Method for grinding roller path of bearing inner ring

A grinding process and technology for inner rings, applied in the field of bearing grinding, can solve the problems of difficult production management, low grinding wheel dressing accuracy, and low efficiency, and achieve improved grinding efficiency, grinding quality, and workpiece size range The effect of widening and expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

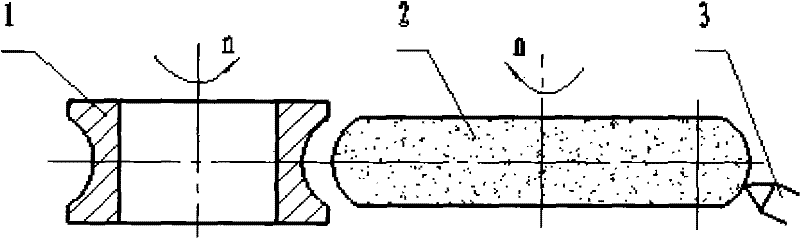

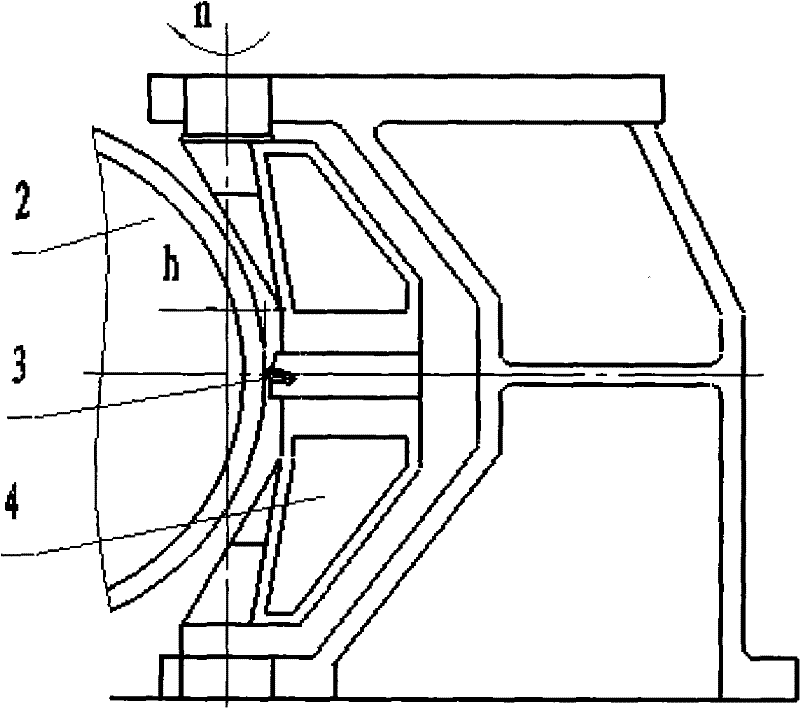

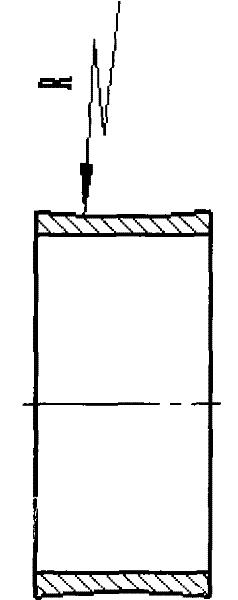

[0032] A grinding method of the bearing inner ring raceway of the present invention, the grinding method first adopts the Fancheng method to trim the grinding wheel, and trims the working surface of the grinding wheel 2 into a spherical ring with the same radius at each point, and then uses the grinding wheel 2. The spherical ring-shaped working face is used for grinding the raceway of the bearing inner ring 1.

[0033] combine Figure 5-6 , the Fan Cheng method dressing grinding wheel 2 is that the center line of rotation of the diamond pen 3 intersects with the center line of rotation of the grinding wheel 2 to form an angle α, and the diamond pen 3 makes a circle with a diameter of d in the tangent plane of the working surface of the grinding wheel 2 around its center line of rotation In this way, during the relative circular motion of the diamond pen 3 and the grinding wheel 2, the working surface of the grinding wheel 2 is fanned by the diamond pen 3 to become the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com