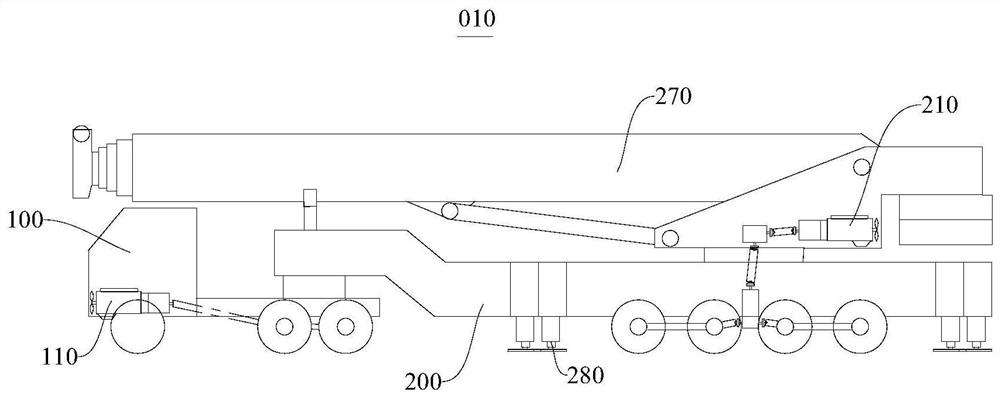

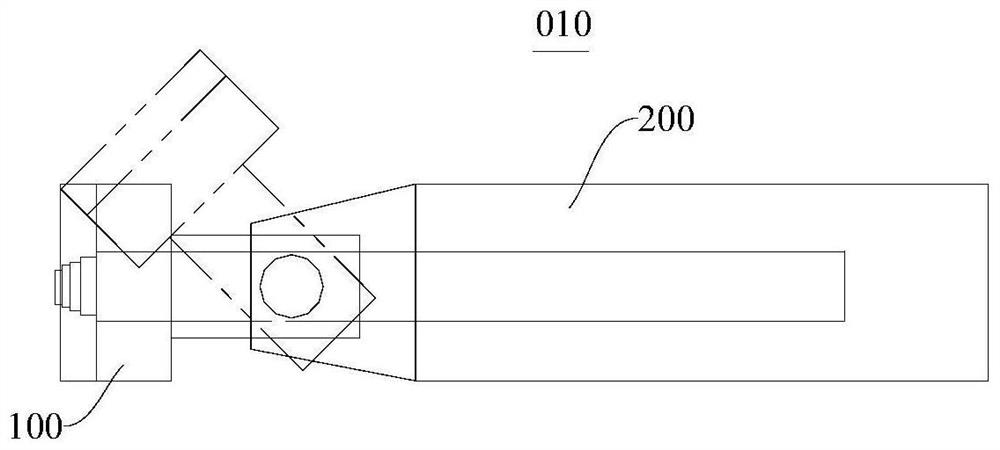

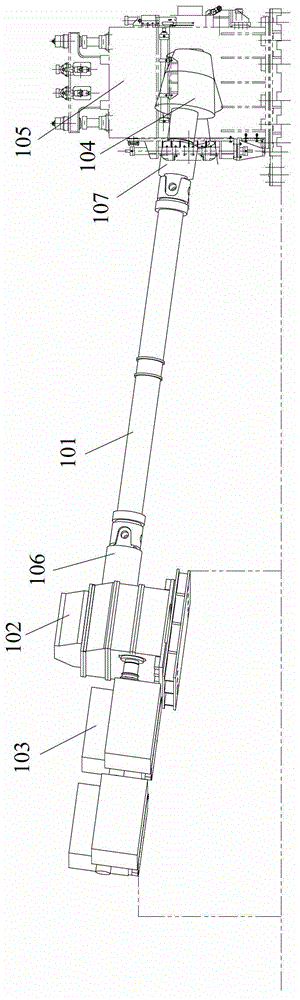

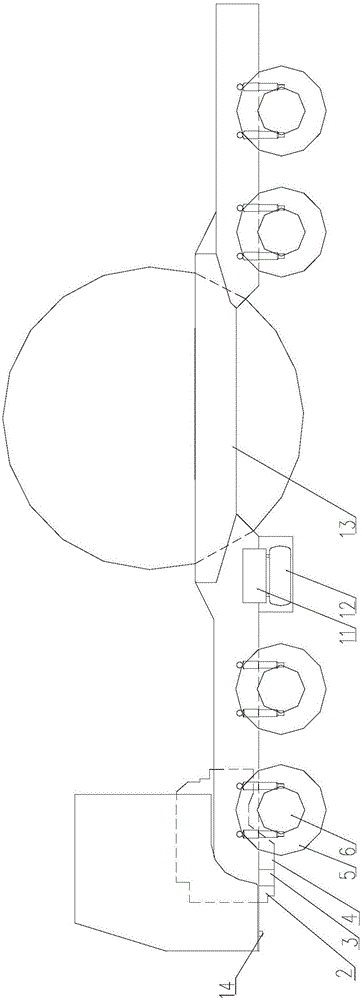

Crane

ActiveCN110758580ASimple and stable steering systemSmall turning diameterVehicle fittings for liftingTractorsTowingSteering system

The embodiment of the invention provides a crane and relates to the technical field of engineering equipment. The crane provided by the embodiment of the invention comprises a towing tractor and an operation vehicle. The towing tractor comprises a first driving part for providing a traveling driving force, a suspended loading mechanism is arranged on the operation vehicle, and the back end of thetowing tractor is hinged to the front end of the operation vehicle, so that when the crane steers in the travelling process, the towing tractor can rotate relative to the operation vehicle. The steering system of the crane provided by the embodiment of the invention is simple and stable and can achieve a relatively small turning diameter.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

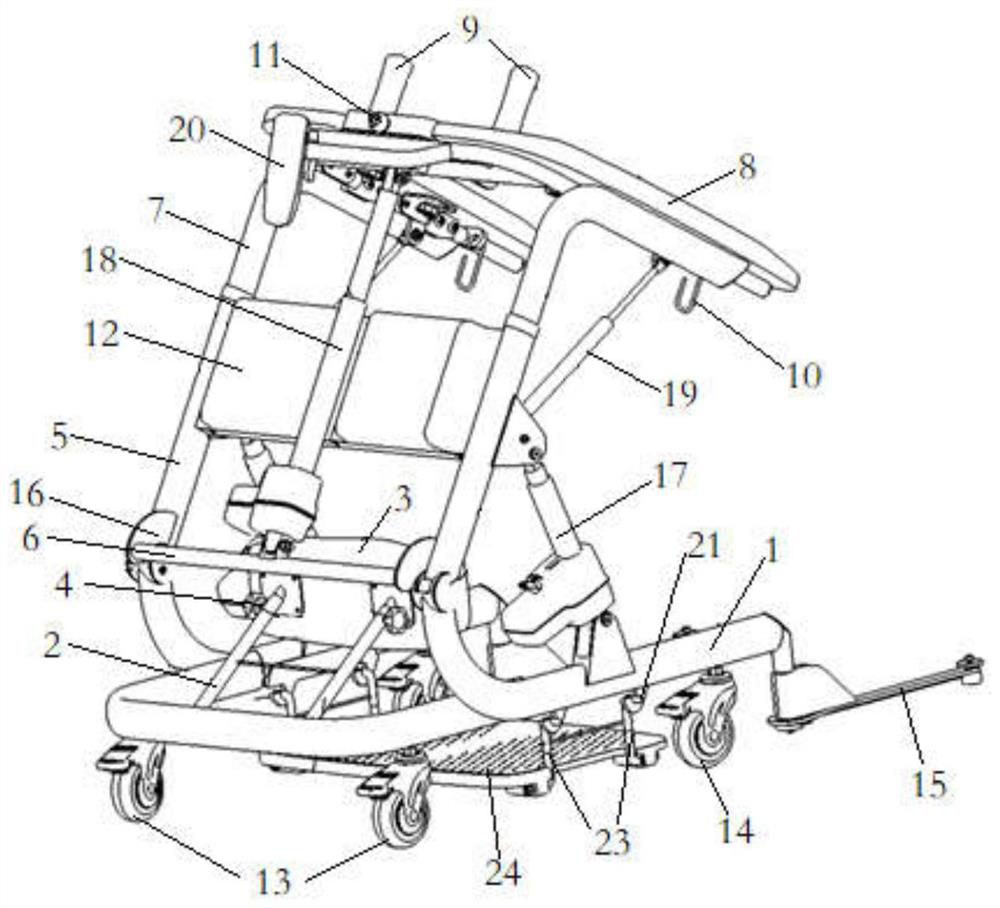

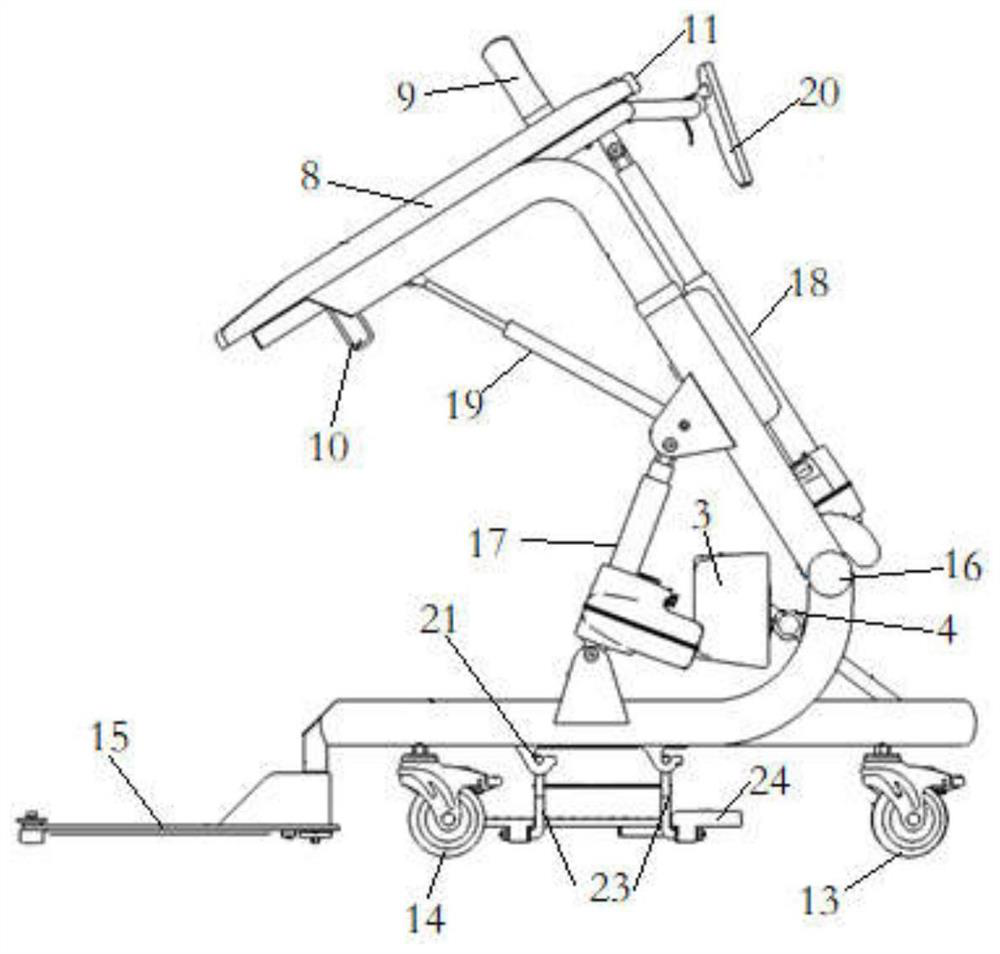

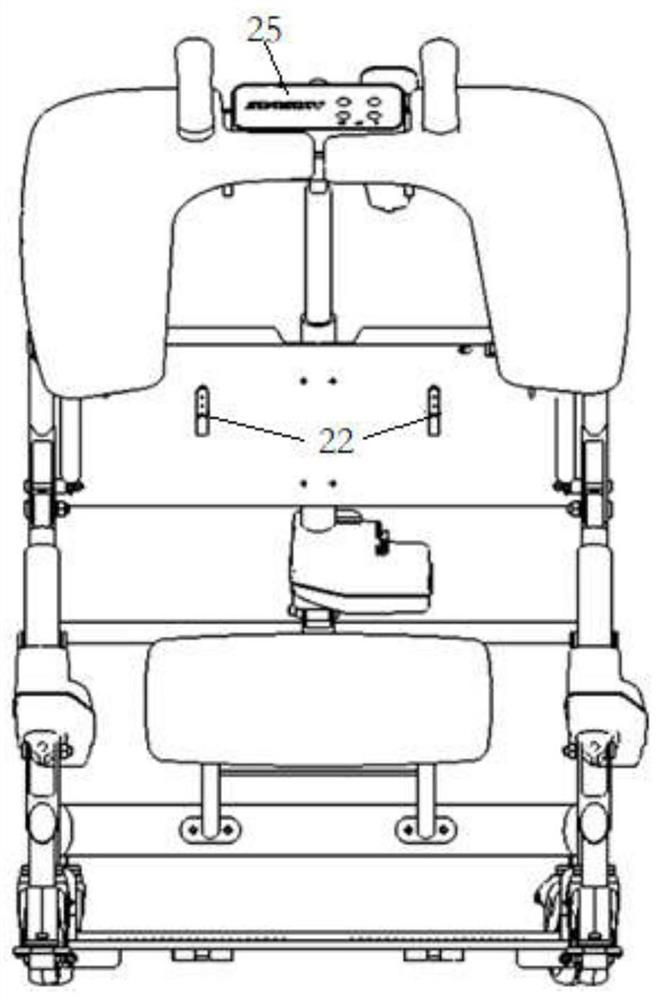

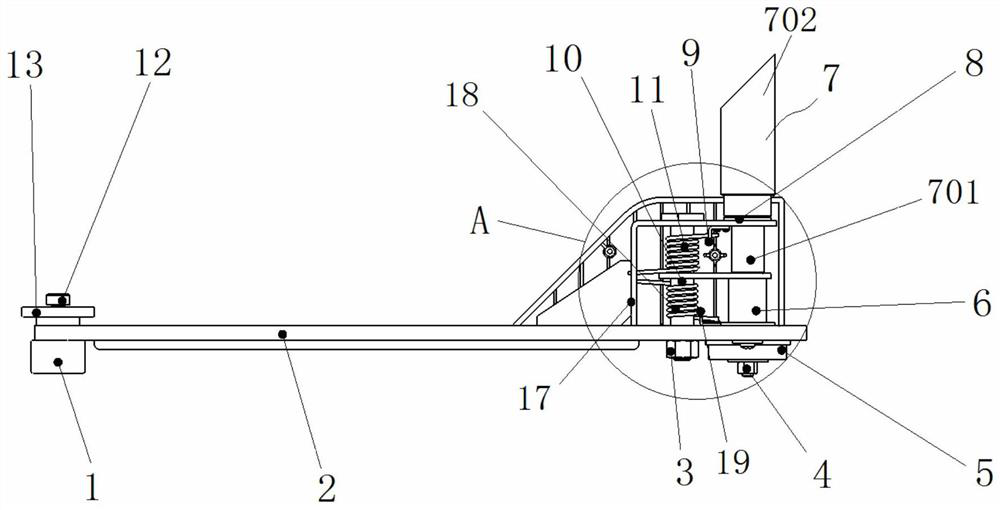

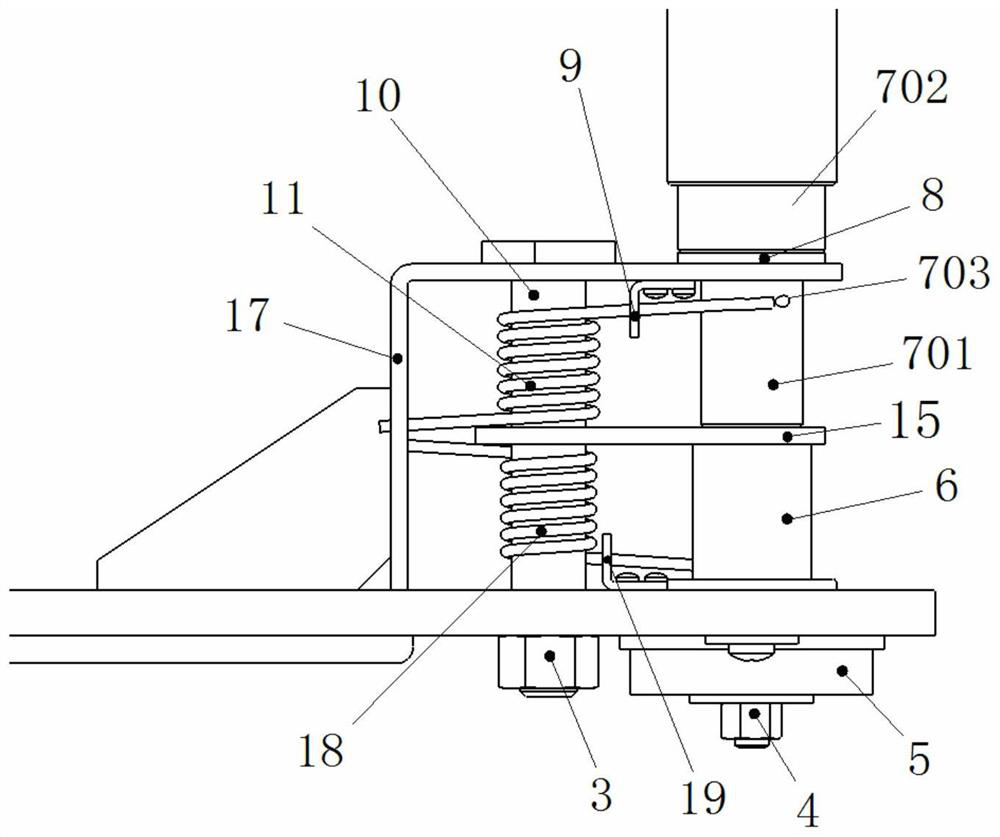

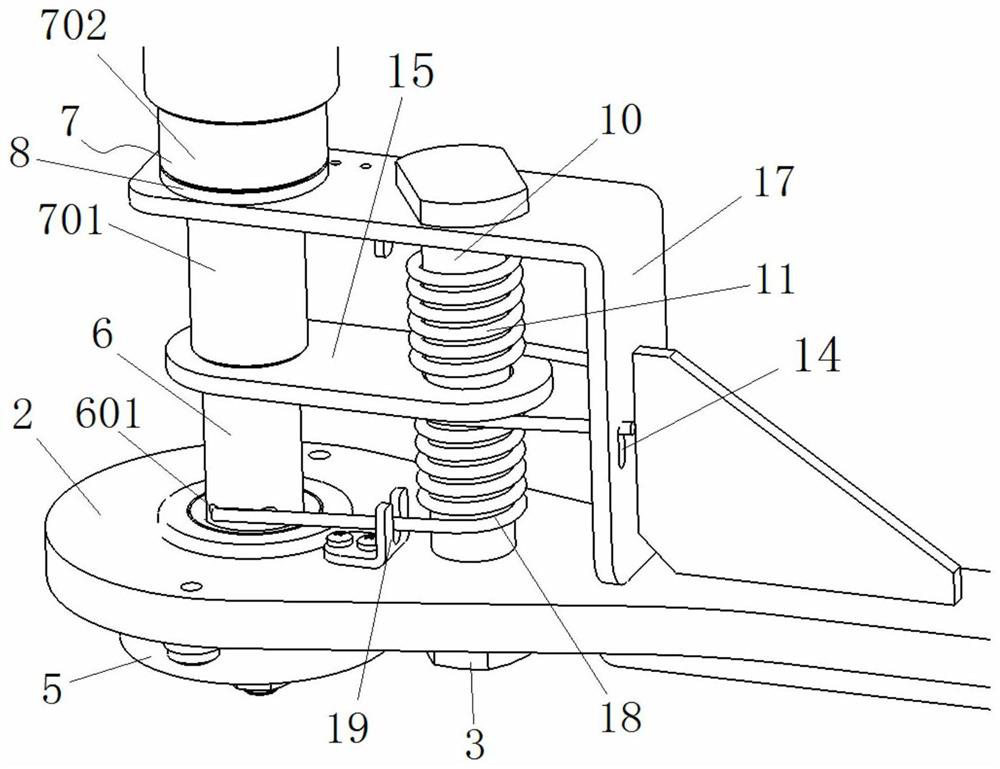

Multifunctional walking aid

PendingCN113018118AReduce in quantityEasy to operateGymnastic exercisingWalking aidsClassical mechanicsEngineering

The invention provides a multifunctional walking aid, which comprises a bottom frame, mounting rods fixedly arranged on the two sides of the front end of the bottom frame, leg baffles arranged at one ends of the mounting rods in an extensible and retractable mode, longitudinal supports rotationally arranged on the two sides of the upper end of the bottom frame, L-shaped bent pipes arranged at one ends of the longitudinal supports in an extensible and retractable mode, U-shaped support platform with opening in the middle, handles fixedly arranged on the two sides of the supporting platform, protector hooks fixedly arranged on the two sides of the lower end of the supporting platform, an emergency stop switch fixedly arranged at the front end of the supporting platform, a controller fixedly arranged on the longitudinal support; two front wheels and the two rear wheels fixedly arranged below the bottom frame, and a trailing tail rotatably arranged at the rear end of the bottom frame. The multifunctional walking aid is medical aid equipment integrating pulling up / putting down, shifting, walking aid and standing training, operation is easy and flexible, and the safety of body position changing is high.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

crane

ActiveCN110758580BSimple and stable steering systemSmall turning diameterVehicle fittings for liftingTractorsMechanism (engineering)Tractor trailer

An embodiment of the invention provides a crane, which relates to the technical field of engineering equipment. The crane in the embodiment of the present application includes a tractor and a working vehicle. The tractor includes a first driving member for providing driving force. The working vehicle is provided with a hoisting mechanism. The rear end of the tractor is hinged to the front end of the working vehicle so When the crane turns while traveling, the tractor can rotate relative to the work vehicle. The steering system of the crane provided by the embodiment of the present application is simple and stable, and can realize a smaller turning diameter.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

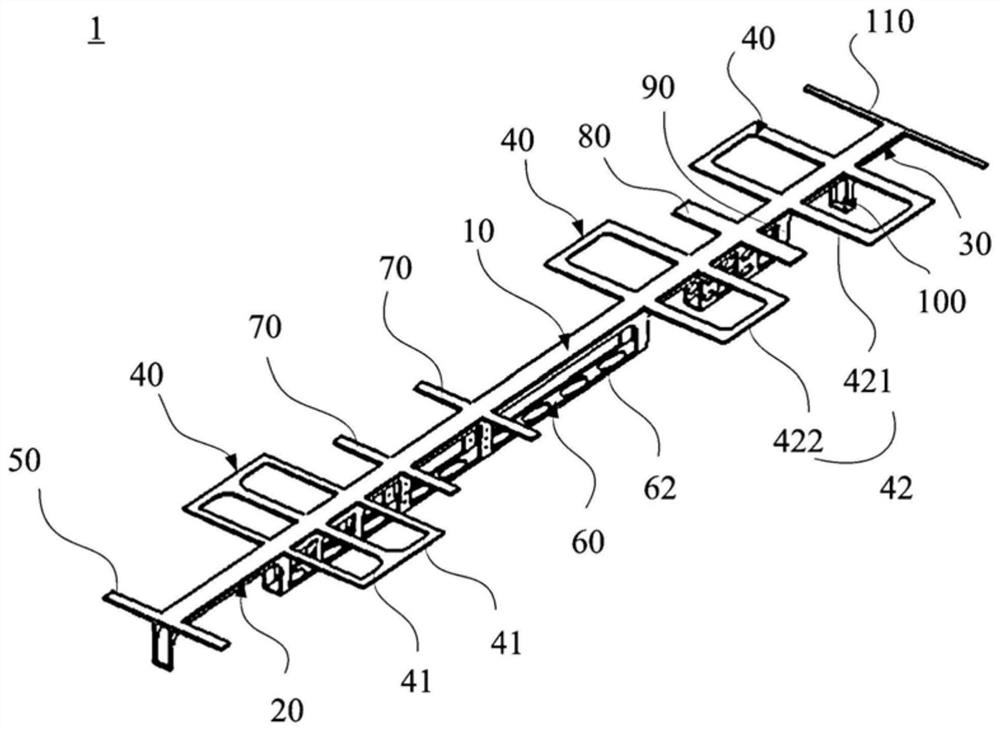

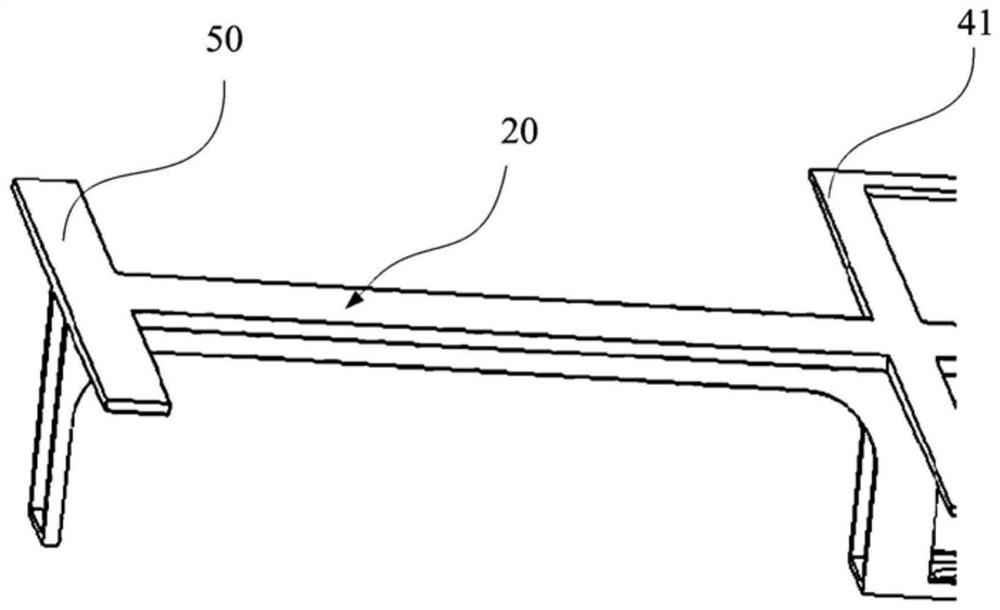

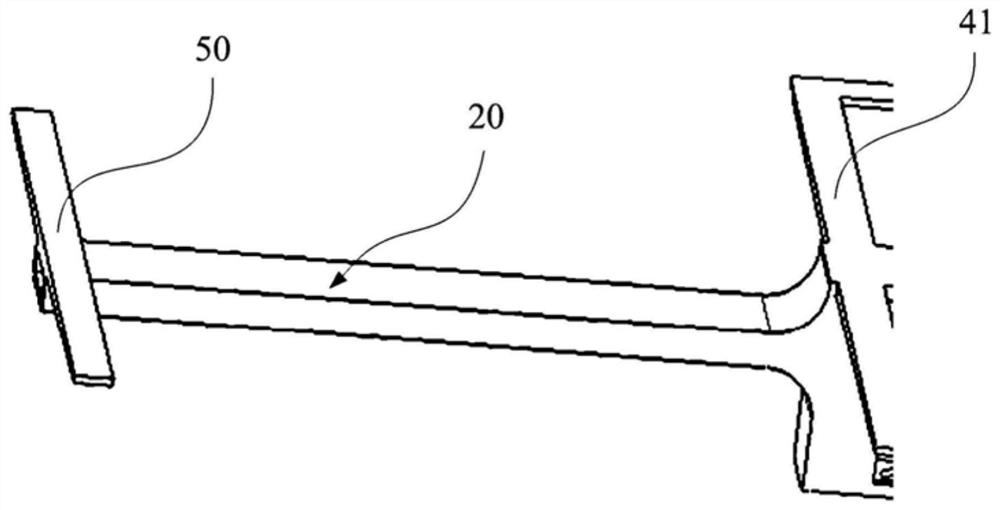

An integrated middle beam frame for new energy vehicles

ActiveCN109533028BAvoid installation processIncrease diversityUnderstructuresVehicle frameNew energy

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

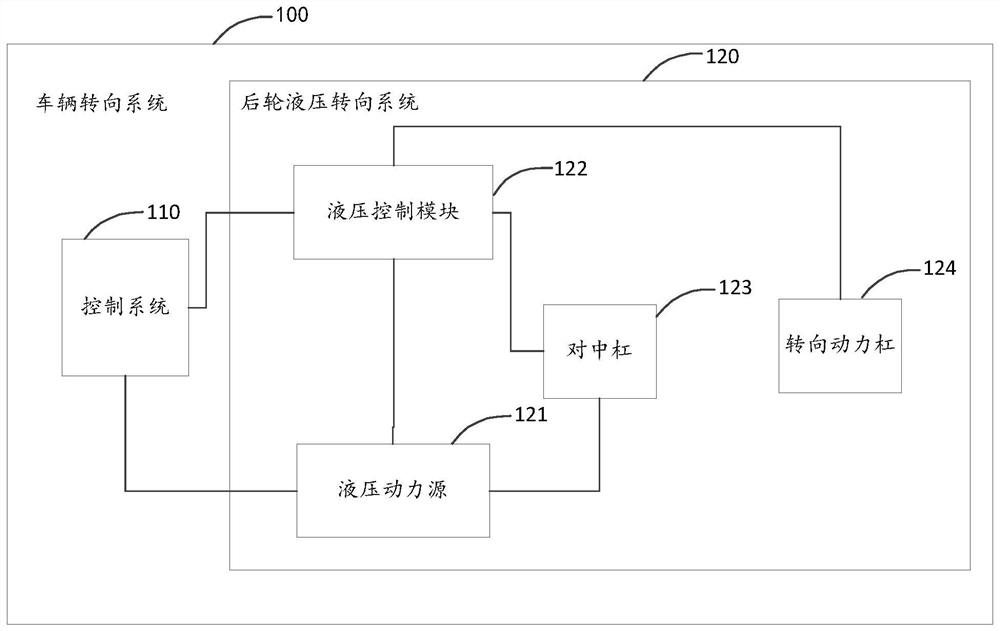

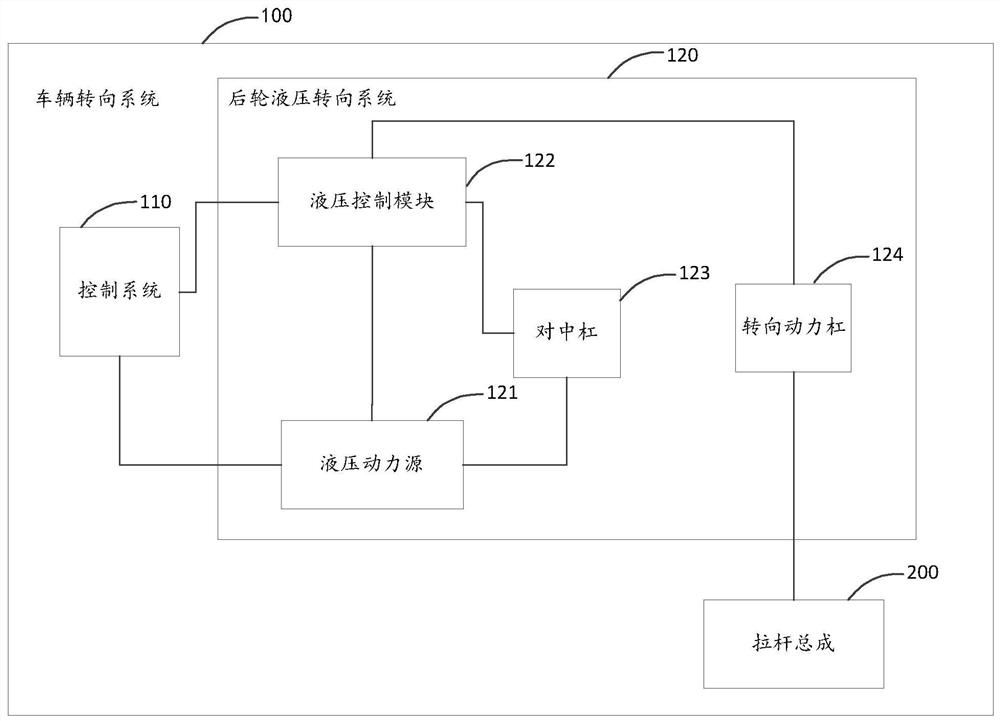

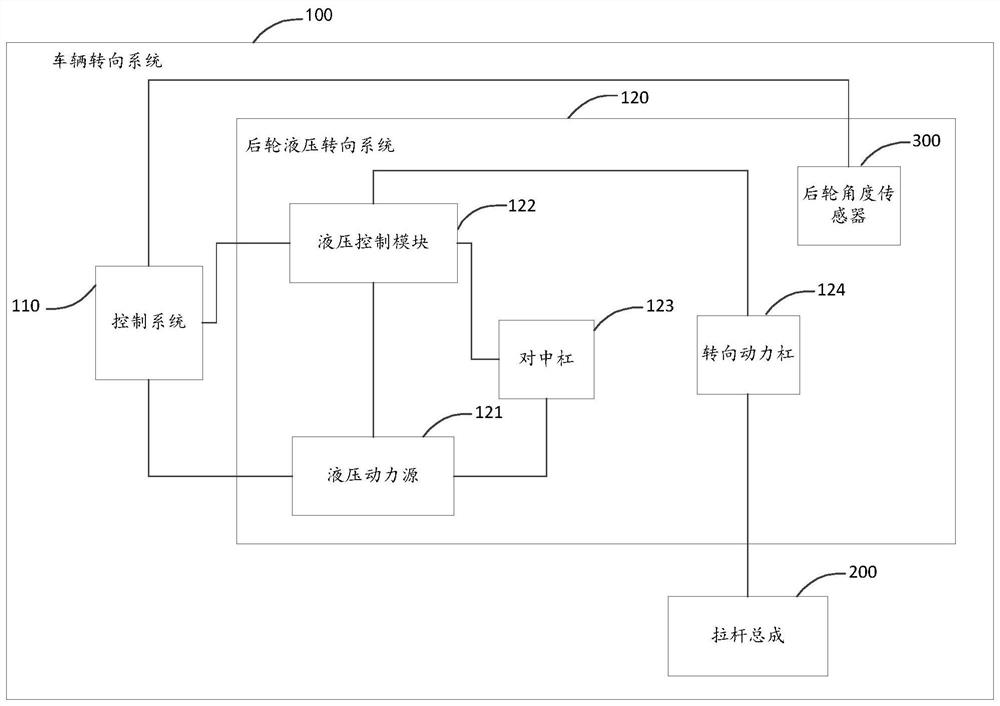

Vehicle steering system and vehicle

The invention discloses a vehicle steering system and a vehicle. The vehicle steering system comprises a rear wheel hydraulic steering system and a control system, and the control system controls the rear wheel hydraulic steering system to realize self-adaptive rotation of the rear wheel steering angle and the steering direction according to the front wheel steering angle and the steering direction; the rear wheel hydraulic steering system comprises a hydraulic power source and a hydraulic control module, and further comprises a centering cylinder and a steering power cylinder; the control system controls the hydraulic control module and the hydraulic power source to work according to the vehicle state information, high-pressure oil is provided for the steering power cylinder and the centering cylinder, ordered actions of the steering power cylinder and the centering cylinder are achieved, and a vehicle working mode corresponding to the vehicle state information is completed. According to the system, rear wheels are controlled to steer through electric control hydraulic pressure, and the rear wheels correspondingly rotate by a certain angle at a low speed according to the steering angle of front wheels, so that the turning diameter is reduced, and the vehicle trafficability is improved. Operation is easy, and operation is safe and reliable.

Owner:BAIC GRP ORV CO LTD

Dual Rotary Drive

ActiveCN104607982BSmall turning diameterReduced external volumeProgramme-controlled manipulatorMechanical apparatusGear wheelDouble rotation

Owner:IND TECH RES INST

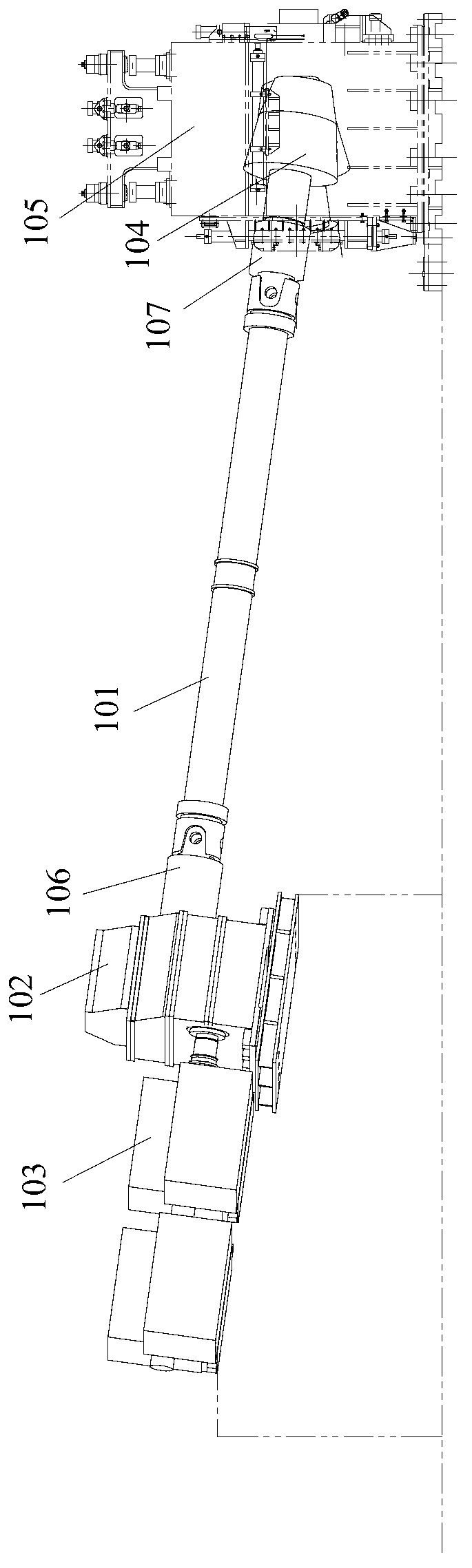

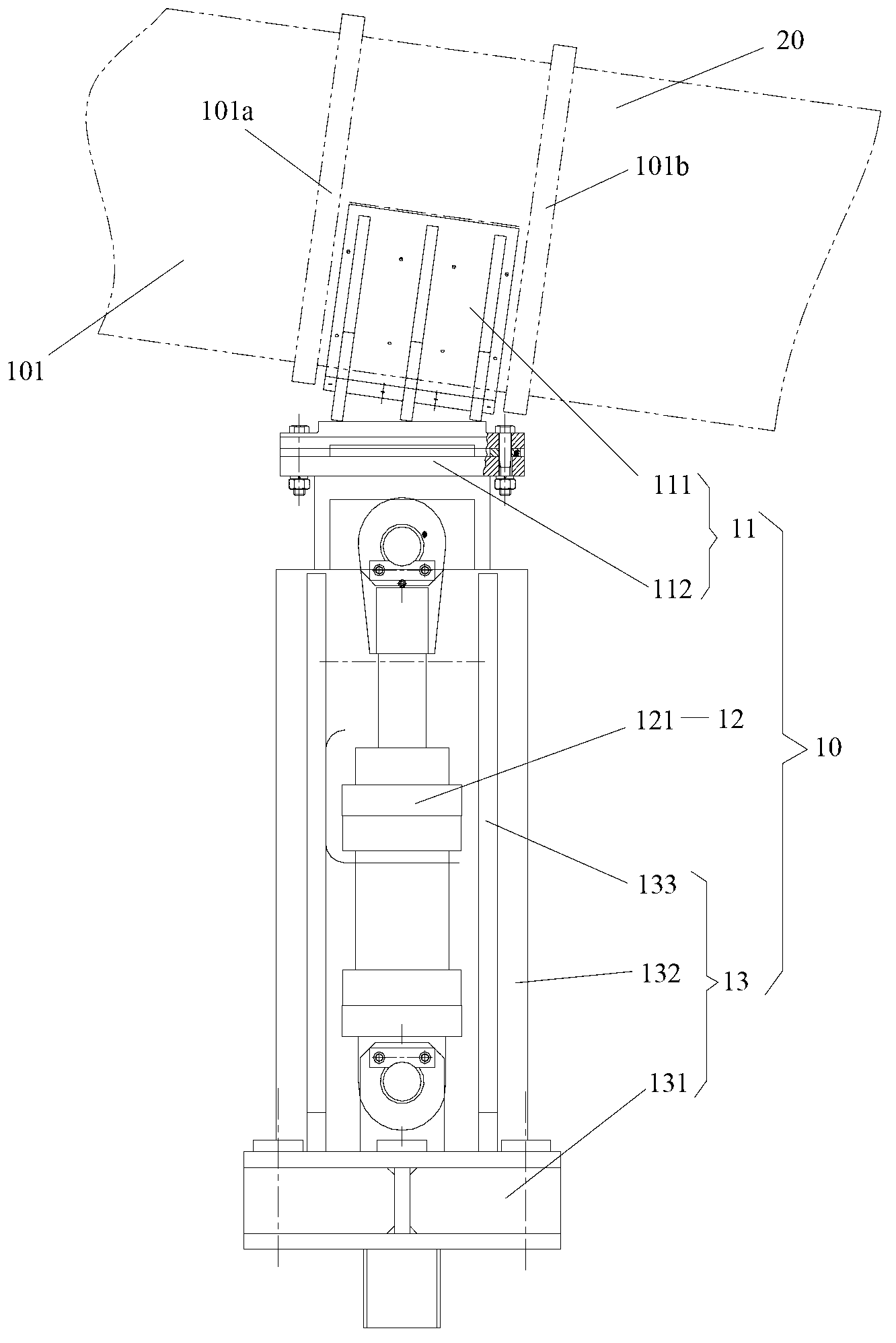

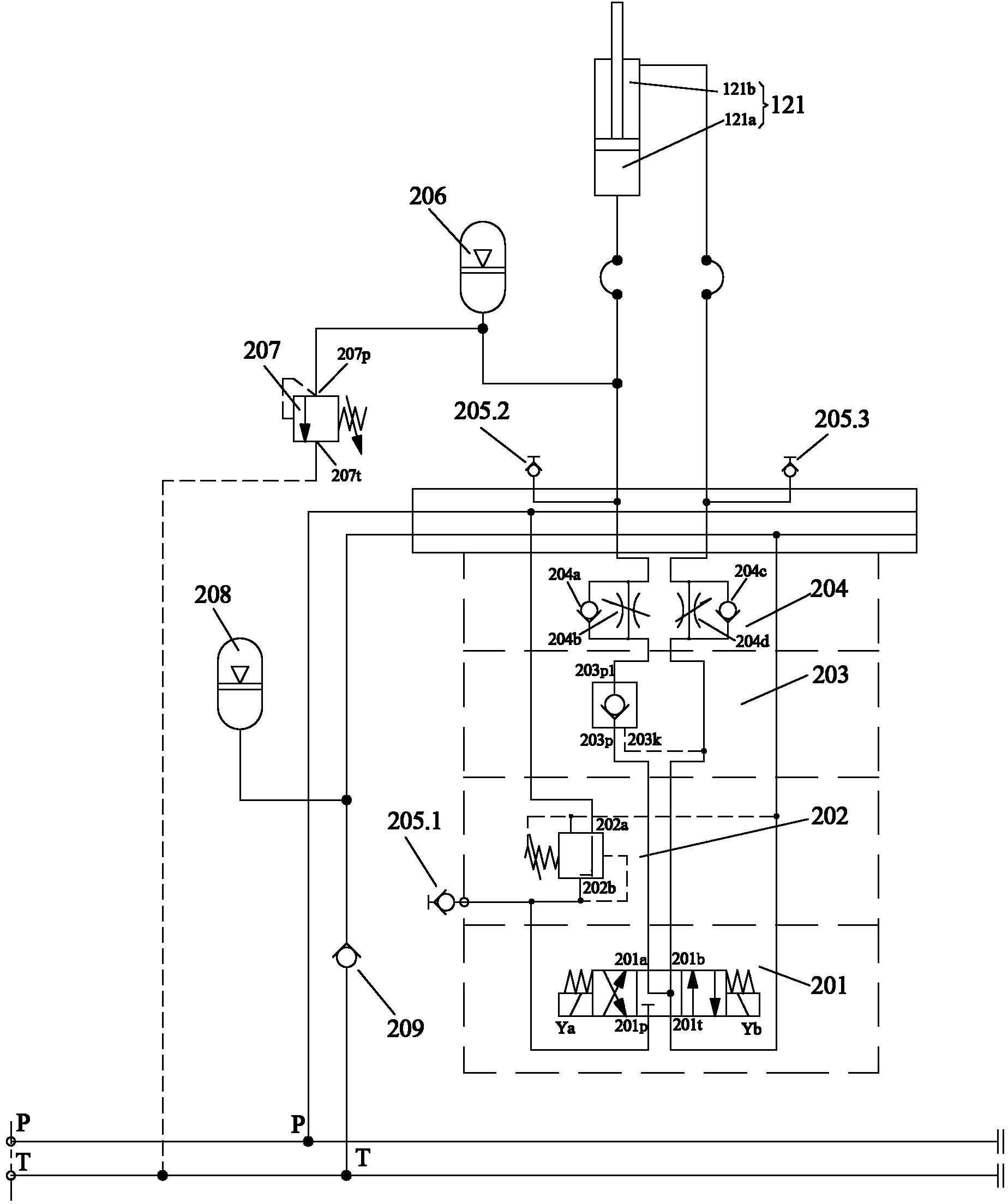

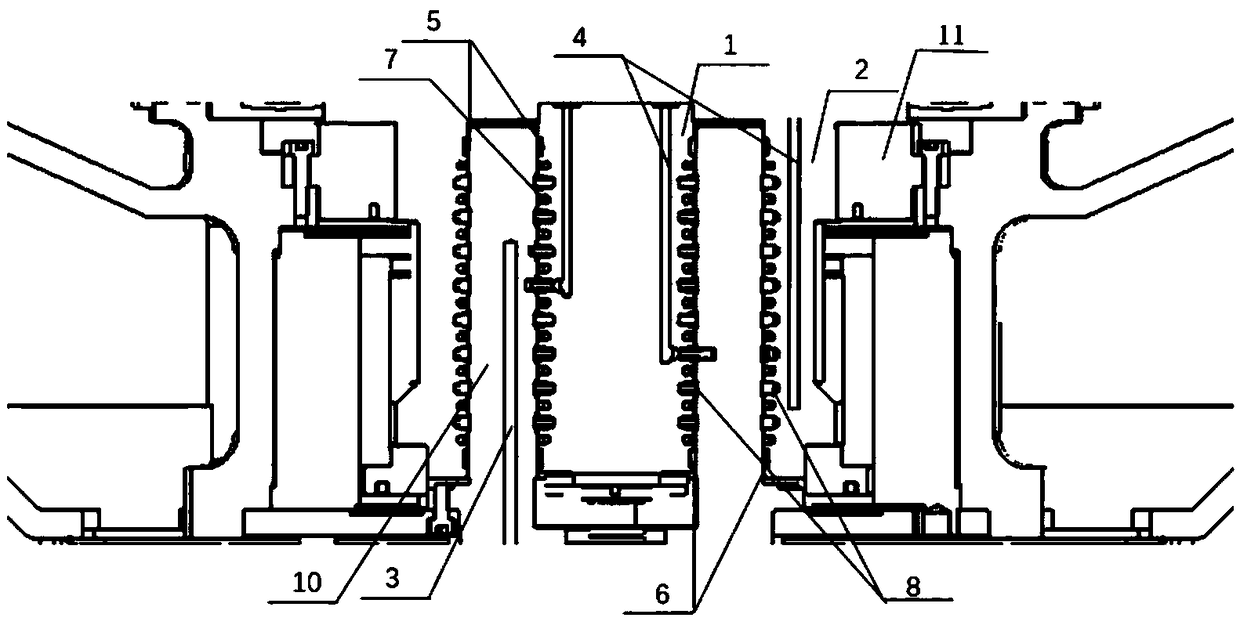

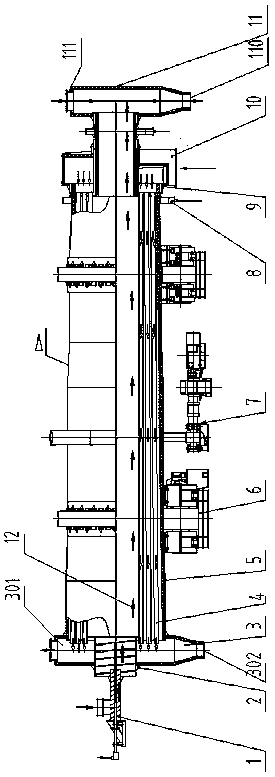

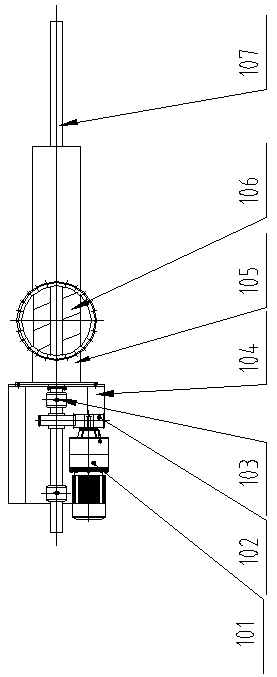

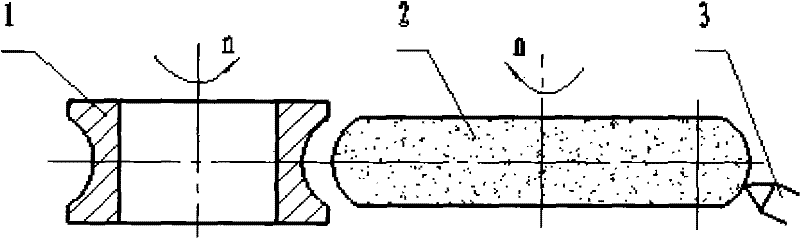

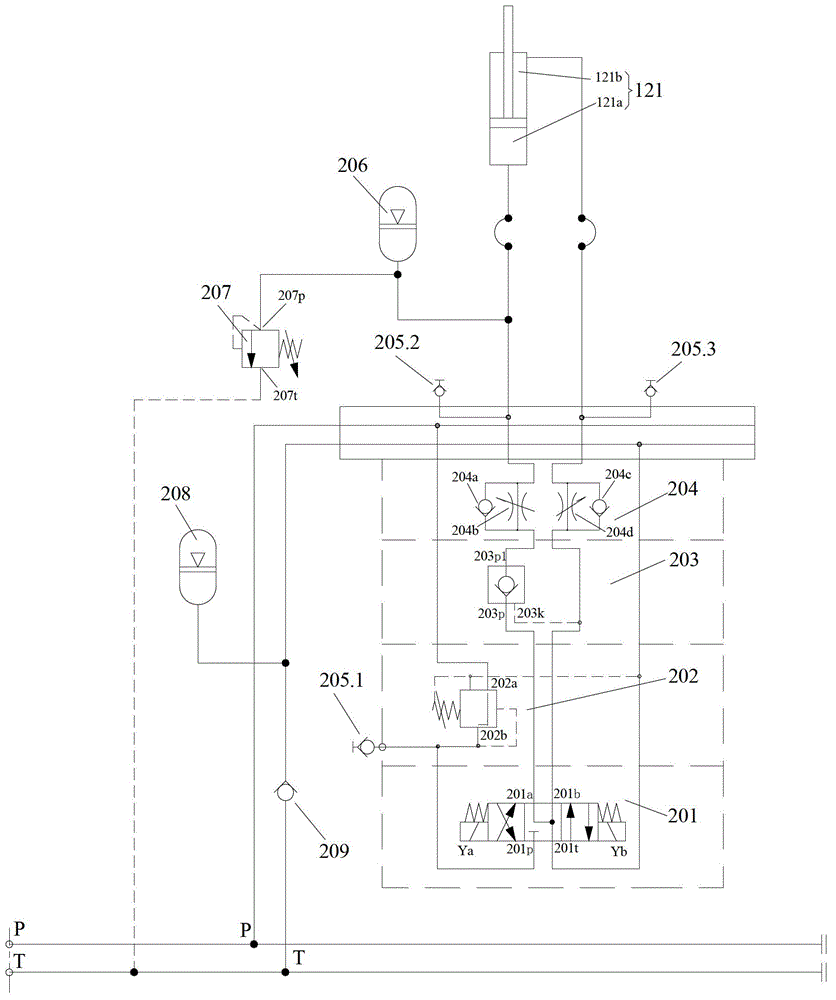

Hydraulic supporting control mechanism of roller connecting shaft and relevant puncher and relevant pipe milling machine

ActiveCN103230937ASmall turning diameterImprove the forceRoll mill control devicesMandrelsHydraulic cylinderControl system

The invention provides a hydraulic supporting control mechanism of a roller connecting shaft and a relevant puncher and a relevant pipe milling machine. The hydraulic supporting control mechanism of the roller connecting shaft is used for supporting the roller connecting shaft dynamically and comprises a connecting shaft supporting base, a hydraulic supporting control system and a hydraulic cylinder installing base. The connecting shaft supporting base contacts with and supports the roller connecting shaft, the hydraulic cylinder installing base is installed on a foundation, a hydraulic cylinder of the hydraulic supporting control system is installed in the hydraulic cylinder installing base, and the hydraulic cylinder can drive the connecting shaft supporting base to move up and down or support the roller connecting shaft in a floating mode. Due to the fact that constant supporting force exists, a sinking range of the roller connecting shaft is limited, rotary diameter of the roller connecting shaft is reduced, simultaneously the stress of handles at two ends of the roller connecting shaft is improved, and the service life of the handles is prolonged.

Owner:TAIYUAN HEAVY IND

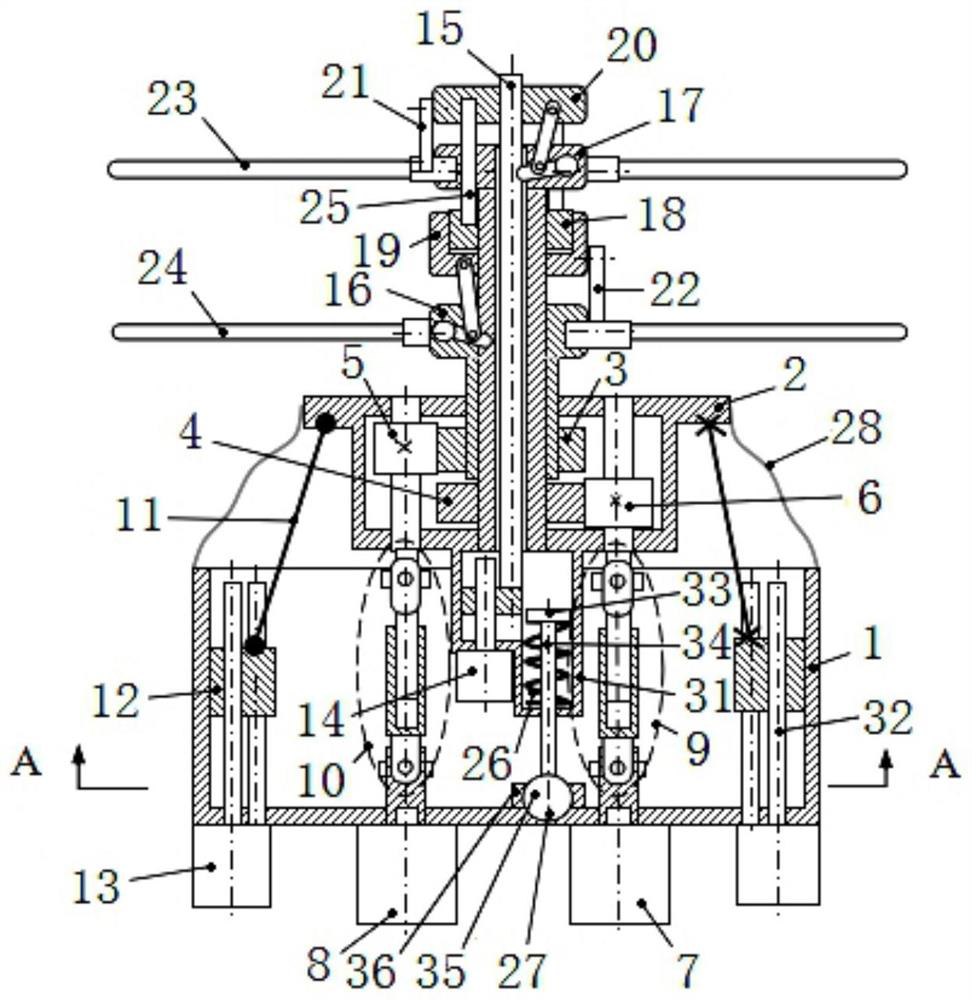

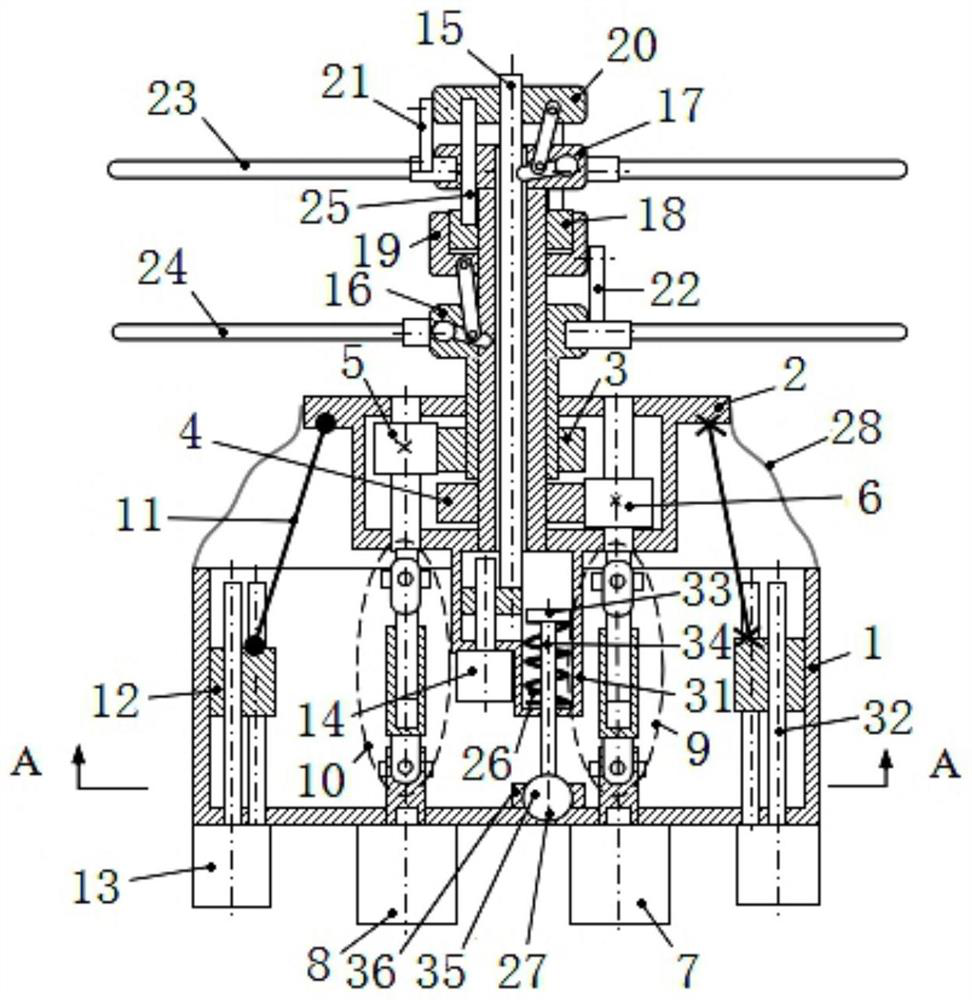

Helicopter coaxial biconical rotor parallel manual device

ActiveCN113086171BChange flight directionSimple control systemActuated personallyWeight reductionCrankGear wheel

The invention relates to a helicopter coaxial double-cone rotor parallel manual device, which includes a rotor group, a parallel mechanism, a forward and reverse rotation mechanism, a variable cone mechanism and a spring; the rotor group includes a core rod, an inner and outer jacket, a tie rod group, an upper and The lower blade set, the upper and lower connecting rod sets, the upper and lower rings; the upper and lower blade sets are rotationally connected with the inner and upper ends of the jacket; the parallel mechanism is connected in parallel with the rotor set, and the hand-operated crank drives the rotor set to swing and telescope; forward and reverse The rotating mechanism drives the coaxial double-linked rotor to rotate forward and reverse through the inner and outer jackets, upper and lower large gears, intermediate wheels and upper and lower gears; the cone-changing mechanism drives the core rod, upper and lower rings and upper and lower connecting rod groups. Changing the angle between the blades and the axis of the rotor group changes the lift and flight speed. The control mechanism of the invention is simple and lightweight, and can change the flight direction, speed and lift flight. It has the characteristics of fast speed, large rotor lift, balanced anti-torque, simple structure, short fuselage, centered center of gravity, aerodynamic symmetry, small rotation diameter, Good stability and other advantages.

Owner:YANSHAN UNIV

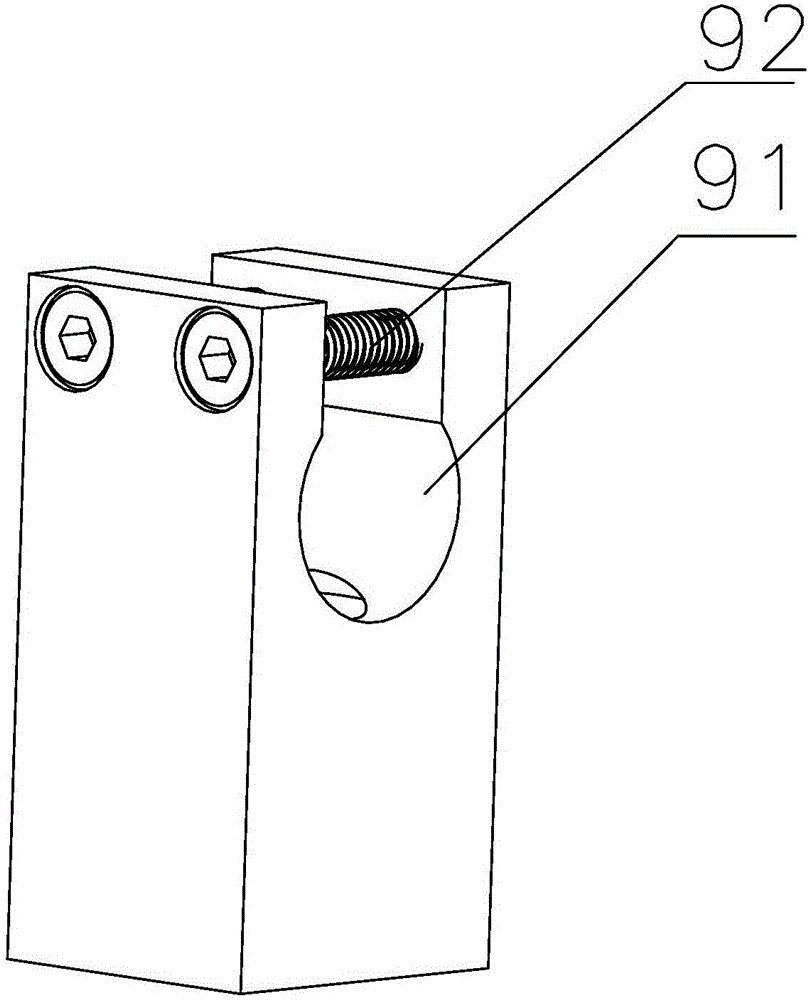

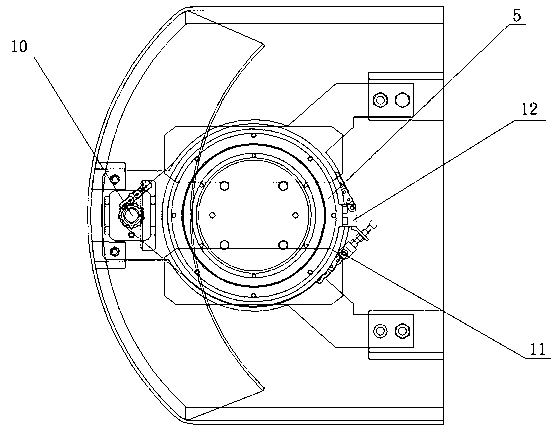

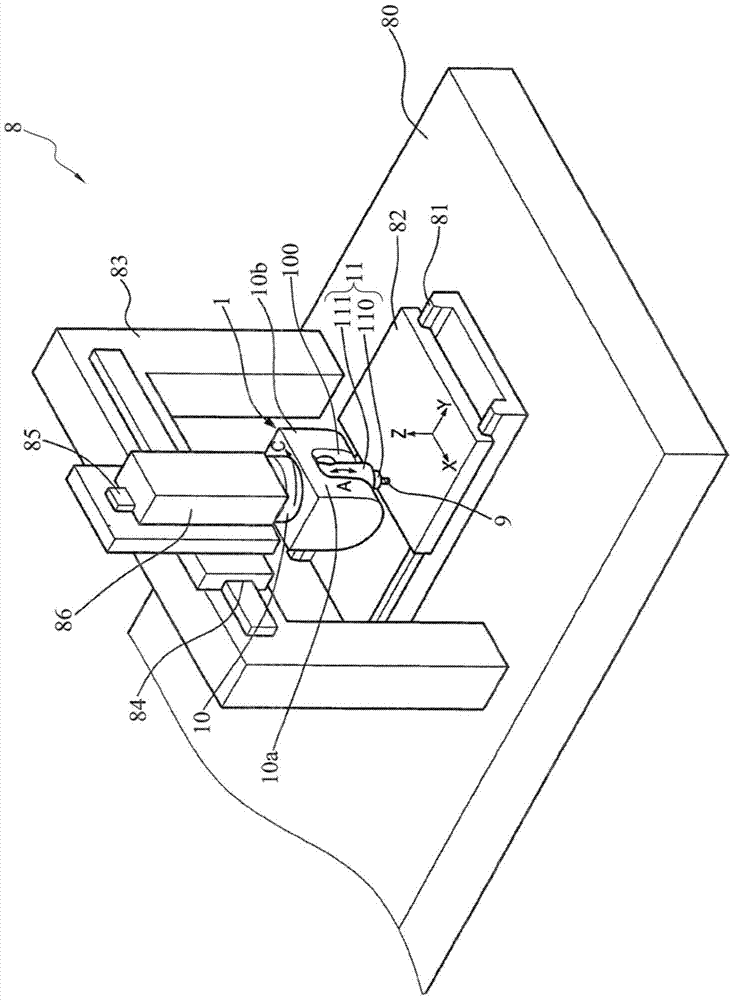

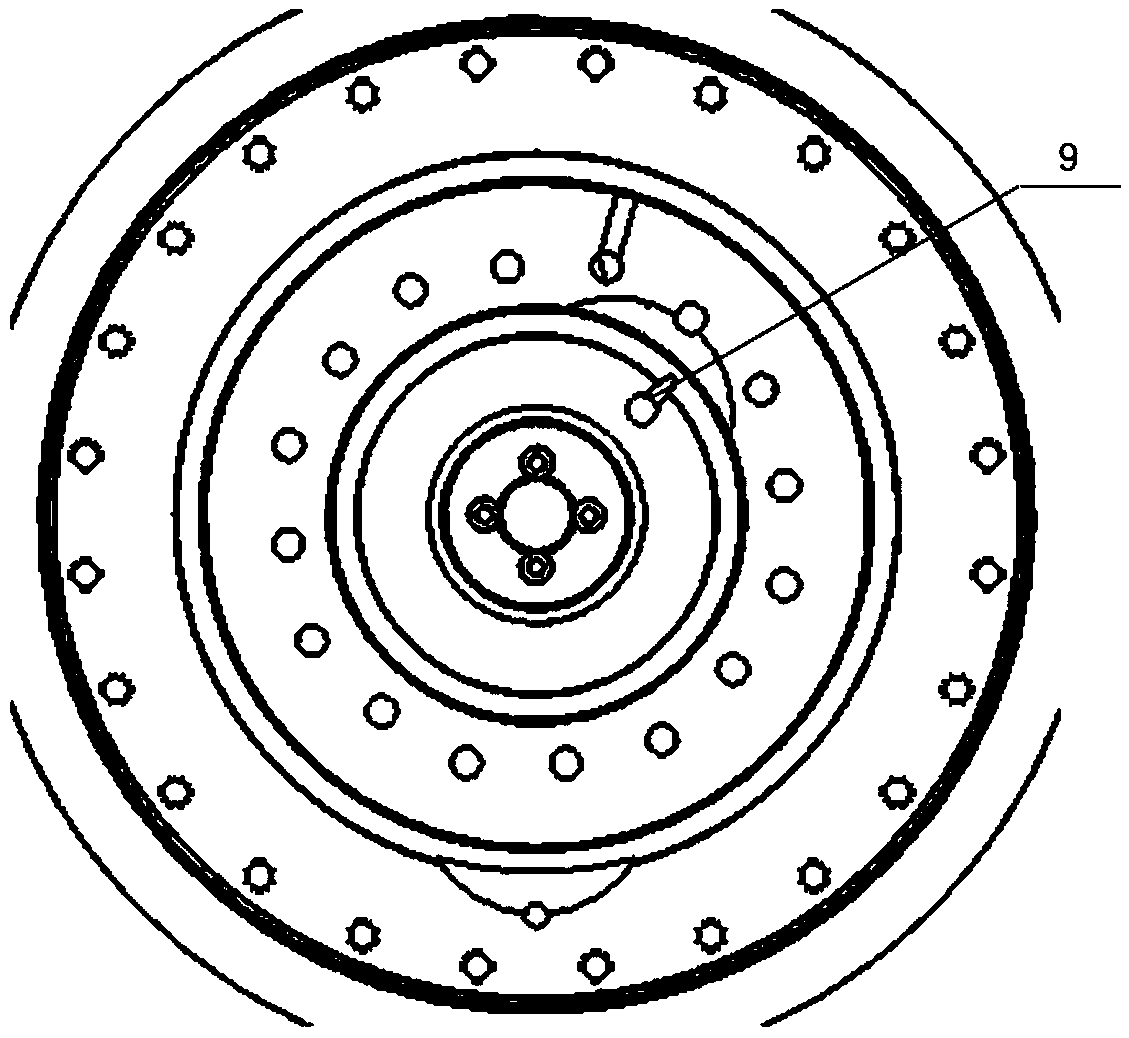

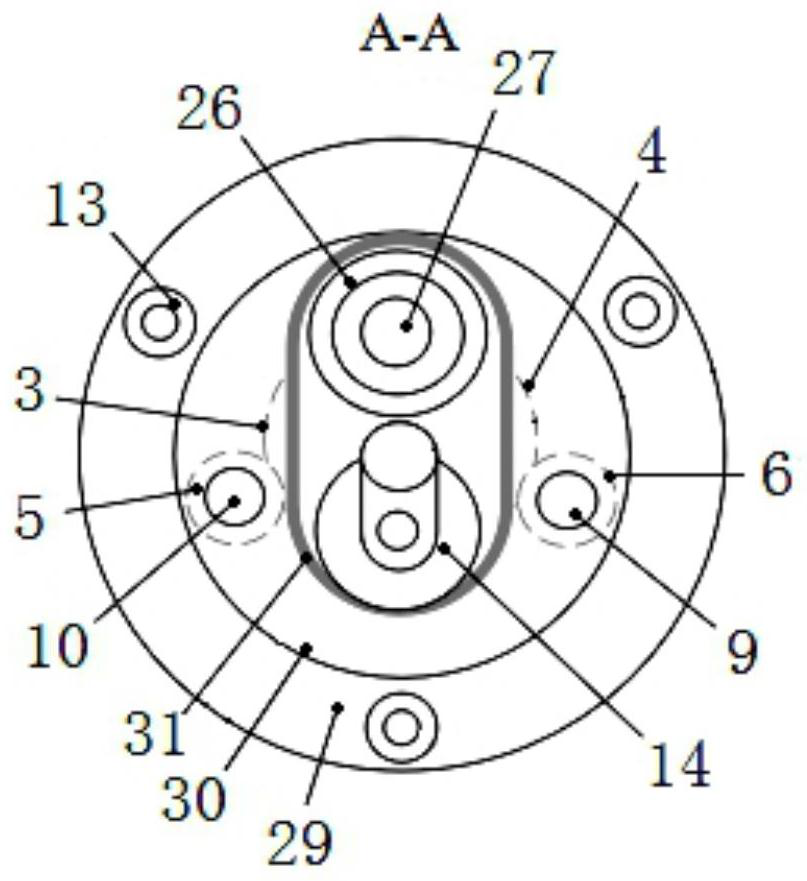

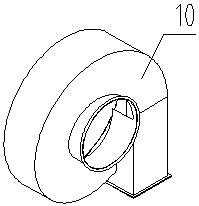

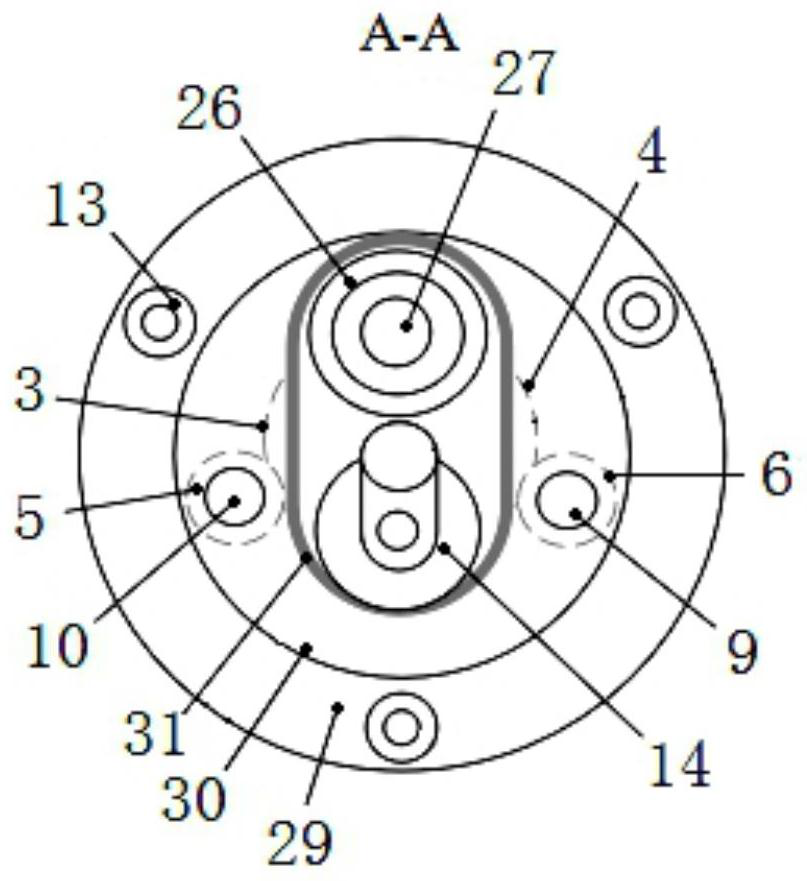

Oil distribution device applicable to five-axis horizontal type machining center rotating table

ActiveCN109318048AEasy to limitOptimize layoutMaintainance and safety accessoriesOil distributionDistributor

The invention provides an oil distribution device applicable to a five-axis horizontal type machining center rotating table. The oil distribution device comprises an external supporting part, a pivoting support bearing (11), a core shaft (1), a main shaft (2) and an oil distributor middle layer (10). The core shaft (1), the oil distributor middle layer (10) and the main shaft (2) are sequentiallyarranged from inside to outside. The core shaft (1) is connected with the main shaft (2). The main shaft (2) and the oil distributor middle layer (10) are provided with inner milling semi-circular oilgrooves (9) correspondingly. The pivoting support bearing (11) comprises a bearing inner ring and a bearing outer ring. The core shaft (1) and the main shaft (2) are connected with the bearing innerring. The oil distributor middle layer (10) and the bearing outer ring are fixed to the external supporting part. According to the oil distribution device, the coordination performance between the oildistribution device and other parts is effectively improved, by arranging a double-layer oil distribution ring, the slewing diameter of the whole rotating table is reduced, space is more compact, meanwhile, the number of fluid channels is increased, and the machining difficulty is reduced.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

Helicopter coaxial double-rotor wing two-rotation three-movement parallel driving device

ActiveCN113086178ACompact structureReduce vibrationPower plant constructionRotocraftDrive shaftGear wheel

The invention relates to a helicopter coaxial double-rotor wing two-rotation three-movement parallel driving device. The device comprises a rotor wing mechanism, a movable table, a base, two PSS type driving rods, a PUU type driving rod, two rotating transmission shafts, two engines and a spring. The rotor wing mechanism comprises a movable table, a mandrel, an inner sleeve, an outer sleeve, a pull rod set, an upper paddle set, a lower paddle set, an upper connecting rod set, a lower connecting rod set, a gear set and an auxiliary electric rod. The upper paddle set and the lower paddle set are rotationally connected with the convex circular truncated cones of the coaxial inner sleeve and outer sleeve; the movable table is rotationally connected with the inner sleeve and the outer sleeve; the two ends of each of three driving rods are hinged to the movable table and the base to drive the rotor wing mechanism to swing and stretch out and draw back. the engine are connected with the bases; the two ends of each rotating transmission shaft are connected with an engine shaft and a gear set input shaft to drive the inner sleeve and the outer sleeve to rotate forwards and backwards; the auxiliary electric rod drives the paddle set to automatically tilt through a lead screw, the core rod, the pull rod set and the connecting rod set; the spring distributes rotor loads to the bases from the movable table. The device of the invention has the advantages of high navigational speed, large lift force, balanced reaction torque, simple structure, good stability and the like, and the engine is arranged on the engine base.

Owner:YANSHAN UNIV

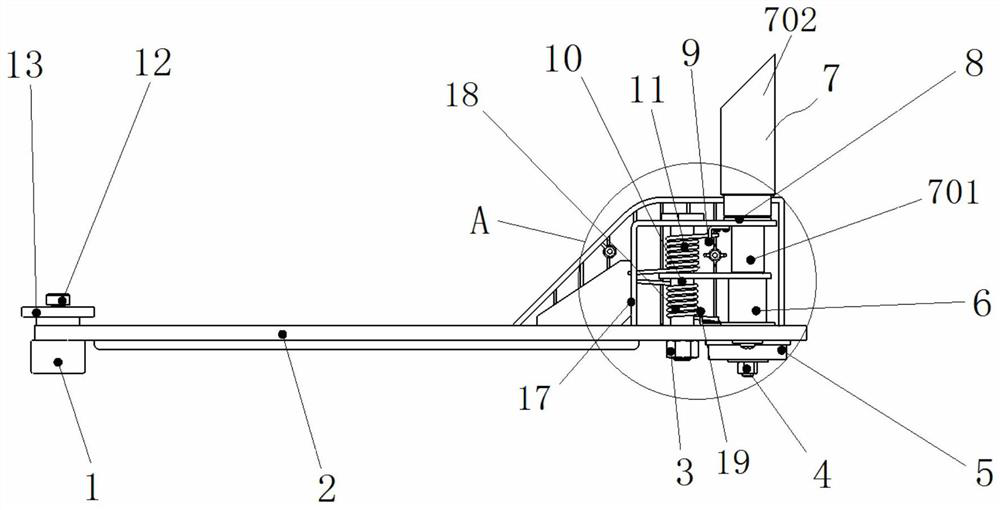

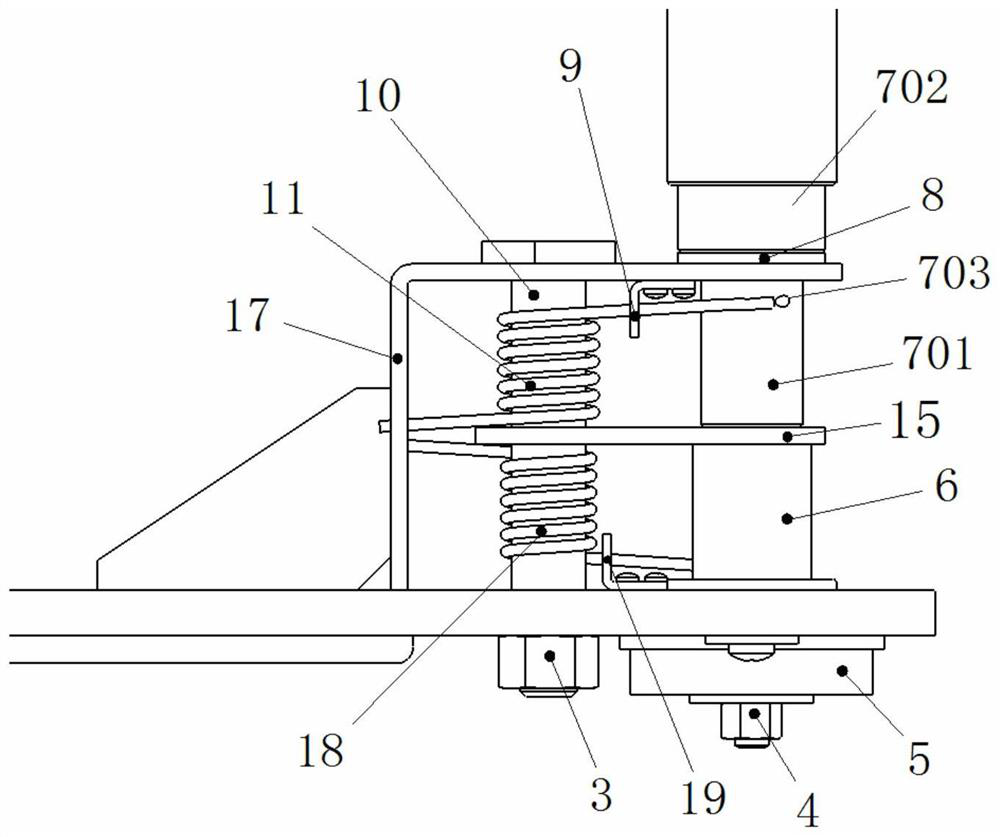

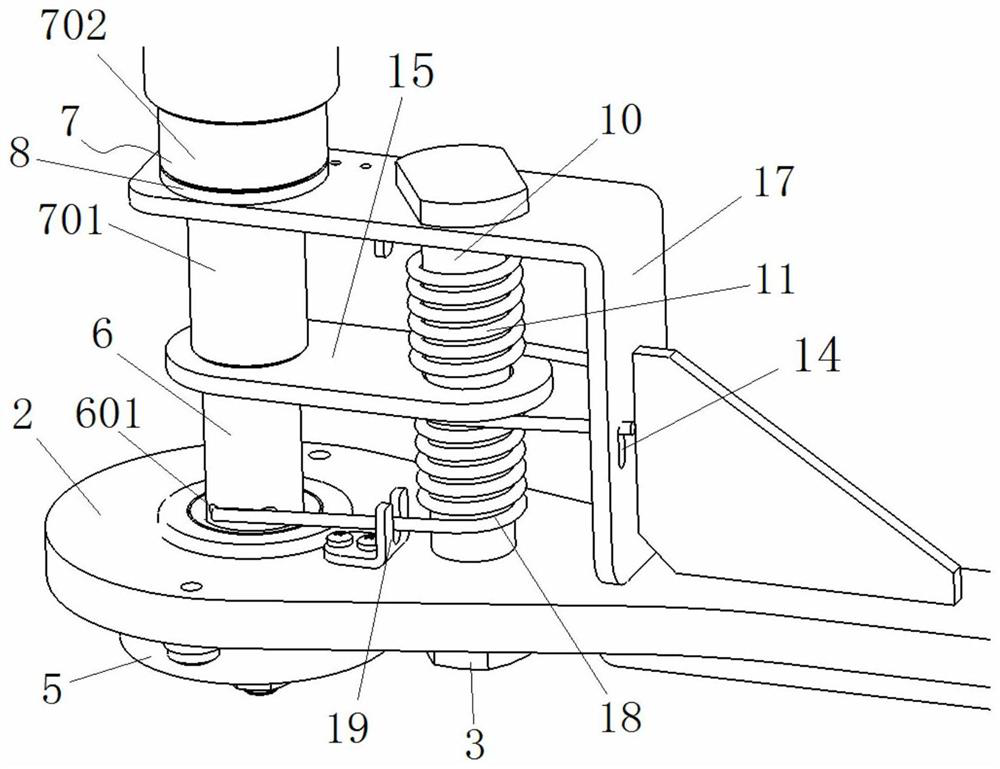

Angle adjustment automatic reset mechanism

The invention relates to the field of walking device auxiliary mechanisms, in particular to an angle adjustment automatic reset mechanism. The angle adjustment automatic reset mechanism comprises an adjusting vehicle plate, a rotating shaft, a first torsional spring, a second torsional spring and a damper, wherein an anti-overturning block and a limiting block are arranged at the rear end of the adjusting vehicle plate; a support is arranged at the front end of the adjusting vehicle plate; a sleeve and a pin shaft are arranged in the support; the lower portion of the rotating shaft stretches into the support and is rotationally installed in the sleeve; the pin shaft is sleeved with the first torsional spring and the second torsional spring; one end of the first torsional spring is connected with the lower portion of the rotating shaft, and the other end of the first torsional spring is connected with the support; one end of the second torsional spring is connected with the sleeve, and the other end of the second torsional spring is connected with the support; and the damper is arranged at the lower end of the rotating shaft. The angle adjustment automatic reset mechanism is installed at the tail end of a walking device, when the walking device rotates in a narrow space, the rotation diameter of the walking device can be effectively reduced, and it is guaranteed that the device cannot turn over.

Owner:苏州新施诺半导体设备有限公司

A large pyrolysis device

ActiveCN106190207BImprove space utilizationImprove energy utilizationIndirect heating destructive distillationSpecial form destructive distillationWater vaporEngineering

The invention provides a large pyrolysis device. According to the technical scheme, a material channel is formed by innermost heat exchange tubes, and the spacing distance between every two adjacent heat exchange tubes is gradually decreased from the feeding end to the discharging end, so that the tapered material channel of which the hole diameter is gradually increased from the feeding end to the discharging end is formed; a feeding device is a sleeve-type spiral feeding device with a hollow shaft, and the hollow shaft is communicated with an inner cavity of a barrel. Due to the fact that the spacing distance among the heat exchange tubes is determined according to volume changes and liquidity changes of materials in a pyrolysis kiln in the different stages, the materials can form efficient heat exchange material screens in all portions of the pyrolysis kiln; meanwhile, the discharging end also is the high temperature end, the diameter of the discharging end is decreased, therefore, the revolution diameter of the portion, located on a discharging cover, of the barrel is small, and a high-temperature-resistant sealing device with the high reliability and the low leakage amount can be conveniently manufactured; meanwhile, the hollow shaft is arranged, and therefore water vapor in the barrel can be extracted or purified gas can be added into the barrel according to the technological needs to meet the technological requirements.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Combined counterweight device and crane using same

The invention discloses a combined counterweight device and a crane using the same and aims to solve a problem that the prior counterweight device cannot move backwards and forwards. The combined counterweight device of the invention comprises a counterweight body, two horizontal slide rails, a counterweight bracket, two vertical oil cylinders and two horizontal oil cylinders, wherein the vertical oil cylinders are fixed on the counterweight bracket through the bodies of the two vertical oil cylinders, and the counterweight bracket can slide backwards and forwards along the horizontal slide rails fixedly arranged on two sides of the tail part of a turntable under the action of the two horizontal oil cylinders. The key design points of the combined counterweight device and the crane using the same include: the counterweight body can move backwards and forwards to effectively improve the length of the big arm and the vehicle stability under a large amplitude working condition of the crane and to reduce the vehicle length to impact the structure of the crane respectively; and at the same time, the crane has a relatively small radius when driving on a curve, so the rideability of the crane is greatly improved.

Owner:XUZHOU HEAVY MASCH CO LTD

Helicopter coaxial double rotor two-turn three-shift parallel drive device

ActiveCN113086178BCompact structureReduce vibrationPower plant constructionRotocraftDrive shaftGear wheel

The invention relates to a helicopter coaxial twin-rotor two-turn and three-shift parallel drive device, which includes a rotor mechanism, a moving platform, a machine base, two PSS-type drive rods, a PUU-type drive rod, two rotating transmission shafts, two engines and Spring; rotor mechanism includes moving platform, spindle, inner and outer jackets, tie rod group, upper and lower blade groups, upper and lower connecting rod groups, gear group and auxiliary electric rod; upper and lower blade groups and coaxial inner and outer jackets The convex circular table is rotationally connected, and the moving table is rotationally connected with the inner and outer jackets; the two ends of the three driving rods are hinged with the moving table and the machine base, driving the rotor mechanism to swing and telescope; the engine is fixedly connected with the machine base, and the two ends of the rotating transmission shaft are connected to the engine. The input shaft of the shaft and gear set drives the inner and outer casings to rotate forward and reverse; the auxiliary electric rod drives the blade set to self-tilt through the screw, core rod, tie rod group and connecting rod group; the spring driven platform diverts the rotor load to the machine base. The invention has the advantages of fast speed, large lift, balanced reaction torque, the engine is installed on the base, simple structure and good stability.

Owner:YANSHAN UNIV

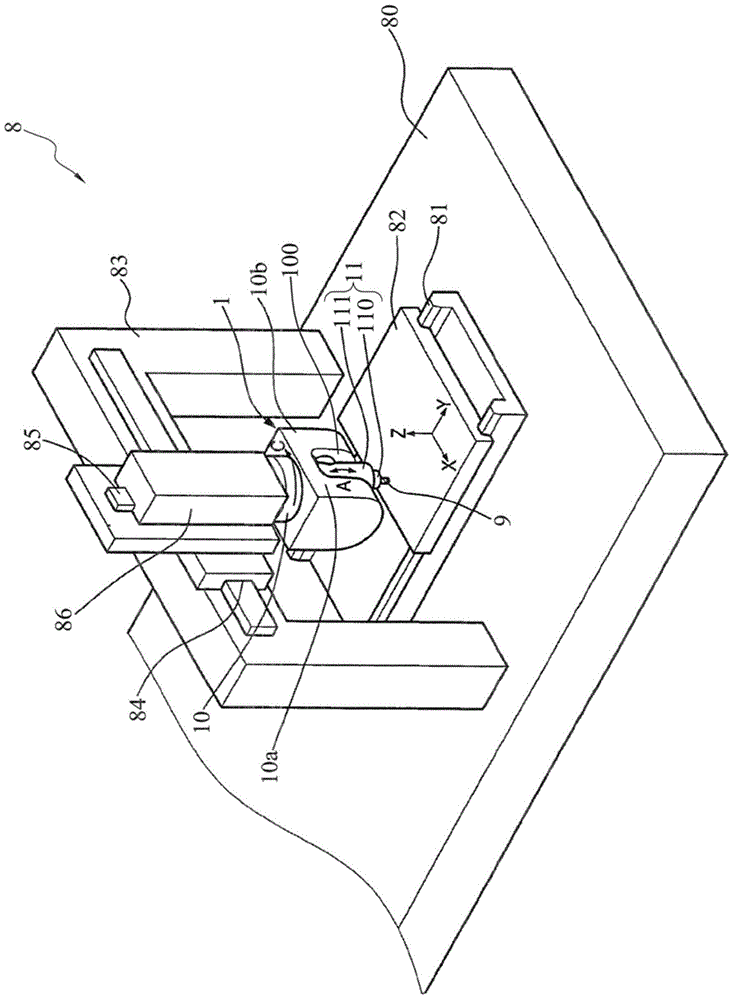

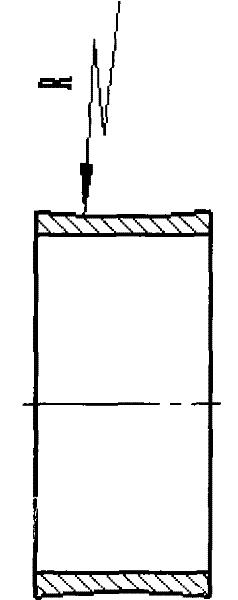

Method for grinding roller path of bearing inner ring

InactiveCN101758435BHigh geometric accuracyRotation accuracy does not directly affectGrinding machinesGrinding wheelAngle alpha

The invention discloses a method for grinding a roller path of a bearing inner ring, which trims grinding wheels by adopting a generating cutting method. In the method, a diamond stylus (3) intersects with a revolving center line of a grinding wheel (2) to form an angle alpha, the diamond pen does a diameter d circular motion around the revolving center line thereof in a tangent plane of a grinding wheel working plane, thus in relative circular motion of the diamond stylus and the grinding wheel, the working plane of the grinding wheel is generated by the diamond into a spherical ring shape with same radius, which takes an intersection point of the revolving center line of the diamond stylus and the revolving center line of the grinding wheel as a center of sphere, and then the trimmed grinding wheel carries out grinding processing on the roller path of the bearing inner ring. An intersection point distance of the grinding wheel working plane is L, the circumferential diameter of the diamond stylus is d, the distance from the revolving plane of the diamond stylus to the spherical center of the spherical ring of the working plane of the grinding wheel is RX, the radius of the spherical ring of the working plane of the grinding wheel is R, wherein R is equal to the curvature radius of the roller path of the bearing inner ring and RX is approximately equal to R, and the magnitude of L or alpha can be adjusted to obtain the corresponding RX for rough adjustment, and the adjustment of d can be used for fine adjustment. The method is simple and practical.

Owner:安徽徽熳动力机械制造有限公司

Hydraulic supporting control mechanism of roller connecting shaft and relevant puncher and relevant pipe milling machine

ActiveCN103230937BSmall turning diameterImprove the forceRoll mill control devicesMandrelsHydraulic cylinderControl system

The invention provides a hydraulic supporting control mechanism of a roller connecting shaft and a relevant puncher and a relevant pipe milling machine. The hydraulic supporting control mechanism of the roller connecting shaft is used for supporting the roller connecting shaft dynamically and comprises a connecting shaft supporting base, a hydraulic supporting control system and a hydraulic cylinder installing base. The connecting shaft supporting base contacts with and supports the roller connecting shaft, the hydraulic cylinder installing base is installed on a foundation, a hydraulic cylinder of the hydraulic supporting control system is installed in the hydraulic cylinder installing base, and the hydraulic cylinder can drive the connecting shaft supporting base to move up and down or support the roller connecting shaft in a floating mode. Due to the fact that constant supporting force exists, a sinking range of the roller connecting shaft is limited, rotary diameter of the roller connecting shaft is reduced, simultaneously the stress of handles at two ends of the roller connecting shaft is improved, and the service life of the handles is prolonged.

Owner:TAIYUAN HEAVY IND

Short-blade multi-rotor wind power generation device

InactiveCN111520288ASolution to short lifeLow costWind motor supports/mountsWind motor combinationsWind drivenGear drive

The invention relates to a short-blade multi-rotor wind power generation device. The short-blade multi-rotor wind power generation device comprises a bracket assembly, a rotating arm assembly, a generator, rotor assemblies and a transmission assembly. A rotary pair of the rotary arm assembly is connected to the top of the bracket assembly, the rotor assemblies are symmetrically connected to the front side and the rear side of the rotary arm assembly respectively through rotary pairs, the transmission assembly is arranged in the rotary arm assembly, the transmission assembly is respectively intransmission connection with the rotor assemblies, the generator is fixedly connected in the bracket assembly, and a driving shaft of the generator is coaxially and keyed to the bottom of the transmission assembly. The wind driven generator has the advantages of multiple rotors, short blades, high rotating speed, high efficiency, low lifting frame, light weight, small vibration, safety, stabilityand the like, the six rotor assemblies can be driven to rotate by small wind power, and the generator is driven to generate electricity through transmission of all gears.

Owner:YANSHAN UNIV

An Angle Adjustment Automatic Reset Mechanism

The present invention relates to the field of auxiliary mechanisms for walking devices, in particular to an automatic reset mechanism for angle adjustment, which includes an adjustment plate, a rotating shaft, a first torsion spring, a second torsion spring and a damper, wherein the rear end of the adjustment plate is provided with an anti- Overturning the block and the limit block, adjusting the front end of the vehicle plate is provided with a bracket, the bracket is provided with a sleeve and a pin shaft, the lower part of the shaft extends into the bracket and is rotatably installed in the sleeve, the first twist The spring and the second torsion spring are sleeved on the pin shaft, and one end of the first torsion spring is connected to the lower part of the rotating shaft, and the other end is connected to the bracket, and one end of the second torsion spring is connected to the sleeve, and the other end is connected to the sleeve. The brackets are connected, and the lower end of the rotating shaft is provided with a damper. The invention is installed at the tail end of the walking device. When the walking device rotates in a narrow space, the turning diameter of the walking device can be effectively reduced, and the device can not be overturned.

Owner:苏州新施诺半导体设备有限公司

Engine power transmission output structure

The invention discloses an engine power transmission output structure. The engine power transmission output structure comprises an engine body with a plurality of cylinders. Each cylinder in the engine body comprises a cylinder sleeve embedded in a corresponding cylinder sleeve hole of the engine body, a piston in the cylinder sleeve, and a piston rod connected with the piston, wherein a rocker crank pin is hinged to the piston rod, and the rocker crank pin is composed of rocker cranks on the two sides and a crank pin connecting the two rocker cranks. The engine body is internally provided with output rocker gears corresponding to the cylinders, and the output rocker gears are in power transmission connection with the rocker cranks of the rocker crank pins. The engine body is internally further provided with torque common rail transmission shafts, and the torque common rail transmission shafts are engaged with the output rocker gears to finally transmit and output power of all the cylinders to engine flywheels. The engine body is internally provided with large guiding gears corresponding to the cylinders. The rocker cranks of the rocker crank pins are sleeved with small guiding gears, and the small guiding gears do the circumferential movement in the large guiding wheels, so that the crank pins of the rocker crank pins do the vertical movement.

Owner:常熟东南高新技术创业服务有限公司

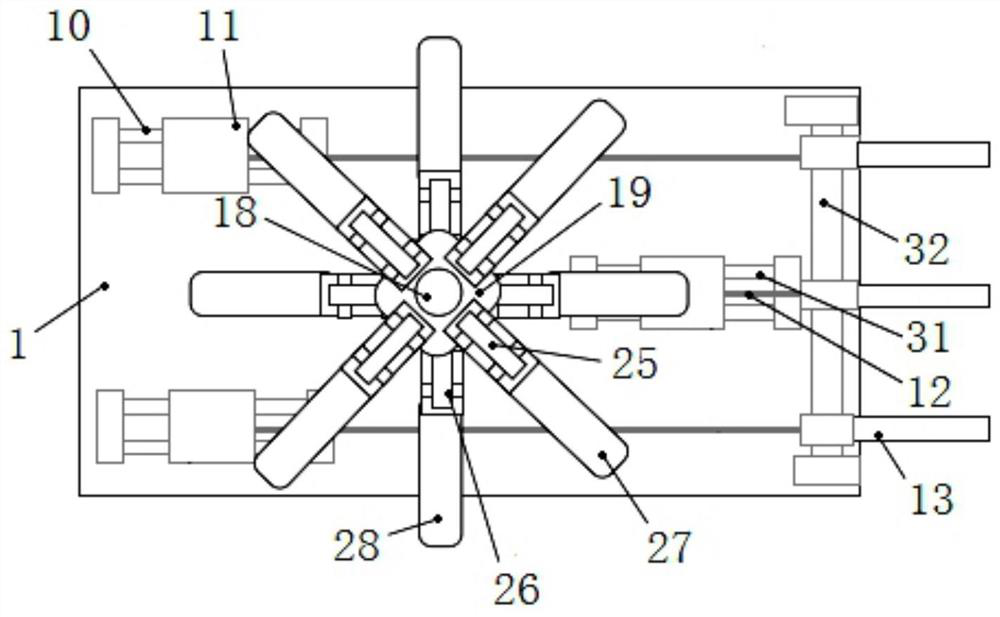

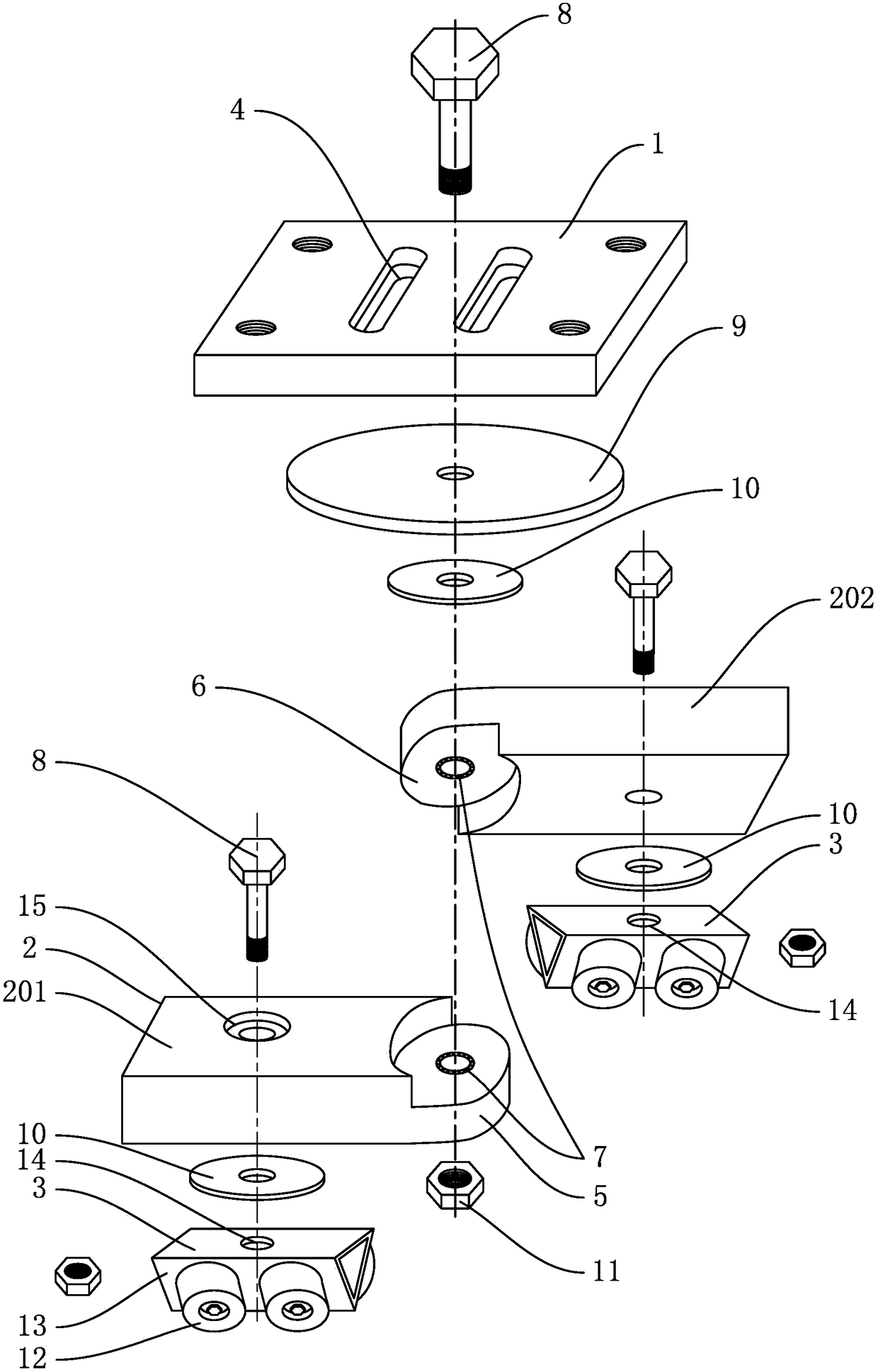

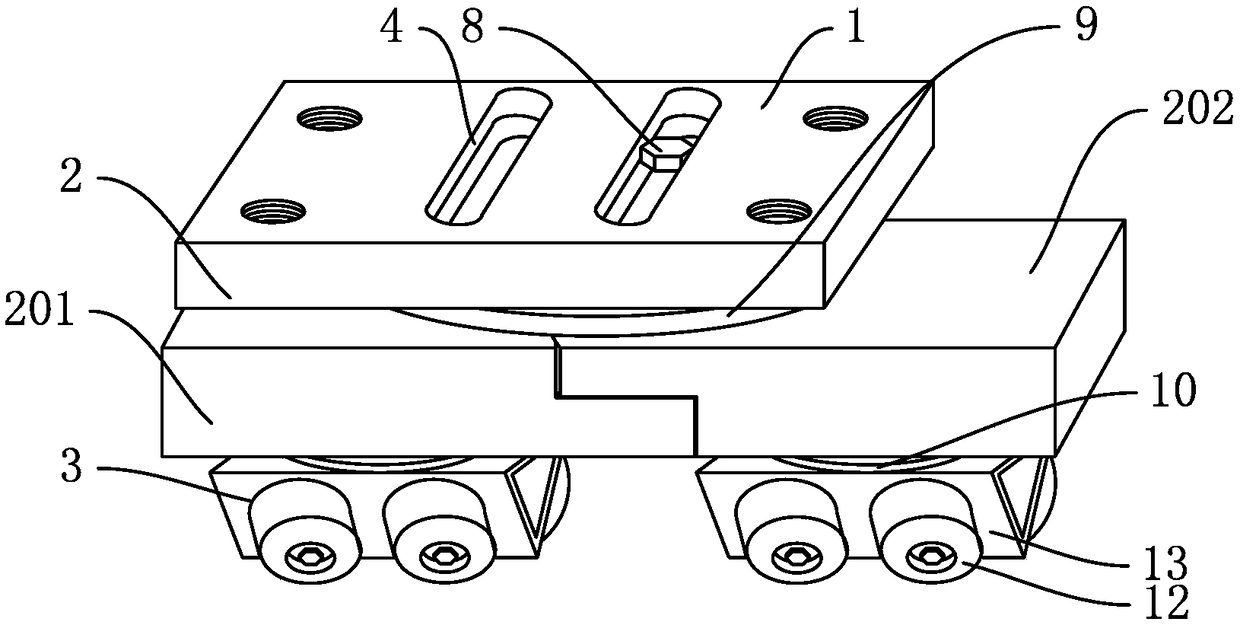

Motor-driven station slewing mechanism combined with wedge-shaped positioning

PendingCN112828650ASmall turning diameterOptimize layoutFeeding apparatusLarge fixed membersDrive wheelRolling-element bearing

The invention discloses a motor-driven station slewing mechanism combined with wedge-shaped positioning. The station slewing mechanism comprises a rack and a mounting plate arranged at the top of the rack; a rotary output mechanism is arranged on the mounting plate and comprises a rotary output shaft and a driven wheel; the rotary output shaft is vertically arranged on the mounting plate through a bidirectional supporting bearing, and one part of the rotary output shaft extends above the mounting plate for mounting a tool mounting base plate; the driven wheel is pivoted with the lower end of the rotary output shaft through a rolling bearing; an elastic rotation driving mechanism is arranged on the lower end faces of the driven wheel and the rotation output shaft, and the driven wheel drives the rotation output shaft to rotate through the elastic rotation driving mechanism; a wedge-shaped positioning mechanism is arranged on the mounting plate and the tool mounting base plate and used for carrying out station positioning on the tool mounting base plate; and a power input mechanism is arranged on the mounting plate and is used for driving the driven wheel to rotate. The station slewing mechanism has the characteristics of low cost, accurate and controllable positioning, elastic driving rotation and the like.

Owner:长春丰盛煜自动化技术有限公司

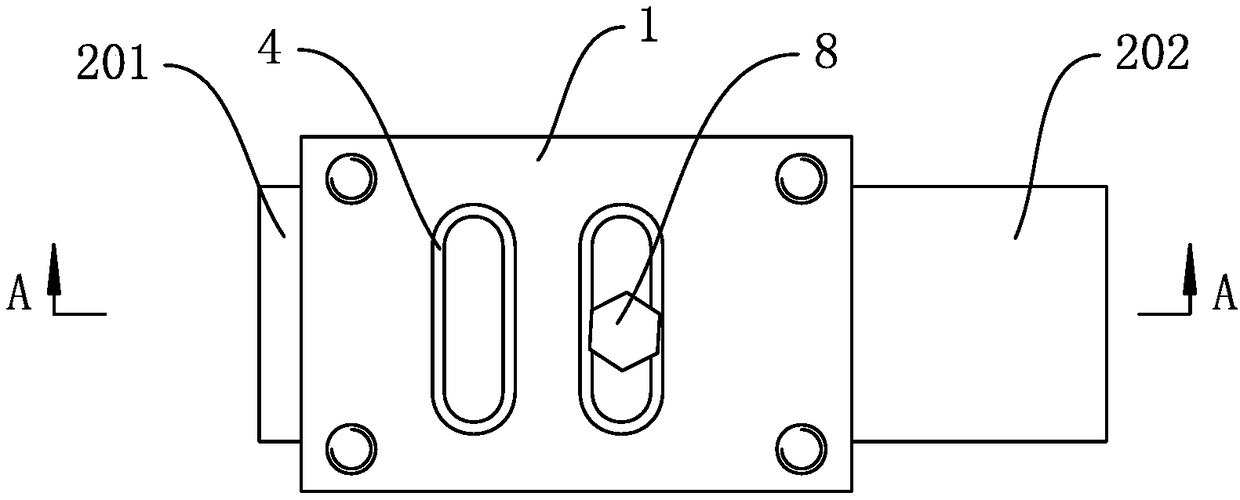

Novel load-bearing wheeled slide plate for camera car

The invention relates to a novel load-bearing wheeled slide plate for a camera car. The novel load-bearing wheeled slide plate comprises a top plate, a pair of slide plate bodies and wheel sets on thebottom surfaces of the slide plate bodies and is characterized in that the slide plate bodies fastened to each other in a staggered manner and hinged to each other are arranged on the bottom surfaceof the top plate, one wheel set is hinged to the bottom surface of each slide plate body, the top surface of the top plate is downwardly provided with a stepped long slot along the width direction, the four corners of the top surface of the top plate are provided with screw holes, the slide plate bodies include a first slide plate body and a second slide plate body, the connecting end of the firstslide plate body extends out of a first connecting plate, the connecting end of a second slide plate body extends out of a second connecting plate, coaxial bearings are embedded into the central holes of the first connecting plate and the second connecting plate, the top surface of the first connecting plate and the bottom surface of the second connecting plate are abutted against and coordinatedwith each other, a half-threaded bolt downwardly penetrate the stepped long slot of the top plate, the polished part of the half-threaded bolt are in close fit with the bearing inner rings of the twoslide plate bodies, and the tail-end threaded part of the half-threaded bolt extends out and is connected with a nut in a threaded manner. By the novel load-bearing wheeled slide plate, the technicalproblems that an existing eight-wheel wheel set has too many dispersed hinges, and the whole wheeled slide plate jitters severely and is unsmooth in turning are solved.

Owner:高鑫

Jawless Tube Chuck

ActiveCN105710592BAvoid damageOmit the jawsWelding/cutting auxillary devicesAuxillary welding devicesMaximum diameterEngineering

The invention relates to the technical field of pipe clamps, in particular to a claw-free chuck for clamping pipes. A through hole accepting penetration of the pipes is formed in the middle of a main plate, and the main plate is provided with a claw-free clamp capable of clamping the pipes and enabling the pipes to slide in the through hole in the axial direction of the center of the main plate. According to the claw-free chuck for clamping the pipes, claws and clamping bases pushing the claws are eliminated, and therefore the thickness of the claw-free chuck for clamping the pipes is reduced, the self weight of the chuck is lowered, and feeding waste of the pipes is reduced; because the claws are eliminated, the problem that claw handles extend out of the maximum diameter part of the chuck (namely the main plate) is avoided, the installation space of the chuck is greatly reduced, the manufacturing cost of the chuck is greatly reduced, and the stability is high; pipe loads are retained by screw rods firstly, worm motors just need to bear small retaining force, and gearboxes of the worm motors are protected against damage caused by overload due to the two-stage retaining function. In addition, the claw-free chuck is simple in structure, small in size and light in self weight and has full stroke.

Owner:常州市力源恒机械有限公司

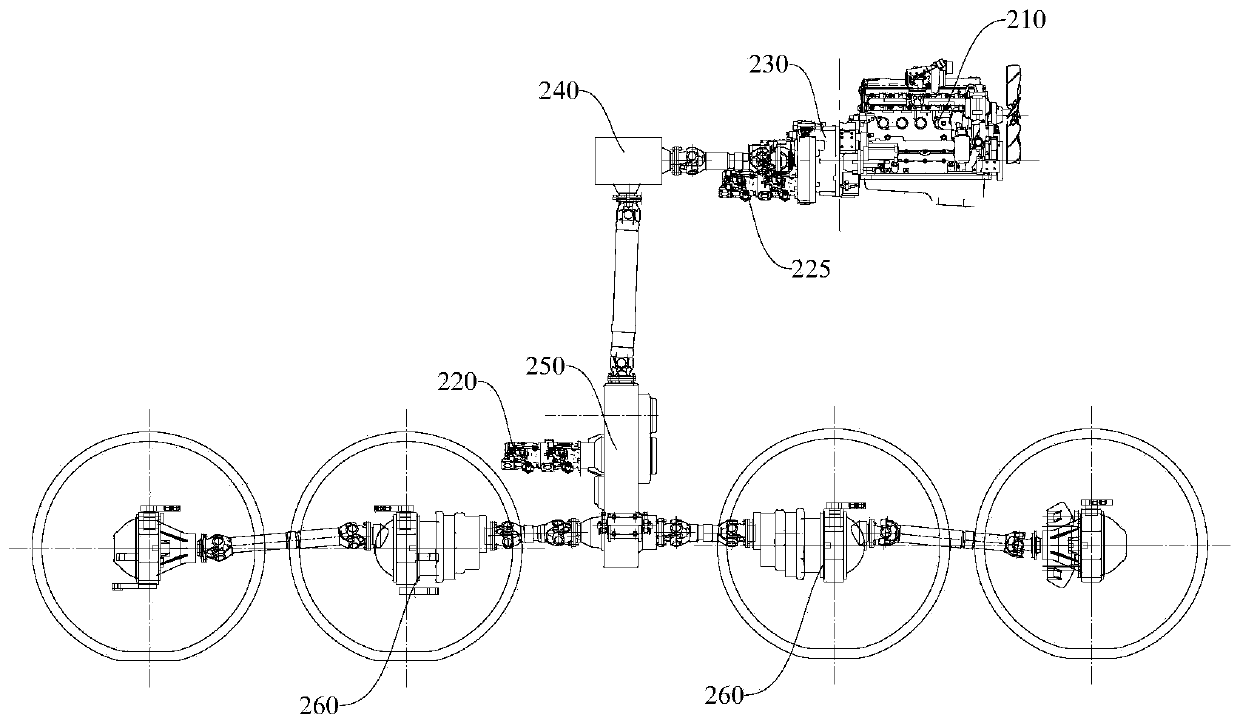

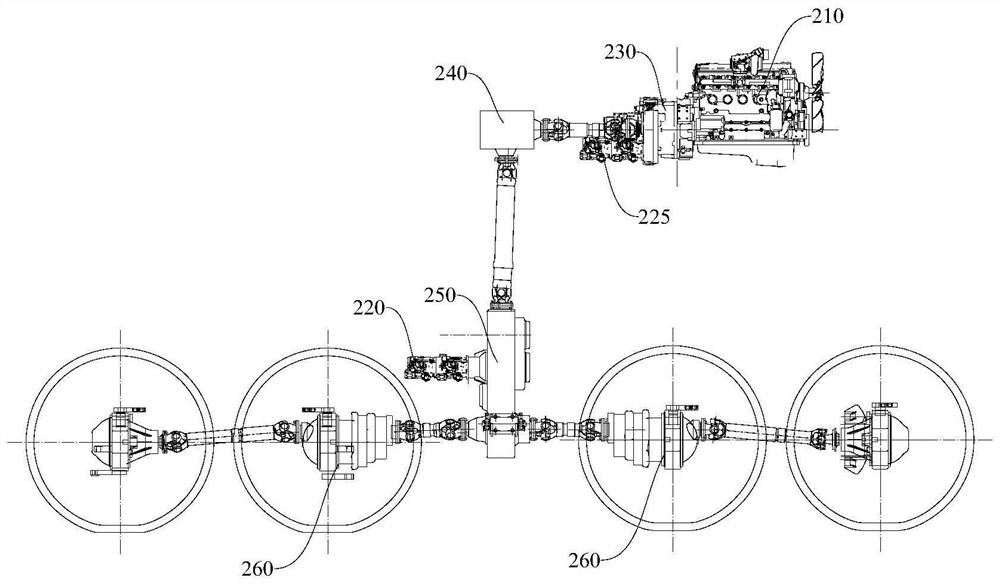

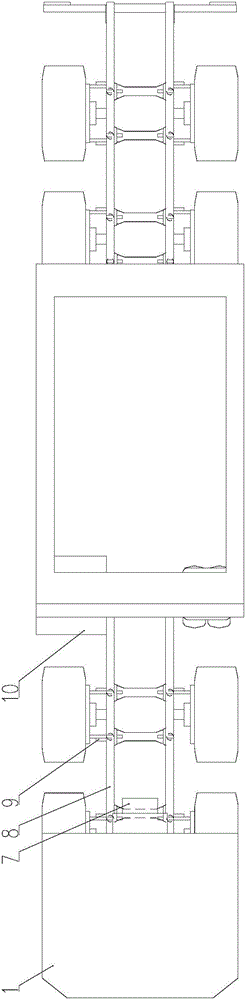

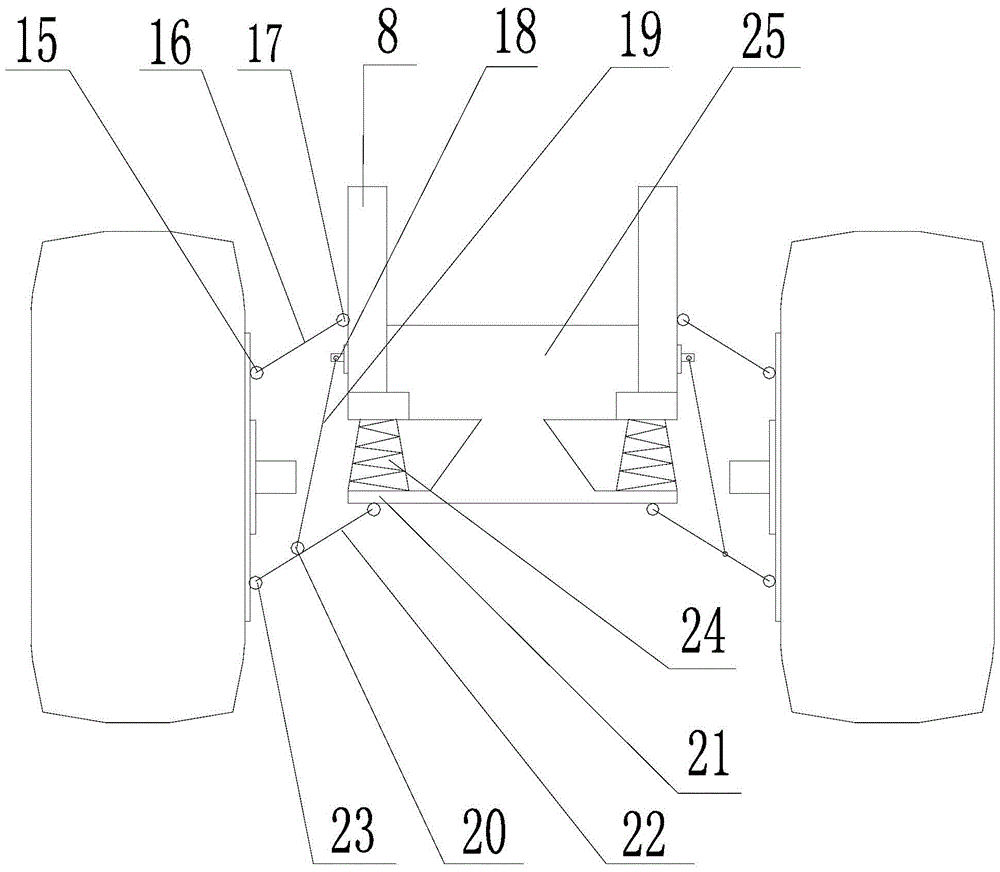

An Electric Drive Hydraulic Independent Suspension Coiled Tubing Chassis

ActiveCN104760481BIncrease the use of spaceImprove versatilityItem transportation vehiclesResilient suspensionsTransfer caseDrive shaft

The invention provides an electrically-driven hydraulic independent suspension coiled tubing chassis. A generator set is provided with an engine, a DC generator and an AC generator. An independent suspension device comprises a first lower suspension arm base, and a hub is provided with a second lower suspension arm base. A lower suspension arm is mounted between the first lower suspension arm base and the second lower suspension arm base. A second dual-function hydraulic damping device base is arranged on the inner side of the lower suspension arm, and a first dual-function hydraulic damping device base is arranged on a longitudinal beam. A dual-function hydraulic damping device is mounted between the second dual-function hydraulic damping device base and the first dual-function hydraulic damping device base. The longitudinal beam is further provided with a first upper suspension arm base, and the hub is further provided with a second upper suspension arm base. An upper suspension arm is mounted between the first upper suspension arm base and the second upper suspension arm base. A clutch device, a gearbox, a transfer case and a transmission shaft are omitted, so that the actual using space is increased. Wheels bounce independently without affecting one another, so that independent steering is achieved. The electrically-driven hydraulic independent suspension coiled tubing chassis has the advantages of high off-road performance, smoothness and universality. An automatic tire inflating and deflating device can be additionally arranged.

Owner:SANJIANG VOLAT SPECIAL VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com