Straight line rolling guiding rail, and guideway slider multiple grinding head combined grinding machine

A technology of rolling guide rails and guide rail sliders, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of poor precision and low efficiency, improve geometric accuracy and dimensional accuracy, and improve Product quality and precision, the effect of ensuring contour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

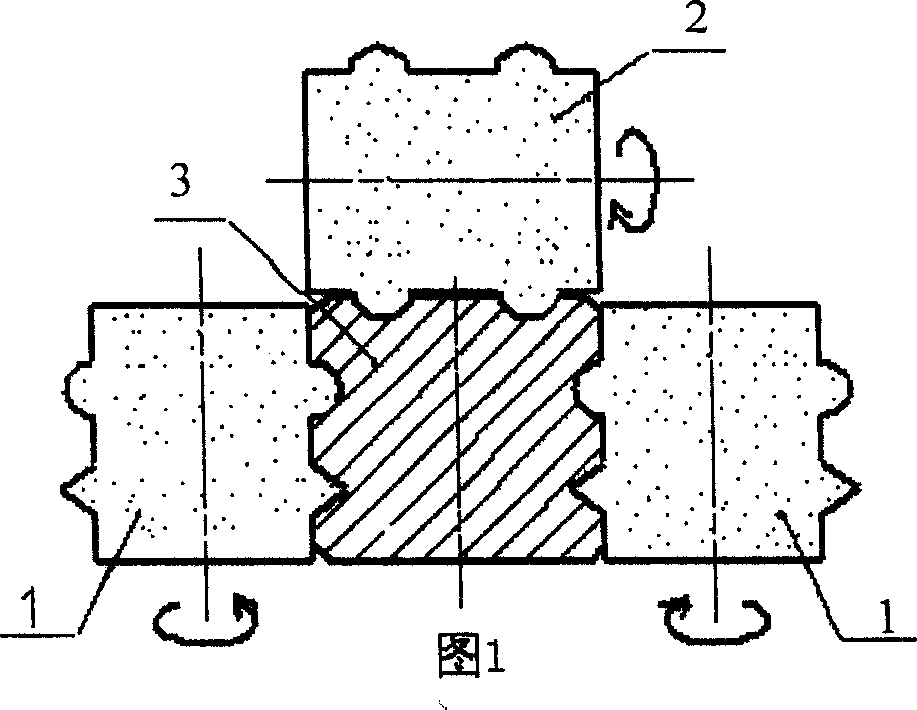

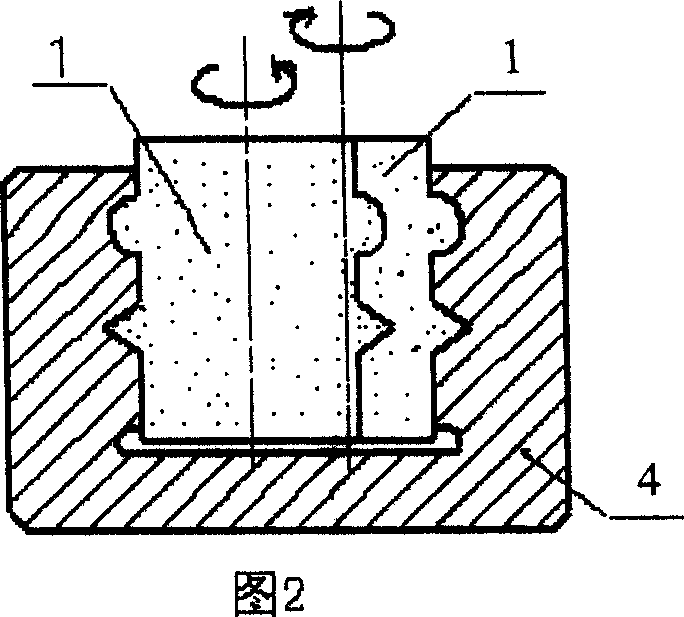

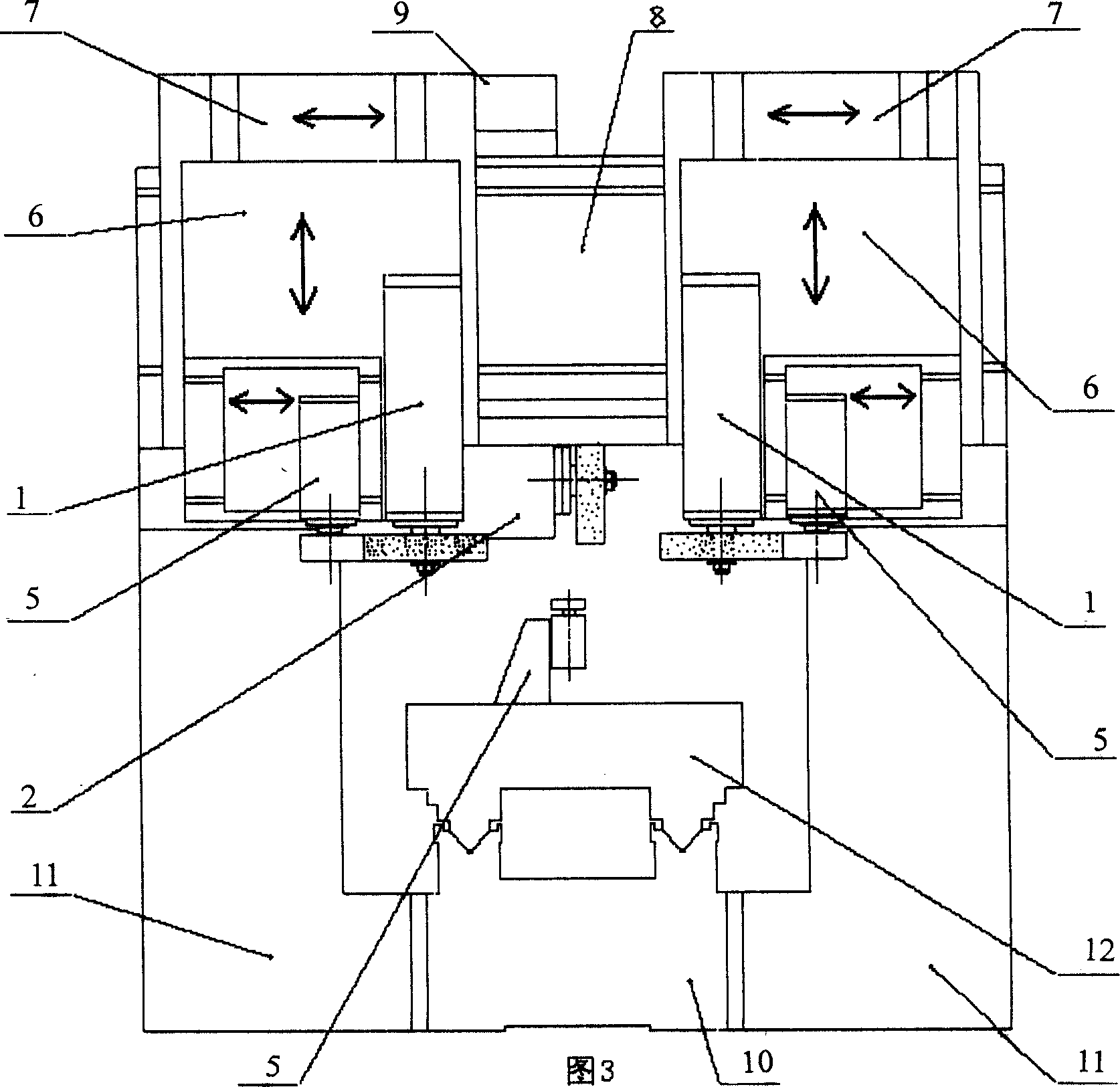

[0018] As shown in Figure 3 and Figure 4, the linear rolling guide rail and the multi-grinding head combination grinding device of the guide rail slider, the crossbeam 8 is fixed on the column 11, the column 11 is connected with the bed 10, and the workbench 12 is installed on the bed 10. Therefore, the linear guide rail or guide rail slider grinding processing equipment that makes up the gantry frame. The front end of the beam is equipped with a horizontal carriage 7, a vertical carriage 6 is installed on the horizontal carriage, and a vertical grinding head 1 and an emery wheel dresser 5 are installed on the vertical carriage 6. The rear end of the beam is provided with a guide rail 13, the horizontal carriage 9 is installed on the guide rail 13, the vertical carriage 14 is installed on the horizontal carriage 9, the horizontal grinding head 2 is installed on the vertical carriage, and the horizontal grinding head is equipped with Grinding wheel dresser 5. Also can adorn gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com